7 tips for choosing a cinder block (slag concrete): pros, cons, calculation, production

Refractory, durable, lightweight, and also quite democratic in terms of price - such building material exists and is actively used for the construction of houses, garages and fences. Slag stones first appeared at the beginning of the last century, but well-deserved popularity came to them only in the 70s. Today, cinder block is actively used in private construction, but this material cannot be called ideal. We deal with the issues of choosing a cinder block, its pros and cons, features of use, we learn to calculate the necessary amount of material, make the right choice and make a cinder block with our own hands.

No. 1. Cinder block: production features

Slag concrete belongs to the category of light concrete blocks. For the first time such material became known at the beginning of the 20th century, when Nicholas II built a garage in the Winter Palace. The cinder block then, however, was made on the basis of coal combustion waste - slag, hence the name. Since then, the production technology has changed somewhat, and the durability of the first cinder block buildings has provided the material with sufficient popularity.

Today, cinder block is made based cement and sandclay, lime or gypsum, as well as various plasticizing agents, may be added. The filler is no longer slag, but crushed stonegranite screenings, expanded clay, the fight bricks, perlite, cullet and sawdust. In terms of environmental friendliness and harmlessness to health, the best fillers are expanded clay, sawdust, gravel and shell rock. Production is carried out on vibroforming equipment.

If in the 70s, when the cinder block began to be actively used in construction, they erected from it garages, sheds and other household and utility rooms, today the advantages of inexpensive material allow you to use it for house building and even industrial buildings.

No. 2. The main characteristics of the cinder block

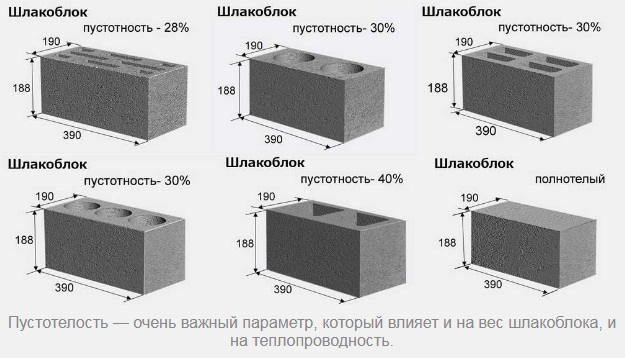

Cinder blocks are produced in the form of a parallelepiped without voids or with voids of various shapes and sizes. You can often find that the sizes of the blocks are rounded to 200 * 200 * 400 mm, but the documents normalize the length from 380 to 410 mm (usually 390 mm), the width and height - from 180 to 210 mm (usually 190 mm).

In hollow blocks voidness can vary from 28 to 40%. Usually two or three round holes are made, two, four or more rectangular holes. The more voids, the better the thermal insulation properties of the material, but its strength is less. On average, the thermal conductivity of the material is 0.27-0.65 W / m2. The use of certain materials is explained by the features of the building. The weight of the unit ranges from 15 to 20 kg.

Frost resistance cinder block can vary significantly, the choice depends on the region. Blocks F15-30 (the number indicates the number of freeze / thaw cycles that a block undergoes without losing basic performance) are suitable for warm regions, blocks with maximum frost resistance F50 are best used in areas with more difficult climates.

Strength is determined by grades M35 to M125: M50 and M75 cinder block can be used for laying partitions, M100-M135 can be used to equip load-bearing walls, and M35 cinder block is used only in combination with other bearing materials. Today, by the way, in addition to the construction of residential and utility rooms, the material is used for arranging ventilation ducts and even for paving sidewalks.

No. 3. Cinder block: pros and cons

Slag stone is a rather controversial material in terms of advantages and disadvantages, so it is not suitable in all cases, but when planning to build a country house or garage, it is worth considering the material as one of the alternatives.

The main advantages of cinder block:

- resistance to fire, namely this is from the basic requirements for the house;

- low price. The construction of a cinder block box will take a minimum of money - the material can compete for the title of the budget;

- the large size of the blocks and their relative lightness allows construction to be carried out very quickly. The relative simplicity of the construction of walls from cinder block allows people who do not have particularly extensive experience in this field to take up construction work;

- light weight of blocks allows to save on construction foundation;

- a high degree of strength and reliability of a cinder block house;

- high durability, not less than 100 years;

- resistance to rodents and mold.

Minuses:

- low thermal insulation qualities, so you can not do without insulation. The exceptions are those cases if the room will be used only in the summer (cottage), temporarily (barn) or not have heating (garage). For warming often use polystyrene foam, but also mineral wool also suitable;

- unpresentable appearance - minus controversial. Firstly, most building materials are in any case additionally revetted, the exception is only a tree. Secondly, today manufacturers began to offer cinder block of different colors and with a decorative surface. In any case, you can finish the walls of the cinder block siding, decorative brick, plaster with painting or tree;

- the complexity of laying communications and mounting heavy objects on the walls;

- high hygroscopicity of the material, therefore good waterproofing;

- material safety directly depends on the name of the manufacturer, therefore it is better to trust companies that are responsible and reputable.

