7 tips for equipping a boiler house in a private house: requirements and standards

Lucky for those who can connect to the general heating system and not know the extra problems. If the house is located in an area where there is no central heating, you will need to get out. It will be necessary to equip an individual boiler room, and what it will be, where it will be located, and which fuel will run on it, depends on a lot of factors. Let's try to figure out all the nuances and understand how to properly equip a boiler room in a private house and what requirements are put forward for such premises.

No. 1. Types of boiler houses by location

Of course, there are safety requirements that must be followed when arranging a room such as a boiler room, but nevertheless they provide us with the right to choose in matters of type of fuel, size and location of the furnace.

According to the type of accommodation in a private house, the boiler room is:

- built into the house. In this case, all the equipment is placed in one of the rooms of the house (usually a kitchen or a corridor). In terms of simplicity and low cost of arrangement, this is the best option, but it will only work if you plan to use a low-power compact boiler. In this case, it is not recommended to use a gas boiler with an inflatable burner due to high noise, and equipment operating on diesel fuel can deliver a lot of inconvenience due to a sharp unpleasant odor;

- in the annex or in a separate room of the house. All boiler equipment is located in a separate room, which is connected to the house by one or more walls. The door to such a boiler room is surrounded by non-combustible materials. This is the best option in terms of convenience and security. If the boiler room is adjacent to the living quarters, then it is advisable to produce additional sound insulation: in the SNIPs nothing is said about this, but it will be much more comfortable that way;

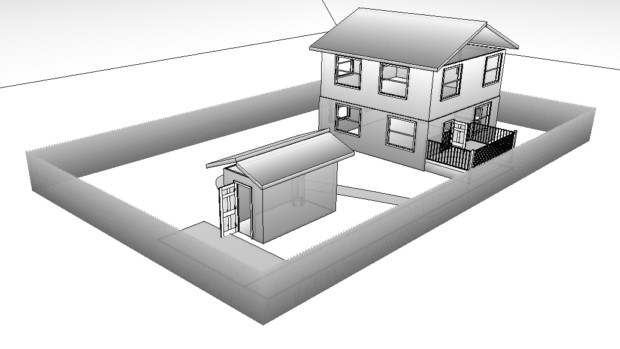

- detached building. All equipment can be completely removed to an independent small building, equipped in accordance with all the rules and regulations. It will be connected to the house through heating mains. In this case, your hands are untied: you can use any type of equipment and not worry about noise or odors. Often such boiler rooms are equipped when a high-power gas boiler is used. Minus - the cost of building a separate building and laying communications;

- block-modular boiler room. All equipment in this case is located in a container that can be relatively easily moved from place to place. It is used as a backup or temporary type of heating at enterprises and industrial facilities, but can also be used in a private house.

Ideally, you need to consider the location of the boiler room at the design stage of the house. If the house has already been erected, the number of possible location options is reduced, and because of this, you may encounter the fact that the choice of heating equipment will be significantly limited. In any case, starting to equip the boiler room, it is better to turn to professionals for help.In Moscow, the region and neighboring regions, Mig-Plus is engaged in the installation of boiler houses: since 1997, the company's specialists have commissioned more than two hundred residential and industrial facilities. Specialists accompany each object from design to commissioning.

No. 2. The main elements of a boiler house in a private house

Well, if the house is small, and the problems of heating and hot water can be solved with one small double-circuit gas boiler. But in most cases this will not be enough - it will take a whole a set of equipment, which may consist of a set of the following elements:

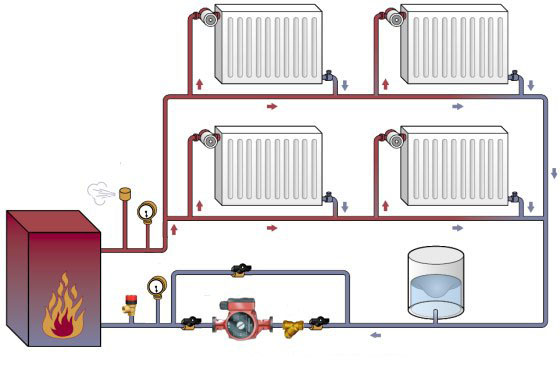

- boiler - the heart of the whole boiler room. He will be responsible for heating the water for the heating system. Heat can be obtained by burning different types of fuel: liquid, gaseous or solid. A separate case is electric boilers. In some cases, establish two boilers at onceto provide a private home with complete non-volatility;

- boiler. If a single-circuit boiler is used, then for heating water for hot water systems will have to use boiler;

