Vinyl: classification, styling, reviews

A large number of flooring, presented on the market of modern building materials, can amaze an inexperienced user and confuse. New technologies make it possible to create a completely new type of floor, which will have excellent characteristics, both in durability and good resistance to physical influences, and according to external data. Of the variety of flooring, a special place is occupied by the new vinyl-based floor. This is the latest development in the field of flooring, which has excellent technical and external data. This floor provides designers with ample opportunities to implement any interesting interior design. To better understand what new vinyl floors are capable of, let's take a closer look at their classifications and other features.

A large number of flooring, presented on the market of modern building materials, can amaze an inexperienced user and confuse. New technologies make it possible to create a completely new type of floor, which will have excellent characteristics, both in durability and good resistance to physical influences, and according to external data. Of the variety of flooring, a special place is occupied by the new vinyl-based floor. This is the latest development in the field of flooring, which has excellent technical and external data. This floor provides designers with ample opportunities to implement any interesting interior design. To better understand what new vinyl floors are capable of, let's take a closer look at their classifications and other features.

What is vinyl flooring or vinyl?

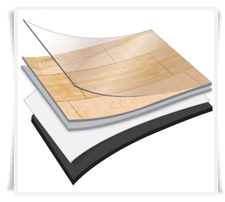

Vinyl is multilayer coating made on the basis of PVC. This artificial turf has high strength as well as excellent flexibility and durability. To give these qualities, plasticizers, special resins, silica chips, inert fillers and stabilizers are added to polyvinyl chloride. Under high pressure, all this mass is fused and the initial multilayer material is obtained, which has excellent physical properties. Layers of vinyl flooring can be distinguished. This will help to understand what constitutes vinyls.

Vinyl is multilayer coating made on the basis of PVC. This artificial turf has high strength as well as excellent flexibility and durability. To give these qualities, plasticizers, special resins, silica chips, inert fillers and stabilizers are added to polyvinyl chloride. Under high pressure, all this mass is fused and the initial multilayer material is obtained, which has excellent physical properties. Layers of vinyl flooring can be distinguished. This will help to understand what constitutes vinyls.

- Base layer - actually polyvinyl chloride with the addition of quartz chips.

- Upper layer - This layer forms a printed pattern that gives a variety of textures.

- Next top layer - a transparent layer of PVC for added strength.

- Finish coat - PVC layer hardened by ultraviolet rays.

- bottom layer - This layer is a self-adhesive surface that attaches vinyl tiles to the floor.

Classification of vinyl flooring

New vinyl flooring is classified in different ways. You can divide the wide range of products offered by different manufacturers in the modern construction market into square, rectangular or triangular-shaped modules of vinyl tiles. They can have a surface, both matte and glossy. Also, the surface of the vinyl flooring may have a rough structure. In addition, manufacturers share vinyl flooring by production methods, which we will discuss below.

New vinyl flooring is classified in different ways. You can divide the wide range of products offered by different manufacturers in the modern construction market into square, rectangular or triangular-shaped modules of vinyl tiles. They can have a surface, both matte and glossy. Also, the surface of the vinyl flooring may have a rough structure. In addition, manufacturers share vinyl flooring by production methods, which we will discuss below.

- First type of manufacture - this is quartz vinyl moduleswhich are 80% crushed quartz. This type of vinyl coating has a strong and resilient structure, which makes it the best type of vinyl coating. He has excellent physical performance. This complete lack of moisture absorption, resistance to chemical influences and is an excellent dielectric.

- Second type of manufacture - this is vinyl pvc slabs, which are made of vinyl itself, special resins along with stabilizers and some plasticizers. This set of materials is pressed and the starting material for flooring is obtained. According to its characteristics, such a coating is much stronger and better than linoleumTherefore, users are increasingly using it for hallways, bathrooms and other residential and non-residential premises.

- Third type of manufacture - this is self adhesive vinyl coatingwhich is very convenient to lay on your own. Its installation does not require special skills in cosmetic repair of premises. Just peel off the protective film and glue the vinyl panel onto the previously cleaned floor surface. It is very convenient to carry out independent repairs in this way, so self-adhesive vinyl is a very useful thing.

Varieties and classes of vinyl tiles

Like laminate flooring, vinyl has three varieties, which are divided into classes according to the strength and wear resistance of the product. This allows you to use it for various purposes, for example, in an apartment of a lower stability class, since there is no intense flow of people, or in an office where high stability is required under a heavy load of many human legs. Let's look at all three varieties in more detail, and you’ll better understand which and where it is best to apply.

Like laminate flooring, vinyl has three varieties, which are divided into classes according to the strength and wear resistance of the product. This allows you to use it for various purposes, for example, in an apartment of a lower stability class, since there is no intense flow of people, or in an office where high stability is required under a heavy load of many human legs. Let's look at all three varieties in more detail, and you’ll better understand which and where it is best to apply.

- Plain household vinyl tile for the floor strength class 23-31, which suggests that it can be used in rooms where the intensity of walking is low. That is, such a flooring is perfect in an apartment or house. The protective top layer is quite thin, but there are a lot of varieties of textures and color solutions, so choosing the right option for any room design is quite simple.

