10 tips for choosing a facing brick

Among all facade decoration materials facing brick takes a leading place. If previously its range was limited to only a couple of shades and shapes, today on sale you can find products of almost any color and shape, with different types of surfaces. Diversity has grown to such an extent that face brick is also used for clearance fences, and in the interior decoration. On the one hand, the expanding assortment is a huge plus, but it is becoming more and more difficult to choose the facing brick in such conditions.

No. 1. Facing brick material

Today, facing bricks are made of various materials, resulting in products with different operational and aesthetic parameters. The most common are types of facing bricks:

- ceramic (red);

- hyperpressed;

- clinker;

- silicate (white).

No. 2. Ceramic cladding brick

Ceramic brick is a real classic. Among all facing (and among ordinary) bricks, it is considered the most popular and most preferred to use. It is made of clay by roasting at high temperatures. Depending on the type of clay used, products of different shades are obtained. The most common is red and its tones, but there is also a brick of a natural peach and yellow hue - the remaining colors are obtained by adding pigment to the raw materials. Surface staining is also used, but its resistance is many times lower.

TO main benefits ceramic cladding brick include:

- high strength and durability;

- good heat-insulating qualities;

- resistance to ultraviolet and frost;

- a wide variety of shapes, colors and surface types;

- versatility of finish and the ability to use the material in any architectural style;

- the relatively low price of facing brick, promotions and discounts, which are often carried out by large sellers, allow us to call the material quite affordable.

Cons the material is practically absent, it will be an excellent decoration and protection for the walls of the house, but it is better to additionally cover the brick with a water-repellent composition, in order to better protect the structure from moisture and prolong its life.

Ceramic brick differs in production features. Plastic products are stronger, stronger and more frost-resistant; they are usually used for construction. They are also suitable for facing the facade, but for this purpose it is more appropriate to use a brick semi-dry and dry moldingwhich differs in extremely precise geometry.

No. 3. Hyper pressed brick

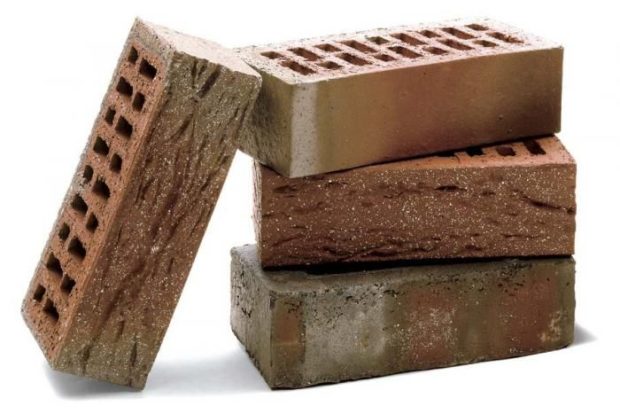

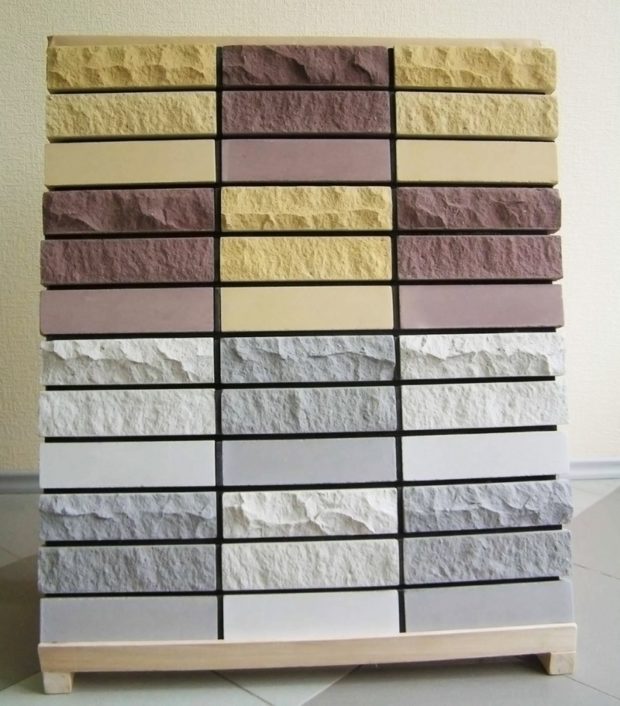

Hyper pressed brick is used exclusively for decorative purposes - houses are not built from it. The basis of the material is crushed limestone or limestone, dolomite and marble can be used. The bulk of this component is up to 90%, the rest is cement, water and dyes. The mass does not burn in furnaces - it is hyper-pressed under the influence of high pressure, hence the name of the material.

