Ebbs for plastic windows: selection and installation

Installation of ebbs is an important step in the installation of window structures and it is not worth transferring it to later, since in addition to the aesthetic function, the external window sills also play an essential protective role. In other words, it is important not only that your windows will look harmonious and complete, but also the safety of the facade from the effects of various weather conditions. Of course, their main function is to prevent moisture from accumulating on the outside of the window unit, penetrating into the cracks, thereby causing harm. And in order for the external window sill to be as reliable and suitable as possible, it is worth paying attention not only to the installation process, but also to the choice itself. That's what we decided to talk to you about today.

1. Types of window tides

Before you begin the intricacies of installing ebb tides for plastic windowsIt’s worth a little understanding of what types are generally available on the market. Along the way, we will also receive answers to questions such as what they have advantages or disadvantages, as well as evaluate their practicality in certain conditions. Today, ebbs are made from various materials, in accordance with the design, given the windows and the facade, which in itself is logical. However, not all of them are equally effective in various conditions, and they have different levels of popularity among users.

Tin

The first and rather common material in the production of ebbs for plastic windows is tin. However, this is not about galvanized tin castings, since they have long ceased to attract the attention of buyers. By the way, there are several extremely good reasons. Once popular, they were made from a thin steel sheet coated with zinc to prevent corrosion. They were considered quite rigid and damped well from rain falling on the ebb tide. However, there were some shortcomings, which turned out to be much more critical than merits. They turned out to be absolutely unstable to the acidic environment, and therefore did not take root in the market.

Installed in large cities where acids are present in precipitates, even in the smallest amounts and in dissolved form, such ebbs quickly deteriorated. As a result of such exposure, zinc was peeled, exposing the ebb, making its appearance unpresentable, and the sheet itself is subject to deformation and corrosion. Fortunately, they were replaced polymer (also known as polyester) castings with much higher protection due to the presence of a polymer coating. Although, in fact, under it all the same galvanized ebbs. And yet they seem much more durable and resistant to the effects of acids than their predecessors.

Another advantage of the latter can also be noted a wide variety of palettes when choosing. That is, you can find or order the tides of the color you need, so as not to disturb color scheme of the window block or facade. They have, however, a small minus, which consists in the fact that in dealing with them you need to be as careful as possible, since leaving a scratch on them is a simple matter. Basically, this type of ebb is usually considered one of the most common, since with the right and high-quality installation they can last at least a couple of decades.

Plastic

Plastic ebbs can be called less popular in the domestic market, since they suffer from a similar mechanical problem, like the previous ones, only several times stronger. It will not be difficult for birds, as well as falling icicles, to scratch them, and the chances of damaging plastic by negligence are much higher. On the other hand, they still have advantages. It would seem, despite such fragility, they are very durable and can withstand various atmospheric effects. True, in a continental climate, external window sills of this type may not withstand a sharp temperature drop.

Plastic ebbs can be called less popular in the domestic market, since they suffer from a similar mechanical problem, like the previous ones, only several times stronger. It will not be difficult for birds, as well as falling icicles, to scratch them, and the chances of damaging plastic by negligence are much higher. On the other hand, they still have advantages. It would seem, despite such fragility, they are very durable and can withstand various atmospheric effects. True, in a continental climate, external window sills of this type may not withstand a sharp temperature drop.

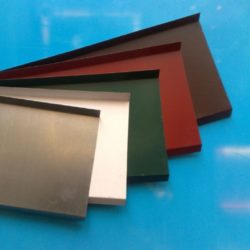

Aluminum

In terms of popularity, aluminum castings are much more in demand than plastic. And this is despite the fact that they are relatively expensive. Although, probably, everything here depends on quality, which completely and fully justifies such a cost. The thing is that aluminum seems to be much more durable than the materials of the two previous options. It does not deform, does not bend, does not fade, and is not susceptible to corrosion, which allows such an ebb to last for a very long time, preserving its factory external features and useful qualities. True, the choice of colors here is increasingly tight and limited, mainly you will come across white, gray, beige and brown options.

