8 tips for choosing tile adhesive: types, manufacturers

Just recently for ceramic tile installation used a sand-cement mixture, and the most advanced craftsmen added glue to it. This is far from the most ideal composition, therefore it is not surprising that the tile began to lag behind the surface over time. Today, to our happiness, many special adhesives have appeared that provide a high degree of adhesion, and there are compositions for different types of tiles, different substrates and operating conditions. Let's try to figure out how not to get lost in this variety and which glue for the tile to choose, taking into account many factors.

No. 1. What determines the choice of glue?

Masters know that there is no absolutely universal tile adhesive, although there is something similar on sale. In difficult operating conditions (for example, a bathroom), it is better not to use universal compounds.

The choice of glue is based on these three main factors:

- dimensions, material and features of the tiles used;

- type of surface;

- Operating conditions. There are adhesives intended for use indoors and outdoors, in conditions of high humidity, constant temperature drops, etc.

Modern adhesive compositions are mostly based on the same cement-sand mixture, only plasticizers and other chemical additives are added to it, which provide high adhesion.

Usually glue is available in dry mix, which must be diluted with a certain amount of water, but there are already ready pasty compounds, or mastics. Paste glue is produced on the basis of refined products, latex and some additives. It costs more, it is not very convenient in transportation, but indispensable when it is necessary to mount heavy large tiles or porcelain tileas well as when required stick tiles on plywood or drywall.

No. 2. The main types of tile glue

Depending on the composition, tile adhesive can be of the following types:

- on a cement basis;

- epoxy;

- dispersive.

Cement based adhesive - This is a classic of the genre. Dry mixes are prepared on the basis of cement and sand, add polymer and latex additives to them, getting different compositions. The main advantage of such adhesives is low price. Installation cost 1 m2 tiles with cement-based glue are 20 times lower than when using epoxy glue, and 10 times lower than dispersion glue. Thanks to the many possible additives, you can prepare the composition that is most suitable for any operating conditions. This means that we can talk about a certain universality. In terms of assortment, such compounds are in the lead. Moreover, it is not difficult to find cement-based glue in any store in any settlement, it is relatively easy to apply, and any craftsman knows how to behave with cement glue, which cannot be said about other compounds.

Epoxy adhesive prepared from several components. These are epoxy-polyurethane resins, organic additives and inert fillers, to which an organic-based catalyst is added. The result is composition with unique properties. It provides heavy-duty connection of tiles with the surface, is not afraid of frost, high humidity, temperature changes, it does not shrink and withstands the highest loads. Minus - price: installing a square meter of tile on such glue will cost almost as much as the tile itself. Epoxy glue is used in places with maximum load: metro, airports, workshops and other premises.

Dispersion adhesive made on the basis of synthetic resins, with organic additives and an inert filler. The composition will cost less than epoxy, but still several times more expensive than ordinary cement. The main advantage is high ductility.therefore, dispersion adhesive is indispensable when it is necessary to install the tile on a moving base, for example, wooden floor and walls. The composition is sold ready to use, it quickly sets and dries.

Since an ordinary apartment does not have such loads as an airport or metro, there should not be any questions about which tile glue to choose - in almost all cases ordinary cement-based glue will suffice.

Separately, it is worth noting such a composition as liquid Nails. The material is based on polymers and synthetic rubber. In terms of performance, neoprene-based liquid nails have shown themselves best. The composition is not afraid of moisture, but has an unpleasant odor, and because of the increased content of toxic substances in residential premises it cannot be used. Safer water-based formulations do not have sufficient moisture resistance to be used for installing tiles in the bathroom. Typically, such glue is used only during restoration of the tiled coating.

No. 3. Tile Material and Features

Going to buy glue is better when the tile is already bought or it is precisely known what format it will be. The larger its size, the more requirements are put forward to the adhesive composition. To hold a heavier tile, the adhesive must have enhanced bonding properties. Pay attention to adhesion parametersindicated on each package of glue and expressed in MPa. So, for example, if we are talking about a small tile that will be mounted on a wall in a dry room, then glue with an adhesion of 0.2-0.3 MPa will be enough. If necessary lining the facade heavy large tiles, it is better to take glue with an adhesion of 1 MPa, and it should be frost and moisture resistant.

For styling floor tiles recommend taking adhesive with high elasticity. Elastanes and plasticizers in the composition of the material will talk about this.

