5 tips on what material is better to build a house

Even in the tale of the three little pigs, the most important and always relevant idea is raised about the correct choice of building material for the house. It’s a fairy tale, but many of us, like the heroes of the famous work, want to build a durable reliable house with minimal effort. However, today it is quite possible to do this thanks to the development of construction technologies. Nevertheless, there are so many different wall materials that the builder has to break his head great when deciding which material is best to build a house from. Brick, aerated concrete, wood, sandwich panels - which is better, more reliable, more durable and warmer?

The cost of erecting walls at home is up to 40% of the cost of all work, so it is so important to weigh the many pros and cons of each material in order to make the only right decision. It is also necessary to take into account the seasonality of living in the house, the requirements for thermal insulation, the cost of the fuel used for heating, as well as the complexity of the work and the budget allocated for construction. There are a lot of materials for building a house today - to find the one that most closely meets the needs is not a problem.

No. 1. Wooden house

The most conservative and traditional material for building a house is wood. Its undeniable advantages include:

- naturalness and environmental friendliness;

- low thermal conductivity;

- optimal microclimate inside the house;

- an opportunity to equip a simple foundation (columnar will do);

- excellent appearance and lack of need additional finish.

Minuses:

- high fire hazard, even despite the fact that today special impregnations are used in the production of timber;

- the tree is sensitive to moisture and pests, they also try to fight this, but without constant care the material will be constantly damaged;

- shrinkage;

- high price.

Under wooden house involve buildings made of logs, planed timber and profiled glued beams. Due to the difference in processing technology, the properties of houses built from these materials can vary greatly.

Round log

For the construction of houses, as a rule, use logs from pine, fir and spruce. They undergo multi-stage processing, including amenable to high temperature drying. Such a house looks thoroughly like a real fortress, it is easy to breathe in it, but if you want to build a house from a log house, you should be ready for numerous material features.

The main problem is shrinkage., which lasts about a year and is about 10 cm per floor. Shrinkage causes the appearance of cracks that will need to be carefully repaired to prevent heat loss. In addition, in the first year it will not be possible to finish and put windows. In terms of heat transfer resistance, a tree, of course, bypasses a brick, but a log house can still not be called 100% energy efficient. There are several reasons, and among them are cracks formed during shrinkage, and insufficient wall thickness. It is impossible to build walls with a thickness of more than 20 cm from a log (the thickness is changed at the seams - the thinnest place), but for most regions this is not enough.You will have to either increase heating costs, or use the house only in the summer, because the wooden walls are insulated and the beautiful natural material is hidden, the hand does not rise. In addition, the tree requires constant care.

Despite a lot of minuses, houses from logs continue to be erected actively, because they give a special home comfort and, subject to normal care, can stand for a long time.

Glued profiled beam

Glued timber while retaining all the advantages of natural wood, it is deprived of its most obvious disadvantages. Material is made, as a rule, from coniferous species, usually spruce, less often pine and larch. The finished product is obtained by longitudinal splicing of individual solid wood slats. The fibers of neighboring fragments are located in different directions. This production technology allows you to get durable material with pre-predicted properties. Profiled ends of such products facilitate the construction process and allow you to get a solid masonry.

To the main material benefits include high strength, the absence of shrinkage and cracks. Such walls do not require finishing either inside or outside, but since the maximum thickness of the beam is 30 cm, it is not possible in any region to build a fully energy-efficient house. Glued beams are more expensive than logs.

No. 2. Brick house

Another classic and time-tested material for building a house is brick. Despite the emergence of a mass of alternative materials, it remains the most popular material for the construction of low-rise private houses, and there are a lot of reasons.

pros:

- high durability and strength;

- inertness to rodentsinsect and mold;

- resistance to fire;

- material passes air;

- brick allows you to translate into reality a project of any complexity.

Minuses:

- the need to carefully prepare the foundation, since brick is a heavy material, and masonry is done in several rows;

- low thermal insulation properties;

- high labor intensity and low construction rate;

- a brick house is more expensive than building from other materials.

For the construction of a 2- or 3-storey building enough brick strength M100 or M125, but the basement is better to build from brick M150-M175. It is also necessary to take into account the frost resistance of the brick, which is determined by the cycles of freezing and defrosting, which the material withstands without loss of basic properties. If for warm regions it is quite possible to use brick F15-30, then for the middle strip it is better to take material with frost resistance F50, and for the most severe regions - F100. After the construction of the house, he is given some time to dry. Brick walls are usually finished facing brick.

