7 tips for choosing a bath barrel: types, advantages, disadvantages

The love of a bathhouse in the Russian person’s blood has even turned into a national peculiarity, so many people dream of having their own bathhouse in their summer cottage. That's just the high cost and duration of construction often scares away lovers of bath rituals, and there is not enough space on any site. But do not rush to despair, because you can buy a barrel bath, a mobile inexpensive design that is in no way inferior to a traditional bath. This ingenious Finnish invention conquered the whole world and gained wide popularity in domestic open spaces. Let's deal with the features of choosing a bath barrel, varieties, advantages, disadvantages and features of a hand-built construction.

No. 1. Barrel bath: design features

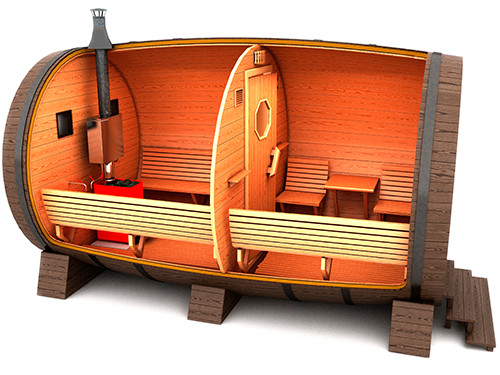

The main feature of the bath barrel is easily understood from the name. This is a design that has cylindrical shape: round (rarely oval) ends are connected by boards and pulled together with metal hoops. The diameter and length of the barrel can vary significantly, which determines the capacity of the bath and the number of zones that can be organized in it. The diameter, as a rule, is about 2-2.5 m, the length varies from 2 to 6 m or more. Doors in a barrel bath are made of wood or tempered glass. In the opposite end from the entrance is located stove. Tanks are usually installed along the walls.

In a small bath barrel only fits steam room for 1-2 people, in a more spacious design can be arranged shower area, relaxation room and other rooms. They are separated from each other by wooden partitions. Naturally, it will be necessary to connect water supply, sewage and electricity to the bathhouse.

The interior of the barrel-bath is not much different from the classic Russian bath, but at the same time the arrangement of the barrel is much cheaper, and the structure itself takes up a minimum of space. The first guessed to do such baths in Finland. In this country, the bathing culture is very developed, and they approach everything with maximum practicality, so cheap and mobile bath barrels have appeared.

The category of bath barrels also include small structures that are placed vertically. They are designed only for one person, and the head receiving bath procedures is outside. Such a bath takes a minimum of space, and instead of a stove-heater, a steam generator is used in it.

If there is enough time, knowledge and skills, then you can build a barrel bath yourselfbut today many agree which is much easier and more profitable to buy a finished design. Residents of Moscow and the Moscow region can contact the Bochkovedov company, which over the 6 years of operation has manufactured and installed about 500 bath barrels of various sizes and configurations. By working directly with the manufacturer, you get significant savings and a guarantee of quality. The order is completed within 2 days, the assembly is carried out by specialists under the supervision of the customer, and payment can be made upon the installation.

No. 2. Barrel bath: advantages and disadvantages

Indirectly, we have already touched on the main advantages of bath barrels, but now dwell on all the pros in more detail:

- compactness. Bath barrels are small in size, so they can be installed on small summer cottage, even when it seems that it is impossible to allocate a piece of free land between numerous beds and greenhouses;

- mobility. The design weighs no more than 1.5 tons, so it is extremely simple to transport. Moreover, such a bathhouse can be repeatedly moved from place to place and even transported. Someone even manages to take the structure with him on a trip;

- no foundation needed due to the low weight of the structure. The selected place, of course, is better to pre-align and provide a slight slope for the outflow of water;

- speed of construction. The team of experts will install the finished barrel bath in a matter of hours - you don’t have to wait for months for that treasured moment when, finally, you can take a steam bath in your own bathhouse. You only need to take care of electricity availability, water and plum. If you suddenly need it, you can disassemble the bathhouse with your own hands and assemble it in a new place;

- quick heat. In just 20-30 minutes, the interior of the steam room warms up to a temperature of 900C. In winter, heat is retained better than in traditional baths, and all due to the lack of corners. The high heat capacity of the structure allows you to melt the bath using fewer logs than when kindling a regular bath;

- ergonomics. Despite the small footprint, in the barrel you can equip all the zones necessary for comfortable bath procedures for 3-8 people;

- original appearance. Probably, it is not worth explaining the fact that a large keg on the site will look spectacular, it will become real territory decoration;

- year-round operation;

- simplicity in leaving. The absence of corners and a small area simplify the cleaning process;

- environmental friendliness. Barrel baths are made of pure wood, so the steam will be healthy and healthy. Constructions are equipped wood stoves, therefore, it will save on electricity;

- low price. A barrel bath is much cheaper than building a regular bath.