Production technology allows us to talk about numerous benefits material:

- exact geometry;

- environmental friendliness, because the composition of hyper-pressed brick is actually artificial stone;

- a huge assortment of textures and colors, so you can implement almost any idea with this material. The textured front side is very similar to a chip of natural stone;

- high frost resistance (up to 150 freeze / thaw cycles), excellent compressive strength (up to M250), durability (up to 25 years), low moisture absorption.

Among cons:

- low heat-insulating qualities, but this is not a problem with high-quality home insulation;

- over time, microcracks may appear on the brick surface, which will increase when moisture enters, so it is better to immediately cover the surface of the material with a layer of water repellent;

- inadequately overpriced.

Experts also note that it is better to take material with indentations or holes on the beds - so the adhesion of the brick to the masonry mortar will be higher. Hyperpressed brick is used not only for facade cladding, but also for fireplace decor and carrying out interior decorating.

Number 4. Brick brick

Brick brick can be called a subspecies of ceramic, but for its manufacture, special refractory grades of clay are used, which are burned at higher temperatures, so a very durable material comes out. It is used not only for facing facades, socles, decoration of window and doorways, but also for paving garden paths, and even with chimney arrangementв - clinker brick withstands constant large loads of a different nature.

The main advantages:

- low water absorption (not more than 3%) and high frost resistance, which is explained by the minimum number of pores, because at high firing temperatures, small particles sinter and completely fill all voids;

- resistance to temperature extremes;

- high strength and durability, clinker can preserve the original properties, shape and color of tens and even hundreds of years;

- vapor permeability.

Different shades of clay allow you to get a brick slightly different colors. The main color of the material is red-brown, but manufacturers have learned to diversify it by adding various pigments.

Minuses:

- high price, so not everyone can finish the entire facade with such material - often clinker bricks are combined with cheaper ceramic;

- high thermal conductivity due to the absence of air pores.

Since the water permeability of the material is low, it is better to use it when working with it. masonry mortar with a minimum amount of water.

Clinker bricks have been used in construction and facing for a long time. When demolishing centuries-old buildings, the clinker is cleaned and used again. Fortresses and churches were erected from such material at one time.

No. 5. Silicate facing brick

Silicate brick is the most a budget option among all analogues, but its operational and aesthetic qualities do not suit everyone. Choosing such material, you consciously compromise and must be aware that for such little money you cannot buy material that will retain its original qualities for centuries.

Silicate brick is made on the basis of sand and lime, as a result, light-colored material comes out, for which it received the popular name "white brick". Adding pigment allows you to achieve almost any color. Firing during production is not used - the mass is set thanks to the reaction of extinguishing lime and pressed, processing can be used at elevated temperature and pressure in autoclaves.

Benefits:

- low price;

- good geometry;

- good soundproof qualities;

- acceptable frost resistance.

As for diversity, the assortment of different colors and surface variations, it seems, is not bad, but in terms of aesthetics, silicate brick is inferior to other types.TO disadvantages material include large weight, fragility, low moisture resistance and low thermal insulation qualities. Despite this, silicate brick is still actively used in private construction, because it’s really inexpensive.

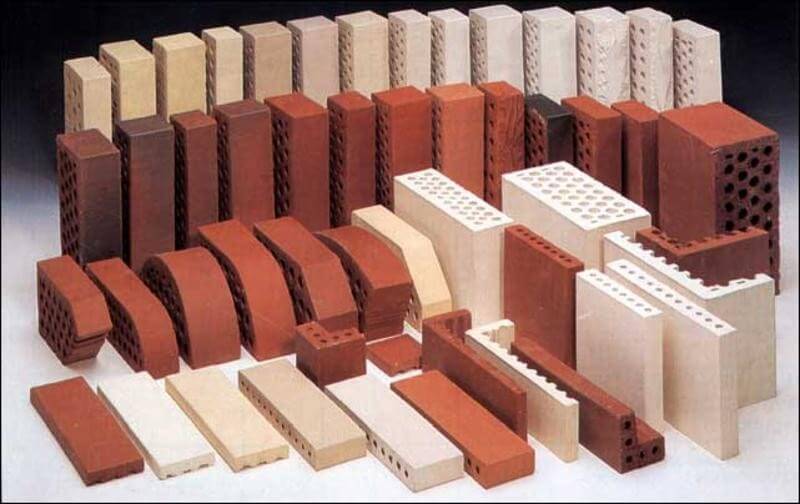

No. 6. Hollow and corpulent brick

A brick may have voids inside or be completely solid. For facing use both one and the other, but the advantage is still on the side of the hollow. It is lighter, therefore, does not create additional load on foundation, and thanks to openings with air, it retains heat better. The cavities can be round, square and rectangular in shape and up to 30% by volume with silicate brick and up to 45% with ceramic.

