8 tips on which steel tub to choose: sizes and manufacturers

Cheap, strong, durable, diverse in terms of design and easy to transport - steel baths have combined a lot of advantages of acrylic and cast iron counterparts. The market offers a wide selection of such products, and they differ not only in size and appearance, but also in quality of performance. It can sometimes be difficult for an unprepared buyer to identify a sample made in violation of technology. To get a really high-quality, durable and durable product, you need to figure out which steel bath is better to choose. We study all the subtleties of the issue and compare steel bathtubs with cast-iron and acrylic analogues.

No. 1. Steel baths: pros and cons

Steel baths are often advised for those who are tired of bulky cast iron bathtubs, but so far has no confidence in suspiciously light and, moreover, expensive, acrylic options. A steel bath has a decent amount of advantages, and the disadvantages that are inherent in it can be very easily fixed.

Advantages of steel bathtubs:

- cost. The most significant plus for many of us. Steel baths are cheaper than the usual cast iron and modern acrylic. This is caused not at all by lower quality, but by significantly cheaper manufacturing technology. If the budget is limited, it is better to stop on a steel bath - in operation it will behave much better than a cheap acrylic bowl;

- light weight. Of course, a steel bath weighs more than an acrylic one, but several times less than a cast iron one. A bowl weighing 30-50 kg can be transported and installed without any problems;

- strength. Steel and enamelled coating withstand severe loads. Such a bath can easily withstand the weight of water and a bathing person, unlike an acrylic product;

- easy care;

- durability, which follows from the two previous virtues. A steel bath will live at least a couple of decades, withstand temperature extremes, washing with various detergents and even smoldering objects;

- wide choose. Features of the material and manufacturing technology allow casting bathtubs of almost any size and shape, which is what distinguishes steel from cast iron and practically catches up with acrylic. On sale, you can easily find both standard rectangular bowls and real works of design art.

Minuses steel baths also have:

- high thermal conductivity. This means that the water in such a bowl will cool down quickly enough, and long water procedures will be difficult. In this parameter, steel is much inferior to warmer cast iron and acrylic;

- high noise. A stream of water falling on the walls of the bathtub will cause a loud loud sound to be heard well outside the bathroom, and often outside your apartment.

Many rank as disadvantages the ability to deform under the weight of water and humans, but this is typical only for products with thin walls (1.5-2.5 mm), which are difficult to recommend for purchase. Also, steel bowls are sometimes accused of instability, which really can make itself felt when mounted on legs.Indeed, a steel bathtub is lighter than a cast-iron one, and therefore it needs to be fixed more carefully. If we are talking about wall mounting and closing the bath with a screen, then you will not notice this drawback. Some complain that steel baths cannot be washed with abrasive products. Note that other bathtubs (cast iron and acrylic) are also not recommended to be cleaned with substances with solid particles.

Turns out that there are only two real flaws in a steel bath - low thermal insulation and strong noise, but sometimes they are enough to refuse to buy such a product. In vain! All can be quite simply fixed. On sale there are special soundproof padswhich are attached to the walls of the tub from the outside. Instead, you can use polyurethane foam, cork or foamed polyethylene - a layer of 3-4 mm will not only increase sound insulation, but also reduce the coefficient of thermal conductivity - 2-in-1. True, the look of such a bath will suffer, so you have to hide her behind the screen. If the bathroom is small, and you were already going to put the bath under the wall, then it's okay, but when you install the bath in the center, you will have to refuse such a modernization system.

By the way, not so long ago, steel baths began to be produced with the use of special sound-absorbing material, but such products are not yet widespread and are expensive.

No. 2. Which bath is better: steel, cast iron or acrylic

We hasten to upset you, it is impossible to give an unequivocal answer to this question, since each type of bath is good in its own way. If compare steel and cast iron bath, then the steel bowl will bypass cast iron in price, ease of transportation and installation, a variety of shapes and sizes. In terms of service life, cast-iron bathtubs are slightly more durable: 50+ years against 20-30 years for a steel product. Enamel on both types of product is durable and resistant, but on cast iron, as a rule, it is applied with a slightly thicker layer. In terms of heat and noise insulation, cast-iron bathtubs are ideal - you won’t have to invent anything.

If you compare steel and acrylic bathtubs, you may find that the steel bowl is easier to install and maintain, more durable (maximum for acrylic - 15 years) and, of course, more affordable. In terms of the variety of shapes and sizes, acrylic and steel bathtubs are almost equal, but the polymer version is still half a step ahead. The acrylic sample weighs less: it simplifies transportation, but somewhat complicates the installation process. Acrylic is much better in heat and sound insulation than steel.