By filling the bricks are divided into:

- corpulent - material for the construction of the foundation, load-bearing walls and partitions. These are more durable and frost-resistant products, from which critical elements are laid;

- hollow bricks are used for laying partitions and cladding facades, but sometimes it is allowed to erect walls of lightweight buildings from them;

- porous ceramic brick - These are large blocks that are produced by a special technology with the addition of sawdust to the clay mass. Products differ in numerous openings, therefore they are able to provide excellent thermal insulation. Often the material is used for the construction of warm houses in earthquake-prone zones, as there are special holes in the blocks for mounting fittings.

For the construction of walls, only two types of bricks are used:

- ceramic (red);

- silicate (white).

Ideally, it is better to build plastic bricks from ceramic bricks. It is made from high-quality clay by extrusion. Ceramic brick of dry and semi-dry formation due to the high accuracy of the geometry is mainly used for cladding. Red brick differs in durability, good sound insulation and durability.

Silicate brick produced on the basis of sand and lime, it is cheaper than ceramic, but more fragile, differs in a small variety, lower thermal insulation and low moisture resistance.

No. 3. Aerated concrete houses

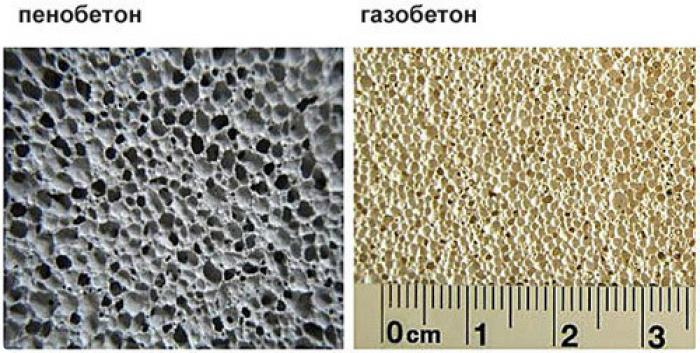

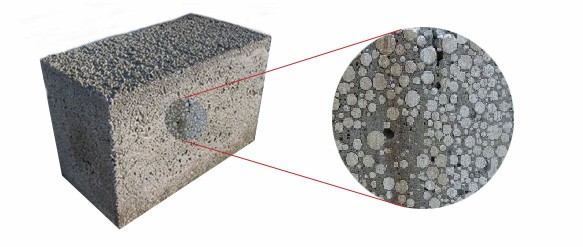

Lightweight concrete blocks are the most promising material for building a house of all existing at the moment. Of all the stone materials, cellular concrete has the best thermal insulation performance. Due to the fact that the block is large (replaces 17-20 single bricks), the construction of buildings is carried out quickly. In terms of strength and durability, the material is practically not inferior to brick. To cellular concrete include aerated concrete, foam concrete, expanded clay concrete and polystyrene concrete, but the first two became most widespread in private construction.

House of aerated concrete (aerated concrete block)

Aerated concrete are based on cement and sand with the addition of blowing agents, and sometimes lime, gypsum and ash. After adding water, a gas formation reaction takes place, and numerous interconnected pores are formed in the mass. It is better to give preference to autoclave production, which provides for drying not under natural conditions, but under the influence of steam. After cutting, standard blocks are obtained, which are used for the construction of load-bearing walls.

pros:

- high construction speed is ensured by the large size of the blocks and their relatively low weight;

- low thermal conductivity, achieved due to the porous structure;

- the material "breathes", approaching the vapor and air permeability to the tree;

- high compressive strength;

- resistance to fire, microorganisms and pests;

- environmental friendliness;

- low price.

Minuses:

- high water absorption, which can reach 35%. Because of this, the strength, durability and thermal insulation qualities are reduced. Reliable waterproofing, high-quality ventilation, a good drainage system and a moisture-resistant lining, this problem can be minimized;

- low bending strength, therefore, with improper installation over time, cracks may appear on the walls;

- problems with fasteners, or rather features. Universal or screw dowels, which are easy to find on sale, are suitable for fastening. Light items can be easily hung on ordinary nails.

For the construction of a private low-rise building brand blocks fit D400. Despite the shortcomings present, aerated concrete is one of the most popular and suitable materials for the construction of a private house, which is used for permanent residence.

