Which concrete to choose. Concrete grade and grade

Leading position among building materials for many years in a row holds concrete. It owes such popularity to its unique operational qualities, including high strength, frost and moisture resistance. Moreover, varying the ratio of the constituent components of concrete allows you to get material with slightly different properties, which allows it to be used in almost any environment. The question of choosing the right concrete remains the most important and difficult, because the further structural properties depend on this.

It is equally difficult to choose a suitable concrete manufacturer. The growing demand for this building material has led to the emergence of a huge number of proposals, which are difficult to navigate. So that the potential buyer of concrete could quickly find the best offer for themselves, the M350 concrete tender system was developed. System allows save time and money.

It is equally difficult to choose a suitable concrete manufacturer. The growing demand for this building material has led to the emergence of a huge number of proposals, which are difficult to navigate. So that the potential buyer of concrete could quickly find the best offer for themselves, the M350 concrete tender system was developed. System allows save time and money.

In order to be able to choose the right concrete mix for specific purposes, you need to know what indicators to pay attention to. Among the most important are the brand and class of concrete, the characteristics of moisture and frost resistance, as well as the mobility of concrete.

Concrete grade

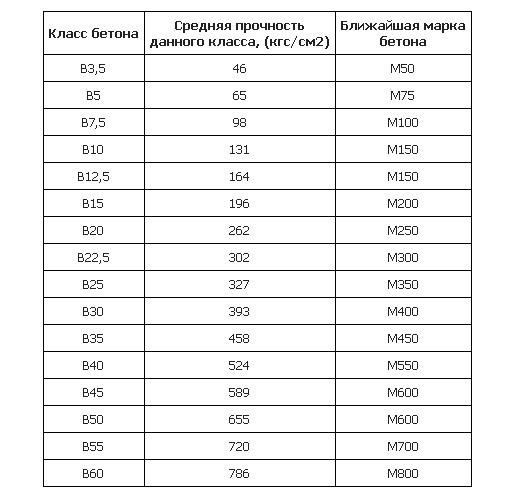

The most important characteristic of concrete is its ability to withstand compressive loads. This parameter is denoted by the letter M, and the index behind it indicates what kind of load each square centimeter of concrete can withstand. The exact value is determined in the laboratory, testing concrete that has hardened for 28 days, and a rounded value is recorded in the marking. For example, concrete that can withstand 98 kgf / m2is denoted as M100and concrete withstanding 196 kgf / cm2, - M200. Simply put, the digital index indicates the number of kilograms that can press on 1 cm2 concrete without destroying it.

Concrete is made today. from M50 to M1000but the greatest demand is consistently used by concrete grades M100-M500. Different levels of concrete strength are explained differences in composition: the proportions of the components used and their quality affect. Concrete composition sand, cement, crushed stone or gravel. Sand and crushed stone (the so-called skeleton) are responsible for the bearing capacity of the future structure, and cement, combined with water, is responsible for the strength of molecular bonds. The higher the proportion of cement in the composition of concrete, the higher the strength of concrete itself.

Concrete is made today. from M50 to M1000but the greatest demand is consistently used by concrete grades M100-M500. Different levels of concrete strength are explained differences in composition: the proportions of the components used and their quality affect. Concrete composition sand, cement, crushed stone or gravel. Sand and crushed stone (the so-called skeleton) are responsible for the bearing capacity of the future structure, and cement, combined with water, is responsible for the strength of molecular bonds. The higher the proportion of cement in the composition of concrete, the higher the strength of concrete itself.

The quality of the components also plays a role. Sand can be either river or quarry - It is important that it is large and with a minimum amount of clay impurities. The optimal size of crushed stone is 20-25 mm; it should be made of strong rocks. The brand of cement also affects the strength of concrete. As a rule, cement M400 and M500 are used, the latter will need less for the preparation of concrete of a given strength.

The least durable grades of concrete are used in the construction of the lightest and less critical structures. Private foundations and high-rise buildings, industrial buildings are created by using more durable compounds (M200 and above). With increasing strength, the price of the composition also rises, so using unnecessarily strong compositions is useless, as is saving.

Concrete grade

The class of concrete also speaks of the strength of the material, it modern derivative of the concrete brand. If the average strength of the material is used in determining the grade, then the strength class involves the determination of strength with guaranteed security. This is a more accurate value, which is expressed taking into account the coefficient of variation of 13%. Despite the fact that the class more accurately determines the characteristics of concrete, today most specialists use the concept of brand.

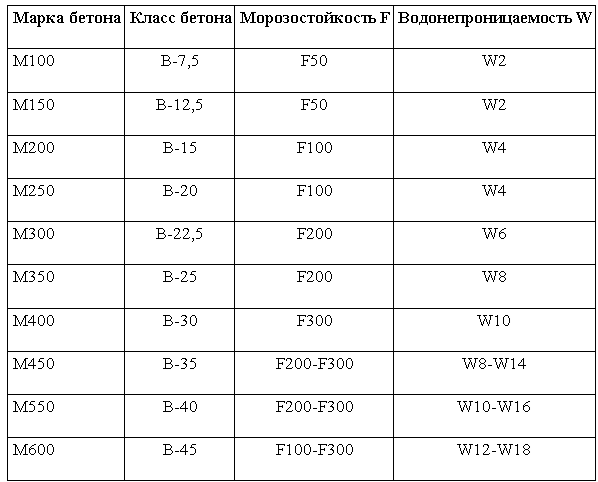

Classes define the letter B and a number from 3.5 to 60: the higher it is, the stronger the composition in front of you. There is a direct relationship between classes and brands: for example, the M100 brand corresponds to the B7.5 class, the M200 brand corresponds to B15, etc.