Corpulent brick in decoration is rarely used, it allows you to get a more durable facade, but also colder. From solid brick for cladding, only elements of complex shape may be needed.

Number 7. The size and shape of the facing brick

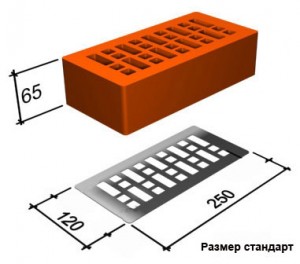

The standard form of brick is a parallelepiped, the dimensions of which are 250 * 120 * 65 mm, this is the so-called single or standard brick. Similar products are actively used in construction and for cladding buildings. However, the front brick can be slightly thinner: the formats 250 * 85 * 65, 250 * 60 * 65, 25 * 85 * 85 and 250 * 22 * 65 are common. The brick of the last format is actually a tile, but outwardly such samples look like a full-fledged brick.

Facing brick is not always the right box. On sale you can find a large assortment figured (shaped) brick. These are products with a non-standard profile shape. Curly bricks, cuts and waves are characteristic of figured bricks, there are wedge-shaped and trapezoidal samples, as well as semicircular and other complex figured products, the shape of which is difficult to describe. The smallest variety of forms is characterized by silicate brick.

With the help of curly brick, you can interestingly design the facade, decorate window and doorways, and turn an ordinary “box” into an elegant house with a unique architectural style.

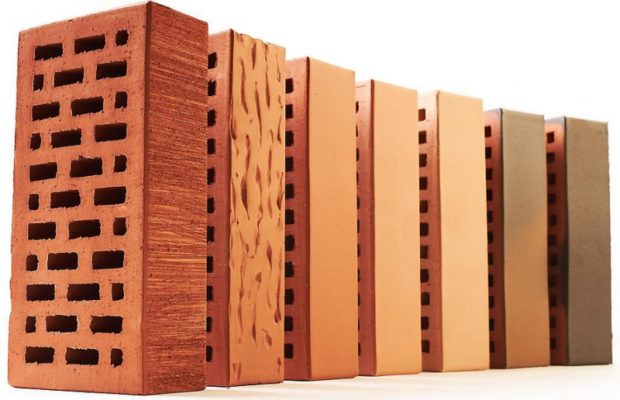

Number 8. Type of front surface

Brick surface may be smooth (the easiest and most familiar option) or textured. From the first, everything is clear: no special techniques are used during production, but the creation of texture and relief is a more interesting process. Depending on the technology, a product with unique aesthetic qualities can be obtained.

On ceramic and brick brick (they must be fired) the invoice can be created in this way:

- standard. On the molded, but not yet burnt bricks, the desired pattern is applied using a stencil. After heat treatment, the required relief is formed on the brick in the stove. Thus, you can create absolutely any pattern, and the strength of the product does not suffer;

- shotcrete. Before firing, mineral crumb is applied to the front part of the brick, which melts and sinteres with the surface under the influence of high temperatures, forming an interesting pattern and characteristic color transitions. Thus, clinker bricks are mainly decorated, since a high temperature is needed to melt the mineral chips;

- engobing. A thin layer of ceramics called engobe is applied to the surface of not burnt, but dried brick. This is a clay suspension with metal oxides, which allow you to achieve a certain shade. Sintering with the mass of bricks, the suspension allows you to form the desired color and texture. It is possible to apply engobe only on part of the brick, so products with the effect of aging are produced;

