How to hang a wardrobe, TV, shelf, and other weight on a wall from drywall

Today it is impossible to imagine construction or repair without drywall. As GKL finishing material, they have a lot of advantages: safety for human health, ease of installation, fire safety, affordable cost, the ability to quickly perform finishing work, getting very smooth, flawless planes, etc. Therefore, it is widely used not only for wall alignment, but also for decoration or the creation of multi-level ceilings, for the construction of arches, partitions, niches and so on. However, and such a popular finishing materials have their drawbacks, which in no case should be forgotten. How to hang a wardrobe, TV, on a drywall wall,the picture, the shelf and other heavy objects, so as not to end up with ruins? This is the biggest problem with this material.

Hang on the wall of the GCR a small object (picture, shelf or compact Wall Clock) is much easier than fixing weighty and bulky objects. Drywall itself is quite soft and loose material, and simple ones are suitable for installing something small and light. screws complete with dowels, self-adhesive hooks or double-sided tape. But the methods of fastening more weighty products and materials necessary for the implementation of this venture should be studied more closely in order to eventually get a functional and stylish interior.

Materials needed for proper and reliable fasteners

Different designs require a completely different approach. If some can be fixed on the GCR in 5 minutes, then others may have to tinker with during the day. Therefore, depending on which mounting method will be selected, different tools, fasteners and fixtures can be used.

- Mortar beam. As a rule, the installation of a wooden beam is provided for in the project and is carried out during the assembly of the profile frame.

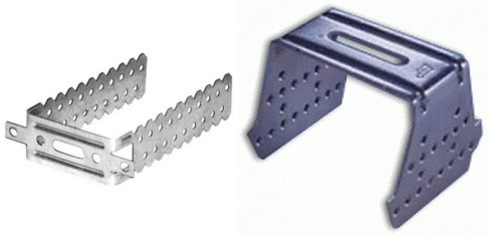

- Tire the special one is a narrow, long metal profile that has holes for fixing it along the entire length of the wall.

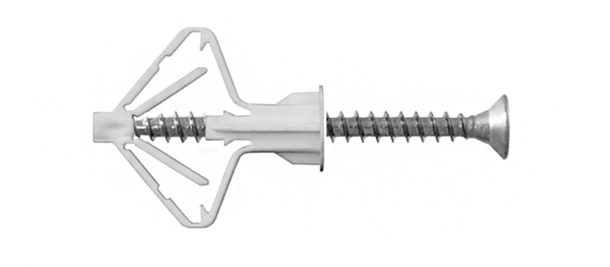

- Dowels (driva, DRIVA, "snail"). Some of the most popular and affordable items. There are: metal - made of zinc alloy, and plastic - polyethylene or nylon.To install the dowel, a hole is required, which is performed by a drill of the corresponding diameter. Using a screwdriver under the “cross”, the inserted dowel cuts into the GCR like a simple self-tapping screw. The next step is to screw a screw or self-tapping screw into a cross-shaped hole inside the fastener. A clear advantage of this type of fastening is the load indicators necessary to tear the product from a specific material: for metal products - up to 32 kg, for plastic - up to 25 kg. Although, for the latter it will be a significant test of long-term resistance to the force with which heavy structures will press on the fasteners.

- Expandable anchors (Molly, Molly). The one-piece prefabricated design that does not require additional elements is the most reliable type of fastener. The element consists of an anchor split hollow sleeve and a locking screw. The nut and flat head at the ends of the sleeve do not allow it to spin when tightened. When installing this mount, the thread is tightened, as a result of which the split part of the element is folded until the triangles of the support form. They are located around the circumference and are responsible for the rigidity of the structure. The advantages of the element include high reliability and relative ease of installation.

- The expansion bolt shield "butterfly". The fastener is a two-blade design. The dowel is inserted into the hole, and when the screw is screwed in again, the blades open. Thus, the mount is fixed to the wall from the back.

- Hartmut dowel (Knauf Hartmut). Special mounting element for hollow structures. The fasteners include a U-shaped anchor plate made of galvanized steel profile, two guide plastic elements (blue), locking sleeve (colorless plastic) and M5 screw (60 mm). A distinctive feature of the dowel is its high load-bearing capacity: one unit can carry a load for walls of up to 55 kg or 6 kg per element for the ceiling or a span of 1 running meter. Hartmut has proven itself in the installation of heavy furniture, bulky TVs, etc.

