7 tips for choosing warm plaster for the facade and interior work

It was worth a little change in the composition of the usual cement-sand plaster, as a completely new material appeared - warm plaster. Manufacturers attribute to him unique qualities and declare that the material can be used as an independent thermal insulation. So what is it true or another tricky marketing ploy? How to choose the right stucco for the facade and interior work, how to apply it, and in which cases can the material really be used as a complete heat insulator?

No. 1. The composition of the warm plaster

Warm plaster was named thanks to its low thermal conductivity compared to conventional stucco compounds. We managed to achieve similar results by replacing the usual sand on special heat-insulating additives.

The composition of warm plaster includes such components:

- binder, which is the basis of the mixture. It can be cement mortar, gypsum or lime. The material affects the scope of the plaster: gypsum and lime compounds are suitable only for internal work, and cement - universal;

- filler, on which the functions of insulation are assigned. Polystyrene, vermiculite, sawdust, perlite sand, foam glass and other additives can be used;

- polymer water-repellent and air-releasing additivesas well as antiseptics, plasticizers and other substances that improve the quality and performance of the plaster.

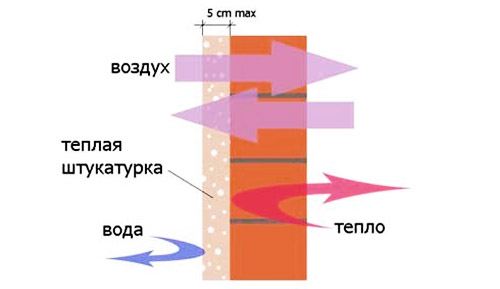

Usually the material is delivered in the form of a dry mixture, and before applying it is enough to dilute it with water. Craftsmen prepare warm plaster on their own, but the composition “works” in any case according to one principle: heat-insulating additives together with air bubbles create a powerful barrier to cold. Tests show that a layer of warm plaster of 5 cm is equivalent in thermal insulation to a wall of two bricks.

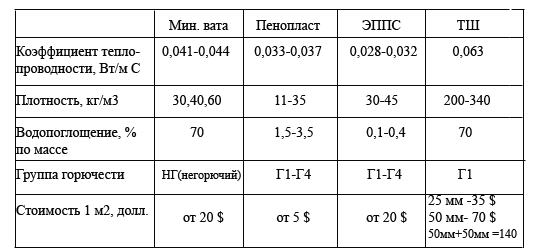

The thermal conductivity of the material is about 0.063 W / m *0C. This indicator is slightly worse than that of polystyrene foamextruded polystyrene foam and even mineral wool, which introduces some features in its application. In regions with cold winters, it is not possible to use warm plaster as an independent thermal insulation - it is usually applied as an additional layer of insulation and plays a crucial role in eliminating the "cold bridges" that arise during the installation of tile and roll insulation. In areas with mild winters, warm plaster can even be used as the only heat-insulating material, but much depends on the thickness and material of the walls. In the future, we will check all this on the calculations.

No. 2. Advantages and disadvantages of warm plaster

Warm plaster is widespread due to its weighty the benefits:

- multifunctionality. The material can be used as the main thermal insulation, as well as an additional insulation that allows you to reduce the core layer or get rid of the notorious "cold bridges". In addition, there is no need to pre level walls;

- high adhesion to most materials, including to a tree;

- less weight compared to conventional plaster composition;

- high strength of the applied layer of plaster;

- resistance to temperature extremes, frosts, rodents, mold;

- ease of application. Anyone can cope, because it is actually about ordinary plastering;

- not bad soundproof qualities;

- environmental friendliness. An exception are polystyrene formulations, which cannot be called completely environmentally friendly;

- fire resistance. Warm plaster based on vermiculite, foamed glass and perlite belongs to the class of non-combustible materials (NG). Stucco with the addition of polystyrene belongs to the class G1, i.e. at high external temperatures it may start to burn from the inside.

