8 tips on which electric heating boiler is better to choose: power, manufacturers

Compact, reliable and easy to operate electric heating boilers, of course, are inferior to analogues in terms of efficiency, but in certain conditions they will be indispensable. They can be used everywhere, installed in apartments and private houses, offices and industrial premises - wherever there is access to electricity. Often electric boilers are used as a backup source of heating. The numerous advantages of such units have led to an increase in their popularity and the emergence of a mass of modifications. Let's try to figure out which electric heating boiler is better to choose for a private house and apartment, what power will be needed to create comfortable conditions, and what is important to pay attention to when buying.

No. 1. Advantages and disadvantages

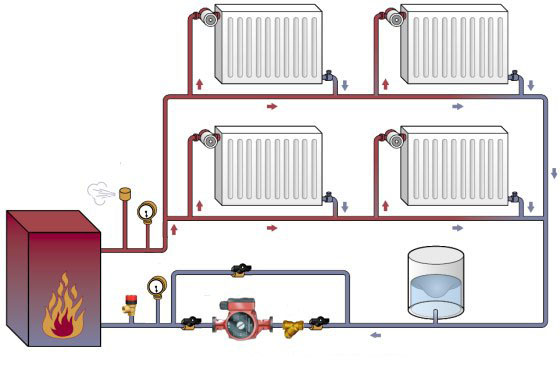

The electric heating boiler works very simply. In it, electrical energy is converted into heat. When the boiler is turned on, the heating elements heat the coolant. Last by pipe system and radiators enters the living room and heats the air in it. In the simplest and most common version, the usual TEN is used as a heating element, but there are also induction and electrode boilers in which heating is carried out somewhat differently. Only the power source remains unchanged - electricity. Many boiler models are equipped with a control and management mechanism.

Despite the fact that electric boilers can hardly be called an economical source of heat, they are very popular, and there are many reasons for this. The benefits of electric heating boilers can include:

- universality. The unit can be installed wherever there is electricity, no permits from technical authorities are needed. Today, electric boilers are used both in private homesand in apartments, as well as in commercial and industrial premises;

- low cost in comparison with gas and solid fuel boilers;

- high efficiencywhich reaches 95-99%;

- ease of installation. Electric boilers have small dimensions, and when connected, there is no need to build chimney;

- ease of operation and temperature adjustment. Most models are equipped convenient control systems and thermostats, so the user should literally press a few buttons or turn the lever - constantly run to the boiler, control its operation or, worse, stoke not have to. Since the boiler perfectly controls its work, its efficiency is increased;

- security. In electric boilers there is no open flame, and flammable fuel is not used. In addition, thoughtful automation is used, so the likelihood of emergency situations compared with other types of boilers is sharply reduced if, of course, the installation was carried out correctly;

- compactness, so the installation of such a unit is possible even in the smallest rooms;

- environmental friendliness, because during the operation of the boiler no harmful emissions are formed;

- noiselessness;

- lack of need for constant monitoring of work (you can leave the boiler unattended) and frequent maintenance. Solid fuel boilers, for example, require constant care and cleaning;

- wide range of. On the market are models with different capacities (from 2 to 60 kW or more) and functionality (single-circuit and double-circuit).

disadvantages also have:

- high cost of operation. Despite the advanced automation and energy saving systems, electric boilers are still quite expensive to operate. For heating large rooms, in most cases, it is disadvantageous to use. Often such boilers are used as reserve heat source;

- dependence on the availability of electricity. If the region is observed frequent power outages, then this heating option is not suitable;

- the need for special three-phase wiring if a boiler with a power of more than 12 kW is used. Some experts recommend using a line with three phases even when connecting a boiler from 6-7 kW.

Despite the existing disadvantages, electric boilers find their customers. Moreover, if you carefully analyze the conditions at the facility where you want to create a heating system and choose the right electric boiler, you can enjoy the positive qualities of these devices to the maximum.

No. 2. Types of electric boilers by type of heating element

Depending on how the water is heated, all boilers are divided into heating elements, electrode and induction.