- Bracket. A support device that allows you to install the desired product on a specific surface. Currently, it is most often used for mounting TVs on walls and even ceilings. There are: fixed, oblique, oblique-rotary, movable, sometimes separate ceiling.

It is interesting that real pros, masters with great experience believe: drywall can withstand very serious weight and a significant load. The main thing is to choose the right mounting method and fastener parts

What and how to hang from a drywall wall

With a standard drywall sheet thickness of 12.5 mm and a standard pitch between frame racks of 600 mm, the load on one fastener point is 50 kg. Therefore, with multi-point fastening, the correct distribution of the load and the correct choice of fasteners, you can safely hang various objects on the walls of the GCR.

TV

Question "Where to install a TV? "Today is not uncommon. Especially if the repair is completed, the apartment has beauty and you want all the equipment to be practical and convenient, and aesthetically pleasing, not occupy much useful space, but bring maximum benefit.

If the walls in the room are sheathed with drywall, and you want to fix the TV directly on the wall, there are several options:

With a small weight - easy installation on dowels

The low weight of the equipment allows the use of “butterfly” or molly dowels for its fastening. So that the load on the gypsum board is not critical, it is better to choose places where there is a metal profile and fasteners are fixed on both drywall and on the crate frame.

Mortgage fasteners installed between the wall and the casing

If there is a desire to hang a TV weighing more than 20 kg on a wall from drywall, then it is worth considering such an opportunity even when carrying out repairs. In place of the future installation of TV, it is necessary to install a wooden mortgage beam, which will strengthen the profile frame. After finishing work, a profile is found (using a magnet) and brackets are boldly installed and the TV is hung.

Installation in niches or on special supports

A large and massive model is unlikely to want to test the walls for strength. In this case, as in the previous one, a previously thought out solution will not hurt. It can be an originally designed niche or arch, interestingly complementing the interior.

There are some other TV installation options. For example, also fastening to the wall, only in this case we are talking about the carrier, the main wall. There simply will not be any problems: powerful dowels are installed directly into the wall through the gypsum fiber wall and a TV is mounted on them. All load from the device will be directed only to the wall.

Equipment of external load-bearing racks

For many, it may become a problem to mount a massive TV onto a drywall wall that does not have bookmarks or reinforced frames. The solution to this problem will be the assembly and installation of external (additional) racks. Supports from a channel, a metal pipe or other similar materials are equipped vertically along the gypsum board and are rigidly fixed to the floor and ceiling. The newly-minted frame can be decorated, crafted, decorated - the main thing is that you can safely attach a large and heavy, but such a favorite TV to it.

Bracket Mount

Today, one of the main types of TV mounts is the brackets. For drywall, this fixture should be enough to keep the weight of the TV on the “sleeve” of a certain length. Butterfly-like brackets are usually included with the TV. In addition, plastic dowels are attached to them, which are very unreliable in business. Therefore, it is better to choose the “butterfly” or “molly” dowels that fit exactly the holes on the bracket and are reliable in operation: when installed, the dowels open behind the back of the wall and hold tightly to it.

Wall-mounted kitchen cabinet and miscellaneous appliances

First of all, for mounting a hinged kitchen cabinet of any size and weight, accurate marking is necessary. It will help to correctly determine the attachment points so that the weight of the structure is evenly distributed at all points. Drywall can not boast of a large margin of safety, therefore, there are several specific methods that allow you to correctly and reliably fix a cabinet or shelf on the gypsum board.

For fastening the indicated heavy structures, a plastic dowel is hardly suitable; therefore, fastenings are used on:

Metal horizontal profile

Often, a butterfly dowel is used to mount medium-sized structures. The fastener itself does not break records in terms of power. But if there are several of them, and they are correctly distributed on the metal profile, which passes under the drywall, the result will be excellent. During installation, the “butterfly” will clamp both the GCR and the profile.

The mounting process is simple:

- Holes are made at the previously designated marks in the drywall and profile.