Now about disadvantages:

- low thermal insulation qualities, therefore, it is impossible to perceive warm plaster as a full-fledged warming material, but this is rather not a minus, but the specificity of the material;

- high weight in comparison with other heaters. If you plan to apply a thick layer of plaster (about 5 cm), care should be taken to strengthen foundation;

- relatively high water absorption, so additional protection will be needed. However, warm plaster does not apply to finish coatings and the use of it is required decorative material. You should choose from those that have waterproof properties;

- if the layer of plaster is thick (2.5-3 cm or more), it is better to reinforce it with a metal mesh in addition.

No. 3. Types of fillers of warm plaster

The properties and scope of use of warm plaster are strongly influenced by the type of filler. The following materials can be used:

- sawdust. The composition of warm sawdust plaster, in addition to sawdust directly, also includes clay, paper and cement. The use of such "delicate" and sensitive to negative environmental factors components does not allow the composition to be used to insulate the facade, but such a warm plaster is perfect for internal work, especially since it can even be applied on a wooden base. Internal thermal insulation will increase efficiency home insulation;

- ground perlite obtained from obsidian, which during high-temperature processing swells with the formation of a mass of air bubbles inside, which increases the thermal insulation properties of the material. The only negative is increased hygroscopicity, so this plaster needs reliable waterproofing;

- expanded vermiculite obtained from mica, the material withstands a wide range of temperatures, has antiseptic properties, is lightweight, absolutely fire resistant, can be used for exterior and interior decoration, but like perlite, it is afraid of moisture, therefore it requires enhanced protection;

- balls from foam glass obtained from foamed silica sand. This is the most preferred material for filling warm plaster, as it is not afraid of moisture, fire, has good thermal insulation qualities, can be used for facade and interior work, does not shrink;

- as mineral fillers, in addition to vermiculite, perlite and foam glass, also use expanded clay crumb and pumice powder. These materials cannot boast of high moisture resistance and are inferior to analogues in many other qualities, therefore they are used infrequently;

- polystyrene foam It is used in warm plasters along with cement, lime and some other additives. These are relatively inexpensive formulations of universal use, but because of the combustibility of expanded polystyrene, they are not used so often. In addition, the surface of the plaster comes out too soft, therefore, requires a mandatory finish.

Number 4. Calculation of the thickness of the layer of warm plaster

To determine whether it is possible to use warm plaster as an independent insulation, you will have to perform a simple calculation, taking into account the region of the house, the thickness and material of the walls:

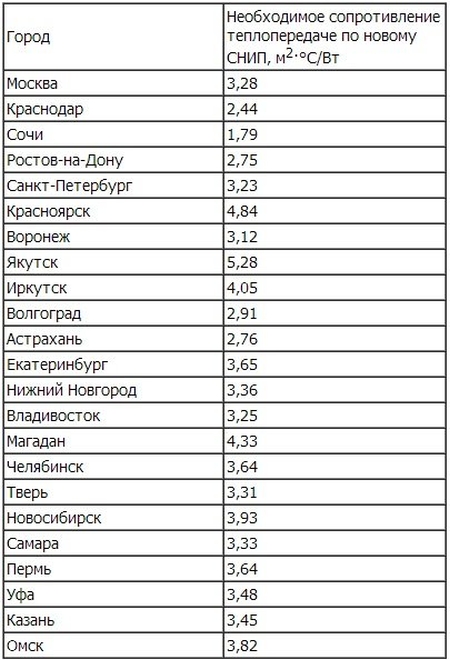

- calculation starts with determining normalized heat transfer resistance of the exterior walls of the house. This value is tabular, predetermined by regulatory documents (for Russia - SNiP 23-02-2003). For Moscow, according to the table, this value is 3.28 m2*0C / W, for Krasnodar - 2.44 m2*0C / W;