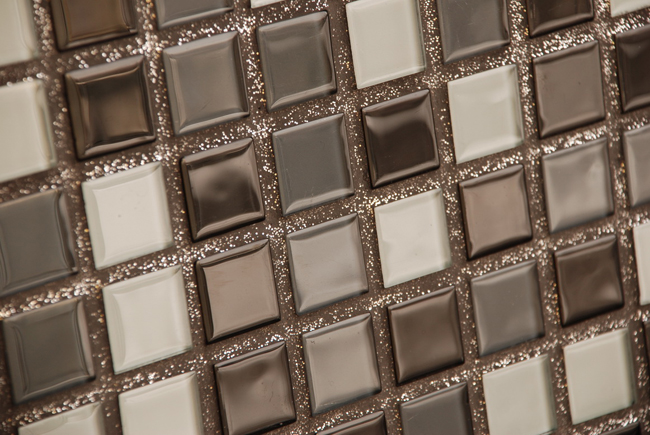

Usually for mounting all types of ceramic tiles, granite and artificial stone use gray glue. When it comes to glass mosaicbetter to take the composition white color. It's not about adhesion (it does not depend on color, contrary to existing myths) - it's about aesthetics, which will be much higher when using white glue.

Number 4. Glue and operating conditions

For external and internal work, different glue compositions will be required. A special glue will be necessary even when it comes to operation in conditions of high humidity, frequent changes in temperature, frost, high mechanical stress. The most common cheap cement-based adhesive is designed for use in dry rooms without temperature extremes. They can carry out the installation of tiles in the living room, dining room or hallway.

For outdoor work produce special compounds that differ in frost and moisture resistance. Such glue is not afraid of frost, sun, rain and other negative environmental influences. It can also be used indoors, however, its use will be justified when its exceptional properties are really necessary.

For laying tiles on underfloor heating it is better to use elastic compounds. Such glue withstands linear expansion of the screed and does not crack, thereby prolonging the initial appearance of the finished surface.

Glue mixes for tiles are divided into the following groups:

- first group (C1) - these are compositions for external and internal works, which provide adhesion at the level of 0.5 MPa. Depending on what substances are included in the adhesive, it is possible to use in dry and wet conditions;

- second group (C2) - these are improved cement-sand mixtures, which include special substances that provide them with certain characteristics. The adhesion of such adhesives is at least 1 MPa, elasticity is increased, and depending on the composition, it is allowed to use in places with very high humidity, constant temperature drops, as well as in the presence of serious dynamic and static loads;

- third group - These are special-purpose adhesives with specific properties. These are heat-resistant compounds that can glue the tile for furnace lining and fireplaces, white adhesives for the installation of mosaic, marble and translucent tiles, special adhesives for use in basins and other compositions.

No. 5. Choosing glue for installing tiles in the bathroom

Particular attention should be paid to the choice of adhesive for tiles in the bathroom. It must be moisture resistant composition, and he may possess fungicidal propertiesto prevent the development of fungus and mold. If the tile will be mounted directly on drywall, it’s better to take a plastic composition. The surface must be treated before installation. primerotherwise, it may absorb glue, resulting in weakened bond strength. Strongly absorbent places should be repainted with a primer. It is also better to use waterproof compounds in the bathroom for grouting.

Often in bathrooms it is recommended to use quick drying formulations, which after 3-5 hours are set and allow you to safely operate the tiled surface.

No. 6. Glue and type of substrate

All the bases on which the installation of ceramic tiles is allowed can be divided into two groups:

- simple groundswhich include concrete, brick, surfaces from cellular concrete blocks, sand-cement screeds and other stable, solid, non-deformable surfaces;

- complex grounds easily deformed. These are wooden, plastic and drywall surfaces, as well as metal, glass and a layer of old tiles.

When choosing glue for tiles, consider the following recommendations:

- for a simple stable base you can take ordinary cement-based glue, compositions with latex additives are excellent;

- on the old tile, the painted surface and drywall installation is recommended to be performed using dispersion glue, but in the case of drywall, ordinary cement glue is often used, but with additives that increase its elasticity;

- if necessary, firmly fix the tile on metal or plastic basethen it is best to take epoxy glue.

Number 7. How to calculate glue consumption?