IN minuses we can attribute the fact that it’s unlikely that you can relax in a big company in a barrel bath. In addition, the walls of the bath are single-layered, therefore strong “chemistry” cannot be used to process them. However, the market offers a lot of special protective equipment for the treatment of bath walls: they combine maximum safety and efficiency. Lots of controversy thermal insulation of the bath and the ability to use it in winter. Many advocate that the barrel bath is an exclusively summer option. Manufacturers say that due to the high heat capacity of wood, powerful stoves and gapless technology for mounting boards, the bath does not need to be insulated and perfectly maintains high temperatures even in cold weather. If the design is made of high-quality material and correctly assembled, even in severe frost with the heating turned off, the temperature will drop by 1 degree every 4 minutes.

The owners of bath barrels share their experience that in winter at temperatures of -13 ... -150C continues to use the steam room, but clarifies that it takes more time to kindle. Some manufacturers produce saunas with an additional layer of thermal insulation, which are suitable for year-round use in areas with harsh climates.

No. 3. Material of execution

When building a traditional bathhouse, the choice of construction material is not so important - it is much more important to choose the right skin. For a bath barrel, it is necessary to correctly determine the material of execution even at the time of design. Usually, use these types of rocks:

- oak - The preferred material for building a bath. This is a strong, durable wood, which has a fairly high resistance to moisture and at the same time boasts a beautiful pattern and color. The minus of this material, as you might guess, is the high cost;

- Linden It has excellent medicinal properties, when heated, fumes emanate from such wood, which positively affect the respiratory system.In addition, they are useful for the skin, have a rejuvenating effect. Linden has excellent thermal insulation properties, but it also has one big drawback - poor water resistance, so linden baths begin to rot faster than structures from other breeds;

- aspen - a relatively cheap breed, which is not inferior to linden in strength, better tolerates moisture, retains its shape and does not crack;

- cedar - the only conifer that is suitable for the construction of the bath. This is a very dense wood, which is not afraid of temperature extremes and high humidity, does not shrink, is not affected by fungus and mold, and that is why it is characterized by high durability. In addition, the cedar bath is also aromatherapy, which comes with a bonus.

Rest conifers contain a large number of resins, which, when exposed to high temperatures, begin to actively stand out. Except for this, a bath frame can be created from such material. Bathing equipment is made from fir, alder and birch - this is cheaper wood.

The thickness of the boards is 30-40 mm. The most common baths with a thickness of 40 mm boards. The thicker the material, the higher the thermal insulation qualities of the steam room.

Number 4. Types of bath barrels

The barrel bath is suitable for organizing the following types of steam rooms:

- Russian sauna, as you know, consists of two departments, a steam room and a washing zone. The steam room is filled with moist hot steam. This type of bath is very easy to organize in a barrel. An oven is installed in the steam room; there must be a place to organize a washing room so that contrasting water procedures can be carried out. It is better to position the furnace so that the chamber with the heater is in the steam room, and the furnace and expansion tank are in the washing zone. Since there is not much space, the heating equipment is selected small. The peculiarity of this type of bath is the formation of a large number of effluents, so that water drainage must be carefully considered;

- Finnish sauna characterized by the presence of very hot dry steam. In this case, it is important to properly organize ventilation with valve systems. The steam room is equipped with benches and a small stove. A feature of this type of bath is the need for rapid cooling for contrasting procedures. If you manage to organize a font near the barrel, it will be great, but you can do with a supply of buckets of cold water;

- ofuro - Japanese type of bath without a roof, i.e. the barrel in this case is put on the end. Inside, heating equipment and benches are installed. The design is easy to install, but requires more time to prepare for bath procedures.

No. 5. The form

The standard form of the bath barrel is round, hence the name, but some manufacturers offer their own variations. The most popular forms are:

- round barrel bath - The standard and most common option. It looks original, requires a small area for installation, quickly warms up;

- oval (ellipsoidal) barrel bath takes up not much more space on the site, but at the same time the internal usable space increases significantly, while the steam room warms up almost as quickly as in a round barrel;

- square, or rather semicircular-semi-square, sectional bathhouse looks like a square with rounded corners. It has the largest usable area among other buildings, here you can comfortably arrange more benches, tables, shelves, etc. The room warms up relatively quickly. Such a bath will look great on the site.

No. 6. Barrel Size

Construction size selected according to several factors: estimated number of visitors, free area and price. It is clear that the smaller the bath, the cheaper it will cost, but it will be less spacious.