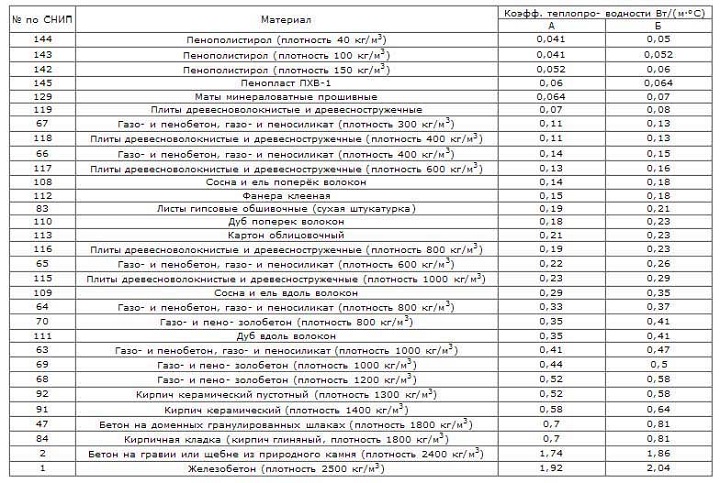

- define heat transfer resistance of the walls of the housewhy we need to divide the wall thickness by the coefficient of thermal conductivity of the material. Let's make a calculation for two houses. One is located in Moscow and built from ceramic bricks, wall thickness 0.5 m, thermal conductivity coefficient from the table - 0.58 W / m0C, therefore, the heat transfer resistance of 0.86 m2*0C / W The second house is in Krasnodar and is built from foam block D600, wall thickness 0.4 m, thermal conductivity coefficient from the table - 0.22 W / m0C, heat transfer resistance - 1.82 m2*0C / W;

- payment additional warming. For a house in Moscow, this is (3.28-0.86) = 2.42 W / m0C. For a house in Krasnodar (2.44-1.82) = 0.62 W / m0FROM;

- payment layer of warm plaster, its thermal conductivity coefficient is 0.063 W / m *0C (maybe a little more - it depends on the composition and manufacturer). For a house in Moscow, 0.063 * 2.42 = 0.15 m; for a house in Krasnodar, 0.063 * 0.62 = 0.04 m. Since it is better not to apply warm plaster with a layer of more than 5 cm, and its weight is decent, then for a Moscow house, it is better to look for another option of insulation, and warm plaster can be used in addition. For a house in Krasnodar, warm plaster can be used as an independent heater.

A more accurate calculation can be carried out if we take into account the heat transfer resistance of all finishing wall materials, and also take into account the number and size of windows and the mass of other parameters. It is easier to do this in special construction calculators, but to understand whether it is worth considering warm plaster as an independent insulation can already be from the above calculation.

Despite the assurances of the manufacturer and calculations proving the effectiveness of warm plaster, it is not very often used as the main insulation in residential buildings. Her usually insulated garages, cottages, are used to eliminate bridges of cold, for the treatment of window and doorways. It is better to use insulation from the outside, but if this is not possible, it can also be applied inside to complement the external thermal insulation.

No. 5. Warm Plaster Manufacturers

Manufacturers There is not so much warm plaster, but among the proven compositions it is worth noting:

Warm plaster "Umka" it is presented by several structures: UMKA UB-21 is suitable for external and internal works, can be applied on brick, concrete, foam and aerated concrete, shell rock and other materials manually or by machine, has the lowest possible coefficient of thermal conductivity - 0.063 W / m *0C. Composition can be mounted without mesh thanks to basalt fibers in the composition. The manufacturer says the possibility of making a layer of 10 cm, but with such a thickness it is better not to experiment. UMKA UB-212 has slightly lower thermal insulation qualities and is suitable for beaconless thin layer application. UMKA UF-2 is a finishing decorative plaster, which has a pleasant “side” effect - heat storage, however, the thermal conductivity is 0.13 W / m *0FROM;

Warm plaster "Umka" it is presented by several structures: UMKA UB-21 is suitable for external and internal works, can be applied on brick, concrete, foam and aerated concrete, shell rock and other materials manually or by machine, has the lowest possible coefficient of thermal conductivity - 0.063 W / m *0C. Composition can be mounted without mesh thanks to basalt fibers in the composition. The manufacturer says the possibility of making a layer of 10 cm, but with such a thickness it is better not to experiment. UMKA UB-212 has slightly lower thermal insulation qualities and is suitable for beaconless thin layer application. UMKA UF-2 is a finishing decorative plaster, which has a pleasant “side” effect - heat storage, however, the thermal conductivity is 0.13 W / m *0FROM;- warm plaster Knauf made with the addition of expanded polystyrene and hydrophobic substances, can be applied with a layer of up to 3 cm;