Heating boilers

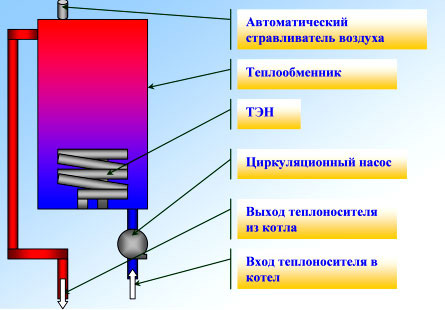

it most popular version, and so popular that when talking about electric boilers, as a rule, they mean structures with a heating element. Such a unit works on the principle of a boiler. Electricity is supplied to a tubular electric heater (TEN), it is heated and transfers heat to the water, which is used as a heat carrier. TEN consists of nichrome spiral and durable sheath made of steel, aluminum or titanium. The space between the spiral and the shell is filled with quartz sand or other dielectric filler.

The rated power in such boilers is reached stepwise, approximately 10-15 minutes after switching on. TEN new boilers operate in flow mode, can be single-circuit and double-circuit. As a rule, several heating elements are placed in the boiler tank.

Since there is no direct contact of the heating coil with water (the dielectric acts as a separator), you can not be afraid of a short circuit. The main problem of such boilers is different. The surface of the heater is in contact with water, appears on it relatively quickly scale, which can gradually disable the boiler. To slow down this process or even completely avoid it, it is better to use distilled water in the system. Special fluids are also sometimes used. The boilers are protected from thermal fluid overheating by a thermal regulator, but if a leak occurs, the unit runs the risk of overheating and malfunctioning.

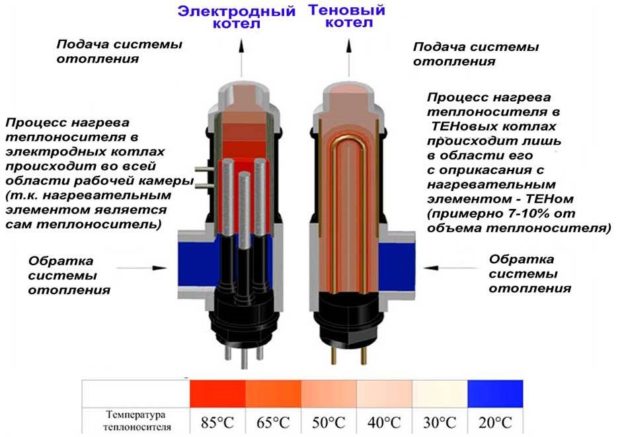

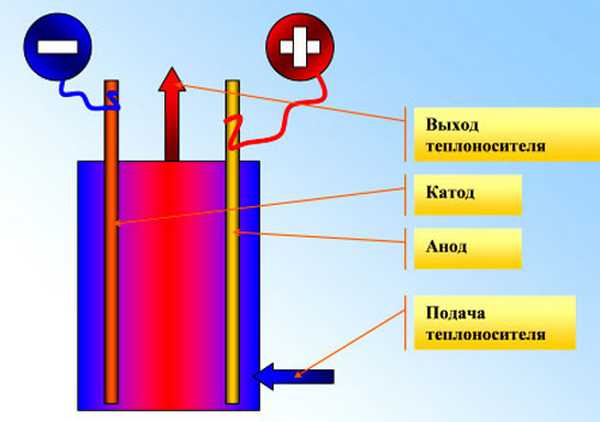

Electrode (ion) boilers

The design of this boiler assumes the presence of two electrodes immersed in a heat exchanger. They are supplied with electric energy, due to which a potential difference is created. Due to the presence of salts in the coolant, it turns into a current conductor. Electricity passing through an electrolyte with high resistance causes it to heat up. Just a couple of minutes is enough for the boiler to reach its rated power. As an electrolyte (coolant) take specially prepared water or ethylene glycol based fluid.

In operation, boilers of this type are sufficient economical, and to provide the same thermal power as the heating boiler, they consume almost half the amount of electricity. Such units, as a rule, have reliable thought-out automation, rarely fail, since there is essentially nothing to break here.If a leak occurs in the system, then overheating will not happen - there is no electrolyte. Electrode boilers also perform well in conditions of unstable voltage. If it drops down to 180 V, the unit will continue to work and generate heat.

Of the minuses only cost of equipment and the need to use a specially prepared coolant. How much energy the boiler will spend on heating will depend on its composition. Another nuance is the need for reliable grounding. The electrodes will have to be changed periodically.