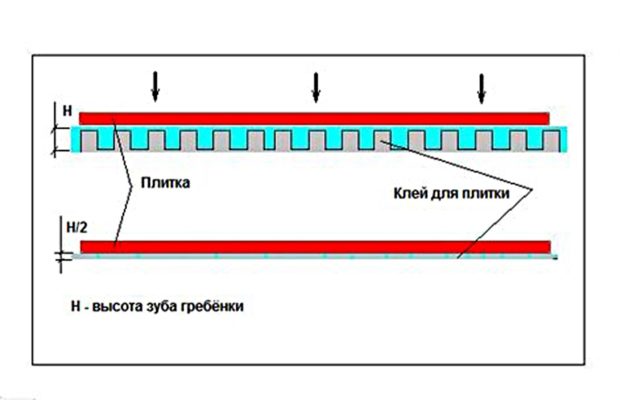

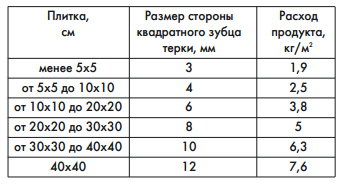

The approximate consumption of glue each manufacturer indicates on the packaging, and the exact consumption will depend on many factors. Only an experienced craftsman can accurately calculate the rate of glue consumption in kilograms of dry mix for each square meter of surface.

The following factors influence the consumption of the adhesive mixture:

- tile size. The smaller each individual tile element, the thinner the glue layer required for fixing it. So, for example, for mounting tiles with a format from 2 * 2 to 10 * 10 cm, the average consumption will be about 3 kg / m2. For tiles ranging in size from 10 * 15 to 20 * 20 cm, the adhesive layer increases and the consumption is up to 4 kg / m2. On a tile from 20 * 30 to 30 * 30 cm, it is necessary to apply a layer of glue even thicker, and the consumption will be about 5 kg / m2. For the installation of tiles larger than 30 * 30 cm, 6 kg of dry mix for each m2 surface;

- tile composition. If the water absorption of the tile is high, then it will absorb part of the glue, and its consumption will increase.For example, most types of ordinary wall tiles have a water absorption of 10%, and for ceramic granite this figure is only 1%;

- flatness of the base. The smoother the surface at the base, the lower the glue consumption. If you or the master are too lazy to conduct a thorough wall alignment or genderthen get ready to overpay for glue. If the irregularities are too large, then the tile may even peel off soon;

- mastery of the one who does the work tile laying, may also affect the consumption of adhesive. If the glue leaves too much, it is worth doubting the professionalism of the performer;

- there is an opinion that even glue application tool, affects the consumption of the composition. Some say that a V-shaped putty knife will save glue, while a U-shaped one does less economically;

- parameters such as humidity and air temperature, ventilation and others.

Many manufacturers of tile adhesives on their sites have special calculators that help calculate how much a particular composition will be needed to lay a particular tile. When the approximate flow rate and surface area to be coated are known, you can easily calculate how many packages of glue are needed.

Number 8. Tile Adhesive Manufacturers

The installation of ceramic tiles is a responsible matter, and so I don’t want the elements due to poor glue expensive tile damaged, and very few people wish to redo the repair in a year and a half. That is why it is better to take glue from a trusted manufacturer, so as not to worry again.

Among the largest manufacturers of tile adhesive we can safely recommend the products of such companies:

- Ceresit Is the most popular adhesive on the market. The manufacturer's range is huge and includes standard adhesives for indoor and outdoor use (SM 9 and SM 11), elastic adhesives (SM 14 Extra, SM 16, SM 17) and special adhesives for porcelain and large-format tiles, mosaics and facade tiles. All formulations are absolutely safe, quality checked by numerous buyers;

- Knauf produces a series of adhesives that can be used for mounting tiles and artificial stone on any surface. There are compounds that are resistant to water and low temperatures, adhesives for exterior and interior use. Adhesion in any case at a height;

- Mapei - An Italian company, offers paste-like adhesives and dry mixes that cover almost all possible operating conditions and surface types;

- Litokol - Another Italian manufacturer that produces cement-based adhesives, dispersion and reactive compositions. It is possible to list all glues of the company for a long time - a suitable composition can be found for any conditions;

- Sopro - A German company that offers white and gray adhesives, elastic and conventional compounds, quick setting and epoxy adhesives;

- Kilto produces glues, mainly in paste form. The compositions have a high degree of adhesion, but they are not recommended for use in rooms with a high level of humidity;

- Unis - One of the largest domestic manufacturers, has its own raw materials base in Perm and 5 production sites throughout the country, so the price of products of the same quality as that of foreign competitors is lower. All products are certified according to the most stringent standards. The range includes adhesives for indoor and outdoor use, compositions for laying tiles on inclined surfaces, on a warm floor, for the installation of mosaics and porcelain tiles, moisture-resistant, high-strength and elastic compositions.

Without good glue, it is difficult to perform high-quality tile laying, but even it will not save if an unskilled person takes on the job, so if there is no confidence in one's own strengths, it is better to call a professional for help.