Liquid glass for waterproofing: 11 tips for choosing and using

Water sharpens a stone. The builders are convinced of the justice of this wisdom every working day. Moisture can destroy even the most durable reinforced concrete. To protect structures and extend their service life, mankind came up with a brilliant invention - waterproofing materials. They all create a protective film on the surface that prevents exposure to water. The range of such compounds is decent, and one of the most popular is liquid glass. It is versatile, inexpensive and easy to use. We figure out how to use liquid glass for waterproofing concrete, foundations, pools, how to apply it and why it is considered so universal.

No. 1. What is liquid glass?

Liquid glass is the same silicate glue. Its base is an aqueous alkaline solution sodium or potassium silicate. Much less commonly used lithium silicate - such material is used in the electrode coating. In Russia, liquid polishes and protective compounds for cars are often called liquid glass, which is not entirely true. They have a completely different composition, and the confusion is caused by the fact that automobiles in Asian countries are called "glass coat", literally - "glass coating", but not liquid glass.

Liquid glass is obtained by firing silica sand or soda. A silicon alkali treatment method is also used. A viscous homogeneous substance during solidification becomes solid and does not allow air or water to pass through. Until the composition has dried up, it easily penetrates into the pores of the base, on which its protective effect is built. Liquid glass perfectly protects against moisture, plays the role of an antiseptic, hardener, acid protector and increases resistance to fire.

No. 2. The main pros and cons of liquid glass

Water glass is often used to hold waterproofing works. It's connected with a number of advantages:

- excellent water-repellent properties, the film is solid, so that moisture does not remain approaches to the material;

- liquid glass seeps perfectly into pores and cracks, has a high adhesion to the base;

- low consumption, especially when adding a substance to a cement mortar;

- low price in comparison with other waterproofing materials;

- the substance can be used in high humidity;

- relatively high durability. Liquid glass will last at least 5 years, and if it is coated with paint, then much longer. Without additional protection, it is able to gradually self-destruct;

- water glass gives the material resistance to fire, acids, alkalis, mold, increases the strength of the base.

However, this material also has there are minuses:

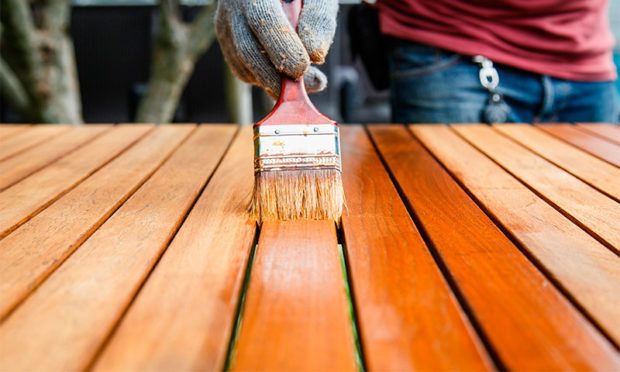

- limited scope. Material is combined only with concrete and tree. On the brick you cannot apply such waterproofing - it will destroy the material.When they talk about the versatility of liquid glass, they mean that the composition can be used to create a coating waterproofing and to add to concrete, and its different concentration in the solution allows to obtain different properties;

- liquid glass, like ordinary glass, is a little fragile and becomes so when frozen. So that the layer is not damaged, it is additionally protected from above with another material;

- it’s almost impossible to put a finish on top of water glass - paints and varnishes do not adhere to it at all;

- it is very important to observe the correct proportions when adding water glass to the cement mortar, otherwise it may harden too quickly;

- although the installation process cannot be called specific, and special tools are not required, you still need certain skills. Do it yourself only when you have experience in waterproofing. It will be necessary to act very quickly, since liquid glass seizes almost instantly.

In one form or another, liquid glass use construction for more than 200 years. During this time, mankind managed to come up with other waterproofing materials, but liquid glass still withstands competition.

As an independent waterproofing material, liquid glass is practically not used - only in conjunction with other materials, but only thanks to it it is possible to achieve excellent results and completely protect concrete and wood from moisture.

No. 3. Scopes of liquid glass

In essence, liquid glass can applied in three main ways:

- the composition is applied to the concrete surface, dries and forms a moisture-resistant film, clogging all the pores. Often protection is applied in several layers;

- the composition is added to the concrete mortar. A concrete structure created in this way receives improved waterproofing properties, but at the same time hardens much faster;

- as an additive for the manufacture of different grades of concrete.