House of foam block

Foam concrete in many ways it resembles aerated concrete, but it is somewhat cheaper due to the nature of production. The feedstock is the same - sand, cement, water and a blowing agent. As the latter, foam based on surfactants is used.

pros:

- good heat and sound insulation qualities;

- light weight and ease of use, high speed construction of the house

- high compression density;

- resistance to fire, mold, rodents;

- low cost (about 25% lower than that of aerated concrete).

Minuses:

- low bending strength. The strength of the material grows with time, so you should not use freshly made blocks - at least 28 days should pass from the moment of production;

- a set of strength explains the small shrinkage of the house (2-4 mm per linear meter);

- not always perfect geometry.

IN private construction can be used foam block brands D600-D700

House of cinder concrete

Slag concrete They are made on the basis of cement, clay, lime or gypsum with the addition of plasticizing additives, and the brick is used as a filler, granite screenings, expanded clay, crushed stone, ash, pergolite, etc.

pros:

- light weight with large sizes simplifies and speeds up installation;

- fire resistance, resistance to rodents and mold;

- sufficient strength and durability;

- low price.

Minuses:

- the need for serious insulation;

- hygroscopicity;

- imperfect geometry of blocks;

- difficulties in laying communications and mounting heavy objects on the walls;

- not always high environmental friendliness.

Polystyrene concrete for building a house

The material is based on cement, sand and balls. polystyrene foam. Polystyrene concrete is not widely used, but as an alternative it can still be considered.

pros:

- low cost;

- ease of installation and handling;

- excellent heat and sound insulation qualities;

- low load on the foundation;

- high durability;

- crack resistance.

Minuses:

- withstands a small number of freeze / thaw cycles, which limits the use of the material in cold regions;

- problems with fasteners, and doors with windows begin to loosen in a couple of years. The reason lies in polystyrene balls, which strive to fall out, which greatly reduces the strength of the blocks;

- low vapor permeability.

The properties of the material make it ideal for use as a heater, and not a building material.

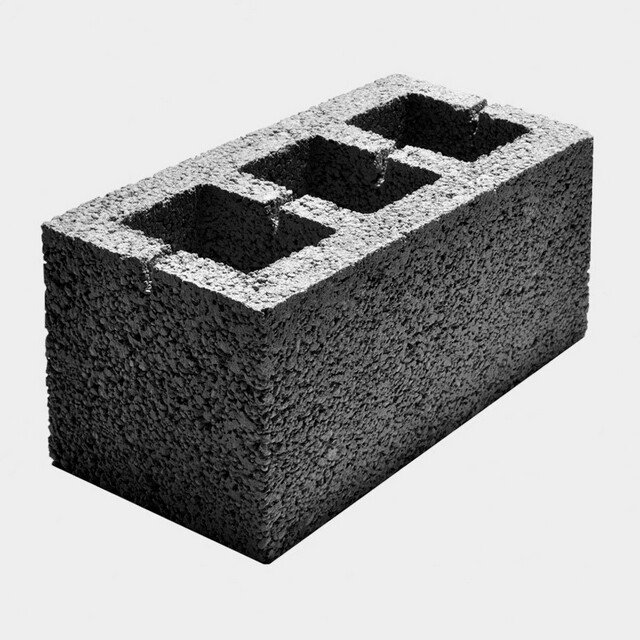

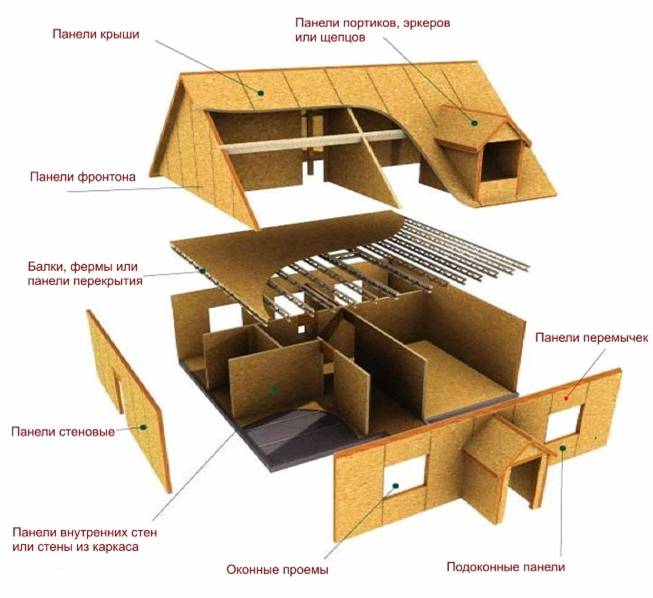

Number 4. Frame house

Fashion for building frame houses came to us from abroad. They are also called frame-panel, Canadian and houses made of sandwich panels. Buildings are assembled on the principle of a designer from ready-made standard factory elements consisting of a wooden frame sheathed with plywood or boards, between which there is a heater (usually used mineral wool or polystyrene foam).