- warm plaster "Bear" made with filler from foam glassdue to which the vapor permeability and fire resistance of the composition are ensured.Thermal conductivity coefficient 0.065 W / m *0FROM;

warm plaster "Hauncliff" It is positioned by the manufacturer as an assistant in insulation, which allows to reduce the thickness of the walls and the main insulation. Thermal conductivity coefficient 0.09 W / m *0C, and the composition includes a filler of its own production, which, according to the company, does not burn, has minimal water absorption, does not require a protective layer, has increased sound insulation and is completely environmentally friendly;

warm plaster "Hauncliff" It is positioned by the manufacturer as an assistant in insulation, which allows to reduce the thickness of the walls and the main insulation. Thermal conductivity coefficient 0.09 W / m *0C, and the composition includes a filler of its own production, which, according to the company, does not burn, has minimal water absorption, does not require a protective layer, has increased sound insulation and is completely environmentally friendly;- Warmmix Warm Plaster It is made on the basis of cement and foam glass, it has proven itself well, and the thermal conductivity is not more than 0.065 W / m *0FROM.

No. 6. DIY warm plaster preparation

Finished plaster is sold in powder form, which must be diluted with water. Proportions are indicated on the package. The main thing is to prepare the solution immediately from all the powder in the package - it is undesirable to divide the mixture, since then it will be much more difficult to achieve the necessary consistency and, therefore, performance. After thorough stirring, the mass is left to ripen for 5 minutes, after which you can proceed to application.

You can save and make warm plaster with your own hands. The most versatile and inexpensive solution is obtained using perlite or vermiculite. It is necessary to mix 4 parts of vermiculite or perlite and 1 part of dry cement. A thoroughly mixed mixture is diluted with a solution of water with a plasticizer. The latter can be purchased at the store, or can be replaced with PVA glue at the rate of 50-60 g of glue per 10 l of plaster. The mixture is diluted with a water-glue composition and constantly stirred for homogeneity. The solution should have a thick consistency. After cooking, he is allowed to infuse for 15-20 minutes, and you can proceed to applying the plaster.

Number 7. Applying warm plaster

The process of applying warm plaster is simple and easy to do with your own hands:

- the necessary amount of solution is prepared;

- the wall is cleaned and primed for better adhesion, but many builders simply moisten the surface with plain water;

- it is better to plaster the lighthouses, although some neglect this rule. As beacons, an aluminum profile is used, which is fixed with putty, the use of prepared plaster is allowed. The evenness of the exposed beacons is checked by the building level;

- modern finished compositions of warm plasters make it possible to do without additional mesh reinforcement, but when applying a thick layer of insulation and at corners, the use of a mesh is desirable;

- the process of applying warm plaster is not original and identical conventional plastering. The solution is put with a spatula on the ironer, after which it is applied to the wall with rubbing movements from the bottom up between the beacons. The surface is aligned with the rule;

- within 2 hours after application, the solution remains plastic, so flaws are easy to fix. During this period, beacons are removed, cracks are erased with the same solution. If desired, the surface can be treated with a decorative spatula or structural roller to achieve an interesting effect. If you need a flat surface, then after the plaster dries, you need to apply a thin leveling layer and smooth it with a plastic grater;

- the thickness of one layer should not be more than 2 cm, otherwise the plaster will fall off. If it is necessary to apply it in several layers, then after installing the first one, you must wait at least 4 hours. The surface completely dries after 48 hours, then you can proceed to its final finish. If it is necessary to process a large area of the wall, then it is better to use the machine method of applying plaster.

Warm plaster is used today basement insulationfor wall insulation outside and inside, for insulation of facades and ceilings, as well as for sealing cracks and cracks, for processing slopes of windows.With proper preparation, application and calculation, the composition fully meets expectations.