10 tips for warming the basement of the house outside

More recently, in the 80s of the last century, utility bills accounted for only 3-4% of the total family income. Today, the share of a communal apartment on average reaches 10-15% of family income, and payment for heating - 30% of this amount. It is not surprising that most citizens of Russia prefer to closely monitor costs, and especially heat leaks in homes. It has been established that the base and foundation account for about 20% of heat loss, therefore, warming the base of the house is just as important and necessary as wall insulation. Properly performed insulation will not only save expensive heat, but also avoid moisture condensation on the basement walls, the formation and development of mold, and also protect the structure from freezing.

No. 1. Basement insulation: outside or inside?

The basement is called one of the most vulnerable parts of the house, because not only a large load is placed on it in the form of the weight of all walls and floors, but also often high humidity. The base is called the continuation. foundationthat rises above the ground and goes into exterior walls of the house. Simply put, this is a connecting element of the foundation and walls of the building, starting from the floor level of the first floor. It protects the house from the penetration of moisture and cold, and also plays a decorative role, since a house without a basement looks somehow squat.

Theoretically, the basement base can be insulated both inside and out.but the effectiveness will be very different. If carried out internal insulation, then to some extent it will be possible to achieve isolation of the room from low temperatures, but condensation will accumulate between the wall and the insulation, from which the base will suffer. In addition, the latter will not be protected from the harmful effects of the cold. The result is not long in coming - the appearance of microcracks from freezing, their expansion, constant wetting, and later deformation and crumbling, a decrease in strength characteristics.

External insulation allows you to protect both the room and the basement material from the cold, and the dew point shifts toward the insulation, which is much more resistant to moisture and low temperatures than the basement. As a result, we get warm room and extending the life of the structure. Thermal insulation works are best carried out at the stage of building a house, but even after its construction it is possible to carry out effective insulation, although it will be a little more difficult to do.

No. 2. Is it necessary to insulate the base of the house?

The peculiarity of the domestic mentality is such that I want to save on everything. Hence the popular question: Is it always necessary to insulate the basement of a private house? Thermal insulation may really not be needed in such cases:

- if the house is intended only for summer living;

- if the house has no basement, and the basement is small (0.5 m) and is arranged in order to avoid flooding;

- if the house is located in an area where there is no harsh winter.

In all these cases, you can do insulated floor. If the climate in the region is severe, the house is used for permanent residence, and in the basement it is supposed to store food, equip garage, boiler room or other utility rooms, then you can not do without insulation.

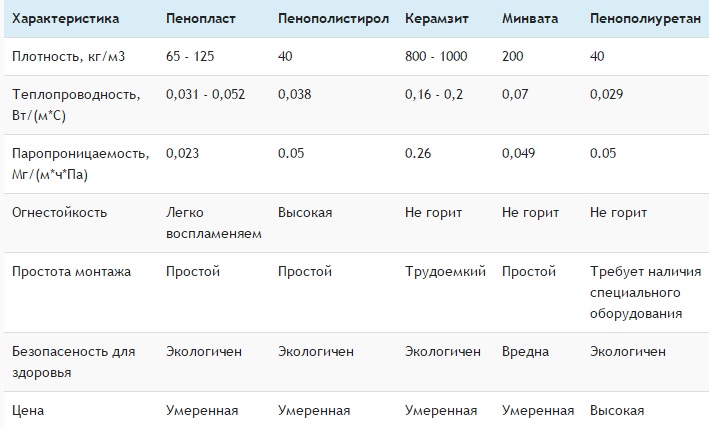

No. 3. Base insulation materials

In the recent past, a mixture of clay and straw was used to warm the basement basement. Over the past few decades, many new, more advanced and convenient ways to perform thermal insulation have appeared. A row advances to them. requirements:

- low thermal conductivity. Thermal insulation properties are better for those building materials in which the coefficient of thermal conductivity is less;

- low water absorption. When the insulation absorbs moisture, it loses some of its important performance properties. Moisture accumulation is especially dangerous during the period of frost, when water increases in volume and can violate the structure of the insulation;

- high compressive strength, because the material must withstand the pressure of the soil.

In addition, the insulation must be durable, vapor permeable, resistant to mold and rodents.

Today, such materials are used for insulation:

- heat-insulating plates (polystyrene, extruded polystyrene foam, mineral wool);

- polyurethane foam, which is applied by spraying;

- expanded clay - the most popular version of bulk insulation;

- warm plaster;

- thermal panels;

- priming.

