5 tips for choosing a bench

If working with metal is your professional activity or just a hobby, then you can’t do without a workplace. It must be reliable, functional, durable to withstand sometimes very solid loads, and durable. All these requirements are met by bench workbenches, special work tables for working with metal. Experienced craftsmen should know well what a workbench should be. If you are new to this business, then it would be nice to deal with the basic issues of choosing a bench. We study the main varieties and determine which equipment is needed for the workshop, and which - for the garage.

Basic requirements for a bench

It is difficult to imagine the work of a metal processing master without a special desktop. A workbench makes the work process more productive, comfortable and safe. Before we move on to the study of varieties of bench workbenches, it is necessary to touch on the theory and recallwhat workbenches generally are.

In addition to locksmith, there are also carpentry workbenches. They are intended only for working with wood, therefore they have nothing to do with our topic at all. Interest can cause universal workbenches. They get a tabletop made of dense plywood with a sheath of steel sheet. On such a surface, you can work with both metal and some wooden parts. Often, a universal workbench means a folding structure, which is very fond of the owners of small garages.

To simplify, the workbench is a desktop made in accordance with a number of requirements. The bench should be:

- strong and reliableto withstand the stresses that your activity suggests;

- functional and ergonomic. The workplace should correspond to the growth of the master and, if necessary, be equipped with storage places;

- sustainable. Serious work is carried out at the workbench, often it is a matter of heavy loads, and a high degree of accuracy is required. That is why the workplace must be motionless;

- long lasting. A quality bench work bench will last at least a couple of decades.

To meet all the above requirements, workbenches have a specific design. The frame is made of durable thick metal, complemented by a powerful countertop. The best option is an MDF board up to 30 mm thick coated with thick galvanized steel. Such a design can withstand high loads, and even hammer blows welding. Moreover, the galvanized countertop well tolerates contact with gasoline, oil, solvents and many other aggressive substances, it is easy to care for, it is quite easy to clean from dirt. For additional protection it is covered with a layer powder paint.

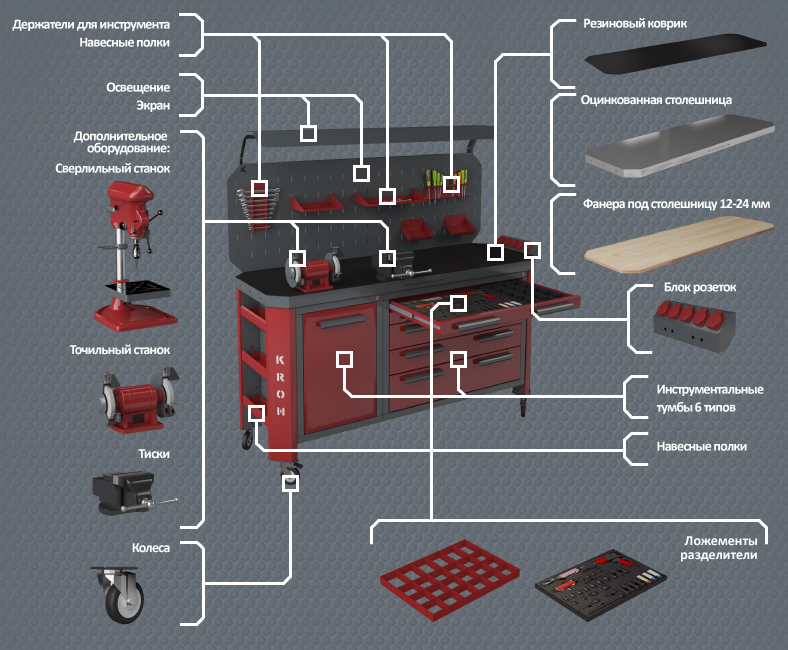

Some workbenches get sides on three sidesthat prevent small objects from falling from the surface. Available may be perforated screen, which serves to fix the mass of necessary tools, for example, screwdrivers, scissors, saws, hammers and other trifles that should be literally at hand when working. The remaining tools and documentation can be stored under the countertop, in specially designed nightstands, drawers, and drawers.The design of this lower part of the workbench can be very different - the choice is based on your own requirements and the specifics of the tools that need to be stored. As a rule, storage sections are made strong enough - they can withstand up to 35 kg. If it will be necessary to store documentation, please note that one of the sections is locked.

If the dimensions and configuration are a matter of personal preference, then the quality of the workbench is a common requirement of all craftsmen.

Here are the main functions the workbench is designed for:

- markup;

- bending and cutting;

- drilling;

- thread cutting;

- engraving;

- dissection;

- riveting;

- polishing, grinding and lapping.

Naturally, in order to qualitatively perform this or that operation, in addition to typesetting, you will also need a specific tool. A workbench is just a solid work surface and a way to organize the storage of numerous fixtures.

A set of locksmith tools will depend on the tasks that the wizard performs, but in 99.9% of cases, the workplace cannot do without bench vise. This tool is mounted on the worktop of the workbench and is designed to fix various workpieces and parts so that it can be conveniently worked with. The vice is made of steel or cast iron, the plates are usually made of steel. In the work of a locksmith, different types of vise are used, but parallel vices are still the most popular.