In terms of popularity, aluminum castings are much more in demand than plastic. And this is despite the fact that they are relatively expensive. Although, probably, everything here depends on quality, which completely and fully justifies such a cost. The thing is that aluminum seems to be much more durable than the materials of the two previous options. It does not deform, does not bend, does not fade, and is not susceptible to corrosion, which allows such an ebb to last for a very long time, preserving its factory external features and useful qualities. True, the choice of colors here is increasingly tight and limited, mainly you will come across white, gray, beige and brown options.

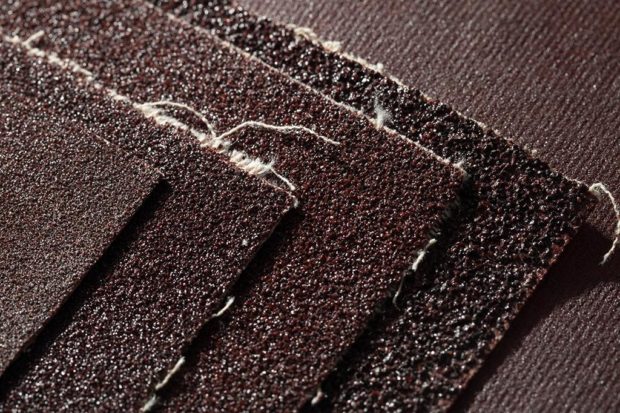

Stone

There are also stone tides on the market, but they are more a luxury than a necessity. They are made mainly of sandstone and granite, and are extremely reliable and weatherproof. And yet, many from the installation of such ebbs are stopped for the most part by the cost, which is beyond the feasibility of such a purchase. Yes, it is beautiful, but, for example, in a high-rise building from such an ebb, there will be no use for nothing. For these reasons, they are not particularly popular among most consumers. However, if you are determined to give the facade of your home exclusive appearance, then they may appeal to you.

There are also stone tides on the market, but they are more a luxury than a necessity. They are made mainly of sandstone and granite, and are extremely reliable and weatherproof. And yet, many from the installation of such ebbs are stopped for the most part by the cost, which is beyond the feasibility of such a purchase. Yes, it is beautiful, but, for example, in a high-rise building from such an ebb, there will be no use for nothing. For these reasons, they are not particularly popular among most consumers. However, if you are determined to give the facade of your home exclusive appearance, then they may appeal to you.

2. Colors

By and large, your choice will be determined precisely by what material you prefer to tint from, as well as the availability of a color suitable for you. It is clear that when installing, say, a brown window block imitating a tree, it would be foolish to set a white tide. However, do not forget that the palette of colors at low tides is not the same and can vary greatly depending on the type. This, of course, is commonplace, but if you want an exceptionally red aluminum cast, you won’t get what you want. However, after listing the main features of each type, you will certainly be ready for what awaits you in the market and decide on ideas in advance.

By and large, your choice will be determined precisely by what material you prefer to tint from, as well as the availability of a color suitable for you. It is clear that when installing, say, a brown window block imitating a tree, it would be foolish to set a white tide. However, do not forget that the palette of colors at low tides is not the same and can vary greatly depending on the type. This, of course, is commonplace, but if you want an exceptionally red aluminum cast, you won’t get what you want. However, after listing the main features of each type, you will certainly be ready for what awaits you in the market and decide on ideas in advance.

3. Installation of ebbs

Before proceeding to the tips and the main aspects of this important event, it is important to understand that for those who have absolutely no construction skills, it is best to turn to specialists for help. This will avoid any gross errors that can subsequently lead to various kinds of problems. However, despite this, it can be much easier to set the tide than it seems at first glance. The main thing here is to strictly follow the technology, which is the same for any ebb, and then the risk of problems will be minimal.