To convince you of the versatility and practicality of this waterproofing material, we give only The most common areas where liquid glass is used:

- basement, walls, ceilings and floors in basements;

- waterproofing of pools and wells;

- waterproofing wood;

- addition to concrete for improvement of water-repellent properties;

- protection of tree trunks after cutting;

- gluing different materials;

- to combat mold;

- for protection against corrosion;

- to protect joints between building materials;

- much less often, the composition is used for dust removal of concrete, as well as as a quick-drying substance. It is also rarely used to create bactericidal grout and in sealant quality.

Number 4. Types of liquid glass

The basis of water glass, as mentioned earlier, can be potassium or sodium silicate. In principle, both compositions are very similar, but still some differences are present:

- potassium silicate is resistant to acids, excellent adhesive properties and the absence of a characteristic glass luster;

- sodium silicate is characterized by the same high performance, but it does not have a characteristic luster.

Liquid glass sells in containers from 500 ml to 10 liters. Be sure to look for information about the composition and manufacturer. Also on the package should be information that the material was produced in accordance with GOST 13078-81.

Less commonly, granular glass is found, which must be diluted with a certain amount of water before use according to the instructions.

No. 5. Ways to use liquid glass

It is clear that liquid glass is used for waterproofing, but it can be applied in different ways - it all depends on the goals:

- coating method involves applying clear liquid glass to the surface. Usually use sodium silicate. The method is suitable for coating substrates that are dusty, characterized by porosity and friability.The insulation layer dries within 30-60 minutes, after which another layer can be applied. On top of the liquid glass, you can use another waterproofing material, for example, roofing material;

- penetrating technique has much in common with coating, but at the same time liquid glass is mixed with water, and sometimes with dry building mix. The resulting composition is used to treat hard-to-reach surfaces, only it will have to work very quickly;

- by adding liquid glass to concrete get more durable and moisture-resistant material, but this technique should highlight a separate section.

No. 6. Liquid glass for concrete waterproofing

The popularity of water glass is connected precisely with the addition of it to a concrete mortar. The essence of the method, it would seem, is clear, but in order to get a really high-quality result, you need to know a few nuances:

- water glass cannot be added to the finished liquid solution. First, a dry mixture is prepared, and then diluted with water, to which a certain part of the liquid glass is added;

- the amount of liquid glass can vary significantly - it all depends on your goals. When choosing a specific recipe, it is very important to follow the specified proportions. The minimum content of water glass in concrete is 2% (this composition is used for foundation waterproofing), the maximum is 25%;

- water glass improves the quality of the solution, but greatly affects the speed of its solidification. It is recommended to prepare the solution in small portions so that it does not freeze even in the container. For the same reason, many do not recommend using concrete mixer.

If only 2-3% of liquid glass is added to the solution, then concrete will set in 45 minutes, and will completely harden after a day. This is a fairly popular proportion. With the addition of 5% liquid glass, the setting speed will be reduced to 30 minutes, and complete hardening will occur after 16 hours. For 8%, these indicators will be 15 minutes and 7 hours, and for 10% - 5 minutes and 4 hours, respectively. For mixing use clean cold water and cement grades M300 and M400.

The mixing principle is as follows:

- take a container of clean water, add liquid glass there, mix;

- the solution is poured into a larger container and a dry cement-sand mixture is gradually introduced;

- quickly but thoroughly mix the mixture until smooth and get to work.

All work is carried out in special clothing and gloves.

Number 7. Application of liquid glass by coating

It is easier to apply liquid glass with a coating method, for this use brushes and rollers, and sometimes a spray bottle. The procedure is as follows:

- make sure that the liquid glass is uniform in appearance, free from impurities and lumps. They do not put forward special requirements for storage conditions - there will be nothing for the material, even if it was lying in the garage at sharply negative temperatures. Frost resistance is one of the strengths of this composition;

- the surface to be coated is thoroughly cleaned of dust, grease stains and dirt, the concrete is brushed to open the pores of the material. It is desirable that the surface is as close as possible to perfectly flat;

- some advise pre-diluting the material with water in a ratio of 1: 2. This is done to save liquid glass;

- for concrete impregnation at a shallow depth, use one layer of liquid glass insulation, apply it with a brush or spray gun. If you need a deeper layer of impregnation, it is better to apply two or three layers, each subsequent one is applied 30-40 minutes after the previous one.

All these are general recommendations, but in each case an individual approach may be needed.

Number 8. Waterproofing the foundation with liquid glass

For waterproofing the foundation and base, plastering technology is usually used. Liquid glass goes well with rolled waterproofing materials. Silica is not compatible with bitumen waterproofing.