- expansion tank. Water from the heating system will enter this tank if the pressure in it rises. Thus, pipes and radiators are protected from breakthrough;

- heat accumulator. It is not always installed, despite the fact that it is a very useful element. Overheated coolant accumulates in this tank, “excess heat”, which is then supplied to the heating system. In this way, resources are greatly saved and safety is enhanced. The presence of this element for solid fuel boilers and in the presence of two boilers of different types;

- distribution manifold. It is necessary for the correct distribution of the coolant throughout the system, regulates the temperature;

- circulation pump. It is necessary only in systems where the coolant circulates forcibly;

- chimney. It is necessary for the removal of combustion products outside the house. The chimney is not needed only for an electric boiler;

- security and control group - a set of devices that monitor the temperature and pressure in the boiler and system. Also, this may include sensors that monitor the state of the air in the boiler room;

- automation receives commands from the user about the required temperature, collects data from the security group and allows you to correctly adjust the basic parameters of the system;

- stop valves necessary in order to control the flow of coolant;

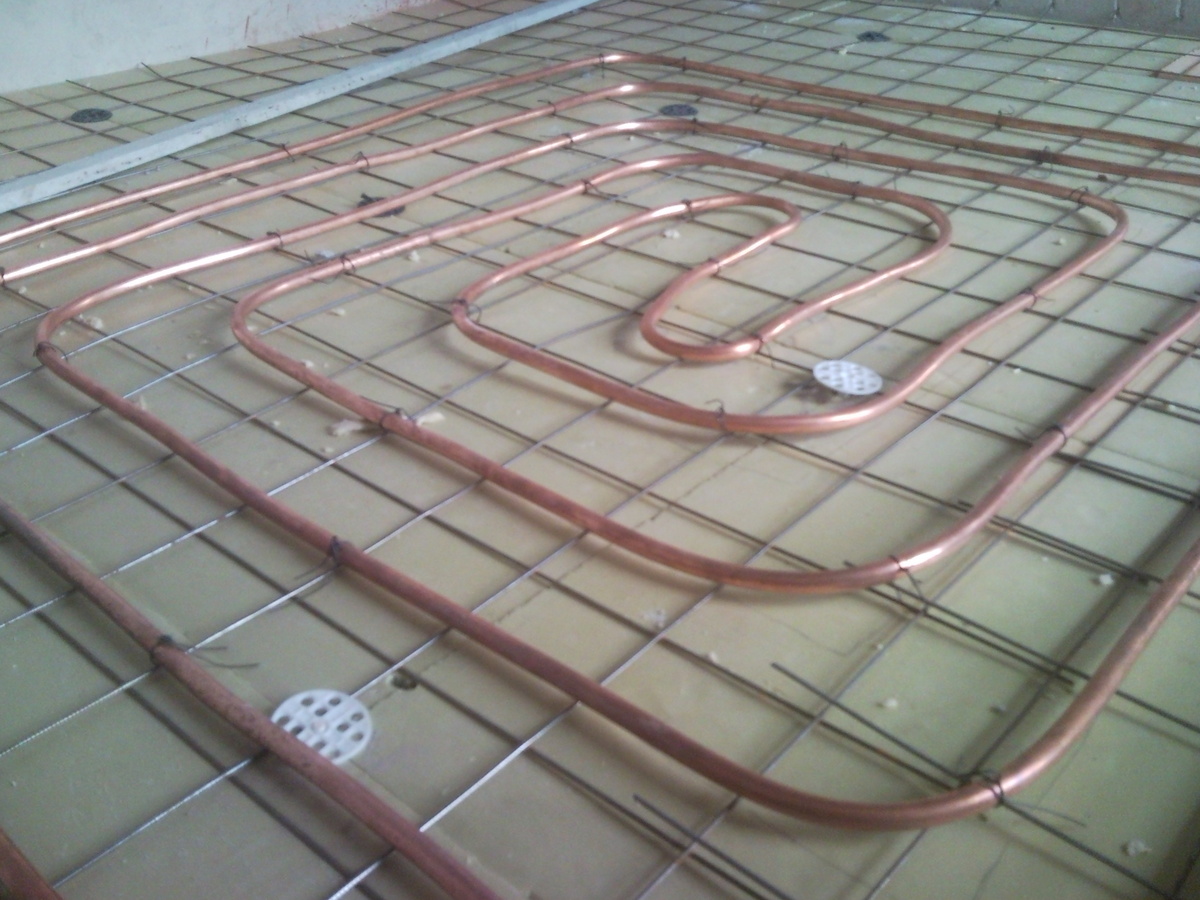

- pipesby which water from the boiler goes to radiators;

- filter It is necessary to purify water before it enters the boiler and boiler. If in the region the water is saturated with salts and contains mechanical impurities, then you cannot do without a filter - otherwise the equipment may soon fail.