- The “butterfly” dowel is inserted, which is tightly fixed with the “petals” opened during clamping.

- The hardware is screwed in and fastened wall cabinet.

Quickly find a profile will help a simple magnet. It is enough to move them along the wall to find the necessary guide. It is best if the frame is made of high-quality, rigid and durable components.

Pre-installed under drywall mortgage bars

The height of the beam depends on the level at which the cabinet will be located. Please note that the location of kitchen cabinets can be single-level and multi-level.

The technique of fastening using embedded bars is known for a long time. And today, many owners are trying to make the future layout of the kitchen in advance. Wooden bars are installed together with the profile, the whole structure is securely fastened and, as a result, a solid support for any fasteners is ready.

If the wall cabinet has significant weight, it should be distributed according to two mortgages: top and bottom, and then the following options are possible:

- Preparation of holes for dowels, which will become fasteners.

- The use of wood screws, with which kitchen cabinets will be fixed.

- Installation of special dowels for screwing in hooks, which are a more convenient option for hanging furniture.

To create a safe and reliable construction, the bars are often fastened directly to the wall with anchors or dowels.

Special supports and suitable fastener designs

Sometimes you have to use additional mounting methods. For instance:

- Fixture to the ceiling. In this case, suspended structures, special cables (at least 4 mm thick) or hooks in the shape of the letter G, fixed brackets are applicable. Mounting elements are attached to the ceiling at several points. It is possible to select decorative, painted or chrome parts to create uniform interior style.

- Floor mount. It is used for some types of furniture for which a strong and reliable supporting structure is required, in the role of which are the legs. Poles with a high coefficient of rigidity can be a useful addition. Installed in the floor and ceiling along the entire height of the wall, they will become additional supporting profiles.

The use of molly dowels

Molly fasteners, although they have an increased cost, but more than justify their price. Installation of kitchen cabinets on metal dowels is possible without any special preparatory work. In this case, the procedure does not practically differ from other methods of fastening:

- Marking places fasteners.

- At specific points of attachment, a hole of the required diameter is made.

- A dowel is installed in the finished hole, and then a screw or other fastening elements (for example, a hook) are installed. During the screwing of the hardware, the petals open on the back, which fix the fasteners to the GCR.

The size of the clamping area is large enough, so the fasteners are very reliable.

Using metal anchors

Fastening of large and heavy items of kitchen furniture can be done using elongated metal anchors. The peculiarity of their installation is that these elements are attached directly to the main wall, through the gypsum wall. Long anchor elements are relevant when the distance between the load-bearing wall and drywall is within 100 mm.

The choice of such fasteners must be approached very carefully, since during installation, the bolts must be included in the masonry at 40-50 mm, at least. If their length is not enough, then you should choose another method of fastening.

Mounting on a bar or rail

Quite often, sets of kitchen mounted headsets are supplemented with metal tires. And this is very pleasing to buyers, because it is not always possible to foresee in advance where and how kitchen furniture will be placed. The narrow curly metal bar has a considerable number of holes for fixing self-tapping screws. Mounting rails of various lengths and configurations can be purchased without problems in construction stores and choose the fasteners suitable for them. The installation diagram is as follows:

- A tire or wooden plank is screwed to the carcass profiles via drywall.

- In places where GCR is without a profile, dowels or self-tapping screws are used, which must be installed at a distance of 5-10 cm to evenly distribute the cabinet weight and the load on the GCR.

- After the installation of tires is completed, furniture is mounted on them with special brackets.Given the different sizes and configurations of headsets, cabinets can be mounted on several tires in length and two in height. Then the fasteners will be held and the upper brackets, and lower.

This method is suitable for hanging fairly heavy elements of the kitchen.

Glued drywall and hanging kitchen on it

There are cases in which a frame from profiles is not used. This method is called frameless. When performing finishing work GKL is glued directly to the main surface.

If it is necessary to hang a cabinet on such a wall, you can take a crocodile dowel (wall - from aerated concrete) or anchor fasteners. As in the previous methods, markings are made on the wall and holes are drilled, dowels are installed, the piece of furniture is hung and firmly fixed.