To reliably protect the foundation from moisture, first the surface must be cleaned and degreased, then sanded, and then with liquid brush, apply liquid glass itself. When the first layer dries, a second is applied, and after the final hardening, you can proceed to roll waterproofing.

To protect joints and seams on the foundation, penetrating technology can be used:

- seams and joints are embroidered, U-shaped gates are made at the places of cracks, then all the recesses are cleaned of dust;

- the mixture is prepared in small portions;

- a solution with a concentration of about 5% is prepared from water and liquid glass, then it is added to the cement. The result should be a thick plastic mass. It is better to mix once, with repeated mixing, crystallization may begin, which will adversely affect the adhesive properties;

- the prepared solution with a spatula is applied to the embroidered joints and seams. It dries very quickly.

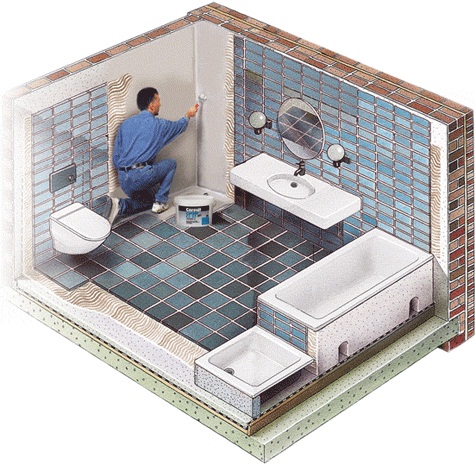

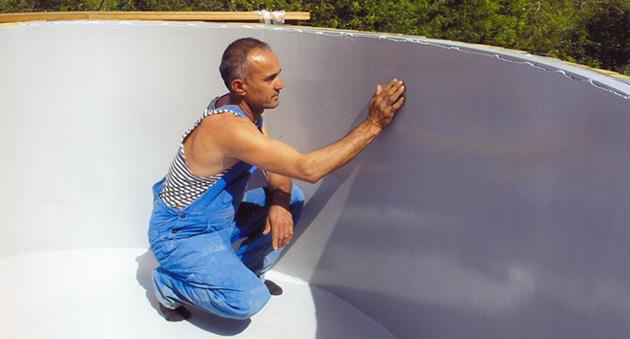

No. 9. Waterproofing of pools with liquid glass

Basin bowl assumes a significant burden. This and tons of water that are poured into the bowl, and the impact of groundwater from the outside. Therefore, it is necessary to carry out waterproofing from two sides. The outer walls are treated by coating technology, apply at least three layers of material. The inner walls can be covered with two layers of water glass. Remember that this type of waterproofing, especially in the case of a pool, cannot be independent.

The processing of internal and external walls is carried out according to the general principle. First, prepare the surface (the presence of tubercles is allowed, but not more than 1 mm), then degrease it and apply liquid glass.

No. 10. Waterproofing a well with liquid glass

Waterproofing works in this case are aimed at protecting the walls. well from moisture, and also process the seams. It is very important that concrete rings were very well fixed, otherwise no waterproofing will save the structure from destruction. Additional fixation can be done with brackets.

When the rings are mounted, and their fastening has taken place, it is better to guarantee the tightness of the seams with linen or jute rope, pre-treated with liquid glass.

After this, you can begin to process the walls of the well. First, clean water glass is applied, and after it is dried, a solution prepared on the basis of water glass and a cement-sand mixture.

No. 11. Basement waterproofing with liquid glass

Processing the interior walls of basements is not much different from waterproofing the foundation, but some experts recommend preparing the mortar according to a different principle, mixing cement, sand and water glass in a ratio of 1.5: 1.5: 4. Mass fraction of water should not exceed 25%.

The surface, as in the previous methods, is first cleaned, you can treat it with an antiseptic for the greater importance. Then the resulting mixture is applied to the base. Cracks and joints are best pre-expanded.

In conclusion

The liquid glass market is quite saturated. Among the manufacturers, one can recommend Willson, AMK-Group, Bitumast, Aqua Well, Profilux, Broseggs and Optimist. If after all waterproofing works liquid glass remains, do not discard. It can be used to wood processing. It will also work for an additive in the grout, so that it does not mold (part of the liquid glass should be up to ¼). Using silicate glue, you can prepare quick-drying glue if you add it to the cement instead of water. Moreover, craftsmen use it when laying rolled floor trim and even for processing cuts of trees. Often, the product is used as a sanitary sealant.