Each manufacturer has its own model line, but they are most popular. bath barrels of such sizes:

- mini format: length about 2-2.6 m, the length of the steam room is 1.8-1.9 m, weight is about 0.5 tons. This design is designed for 2-4 people, but if you try hard, you can accommodate the company in 5-6 people. The approximate cost of $ 1200-1300;

- the “economy” format - this baths are 20-30 cm longer than the “mini” ones; they cost a little more;

- the format "standard" and "optimal" is different 3-3.5 m long, weighing about 1.1-1.3 tons. In this bath, in addition to the steam room, you can place a dressing room. Cost is about 1700-2000 $;

- formats that are called by different manufacturers “premium”, “maxi”, “lux”, “mega” and the like, have a length from 4 to 6 m, may include not only the steam room and the dressing room, but also the wash. The room is designed for 6-8 people, prices vary significantly and revolve around the mark of 2100-2700 $;

- format "exclusive" and the like in length about 6 m and moreare distinguished by the presence of a lounge with a large table. The cost is about $ 3,700.

In addition, any barrel bath can be equipped with small covered terrace with benches for rest in the fresh air, steps, little tables, window leaves, protections for the furnace and other elements. Based on the standard project, it can be understaffed to your taste, while receiving the bath of your dreams.

Number 7. DIY barrel bath

Even despite the fact that the finished bath barrels are inexpensive, some decide on an independent manufacture of the structure. In this case, we can talk about savings and maximum confidence in quality. At the same time, responsibility for the result obtained and time costs are increasing. We’ll immediately warn you that it’s recommended to take up the manufacture of a bath barrel with your own hands only if you have confidence in your own abilities.

The whole process can be divided into such stages:

- site preparation. To equip foundation it will not be necessary - an even, solid surface will suffice. Suitable asphalt, concrete or paved paving slabs area. As a base, you can use the territory covered with gravel or gravel. If there is no suitable place, then the work will become somewhat more complicated. It will be necessary to dig a hole with a depth of 20 cm and a width equal to the width of the barrel plus 50 cm, fill it with sandstone and gravel, fit reinforcement and pour it all concretehaving previously built the formwork from the boards. Concrete will harden for about 3 weeks, and then you can proceed to the next stage. The platform can be performed with a slight slope, so that the drain from the bath occurs more efficiently. At this stage, you can dig a hole for collecting wastewater, equip it accordingly and withdraw a drain pipe from it, the second end of which will be connected to the drain from the barrel;

- barrel stand making. Supports are made of edged boards with a minimum thickness of 5 mm. They are mounted in increments of 150 cm, the number of supports depends on the length of the bath. In the supports it is necessary to make a rounded neckline, which corresponds to the diameter of the barrel. It will be more convenient to work with a pre-prepared drawing. Supports fasten together with a rigid hitch;

- installation of longitudinal boards start by calculating the middle of the supports. The first long board is fixed clearly to the center of the supports on the screws. Later, metal corners will be used to reinforce the structure, they will need to be fixed at the joints of supports and longitudinal boards. The number of longitudinal boards can be calculated if the circumference is divided by the width of one board. For these purposes, 40 mm thick boards are taken. After mounting the first center board, all the others are installed in series with the grooved connection method. Carefully monitor the tightness of the structure. The boards do not interfere with grinding well beforehand; you can treat them with antifungal agents that are as safe as possible for humans. Installation of boards continues until the surface of the supports is completely covered. After that, the adjustment bars are mounted;

- installation of vertical walls (ends and partitions).They are made from square shields, of which jigsaw cut out a circle of the required size. It marks the location of doors, windows and walkways, after which a jigsaw cutting is carried out again. A door will be located at the entrance, a window at the opposite end, the number of partitions is regulated by the project. Vertical walls and partitions are attached to the base and at this stage should be so strong as to hold without assistance;

- installation of longitudinal boards ends and their tightening with steel clampsthat are attached to the frame with bolts and nuts. The screed will provide additional strength and reduce heat loss during the operation of the structure;

- installation of doors and windows, joints are caulked, sealed with sealant;

- roof covered with soft tiles or metal sheets;

- the final touch - arrangement of internal space. At this stage, a drain hole is made and pipes are connected, a wooden grating is made, shelves, a table, benches, etc. are mounted. Install heating equipment and a fence around it; chimney thermally insulated around it. It also runs water pipes, connecting them to the oven and shower, all the necessary plumbing equipment is installed. Do not forget to pave wiring;

- as heater You can use either a traditional wood or electric stove. The main thing is that her size is small. Around the firebox, the walls and floor are sheathed with protective materials;

- all wooden elements can be treated with linseed oil to protect the surface from decay and deformation;

- if desired, you can perform external thermal insulation.

This is not a very simple matter, so think seven times before you get to work. It is simpler and often cheaper (given the mass of possible errors in the process of self-installation, for which you have to pay) to turn to professionals. A compromise option is to buy a ready-made set of bath-barrels, which you can simply assemble on the spot according to the instructions.