It is not necessary to use all of these elements - their set depends on many factors. First of all, this is the area of the house and the type of fuel.

No. 3. Types of boilers for a boiler room

It is on what type of boiler will be used that many of the nuances of equipping a boiler room depend.

By type of fuel boilers are:

- gas, work on natural or liquefied gas, are characterized by high efficiency, ease of management. They can be transferred from one type of gas to another. The best choice for most private houses;

- solid fuel (coal, firewood, peat, briquettes) in terms of operation are more economical, but you will have to constantly monitor the system and toss fuel;

- fuel oil (diesel). Such boilers are usually installed where it is not possible to use natural gas or transport liquefied gas. If, over time, a gas pipeline appears in the area, then such a boiler can be converted to work with gas;

- electric boilers the safest, most comfortable and quietest, but also the most expensive. It is unprofitable to heat the whole house with them, but they are suitable as a backup source of heat.

According to the installation method, boilers are:

- wall mounted;

- outdoor.

Wall mounted boilers in a compact housing contain such necessary elements as automation, sensors, expansion tank, etc. In this design, boilers up to 60 kW are produced. If the boiler power does not exceed 35 kW, it is allowed to install it in the kitchen or hallway. Wall-mounted models are often more sensitive to water conditions. Floor models can be of any power, they are indispensable for heating large areas.

What capacity does a boiler need? It is better to entrust the calculation to specialists who know that it is necessary to take into account many parameters. To approximately understand what capacity the equipment will need, you can use the rule according to which 1 kW of boiler power is needed for every 10 square meters of the house. If it will be used in a hot water supply system, then add another 10% to the capacity. So that the boiler does not work at the limit of its capabilities, another 20% is added to the obtained value.

Number 4. Boiler room in a private house: security requirements

The fact that the boiler house is an object of increased danger does not need an explanation. The question is different. How to equip a room so as to ensure maximum safety, comfort and ease of access to equipment?

General requirements for a boiler house in a private house:

- walls should be made of concrete or building bricks. Allowed to use ceramic tiles or plasters - it is non-combustible materials;

- when installing the boiler on the floor, a concrete screed is required, also the floor can be covered with a sheet of metal;

- when installing a wall-mounted boiler, a section of the wall must be tiled or covered with a sheet of metal;

- Explosive and flammable substances must not be stored in the boiler room. This does not apply only to fuel that will be stored in a special way;

- sufficient space should be left around the boiler so that it can be easily accessed for operation, maintenance and repair. If a small room is reserved for the boiler room, then it will not be easy to place all the equipment - it is better to make layout of the boiler and other elements;

- the door that leads from the boiler room to the house must be fireproof.

Ideally, even before the construction of the boiler house, it is better to draw up a project for the placement of equipment and take into account all the requirements that are put forward by such regulatory acts as SNiP for boiler plants II-35-67, the Code of rules for the design of autonomous heat supply systems SP-41-104-2000 and the Instruction for placement of heat generators MDS 41-2.2000.

Boiler rooms with gas boiler

Gas boilers improper installation and operation can cause fire or even explosion

When installing a gas boiler, the following features should be considered:

- the room where all equipment will be located should be at least 6 m in area2;

- room height not less than 2.5 m;

- volume of the room - 15 m3 and more;

- boiler room walls adjacent to residential premises must have fire resistance of at least 0.75 hours;

- the minimum size of the window opening is 0.03 m2/1m3 premises;

- the presence of a podium for a floor boiler with a height of at least 5 cm;

- 1 m free space should remain in front of the boiler2, between the equipment, walls and other objects there must be a passage with a width of at least 70 cm, otherwise access to the boiler will be difficult;

- mandatory ventilation and sewers;

- the width of the doorway is not less than 80 cm, the door opens outward;

- for boilers with a capacity of more than 350 kW it is necessary to build a separate building;

- if the boiler room is located in the extension, it is necessary that it is near a blank wall. The minimum distance to the nearest window is 1 m.

This is not to say that it is necessary to fulfill all the general requirements.