Using the described method, it is important to pay special attention to the correct selection of fasteners for a particular wall material. Since fragile blocks will not hold standard dowels made of plastic.

Boiler

Water heaters Different shapes and sizes are more relevant today than ever. A storage appliance can have significant weight, therefore, among the possible installation methods, it is necessary to choose the most optimal option.

Mounting on a wooden tab

It’s good if the owners of the apartment planned to install this equipment in advance. In such cases, as a rule, the parameters and weight of the boiler are taken into account. And when repairing or decorating the wall with drywall, they add to the frame from the profiles of the embedded beam. The structure, reinforced with hardwood boards, can withstand the entire weight of the water heater without any problems. To install the unit, the weight of which varies within 50 kg, you must:

- Drill to make a hole in the mortar beam through drywall.

- Through the GCR, a dowel is inserted into the tree and a screw, hook or bracket is screwed (the latter must be selected for a specific boiler model, in addition, some water heaters are already sold with a set of fasteners).

- The same process is repeated at all attachment points.

- Mounting locations are being processed siliconebecause during their installation, small gaps are formed, which can become a place of moisture ingress.

- A boiler is hung on well-fixed screws, brackets or hooks. If we are talking about equipment of significant weight and size, it is worth considering the option of using anchor bolts.

Installation on pre-assembled metal mount

Quite often, there is a need to install a massive multi-cylinder water heater. In order not to doubt the strength and reliability of the wood bookmarks, you can safely use metal mounts made of steel plates and trimmed screws or bolts:

- A bolt is welded onto the plate in the center, and its length is equal to the sum of the width of the profile, the thickness of the drywall, tile and the necessary length for the correct fixing of the boiler eyes with nuts.

- The required number of parts is made, usually 4.

- The resulting structures are attached to the wall or tab so that the bolt (boiled) is located just in the center of the future hole for mounting the water heater.

- GKL wall sheathing is carried out so that the ends of the screws come out - holes are made.

- Any cladding material can be laid on top of the drywall.

- When the finishing work is completed, the boiler mounting eyes are put on the prepared bolts, where they are fixed with nuts of the appropriate size.

It is clear that such a method of installing a water heater is possible only before the installation of drywall.

Shelf installation

The method is one of the most reliable and safe. In this case, the shelf is made independently of drywall or a finished product is taken that is suitable in size.Best of all, if the design is made of durable material, and fastening is made on metal profiles, which makes it possible to evenly distribute the weight along the stiffeners of the frame.

- At the height required to install the boiler, holes are made to secure the shelf.

- Dowels are inserted into the holes.

- Screws are screwed in and a shelf is hung on which a water heater is installed.

So, thanks to the simple design, you can evenly distribute the entire load over the entire section of the wall or to the floor and wall.

Using chemical anchor

This method is applicable for the installation of heavy and overall boilers. The action plan is basically similar to the previous ones:

- In places of future fastening, holes are made in the wall according to the marking through the GCR.

- Each hole is thoroughly dustproof.

- Using a construction gun, a chemical anchor solution is injected.

- Using a hairpin, a mesh sleeve is tightly inserted into the hole.

- After removing the studs, the hole is re-filled with a chemical anchor.

- 5 minutes of “settling” the solution and the pin is screwed into the elastic material until it stops.

- After a day, the solution solidifies well and the fasteners are ready in order to install a water heater on it.

Fasteners for small water heaters

All boilers are different in weight and size - as a result, the mounting holes for all are at different distances. To install the boiler:

- Markings are made on the plasterboard wall, each of which can be glued with tape to avoid a large amount of dust and debris during further work.

- In drywall and profile, holes of the desired diameter are drilled.

- Dowels are installed in the holes, and then hooks or brackets are mounted.

Having become acquainted with the various types of dowels and their capabilities, it is easy to determine how to install other various interior items, decor elements, etc.

Shelf, photo or picture weighing no more than 15 kg

Items weighing up to 15 kg can be hung on the gypsum board with the help of:

- A self-tapping screw, which can be screwed into drywall without first drilling a hole. The element fits tightly into the sheet and is firmly held in it.

- The hook, the fastening of which is made up of screws in the amount of: one, two, three with the corresponding weight of the cargo - 5 kg, 10 kg and 15 kg.

