10 tips on which liquid nails are best to choose: application, types. How to glue with liquid nails

We've all heard about liquid nails. This is a special kind. construction glue, which can simply and quickly stick literally everything: drywall, ceramic tiles, glass, metal - this composition can be called universal. It appeared not so long ago, but has already conquered the whole world and is actively used in carrying out construction and repair work of varying complexity. Depending on the operating conditions, materials and surfaces that will be glued, choose one or another type of liquid nails. Let's try to figure out which liquid nails are better to choose and what is important to pay attention to when buying. We will determine the scope of application of liquid nails and installation technology.

No. 1. Composition of Liquid Nails

Liquid nails were invented in the USA. There in the 60s, Macco first decided to pack conventional glue into individual cartridges for ease of use. A couple of years later, a new development appeared - Liquid nails. In a matter of years, liquid nails won over American users with a host of advantages, and they only hit the domestic market in the 90s.

The basis for a new type of glue has become synthetic rubber with polymer additives. As a filler used special grade of clay with increased ductility. In the US, the state of Texas has concentrated huge deposits of this clay, where the main industrial facilities of most local producers are located. Instead of unique clay, common chalk is often used today. Thus, manufacturers kill two birds with one stone: on the one hand, chalk acts as a filler, but at the same time it gives the glue the necessary white color, which is achieved by classical technology by adding titanium oxide. Glue with the addition of chalk is significantly inferior in terms of quality.

Previously, toluene was added to the liquid nails to improve adhesion and acetone to speed up drying. The increased toxicity of these substances forced to abandon their use. However, some companies still use similar additives to reduce the cost of the composition. Their adhesives have an unpleasant odor and, as a rule, at a suspiciously low price. In the room, such compositions can in no case be used.

No. 2. Liquid nails: advantages and disadvantages

The unique composition and convenient packaging allows you to talk about The many benefits of liquid nails:

- highest bond strength. The composition can withstand loads up to 80 kg / cm2;

- good adhesion with almost all existing materials;

- ease of use;

- the composition can be used for bonding not only smooth surfaces, but also with a loose fit of materials. Liquid nails simplify installation on curved surfaces;

- such glue does not destroy the surface, does not damage its integrity, unlike ordinary nails;

- liquid nails are not subject to corrosion;

- the installation process takes place without noise, knocking, dust and dirt;

- glue sticks in seconds;

- modern formulations are non-toxic.A rare exception is the dubious products of nameless companies at an unreasonably low price;

- high fire resistance. Moisture and frost resistance is characteristic only for neoprene compounds, is weakly expressed in water-based adhesives;

- most formulations have a fuzzy, almost neutral odor;

- economical consumption. One drop of material can withstand loads of up to 50 kg.

Disadvantages liquid nails actually do not, if you do not take into account some restrictions on the use of different types of glue.

No. 3. Types of liquid nails by type of solvent

The type of solvent used actually determines the scope of the composition. Today, these types of liquid nails are produced:

- on a synthetic basis;

- water based.

Neoprene Liquid Nails are made based on synthetic rubber. Such structures can be used to glue fairly heavy structures, including and metal. Glue perfectly tolerates the effects of high humidity, temperature extremes, frost, provides high speed and setting strength. Less material - pungent odor and low toxicity. When working with glue, it is necessary to protect the hands and respiratory organs, to well ventilate the room. Bad odor will persist for about two days after work. There is another limitation - it is not recommended to glue synthetic materials with such a composition.

Water based acrylic liquid nails absolutely non-toxic and practically do not smell. Their strength is slightly lower, so they are used for fastening lighter materials. It is this composition that must be used when working with porous surfaces. We take the minus sensitivity to temperature changes, low frost and moisture resistance, therefore, such compositions are not suitable for large-scale work in the kitchen and in the bathroom.

Number 4. Types of liquid nails for the intended purpose

According to the purpose, liquid nails can be divided into the same types:

- universal;

- special purpose.

It is clear that universal adhesives can be used in any conditions and for mounting on any surface. However, such universality does not always work well when conditions are very specific.

Special compounds have clear recommendations for use. On sale you can find such liquid nails:

- for wet and dry rooms;

- for indoor and outdoor use;

- for fastening heavy structures;

- formulations of increased strength and high pour point;

- glue for mirrors, glasses and ceramics;

- glue for polystyrene panels and others.

Which liquid nails are better to choose, it is necessary to decide depending on what and where you are going to fasten. On the packaging, manufacturers indicate under what conditions one or another composition can be used, and for which it is mainly suitable.

No. 5. Liquid Nails: Application

Liquid nails are a universal material that is suitable for working with such materials:

- brick structures;

- drywall;

- glass, mirror and ceramics;

- wood, fiberboard, particleboard and MDF;

- polystyrene;

- plastics;

- aluminum and other metals;

- cork panels;

- bathtubs and shower cabins, sinks;

- door frames and window frames, siding.