Workbench Size

Depending on the size and number of jobs, bench workbenches are:

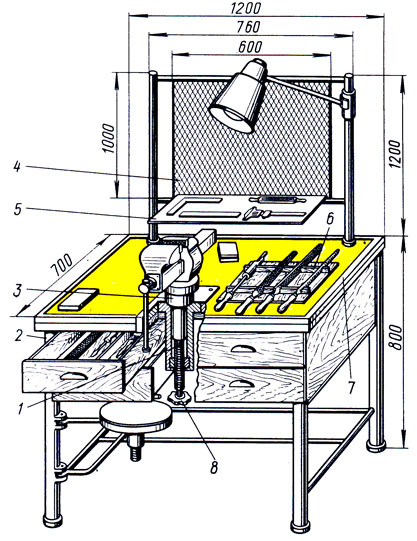

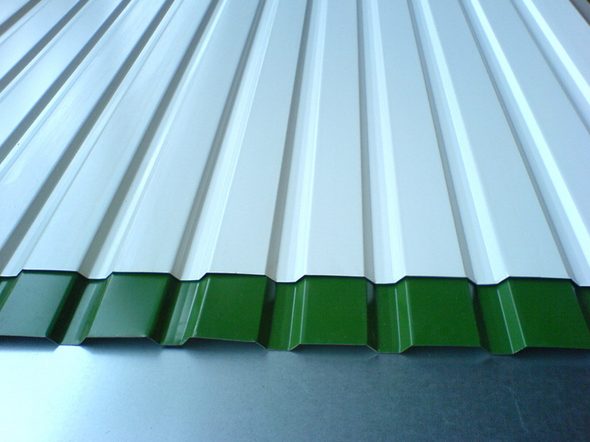

- single, 70-80 cm wide and 1.2-1.5 m long. They are well suited for a garage and small production, they are used even in many large workshops, as they allow you to organize completely isolated jobs so that the workflow of one master does not affect the activity another;

- multi-seatup to 80 cm wide and up to 3.5 m long. It is convenient to put in large workshops for more thought-out organization of space. The downside is that if masters do all kinds of work, then they can greatly interfere with each other. For example, if one master, after his part of the workbench, is sawing something, then this may affect the other master, who is currently doing the marking work. Therefore, even at large enterprises, the idea of multi-seat machines is often abandoned.

Workbench single (left) and multi-seat (right)

When choosing a bench work bench, it is important to consider its height. The optimal height does not exist - it all depends on the growth of the master. The workbench will be correct if the master, laying the elbow on parallel longings, rests his fingers on his chin. If it is a chair vise, then the hand should rest on the chin when the fingers are closed in a fist. The height of the workbenches ranges from 92 to 112 cm. If you take a workbench to your garage, and know that only you will work for it, or someone as tall as you, then you can safely dwell on a product with an unregulated height.

When it comes to the production hall, i.e. it is assumed that there may be different masters behind one workplace, it makes sense to pay attention to workbenches with adjustable height. The special design of the legs allows you to adjust the height of the countertop within 5-25 cm. This is more convenient than arranging the flooring near the workbench so that the master of short stature is comfortable behind the workbench.

Do not forget that there are single mobile workbenches that allow you to organize a mobile workplace, and in some cases this is an invaluable opportunity.

Configuration and storage

Locksmiths at hand should have a ton of tools at hand, so workbenches are equipped with storage areas. By type of configuration and location of storage locations, bench workbenches can be divided into:

- boxless. There are no storage places under the tabletop; maximum is an open shelf.Such workbenches occupy a minimum of space, suitable for garages;

- single pedestal. The storage place is located only on one side under the table. This can be a large drawer with a swinging door, several drawers of the same or different sizes, or a cabinet with a drawer. The remaining space under the table is either empty or used to organize an open shelf. Single pedestal workbenches are excellent for rooms cramped in the square. They allow you to store a sufficient amount of tool, but at the same time remain compact;

- two-drawer workbench involves the placement of storage places on both sides under the worktop. The layout may be different. Most often drawers and cabinets are used, carousel-type boxes are less common;

- three-drawer workbench comparable in size to a two-pedestal, but instead of free space there is another part for storing things. If there are a lot of tools, and it is important that they always remain literally at hand, then pay attention to such models.

Drawers can be equipped with trays to conveniently store hardware. Instead of special trays, you can use the good old banks, which have long been settled in all garages of the country and do an excellent job of sorting and storing small fasteners.

It is important to pay attention to the design of the drawers. They must be fully extendable to provide access to the farthest corners. In addition, the guides must be strong enough to support the possible weight of the tool.

Additional storage can be arranged with perforated screen. It is enough just to hang shelves, holders, hooks and other devices for storing the tool on it. You can attach a lamp to the screen. All screwdrivers, pliers, keys and other little things will be before your eyes. If necessary, shelves are easy to outweigh and modify the storage system.

How to choose a bench for a garage?

Here, first of all, it is necessary to take into account the size of the room and the tasks assigned to the workbench. If there is not so much free space, then a compact single benchless or single-bench workbench is suitable. Bestumbum takes up very little space, and provided that all the tools are stored on shelves or racks, this option will be ideal for small garage. Of course, in advance it is worth measuring all the parameters of the free space intended for the workbench, and already on this basis, make a choice.

When organizing a workplace in the garage, do not forget to think through a lighting system. Locksmiths require precision, and it is impossible to achieve in the twilight. Together with general lighting, it is appropriate to use a spotlight. The lamp can be hung on the wall or fixed on the same perforated screen. If you plan to work with aerosol chemicals, you must take care of good hood.

If the garage is very small, then you can consider hinged version. With a depth of 60 cm and a length of 80 cm, such a workbench can withstand a load of 200 kg, and reinforced structures with a length of 140 cm can withstand 300 kg - this should be more than enough for a home foreman.