Mirror

Depending on the size, weight, configuration and future installation location of the mirror, fasteners are selected for it. Here you can highlight: glue "liquid nails", double-sided tape, dowels - "umbrellas", "butterflies", molly or drives.

The easiest ways to fasten lungs mirrors - This is gluing using liquid nails or double-sided tape. Using the latter, it is possible to attach a very small small weight mirror to the GCR. Glue is a more reliable means and can withstand more weight.

For medium-sized mirrors, butterfly dowels are perfect. Despite the plastic expansion bolt shield, they are well fixed and reliably hold an object. Heavier mirrors are mounted using a Molly metal dowel. When calculating the maximum load, it is worth considering that each fixture individually can withstand a load of up to 25 kg.

Pictures, small shelves

In order not to doubt the reliability of the fasteners, it is best to use in this case metal dowels having expansion (expanding) elements. The algorithm of actions is repeated: a hole of the required diameter is made, the corresponding dowel is inserted, a screw is screwed in, forcing the “petals” to open for firm fixation.

Cornices and pendant lights

With the help of Molly dowels or anchor fasteners, structures can be suspended from plasterboard ceilings. In addition, special metal hooks that hold self-expanding spring-loaded “paws” will be a good solution.The design works according to the principle of action of dowels for gypsum plasterboard: it is installed in the prepared hole and is independently fixed, while it can rotate.

Sinks, toilets, etc.

The most acceptable mounting options for hanging plumbing:

- Installation. For the installation of plumbing fixtures, a special welded construction is often used, which is very rigidly attached to the floor, walls and base partitions. Installation installation occurs simultaneously with the installation of GKL. Fasteners sinks It is made by power traverses.

- Using special brackets. Plumbing fixtures on drywall can occur using special brackets, which are a wide support, fixed inside the structure on the gypsum board.

- Installation of mortgages. The proposed method consists in laying in the design of the beam or even simple boards. Additional elements will share the load from the sink. Installing the latter on drywall is done using long bolts and studs.

Everything will not seem so complicated if all the work is done at the stage of assembly and installation of the structure.

For installation air conditioning unit for gypsum plasterboard casing, it is necessary to reinforce the frame under the gypsum board. The implementation of such work is associated with vibration, which is present during the operation of the air conditioner.

Radiators and batteries

Even in the process of repair, many have the question of how to hang and fasten on drywall heaters. Depending on the type of structure (cast iron, aluminum or steel), its weight and type of base, various methods from the installation are used.

Pre-installation of mortgages

Here the action algorithm is as follows:

- In the process of assembling the profile frame, we mark the place of the future battery installation.

- Prepared wooden blocks are attached to the profile or wall with anchor bolts or dowels, nails.

- On each side, mortgage fasteners to the profile are also required (self-tapping screws are used).

- This section of the GKL wall is being finished.

- The design is mounted on well fixed massive hooks or brackets.

Installation under the subject of special fasteners and supports

Modern models of heating appliances can be mounted directly on the GCR. With these methods of fastening, it is best to use:

- Molly dowel, which can withstand a load of up to 35 kg per bolt (with an increase in the number of fasteners, the load capacity increases).

- The Hartmut dowel (from Knauf) can withstand up to 50 kg of load even on a single layer of skin. The use of several such mounts allows you to hang bimetallic and aluminum radiators on a wall from drywall without installing supports on the floor.

Integrated use of hardware for fasteners and mortgages

To mount a cast-iron radiator, you can use several Hartmouth fasteners and they will successfully cope with the task, but provided that double or triple sheathing with plasterboard walls is performed (this is a prerequisite for installing structures with a weight (nominal) of 100 kg or more). But, for greater reliability and safety, it is better to play it safe and use long hardware for installation in a bearing wall or mortgages, which will ensure both the strength of the fastener and its durability.

Drywall, despite its fragility, is grateful material. If you work with him correctly and take into account possible nuances, he shows his strength and versatility. You can hang a variety of objects on the gypsum board - the main thing is to take this issue responsibly: correctly calculate the load, determine the fastening method, select high-quality fasteners specifically for drywall and related materials (brick, concrete, etc.), skillfully perform the work.