Number 4. Basement insulation with extruded polystyrene foam

Extruded polystyrene foam - the most popular material for basement base insulation. Often its also called penoplex by the name of the company that releases the material under the same name brand. The heater reminds familiar to all of us. Styrofoam, but more rigid and durable, withstands soil pressure well, does not crumple and does not sag.

Benefits:

- excellent heat-insulating qualities and low coefficient of thermal conductivity;

- moisture resistance and inability to absorb it, which is explained by a closed cellular structure;

- sufficient compressive strength;

- high durability, which reaches 50 years or more;

- the material is not damaged by rodents and is not affected by mold;

- ease of installation and processing, the ability to carry out insulation work on their own and without the use of mechanical fasteners;

- affordable price.

Moreover, penoplex has soundproofing properties, and due to its impregnation with flame retardants, it gets fire resistance. TO disadvantages include a large number of joints - minus all tile materials. Even the largest sheets of polystyrene foam do not allow you to create a monolithic design of insulation, and the joints will have to be carefully coated or foamed. It is better to take sheets with a lock, thanks to which they are more tightly joined, reducing the risk of cold bridges. In regions with a harsh climate, it may be necessary to install a foam complex in two layers, and the plates of the second layer should close the seams between the plates of the first.

In addition, the material, although not as fragile as polystyrene, can withstand decent loads, but crumbles when cut. Installation is simple, but requires accuracy and care, it takes a lot of time. It’s better to do this summer, in warm, dry weather.

A more affordable analogue of the material is polystyrene foamwhich is obtained in a non-extrusive way. It holds heat well, but has a lot of flaws. Firstly, it is fragility, therefore, to protect the material from soil pressure, they build a half-thick wall bricks. Secondly, it is damaged by rodents. Moreover, the material is able to absorb moisture, therefore, without a high-quality roll or bitumen-polymer waterproofing not enough, and the need to carry out all these works nullifies all the benefits of buying polystyrene foam, so the material is less and less used for warming walls and socles.

No. 5. The made foam polyurethane foam for warming of a socle

Polyurethane foam can safely be called ideal insulation performance. Application of the material is carried out by special installations in which polyol and isocyanate are mixed under pressure, which leads to the synthesis of the polymer and the formation of carbon dioxide. The latter creates isolated bubbles. Spraying is carried out in a thin layer on a prepared base.

Benefits:

- high thermal insulation properties, which are ensured in particular due to carbon dioxide bubbles, because its thermal conductivity is lower than that of air;

- resistance to mold and mildew;

- monolithic insulation layer, filling all cracks and defects, the absence of seams;

- strength, stiffness, elasticity and lightness of the material;

- high degree of maintainability. In which case, the damaged area can be repaired with a new portion of the polymer;

- high speed of work - the basement thermal insulation is carried out within one day.

Among disadvantages the high price of the material and the impossibility of independent performance of work - special equipment, reagents and handling are necessary for them. In addition, the insulation is afraid of sunlight, so it’s better to try as quickly as possible facade finish.

No. 6. Mineral wool for basement insulation

Under mineral wool understand a number of materials, but to warm the basement base Basalt wool is usually used.. Rocks are used as raw materials, which are melted and pulled into thin threads, from which they create a heater. It is produced in rolls and slabs, you can use both of these: rolls allow you to get a minimum number of seams, and the plates are characterized by increased strength.

Benefits:

- low coefficient of thermal conductivity, achieved due to the fibrous structure;

- soundproofing;

- fire resistance, since it is based on mineral substances;

- high vapor permeability;

- strength and resistance to mechanical damage;

- resistance to mold;

- high durability;

- simple installation.

Manufacturers say that mineral wool passes water well and does not absorb it, but still this is not entirely true. Material has property accumulate moisture, which significantly reduces its heat-insulating properties, therefore, special water-repellent substances began to be added to it. But even this does not exempt from the need to arrange a powerful waterproofing, and this is tiring, laborious and expensive, therefore, mineral wool is used very rarely to insulate the basement - but it is perfect for walls and balconies.