Frame houses repeat many of the advantages of wood, but are built quickly and are cheap. They are excellent in quality and durability, unless, of course, high-quality materials have been used and the technology has been fully observed.

pros:

- high thermal insulation qualities, as the panels use the most effective heaters;

- high speed of construction, because the house is assembled from finished panels of standard sizes;

- finish You can start immediately after construction - wait for the solution to dry or shrink unnecessarily;

- panels pass processingprotecting them from mold and pests;

- low weight and low load on the foundation;

- relatively low cost.

Minuses:

- fire hazard, like a wooden house;

- frame houses are characterized by some uniformity, because they are built from typical elements;

- the high complexity of the finish, and engineering systems will have to tinker with, because wiring, for example, it is necessary to lay it over walls - it is forbidden to equip it inside with combustible structures;

- the need to strictly comply with construction technology. This is important for any home, but panel-frame errors will be difficult to fix;

- not the highest strength, so the calculation of loads must be carried out especially carefully;

- low sound insulation;

- You can hang objects only on the supporting frame;

- polystyrene is a good environment for the life of rodents.

Low cost and high speed of construction have made frame houses very popular, as whole cottage villages are being built.

No. 5. Reinforced concrete panel houses

Another option for quick construction is the technology of building houses from prefabricated reinforced concrete panels. A low-rise house can be built in a few days! The technology resembles the one that was so actively used in the Soviet Union to quickly erect millions of square meters of housing.

pros:

- high speed of construction, because the panels are manufactured in the factory;

- the ability to immediately start finishing work;

- perfect geometry;

- high strength and durability;

- low price;

- fire safety;

- panels are already insulated;

- no shrinkage.

Minuses:

- a solid foundation is needed;

- a small number of offers on the market (few companies cast plates for the created project - elements of typical sizes are usually made);

- such a house "does not breathe";

- concrete does not hold heat well.

When it is necessary to quickly build a reliable and durable house of a decent size, this is one of the best options, especially since today it is possible to cast panels of strictly necessary shapes and sizes to erect a building according to individual project.

When choosing material for building a house, it is important to take into account the climate, the type of soil, the future heating system, and many other factors. But even the highest quality building materials can disappoint if there is a violation of construction technology or an incorrectly laid foundation, so these points should be given no less importance.

Now the gas block has gained popularity and this is primarily due to the low cost and quick assembly of the box due to their size

The cost and speed of assembly can argue and frame construction technology

Our neighbors in the site built a house of foam concrete, they like it. And they say warmly and inexpensively turned out

This is a normal review article, but I would like to avoid such material as arbalite. For some reason I like it and light and warm and durable, I think undeservedly forgotten.

Agree, arbolite is now widely used, but, alas, it has significant disadvantages. We once wrote about the choice of blocks from wood concrete and their characteristics https://repair.techinfus.com/en/natalia/2017/08/11/7-sovetov-po-vyiboru-blokov-iz-arbolita-plyusyi-minusyi-sostav-proizvodstvo/

It seems to me that glued timber was completely cheated in the article) We have a home for 1.5 years, the Tver region, the climate has become softer in winter. About the complete absence of shrinkage, they probably overdid it, it is, but minimal, there are no problems so far. Glued beams - ideal if manufacturers don’t get anything and builders comply with the technology.

Interesting article

Good afternoon. Before building a house I collect information. Exactly on the 1st floor. To warm What is better to build?

Brick or aerated concrete + a suitable layer of insulation

We are going to order a house using red technology from the tower. Has anyone had experience living in a framework?

Hello. We’ve been living in the framework for the fifth year now. Very warm house. in winter for heating 1-1.5 thousand rubles

The sound insulation is excellent, the TV in the next room is not audible. The only thing when the children jump on the 2nd floor is then yes. But we have ECOWATH insulation. 106m2