So, summing up, we note that the steel bath is a kind of compromise. It is cheap, it takes a long time, it weighs a little, you can find any form, that's just to solve the problem with thermal insulation and noise - and everything will be fine. If such homemade products and improvers are not for you, then take an acrylic bowl, and if you want an option for centuries, then - cast iron.

No. 3. Types of steel bathtubs

Usually, when talking about steel bathrooms, enameled samples are meant, but if we look at the topic in detail, it should be noted that there are two types of steel baths:

- made of structural steel with enamel coating;

- from stainless steel.

Structural steelcovered with a thick layer of durable enamel is a classic in the world of plumbing. Such products are affordable, excellent in operation, easy to care for. Enamel is so durable that it does not care about everyday stress. Of course, over time, cracks and chips may form on it, but with proper care, this will not happen soon, and the enamel coating can be quite simple restore.

Stainless steel bathtubs still a gimmick. They look beautiful and quite unusual, will become a decoration of the bathroom in modern stylebut they cost a lot. Another minus is limescale, which can quickly spoil the appearance of such a bath. Get ready to wipe the walls with a dry cloth every time.

Number 4. Steel bath size

We all sometimes want to soak up the spacious bathroom, but such a luxury will fit in not every apartment. Common sense and logic tell us that we need to take the largest possible bath, which can fit in the room and not interfere with the movement and placement of other important objects. Since the vast majority of bathrooms have enough modest sizes, the choice is sometimes not easy.

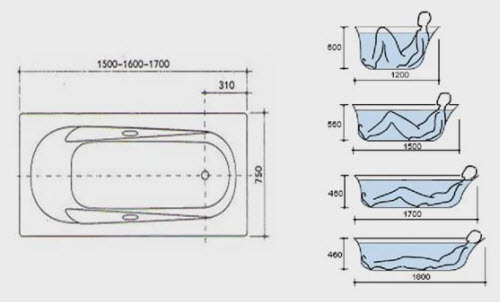

Steel bathtubs are available in different sizes, from 120 to 200 cm long, 70-85 cm wide:

- bathtubs 120 cm long called sedentary. They can be installed near a short wall in the bathroom, while saving space. Of course, you don’t have to rely on the most comfortable water procedures (if you are not a child under 10 years old), but if free space is in short supply, and shower tray for some reason does not fit, then there is no choice;

- bathtubs 140-150 cm long a little more comfortable, but tall people still have to bend their knees. However, many of us opt for 150 cm bathrooms, which is why they were called standard;

- bathtubs 160-170 cm long with a headrest will be comfortable for people with a height of up to 180 cm;

- the largest bathtubs have length 200 cm and will allow you to get maximum pleasure from water procedures.

Bath width it is selected depending on the size of the room and the size of the bathing person: it may not be very convenient for fat people in bowls of a standard width of 70-75 cm. As for the depth (defined as the distance from the bottom of the bathtub then overflow holes), it will be most convenient to bathtubs with a depth of about 50 cm.

No. 5. Steel bath shape

The market offers us a lot of different options for steel baths:

- standard rectangular and oval Samples will be appropriate in any bathroom. They are convenient, compact, but quite ordinary and familiar, so if you want something special, it is better to look in the direction of other options;

- corner baths find use in square bathrooms and become their decoration. They give a little more space for swimming, but it’s a little more difficult to take care of such a product than the usual rectangular one, since the width in the corner region is increased;

- round baths beautiful and elegant, usually installed not under the wall, but in the center of the room, so they require a sufficient amount of space, and neatly let down communications not so easy. Round bathtubs provide ample space for a swimmer who will feel like in a small pool. Such products in private homes are often built into the floor. In this case, the aesthetics are in place, and even the problems with heat and sound insulation can be solved by using mounting foam or other materials mentioned above;

- asymmetric baths complex shapes are also more suitable for spacious rooms and can become an interior decoration.

If the bathroom area allows, then you can decide not only on freestanding bathbut also put it on podium, - will look very impressive. The final touch is interesting spotlight integrated in the floor or podium, and you won’t want to leave this bathroom.

No. 6. The thickness of the walls of the steel bath

The strength of the bath depends on the wall thickness, its ability to withstand the constant loads of water and swimmers, and not be deformed. In addition, the thicker the walls, the higher the heat and sound insulation. It is better not to take products with wall thickness less than 2.5-3 mm. Even better is to stay on a product with a wall thickness of 4 mm.