Experts recommend erecting walls from cinder block only in dry weather and not leaving the box for a long time without a roof. In addition, it is advisable to lay on a high foundation in order to reduce the negative effect of moisture. With the application of a decorative coating, it is better not to delay.

Number 4. What to consider when choosing and transporting cinder block?

When choosing a cinder block, consider these points:

- It is important to find out from the seller the main characteristics of the material, including thermal conductivity, frost resistance and strength grade;

- does not bother to inquire about filler used. In principle, there is nothing dangerous in the composition of the cinder block. The only caveat is the use of granite screenings, as this stone may have natural radioactivity. Measuring the background will allow you to choose the most secure option. For greater importance, you can ask the seller for quality certificates;

- geometry integrity blocks speak of high quality material. You can inspect several blocks for chips, cracks and deformations. It is necessary to make selective measurements and check the correspondence of the sizes of the faces;

- an easy way to check the quality is to manually try sticking nail to the surface of the block. If possible, it is better to refuse to buy such a cinder block;

- if the material was made without using a vibrating machine, then there is no need to talk about high strength - it cannot be used for the construction of residential premises.

The thickness of the masonry is determined by the characteristics of the climate of the area. It is better not to do too thick a mortar layer, otherwise you can greatly reduce the heat resistance of the walls (optimal seam is up to 1.5 cm).

It is better to transport the cinder block on pallets, it is better to store them under a canopy so that they do not absorb moisture harmful to them.

No. 5. Calculation of the number of cinder blocks

It is not difficult to calculate the required number of cinder blocks for building the walls of the house - it is important to know only the parameters of the erected building and the dimensions of the blocks.Take as a basis a block of standard sizes 390 * 188 * 190 mm:

- if you build a wall half a block thick (190 mm), then the area of the side surface will be equal to 0.39 * 0.188 = 0.073 m2. On 1 m2 walls will need 1 / 0,073 = 13.7 blocks. If you take into account the thickness of the joints in 8-10 mm, then 1 m2 13 blocks will be needed. It remains only to know the area of the walls and multiply this value by the number of blocks. If laying in two layers is planned, then the value is multiplied by 2;

- a similar calculation is carried out when laying one block thick (390 mm). In this case, the side surface area will be 0.188 * 0.19 = 0.0357 m2, and at 1 m2 - 1 / 0,0357 = 28. If we discard the thickness of the seam, then we can talk about 27 blocks per 1 m2.

10-15% of possible losses are added to the obtained value. The area of windows and doors can not be taken away. When calculating, it is important to consider how the blocks will be fastened together: the thickness of the solution is 5-10 mm (not more than 15 mm), the thickness glue - 2-3 mm. As a rule, 60 blocks are placed on one pallet. Having calculated the required amount of material, you will know how many cinder block pallets to order.

No. 6. Large manufacturers of cinder blocks in Russia

The quality assurance of the cinder block and the safety of the house erected from it is the name of the manufacturer. It is no secret to anyone that it is better to give preference to proven large companies, and it is on them that we will stop:

- "Stroyindustriya" - a plant founded in Chelyabinsk in 2000, produces a lot of building materials, including cinder blocks of standard sizes and in an assortment of colors;

- Modern Stone is another Chelyabinsk company. It produces a standard and partition block (120 and 90 mm thick) of different voids;

- Stroykomplekt Plus is a Stavropol enterprise that produces cinder block and sells a wide range of building materials. It produces wall and partition cinder blocks of varying degrees of voidness;

- Block Expert produces cinder blocks in Yekaterinburg and delivers it to many regions of the country. The only negative is that only M75 blocks are produced in strength and with voids inside.

Number 7. DIY cinder block production

When a cinder block is needed in small quantities (building a shed or producing the missing amount of material), you can also resort to the independent production of a cinder block, however, you can not do without a vibration table or a vibroforming machine.

At home, as a rule, blast furnace slag is used, large sand and cement M400. Proportions Each home master chooses his own, but the classic recipe is this: slag - 7 parts, sand and gravel - 2 parts, cement - 1.5 parts, water - 1.5-3 parts. In addition to blast furnace slag, you can, of course, use gravel, sawdust, perlite, and brick fight. You can also add a plasticizer - 5 g per block. They take so much water that the solution is well connected in a fist, but it falls apart when dropped.

The resulting solution is poured into a mold with a slide, rammed with vibration for 3-5 seconds. If the solution is strongly precipitated, you need to report a new portion, lower the clamp and turn on the vibration. After that, the block is removed from the mold and dries for 5-7 days, then it gains strength for about a month. Of course, it is possible to produce cinder blocks in metal or wooden forms, but without vibration formation they will turn out to be insufficiently strong.

The cinder block impresses with its budget, durability, fire resistance and a host of other positive operational qualities, but it did not acquire wide distribution (such as a gas block) due to some features, but it is definitely worth considering it as a material for building a house or a garage.