Positioning

At the initial stage of the installation, you will need to carry out a simple, but rather important manipulation, namely, to correctly trim the ebb so that it fits in the required space. The main thing, by the way, in this matter is not to forget that it will be necessary to leave enough space at the edges, since they must be bent to the side slopes. It will be enough to leave at least 1 cm from each edge, as it is better to do it this way if you want to avoid getting wet slopes and protect them more reliably.

At the initial stage of the installation, you will need to carry out a simple, but rather important manipulation, namely, to correctly trim the ebb so that it fits in the required space. The main thing, by the way, in this matter is not to forget that it will be necessary to leave enough space at the edges, since they must be bent to the side slopes. It will be enough to leave at least 1 cm from each edge, as it is better to do it this way if you want to avoid getting wet slopes and protect them more reliably.

True, this is not so bad, since it is important to remember the width of the tide.In no case do not install the ebb flush with the wall, otherwise the water will drain exactly on it, and this is exactly what you seek to avoid by installing the ebb. True, a visor too long is also not worth doing, because, despite the high-quality and reliable fastening, with a strong wind, a far-reaching ebb can even bend, if not tear off at all. The latter, however, is more relevant for residents of resort towns, where the crazy wind often walks. In other words, when adjusting the sizes, it will not be superfluous to take into account the weather conditions familiar to your places.

Training

Of course, before proceeding with the direct installation of the ebb, it is necessary to thoroughly prepare the lower part of the slope, otherwise experts do not recommend immediately starting to mount it. Fortunately, nothing particularly complex expects you. It will be enough to clean the bottom end of the window opening from possible dirt and open it primer. After that, it remains only to glue a special vapor-proof tape that protects this area from liquid, even in a gaseous state, as you might guess from its name. It is also able to remove excess moisture from the wall. To stick the tape is one edge on the frame, and the other on the lower tide.

Of course, before proceeding with the direct installation of the ebb, it is necessary to thoroughly prepare the lower part of the slope, otherwise experts do not recommend immediately starting to mount it. Fortunately, nothing particularly complex expects you. It will be enough to clean the bottom end of the window opening from possible dirt and open it primer. After that, it remains only to glue a special vapor-proof tape that protects this area from liquid, even in a gaseous state, as you might guess from its name. It is also able to remove excess moisture from the wall. To stick the tape is one edge on the frame, and the other on the lower tide.

Mount

The final step in installing window tides is to mount. And first you have to take care of the pillow for the ebb, if you want to approach this issue as qualitatively as possible. Previously, it was most often made of cement, but today it is all done much more simply - frost-resistant polyurethane foam blown under the ebb itself. And if you do not want the accurately calibrated angle of inclination along with the smooth surface of the tide itself to be distorted, it is best to use foam with a minimum expansion force.

The final step in installing window tides is to mount. And first you have to take care of the pillow for the ebb, if you want to approach this issue as qualitatively as possible. Previously, it was most often made of cement, but today it is all done much more simply - frost-resistant polyurethane foam blown under the ebb itself. And if you do not want the accurately calibrated angle of inclination along with the smooth surface of the tide itself to be distorted, it is best to use foam with a minimum expansion force.

From the side of the window, the ebb is fixed to the frame expander with the help of “fleas”, so often called small screws for metal. You can also walk in advance sealant at the place of its connection with the window frame to prevent moisture from entering the lower part of the window. When installing the ebb for plastic windows, it will be most logical to use a special groove, which is provided by the manufacturer for this purpose. Some experts also recommend using a stand profile to enhance waterproofing in cases where it is necessary to set the tide below the frame level.

The finishing touches in the installation of the ebb will be the sealing of the joints at the places of its connection with the walls. This can be done with sealant or a simple cement mortar.

Conclusion

So, as you have seen, in fact, the process of installing the ebb for plastic windows is not something incomprehensible and unbearable. All this can be done without having highly specialized skills, and any of the components for work is available in every hardware store. Of course, you can do it everywhere, so do not be afraid to turn to specialists for help. You may want to observe the work once and bring the next window to mind by your own efforts.