Some manufacturers and sellers deliberately go to the trick, and in the documents they overestimate the wall thickness indicator. Especially cunning manufacturers on the sides of the bathtub, where you can see the cut of the product, make the walls thicker. If the buyer guesses to look at the end, then he will see that everything is in order. The best way to make sure you are not being fooled is to check product weight. A full-sized bathtub with walls of at least 3 mm weighs about 30-40 kg, miniature bathtubs cannot weigh less than 20 kg.

Number 7. What to consider during an external examination?

What steel bath is better to buy in order to be sure that it will last at least the declared 20 years and maintain its performance over the entire life cycle? During a personal inspection in the store, pay attention to such details:

- product surface It should be smooth and even, without hollows, bumps, cracks and other defects. This is evidence that the production technology has not been violated;

- enamel quality. Enamel is a protection and decoration of a steel bowl. Normal manufacturers use strong formulations and special application technology. If you saw smudges, chips or similar defects, then it is better to refuse to buy, otherwise after a year or two you will have to repair the bath or buy a new one. By the way, the color of the enamel is usually light (beige, bluish, white). The choice of color is a matter of taste and combination with other plumbing items. On sale you can find quite extravagant black, blue, red and other bathtubs, but you should use them very carefully, otherwise such a product can turn into a complete bad taste with a stylish decoration;

- if knock on the walls of a quality bath, you can hear a clear, smooth sound without extraneous vibrations.

As for the additional options, many steel bathtubs are equipped with headrests and handles. There are also steel baths with hydromassage. A special motor in them pumps water from the bowl into nozzles and delivers it under pressure, mixing with air. The effect of such aerated jets of water on the human body produces a relaxing effect.

Number 8. Top Steel Bath Manufacturers

Large companies that have worked for years to create an honest name, have the means to timely modernize production and value their reputation, will not produce products of dubious quality. That is why when buying a steel bath it is better to pay attention to the products of reputed brands.

Among top steel bath manufacturers it is worth highlighting such companies:

- Kaldewei, Germany. A manufacturer with extensive experience in the manufacture of steel bathtubs. It uses high-quality steel and glass enamel, which, by the way, is the only one in the world that makes independently, using a special recipe and modern melting furnaces. The main factory of the company is located in Germany, quality is strictly controlled at all stages. The products are presented in several collections; there are bathtubs of different sizes, classic rectangular, oval and asymmetric in shape, with different discharge locations;

- Roca, Spain. A well-known company that produces plumbing, tiles and fixtures, has dozens of factories and hundreds of representative offices around the world. In the domestic market, the company’s products are especially treated as they are of the highest quality. Despite a decent price, Roca steel bathtubs are in high demand;

- Estap, Slovakia. The company has been operating since 1991, but is already competing with more experienced players in the market. Here they developed and apply a unique technology of powder coating of enamel in an electrostatic field, which allows to achieve high quality coatings. The product range is quite extensive and is constantly updated;

- Emalia, Poland. The company makes strong, durable, fairly simple in form and affordable products. The combination of all these features provided the manufacturer with high popularity in a number of European countries and in the domestic space;

- BLB, Portugal. The company exports products to 50 countries. The increased demand is explained by high quality and a wide range. Particular attention is paid to enamel coating durability and design.In the domestic market, bathtubs of the company appeared not so long ago, but already managed to prove themselves perfectly;

- Jika, Czech Republic. It produces sound steel baths. It does not differ in a large assortment, but it manufactures products of all standard shapes and sizes, and this, together with a small price, has brought the company success;

- LLC "VIZ-steel" (Verkh-Isetsk Metallurgical Plant). Domestic enterprise, which will give odds to any foreign. Enamel is applied in two stages, which allows you to get a strong, smooth, even surface with ideal protection. In addition, the manufacturer uses an enlarged foot mount area, vibration damping plates and anti-slip coating. In terms of variety and price, you will not find fault;

- LLC Lipetsk Pipe Plant It has been producing steel bathtubs for over 70 years, but today they are not so easy to find in stores. For the most part, these are products with a length of 150-170 cm. The wall thickness is usually about 2 mm, but there is no need to complain about durability - the products last about 20 years. The main advantage of the plant’s bathtubs is its very low price.

In conclusion, we note that when buying, it is important not only to assess the wall thickness, product weight and enamel quality, but also to ask for product documentation confirming its quality and the availability of a guarantee for it.