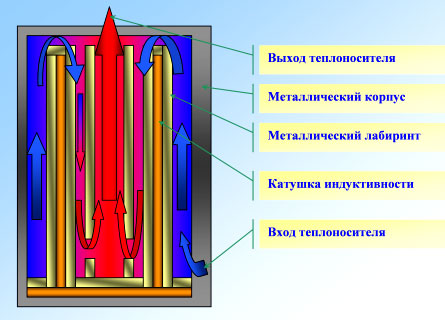

Induction boiler

Boilers of this type began to be used back in the 80s of the last century, but at first they were installed only in production. The release of household models began only by the end of the 90s. The principle of their work is quite complex and resembles a transformer. The heart of the unit is an induction coil, which converts electrical energy into a magnetic field, directing it to the core. The latter is a system of steel pipes with a coolant inside.

The system performed well. Induction boilers economical and very compact, durable (service life of 30 years or more) and fireproof, and the problem of scale with them is not terrible. There are no strict requirements for the coolant, as in the two previous types of boilers - even refined petroleum products can be poured.

The main minus is high price. In addition, induction boilers weigh decently, despite their miniature dimensions. Finding a model lighter than 20 kg will not work.

Which boiler is best to choose depends on the budget and the requirements put forward - all three types can be found on sale.

No. 3. Type of connection

Before buying a boiler of a certain capacity, you need to find out the features electrical wiring in the house. Among boilers with a capacity of up to 10-12 kW, you can find models that can be connected both to single phase (220 V), so to three phase network (380 V). More powerful boilers with a single-phase network cannot be used - it will be necessary to connect the house to a three-phase network.

To connect the boiler to the shield, it is better to take a stranded copper wire, which will be less heated at a higher conductivity.

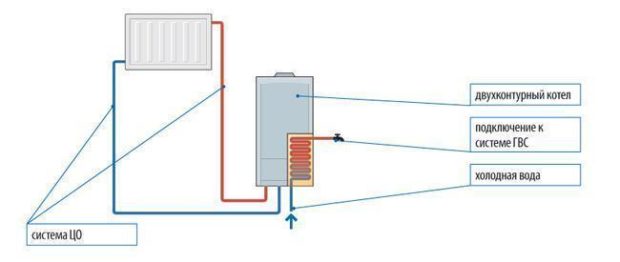

Number 4. Number of circuits

Among electric boilers, the most popular single-circuit models. They are only responsible for the heating system. In order to provide yourself with hot water supply, it is necessary to equip the system with a water heater or take double-circuit boiler. The latter has two independent circuits for heating water. Double-circuit electric boilers consume a lot of electricity, so they are rarely used.

No. 5. Calculation of electric boiler power

The power of electric boilers ranges from 2 to 60 kW (for production and commercial premises there are even 400 kW models) and is selected depending on what area the area needs to be heated and if there is a need to heat water for hot water supply. Ideally, to determine the power, it is necessary to carry out a complete heat engineering calculation, taking into account not only the area of the room, but also the height of the ceilings, level thermal insulation, quantity windows, doors and other factors. To do this, it’s better to turn to professionals, but calculate approximate power You can do it yourself.

The easiest way is to use the proportion according to which it is necessary to provide 1 kW of boiler power for every 10 m2 area provided sufficient insulation and with a ceiling height of not more than 3 m. It is better to throw a little more margin (10-15%), and if you use a double-circuit boiler, then add another 25% to the obtained value. This calculation is rather arbitrary, but to obtain more accurate results, you can use another, slightly more complex, formula.

The power of the electric boiler can be calculated as follows:

- W = (40 * S * h + Qo+ Qd) * kwhere

- 40 - average required boiler power per 1 m3, 40 W / m3;

- S - area of the house / apartment;

- h is the height of the ceilings;

- Qo - heat loss through the windows, 100 watts each;

- Qd - heat loss through the doors, 200 W each;

- k - coefficient depending on the region, for the southern regions of the country it is possible to take 0.7-0.9, the central and European parts - 1.2-1.4, for the north and the far east - 1.8-2.0.

If the calculation is for private home, the result is multiplied by another 1.5.

Let's say there is a house with an area of 85 m2, with a ceiling height of 2.8 m, with 6 windows and 2 doors, it is located in the southern part of the country. The required power will be W = (40 * 85 * 2.8 + 600 + 400) * 0.8 * 1.5 = 12.6 kW.