Water resistant concrete

The water resistance of concrete is understood to mean its ability to not pass water. Previously, this characteristic was denoted by the Russian letter B, now use W, and the numerical designation next to it may begin from 2 and reach 20, equal to the pressure of the water column in kgf / cm2in which a cylindrical concrete sample of standard height does not allow water to pass through.

If concrete is being built in conditions elevated groundwater, it makes sense to choose a composition with a high value of water resistance, in which special hydrophobic additives are added. By the way, the use of such material will reduce the cost of full foundation waterproofing.

If concrete is being built in conditions elevated groundwater, it makes sense to choose a composition with a high value of water resistance, in which special hydrophobic additives are added. By the way, the use of such material will reduce the cost of full foundation waterproofing.

The highest water resistance and water resistance hydraulic concrete. For its production, hydrophobic or plasticized Portland cement, sand and gravel of higher quality are used than for ordinary concrete. High waterproof performance is also achieved through installation with maximum sealing.

Concrete frost resistance

Concrete frost resistance is indicated by the letter F with a numerical value from 25 to 1000: the higher it is, the greater the number of freezing and thawing cycles that concrete can withstand without losing its strength properties. The choice will depend on the conditions in which the finished structure will be operated, on the climate, the number of periods of freezing and thawing during the cold season.

For the construction of hydraulic structures, airfield coatings and bridge supports, it is better to choose the most frost-resistant compounds. In private construction, concrete of the class F100 or F200 is suitable for the construction of the foundation. You can focus on density: the higher its value, the more frost-resistant the composition will be.

Concrete mobility

The mobility of concrete (P) speaks of degree of fluidity, which directly affects the convenience of working with the composition. The numerical coefficient is expressed in the range from 1 to 5: the higher it is, the more liquid the composition will be. In private construction, concrete is used to equip the foundation P2 and P3. More fluid formulations are used only in cases where it is necessary to fill in a tightly reinforced base, or when concrete is supplied using concrete pumps.

Of course, working with a more fluid composition is more convenient, but you cannot add water to ready-mixed concrete to increase the mobility of the composition. In this case, the grade of the solution immediately decreases, reducing the final strength.

Areas of use of different grades of concrete

Concrete is widespread, it is used to create foundations and many other structures. Depending on the purpose of use, concrete of a particular brand is selected. Here are the main areas of use of the most common brands of concrete:

M100 used to create road borders and before pouring the strip foundation;

M100 used to create road borders and before pouring the strip foundation;- M150 suitable for pouring floors, foundation under fence, as well as for the organization of parking for cars;

- M200 used in the restoration of buildings, fill paths, as well as to create the blind areas and the foundation of light buildings;

- M250 suitable for creating different types of foundations, as well as for sites and paths;

- M300 used to create the foundation of brick houses, paving slabs and roads subject to heavy loads;

- M350 suitable for creating monolithic foundations and foundations for multi-storey buildings;

- M400 It can be used both for building foundations of residential buildings, and for the construction of bridges and structures on the water;

- M450 and M500 Suitable for the construction of tunnels, sewers, bridges.

The choice of concrete for the foundation

Since concrete is used in the organization of the vast majority of foundations, the question of its choice specifically for these purposes requires a more detailed consideration. To select the necessary brand, you need to know the weight that will be assigned to the structure, the conditions for its operation, take into account the type of soil, the level of groundwater, etc. All of this should be mentioned in design documentation, and for those who are building independently, we’ll give information about the scope of use of different brands of concrete.

The less load from the building being erected, the less durable concrete will be needed. If will be built frame house, then you can do with concrete M200for wooden house it is better to arrange the foundation of concrete M250. For two-story wooden houses, houses from gas silicate and expanded clay concrete blocks it is better to choose concrete M300. If reinforced concrete wall panels will be used or in the plans for the construction of a brick house, then concrete M350, M400 and higher are used for the foundation.

The less load from the building being erected, the less durable concrete will be needed. If will be built frame house, then you can do with concrete M200for wooden house it is better to arrange the foundation of concrete M250. For two-story wooden houses, houses from gas silicate and expanded clay concrete blocks it is better to choose concrete M300. If reinforced concrete wall panels will be used or in the plans for the construction of a brick house, then concrete M350, M400 and higher are used for the foundation.

Affects the choice of brand of concrete and soil type. The more heaving the soil, the greater the differences in load are on the foundation. So, for clay soils, it is better not to use concrete below M350, and for sandy and rocky soils, M200 is also suitable. If the groundwater level at the place of construction of the house is high, then it is better to choose concrete with increased water resistance: even if M250 is suitable for loads, it is better to use M350, for which W is almost twice as high.

Whatever brand of concrete is used, the characteristics of the finished structure are also largely affected by the correct dilution of the mixture with water, as well as the process of filling the mold with concrete and the uniform distribution of concrete.

Thanks to the author, informative article. Thank you for the comprehensive information on the selection of concrete mixtures.