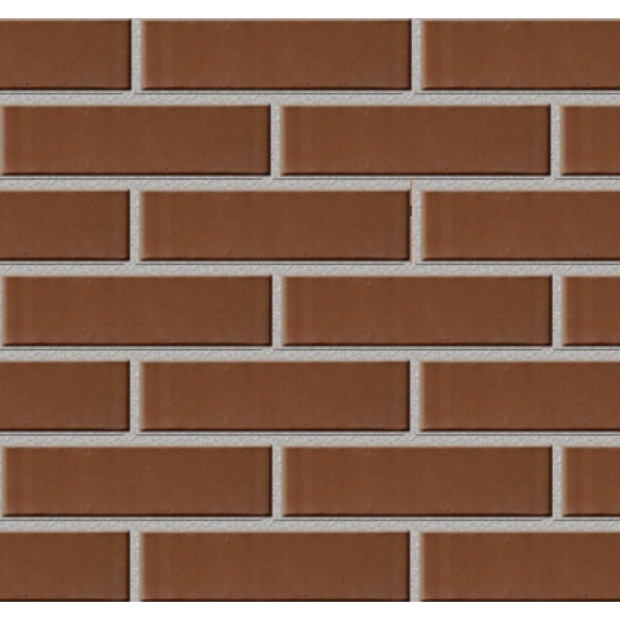

- glazing. The technology resembles the previous one, only instead of ceramics they use glaze, which, sintering with a brick, forms a beautiful glossy surface. It protects the material well from moisture and is not as intense as others, it is contaminated.

Hyper pressed brick during the production process does not go through processing in the furnace, so the texture here is created in a different way. To give a relief, a split is used. Special equipment resembling a guillotine splits a large stone in certain places into separate bricks. Additional processing by special machines can be carried out - new small chips will complicate the drawing. Hyper-pressed brick is produced in textures such as “wild stone”, “rock”, “marble”, “chipped”, “Finnish” and some others. Manufacturers strive to come up with exquisite names, so different names can be used for the same relief.

Silicate brick worst of all is amenable to processing, but today we have learned to achieve a rustic and stabbing texture.

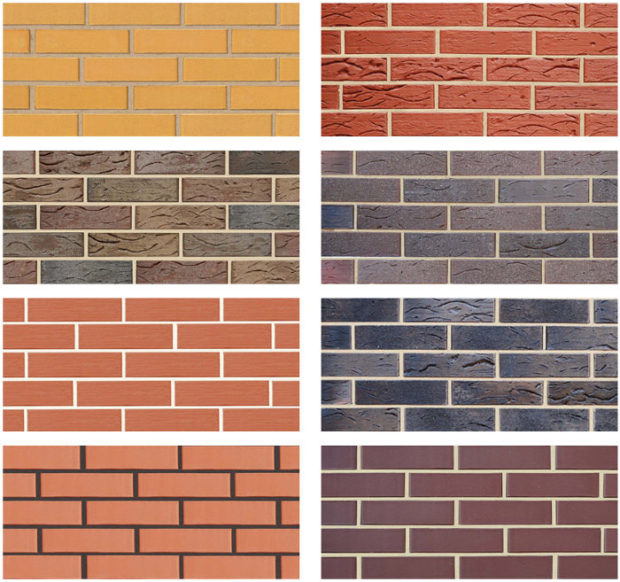

No. 9. Brick color

The natural shade of the brick depends on the type of raw materials used and production technology. Ceramic and clinker bricks can do without adding additional pigments - they already have a noble beautiful shade. Natural color means that one manufacturer may have slightly different shades of brick, so it’s better to take as much material as needed to equip the entire facade and mix products from different lots.

Hyper pressed and silicate bricks are painted in mass and can be almost any color. If necessary, tinting of ceramic and clinker bricks is carried out. The brighter the color as a result, the more dye is used, and the lower the strength of the product.

Brick can be painted superficially, only on the front side, but the quality of such painting is lower.

Choose a color depending on your own preferences, used architectural style and with an eye on color the roof, fence and other elements, if they already exist.

No. 10. Durability and frost resistance

Facing brick does not have such stringent strength requirements as ordinary. On the other hand, the decoration takes on some of the functions of protecting the walls of the house from negative natural influences, therefore it should be sufficiently resistant to them.

Durability They call the ability of a brick to withstand the load without breaking. Brick brand M100 withstands 100 kg per cm2 surfaces, M150 - 150 kg, etc. Ceramic and silicate brick has strength up to M150, clinker and hyper-pressed - M250. For cladding, you can use a brick with a strength of M100-M150.

Frost resistance - this is the ability to withstand freezing and thawing, without being deformed at the same time. Frost resistance is measured in cycles: a brick that carries 25 frost-defrosts is marked as F25. For cladding, it is worth taking a brick of at least F50, and for regions with a difficult climate - F75.

Finally, we note that it is better to use products trusted manufacturers, and before buying, consider a sample in sunlight to evaluate the real shade and relief.