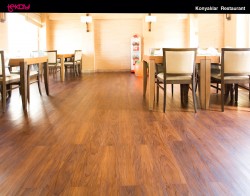

- Next strength class refers to commercial vinyl tile and possesses value 32-42. This option is used in rooms with medium traffic. Quite often you can find this vinyl flooring in small offices or small retail premises. This type differs from household vinyl in a denser and thicker protective layer, which allows for greater strength.

- Tritium type strength is maximum and has class indicator 43. This type is used in rooms with maximum traffic, for example, in industrial premises or workshops, as well as sports grounds and shopping and entertainment centers. The protective layer of this vinyl flooring is 3-4 millimeters. For greater strength, special mineral additives are added to it. Also, such a coating has antistatic characteristics and has a non-slip surface.

Laying vinyl flooring

Laying vinyl flooring is a fairly simple process that does not require special building skills. Moreover, there is a kind of vinyl, which has a self-adhesive surface. It is enough to remove the protective coating and stick the material to a flat surface. This can be done even by a person who has never done repair work on the floor. First of all should level the floor and eliminate cracks, potholes and remove construction debris. You can make a screed or use self-leveling cement mixes.

Laying vinyl flooring is a fairly simple process that does not require special building skills. Moreover, there is a kind of vinyl, which has a self-adhesive surface. It is enough to remove the protective coating and stick the material to a flat surface. This can be done even by a person who has never done repair work on the floor. First of all should level the floor and eliminate cracks, potholes and remove construction debris. You can make a screed or use self-leveling cement mixes.

It would be better if The surface of the floor is sanded and smoothed as much as possible before laying the vinyl coating. When laying vinyl flooring on concrete should measure the humidity level of the room, which should be no more than 45-65%. This indicator is optimal.

Bonding vinyl tiles carried out in several ways. it bonding around the perimeterwhen the adhesive composition is applied along the edges of the tile, that is, the seams and thus the material is laid around the perimeter of the room. Another way is to complete glueing the inner surface vinyl floor and subsequent gluing to the floor surface.

Vinyl Flooring Reviews

Reviews about vinyl flooring are overwhelmingly very positive, since the material has good physical abrasion resistance, significantly superior in strength linoleum and very similar in texture and surface structure to laminate. This flooring is perfect for the implementation of underfloor heating, as it perfectly transmits heat and is resistant to the heating temperature of the warm floor.

- A significant advantage of the vinyl floor is that users give off a fairly dense protective surface that perfectly resists caustic chemical detergents and is easily cleaned from almost any impurities. For example, in a children's room, where your kids can paint the floor with felt-tip pens, smear the surface with plasticine or smear the floor differently, such a floor covering will be ideal.

- In addition, vinyl tiles have excellent moisture resistance and sound insulation. And also it should be noted that laying vinyl flooring is a very simple task that anyone can handle, even one who does not think anything about repair. Therefore, the popularity of this floor covering is very high and growing every day. Try to ask the seller at the nearest building supermarket and you will surely get an answer that the vinyl coating is taken apart very quickly.

Summarizing negative customer reviews, the following can be distinguished:

- Peeling off the top protective layer on vinyl tilesmainly in the corners. Most likely this drawback is inherent in the cheapest samples produced in a handicraft way. Therefore, you should not buy the cheapest goods and products of an unknown manufacturer.

- Changing the shape, punching, sprawling vinyl tiles. High-quality vinyl is not inherent to these shortcomings, however, on the market you can find fake and artisanal products. Advice in this case, be careful when choosing, pay attention to the availability of certificates from the seller, do not choose products at the lowest price from little-known manufacturers.

Indeed, vinyl floors are a great choice. We decided to try it in this repair and were not disappointed. We have been walking on it for a year now and everything is fine.

Vinilam laid the color "steel oak" in the hall.

Very like! Easy to clean, with a small child, I thought that there would be scratches after the games, but I was pleasantly surprised, there were no scratches left))) I advise) I like it very much!

They installed a warm floor in the nursery and could not decide which coating would suit us. Friends advised us to contact VINILAM, we were provided with detailed information and we decided to try it. We picked up a light color, it looked very harmonious with our wallpaper. Laying took no more than an hour. Vinyl coating is ecological, which is an important criterion for a children's room. On the floor it is exactly covered, there is no roughness and cracks. We were satisfied with the choice.

We were advised by the foreman who made repairs to lay the Vinyls. At first they doubted, but when he told us more about this material and its advantages, then all doubts immediately disappeared. It looks cool, there are no gaps and other things, everything looks like a whole.

During the repair, my husband and I argued for a long time about what kind of coating to choose, "sank" between the laminate and vinyl. After comparing wear resistance, we settled on the second option, although it is slightly more expensive.The coating was ordered from the manufacturer Vinyl, on the Internet they chose the right shade, this is Oak Tournai (10-038), they also came under a discount of 10%. Vinyl covered all the living rooms + hallway, it cost us 100 thousand rubles. The coating was installed by itself, it is laid simply, thanks to a mechanical lock. In use, vinyl is not afraid of water, shock, gravity, easy to clean, does not absorb anything. For those with small children or animals, this cover is a great option!