Sometimes liquid nails are used even when sealing gaps in walls, corner joints, countertops, ventilation holes, although it is better, of course, to use special sealants. It is not recommended to use liquid nails when working with a wet tree, as well as for gluing aquariums.

No. 6. What else to consider when choosing liquid nails?

When buying, carefully study the packaging and everything that is written on it. Pay particular attention to such things:

- glue setting time. This parameter in different compositions may slightly, but vary. If we are talking about installing some elements on the walls or on the ceiling, it is better to take quick-setting adhesives in order to simplify the installation process;

- composition. It is better to take glue, in the composition of which there is no chalk, it can slightly degrade the quality of the connection. If we are talking about responsible fastening or gluing heavy parts, then the composition with chalk is definitely better not to take;

- acetone in the composition also not desirable;

- for the bathroom and other rooms with high humidity should definitely be taken moisture resistant composition.

Number 7. Liquid Nail Manufacturers

The quality of liquid glue, its composition and compliance with what is written on the package depends on the name of the manufacturer. The fastening of materials and structures is a responsible matter, so there is no need to save money. The choice is best entrusted to products from manufacturers such as:

- Henkel - A German company whose products are in high demand all over the world precisely because of its high quality. Produces trademark liquid nails "Moment Installation" and Makroflex. There are universal compounds and adhesives for skirting boards, polystyrene foam panels, superstrong adhesives for metal, wood and chipboard. Clay "Moment Installation Superstrong Plus" withstands load up to 100 kg / cm2;

- Kim tec - Another German manufacturer, produces universal liquid nails, moisture-resistant compounds, as well as adhesives for decorative elements, mirrors, adhesives of especially strong fixation;

- MACCO - An American company that has become a pioneer in the industry. Its products are of high quality, and the range is constantly expanding;

- FRANKLIN - an American company that produces liquid nails under the brand name Tititebond. The compositions are characterized by increased strength and a sufficient range;

- SELENA GROUP - Polish company, produces liquid nails Titanwhich are distinguished by good value for money.

Number 8. Liquid Nail Gun

It is very simple to work with liquid nails - even a beginner in the repair business will master. It will be necessary to stock up only with a suitable composition and a special gun, where the cartridge with glue will be inserted. Despite the formidable name, this gun looks more like a syringe, however, quite bulky. A tube of glue is installed in the prepared niche so that on one side it abuts against the tip, and on the other hand, into the pressure surface. The design is very simple, installing a cartridge with glue is also easy.

There are pistols frame and sheet. Frame more reliable, as they allow more tightly fix the cartridge.

Depending on the design features, guns may be with or without reverse gear. The latter are used mostly by professionals when the volume of work is large and constant. For private construction, a reverse gear design is more suitable.

No. 9. How to glue with liquid nails?

The whole process is quite simple, it does not require any special skills:

- surfaces to be bonded must be thoroughly cleaned and degreased;

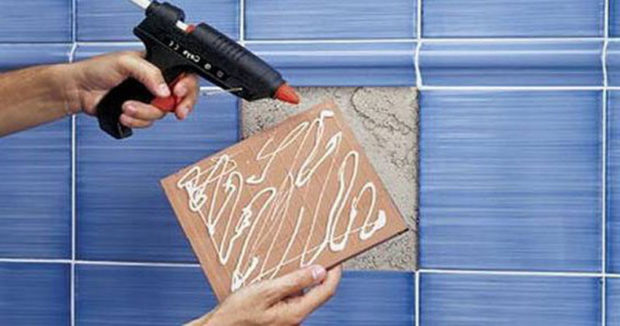

- glue must be applied pointwise or with a snake if the part is heavy. For application use a special gun;

- after application, the material is quickly applied to the surface and pressed tightly. It takes about 1-2 minutes to hold the part in the required position, then you can carefully remove your hands. At this stage, if necessary, controlled by vertical and horizontal level;

- glue drying time - 12-24 hours, it all depends on the type of composition, temperature, humidity and ventilation in the room. Final polymerization occurs after about a week.

When working with liquid nails based on an organic solvent, gloves should be used, or better, a mask to protect the respiratory tract.

No. 10. How to remove liquid nails?

When the installation takes place carefully and slowly, the probability of glue getting on the front side of the surface is low. If this still happened, then try wipe off the glue as soon as possible. While the composition has not yet dried, it will be possible to remove it with a damp sponge or a mineral-based solvent.When the glue has finally dried up, special cleaners will help, or a rough mechanical method using a scraper, but it is necessary to act very carefully so as not to damage the surface. Another way out - heating to a temperature of 55-60 degrees, for example, with a construction hairdryer - the nails will go into a liquid state and it will be much easier to remove them.

The most important thing is to be careful at the time of purchase and not to trust attractive offers from little-known manufacturers. In the best case - the glue will be fragile, in the worst - it will be harmful to health.