No. 6. Power control and boiler control system

In electric boilers, it is quite simple to adjust the power and temperature of the coolant. Actually, these two parameters are interconnected, therefore it is impossible to consider them separately from each other.

The boiler power adjustment is carried out in one of the following ways:

- stepwise - A frequent option in TENovy coppers. In this case, the design provides one heating element, which provides half the power, and two, which give 25% of the heating. It turns out that the boiler can work at 25, 50, 75 and 100% of the maximum power, more precise adjustment can be made in each room thanks to the valves on radiators;

- smooth adjustment achieved through the use of a rheostat. This is the privilege of more expensive models. In simple low-power boilers, there may not be any adjustment at all.

The user sets the boiler the necessary temperature of the coolant to maintain comfortable conditions in the house, and the boiler turns on the heating and turns it off when the coolant is sufficiently hot. Automation can work with the help of mechanical and electronic temperature controllers. Both options save energy and maintain a comfortable temperature without constant monitoring of the boiler.

Mechanical temperature controller shuts off the coolant current or opens the electrical network when the user-specified coolant temperature is reached. When the temperature drops, the boiler switches on again. This is a simple and cheap way, but not the most accurate - the temperature of the coolant at the outlet of the boiler can be 2-30C differ from the set. Electronic thermostats more accurate, they consist of a remote sensor and a control unit. The sensor is attached to the heating element and transmits information about its temperature to the unit remotely or using wires. Naturally, such boilers are more expensive.

Number 7. type of instalation

Electric boilers can be:

- wall mounted;

- outdoor.

It is clear that the wall-mounted ones take up less space and are suitable in cases where this very place is very limited. Western manufacturers prefer this particular installation format. In the floor-mounted version, as a rule, more powerful boilers are produced, which need to heat a large volume of coolant.

Number 8. The best manufacturers of electric boilers

Dozens of manufacturers, both foreign and domestic, work in the market of electric boilers. European boilers usually get smooth adjustment, assembled from more expensive components. Our boilers mainly receive step-by-step adjustment, therefore they are cheaper. Probably, each of us understands well that it is better not to save on the heating system, therefore it is not worth trusting little-known companies. The most large, proven and reliable manufacturers electric boilers in the world and Russia:

- Protherm - A Czech manufacturer, which began precisely with the production of electric boilers. Today, other types of heating boilers are also produced, as well as boilers, temperature regulators, etc. The company's electric boilers have wall-mounted design, power from 6 to 28 kW, efficiency 99.5%, are available in single-circuit design. In 2001, the company became part of the German group of companies Vaillant;

- Vaillant produces slightly more expensive boilers than Protherm, power up to 28 kW, all models are easy to use and reliable;

- Buderus - a large German company, produces electric boilers for private homes and commercial facilities, the power of wall single-circuit models 30-60 kW;

- Kospel - reliable Polish electric boilers, presented in a wide range. Power is from 4 to 36 kW, models up to 8 kW are presented in two versions, for work with a network of 220 V and 380 V;

- Bosch It also produces electric boilers, power from 4 to 24 kW, wall-mounted, with one circuit, but it is possible to connect an indirect heating boiler. You can buy both a simple boiler and a boiler complete with an expansion tank and a pump;

- Ferroli - High-quality Italian electric boilers with power from 6 to 28 kW with very thoughtful automation and a wide range of additional functions. In the boilers there are connectors for connecting room and outdoor temperature sensors, a large display, the ability to daily program the operation of the boiler and even control the boiler using the remote control;

- Zota - Domestic boilers that differ in the most affordable price and quite high-quality performance. Power is from 3 to 400 kW, boilers are presented in several lines, TENs are used as heaters;

- RusNIT - budget good boilers from the Ryazan company, power from 3 to 99 kW;

- Evan - a large domestic producer, part of the NIBE concern, produces boilers in different price segments. Power from 2.5 to 480 kW.

Also worth noting are the products of Dakon, ACV and RECO, Intoys, Alvin, Resource.

Finally

You can not take into account such a selection factor as efficiency for electric boilers - all models work with efficiency above 95%, often this figure reaches 99%. Pay attention to the equipment. If the heating system is built from scratch, then it is more profitable to take a boiler in the maximum configuration with an expansion tank, a pump and other elements.