Boilers with solid fuel boiler

In this case, the following requirements should be taken into account:

- the distance from the boiler to the nearest walls and objects is from 10 cm;

- for every 1 kW of power, it is necessary to provide 8 cm2 window opening;

- the chimney along the entire length should have the same diameter and as few turns as possible;

- the inner surface of the chimney can be plastered, but this is not necessary;

- in the chimney there should be a special hole for its maintenance;

- for boilers that will run on coal or wood, the boiler area should be at least 8 m2;

- when using a coal-fired boiler hidden wiring, since coal dust is highly explosive;

- the space in front of the boiler must be free so that it is possible to toss up fuel and clean the ash pan;

- walls made of insufficiently fireproof materials are sheathed with a sheet of steel 2.5 mm thick.

Boiler room with diesel boiler

The list of requirements is as follows:

- in the boiler room, and preferably outside it, it is necessary to place a metal thick-walled tank with a volume of at least 1.5 m3. From it, fuel will flow into the boiler tank. Access to the tank must be free;

- There must be at least 1 m of space from the boiler burner to the opposite wall.

Boiler room with electric boiler

Electric boiler Does not burn fuel, does not make noise and does not smell. It is not necessary to allocate a separate room for it, and there are no special requirements for ventilation. The only thing to remember is that the conductive terminals of the boiler must be grounded.

No. 5. Boiler room chimney requirements

The combustion products of a gas, liquid and solid fuel boiler must be diverted outside the boiler room using a chimney. When designing and arranging, consider the following nuances:

- the chimney should be above roof level. This is a prerequisite for normal traction;

- as chimney material You can use bricks, single and double-walled steel pipes, ceramic, asbestos-cement and vermiculite pipes. The most popular option is still steel, followed by brick. Sometimes single-walled steel pipes are placed in a brick chimney;

- whatever the material, a hole must be provided for auditing and cleaning;

- if the chimney goes along the wall of the house, then it must be firmly fixed;

- It is recommended that the diameter of the opening of the boiler designed to exhaust the flue gases be less than the diameter of the chimney.

No. 6. Boiler room ventilation requirements

For an electric boiler, ventilation is not particularly needed, in other cases it will be necessary to carefully study the existing requirements:

- boiler room ventilation can be combined with a common supply home ventilation;

- it is necessary to provide 3-fold air exchange in 1 hour, i.e. if the boiler room volume is 15 m3, then for an hour it should enter 45 m3 air. It is necessary to maintain the combustion process, part of it is necessary for drawing;

- to organize natural attractive ventilation in the wall opposite the boiler, make a hole with a diameter of 13-15 cm with a boiler power of up to 40 kW and 17 cm with a higher power. A special ventilation pipe with a shutter and a mesh is placed in the hole;

- if the boiler room is a separate room, then ventilation can be arranged due to the presence of louvres at the bottom of the front door. I provide 8 cm for 1 kW of boiler power2 vent area;

- when using common house ventilation, the hole size is calculated based on the proportion: per 1 kW of boiler power 30 cm2 openings;

- forced ventilation should work more efficiently, will not depend on various weather factors, but will consume electricity. To save a little, you can synchronize the operation of the boiler and ventilation so that the fan turns on only when the boiler is running. When using gas and diesel boilers, the fan is placed in the housing so that ignition does not occur.

Number 7.Modular boiler rooms

If the house doesn’t manage to find a suitable room for the boiler room, the extension seems unaesthetic, and there is no way to build a separate building, you can use special modular boiler rooms. They are produced ready-made, they have the whole set of necessary elements, so the installation takes a minimum of time.

A modular boiler room is a metal container with a length of not more than 2.5 m. The walls in it are double, between them a special felt insulation is used. The power may be different, but usually such boiler rooms are used to heat rooms with a volume of up to 1300 m3 (with a ceiling height of 2.7 m it is about 480 m2) Depending on what type of boiler is used, diesel, coal, firewood, etc. are used as fuel.

A three-layer metal pipe with a heater leads from the modular boiler room to the house. The standard length is 6 m, but it can be increased. Installation of such equipment is simple. It just needs to be installed near the house (if necessary, then the boiler room can be transported to another place), connected to electricity and fill the heating system with water. Typically, such equipment provides backup power.

Finally

Starting to design a boiler room, carefully study all the legislative framework. If you plan to use powerful equipment, it is better to entrust the preparation of the project to specialists. If the equipment is not particularly powerful, then it is advisable to show the project drawn up with your own hand to a professional. Consultation of regulatory services will not be superfluous.

Colleagues, this is a particularly correct article.

Thank you for the correct, beautiful technical material for the Internet!

Engineering bow!))

An excellent article has something to read, a lot of useful material. I have a boiler house near my house, a 10 kW pyrolyzer is installed. I have never regretted that I made a separate boiler room and installed a boiler. Lining is enough for 5-7 hours. Firewood raw birch.