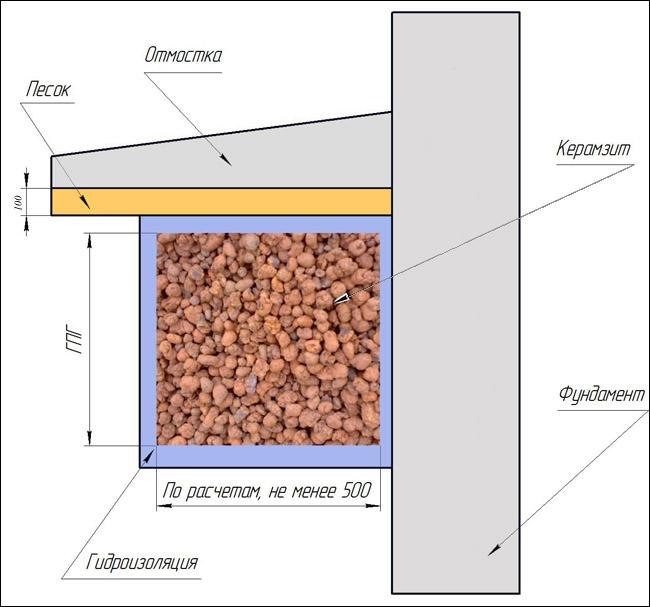

Number 7. Expanded clay insulation

Expanded clay - lightweight material, having the form of fairly large granules. It is made from fusible clays in drum sets in which swelling and hardening takes place. It turns out environmentally friendly and completely safe material, which is called one of the most budgetary heaters. It is usually used for thermal insulation of the basement base in houses that are not used for year-round use.

Benefits:

- porous structure provides good thermal insulation and sound insulation;

- low weight;

- fire resistance, because clay and frost resistance are at the core;

- environmental friendliness;

- low price.

The porous structure leads to the ability to absorb moisture, which is just not recommended for the cap. However, if you try and perform thermal insulation in science, then the influence of this property can be negated. Expanded clay insulation requires a mandatory arrangement drainage: dig a ditch deeper than the foundation, lay one on one geotextile, pour crushed stone and mount a pipe with holes for removing moisture. Sprinkled on top crushed stoneagain lay the geotextile and fall asleep sand. After preparatory work, a wooden formwork is installed at a depth of about 1 m at the depth of the base, lay roofing material so that it covers both the walls of the house and the wall of the trench, the seams are glued. Expanded clay is poured into a heterogeneous fraction, as it falls asleep, it is rammed. After the formwork is completely filled with expanded clay, it is closed with a lid at an angle of at least 45 degrees - this is done to protect the base from the accumulation of rainfall.

Number 8. Thermal insulation

Thermal panels - a German invention, based on - rigid polyurethane foam with properties already familiar to us, on top of which decorative overlays are mounted that imitate any kind of noble material: stone, brick, tile, etc. It turns out the most natural sandwich panel, which greatly simplifies installation and copes with several functions at once.

Benefits:

- good thermal insulation and moisture resistance;

- excellent appearance;

- resistance to mold and rodents.

Modern and seemingly perfect material has some drawbacks, and it is not only a high price. Firstly, special care and pedantry are required during installation: the panels should be properly fastened with strong glue, some also use dowels for warranty. Secondly, thermal panels can only be mounted on a perfectly flat base, and otherwise you will need to arrange the crate. But all these difficulties are more than offset by excellent energy efficiency.

No. 9. Warm plaster insulation

Warm plaster called dry adhesive mixtures, which have little in common with a decorative analogue. The composition of the heat insulator may include sawdust, vermiculite or expanded polystyrene.

Benefits:

- solidity of thermal insulation;

- ease of installation, because you can start applying warm plaster immediately after the coat of preliminary primer dries. If you plan to apply thermal insulation in one layer, you can do without even a reinforcing mesh;

- relatively low price.

Disadvantages quite a few:

- water absorption, therefore, thorough waterproofing is necessary;

- it is impossible to make the layer thicker than 5 cm, otherwise you will have to apply insulation not only outside but also inside;

- heavy weight;

- warm plaster cannot play the role of finishing material.

No. 10. Ground insulation

Earth or sand can also be used as heat insulators, but this is an option in the case when there is very little money, or it is necessary with minimal investments to arrange temporary insulation. The essence of the method is simple: the basement is covered with a thick layer of soil, which forms a shaft up to the floor of the first floor. In this way, good results can be achieved, but nevertheless, the thermal conductivity of the earth is far from ideal, so the basement will still allow cold, albeit in a smaller amount. Other disadvantages include the need for a large amount of soil, attracting the help of strangers, since one cannot cope with such physically hard work alone. Moreover, if it is planned to make the basement residential, then the windows will not work, and the ventilation ducts will have to be led above the earthen rampart.

The best insulation options, of course, are extruded polystyrene foam and foamed polyurethane foam, but, as we see, under certain circumstances other thermal insulation materials are also entitled to use.

Thanks for the article, the topic was revealed from a to z. We are building a house now, so we study everything carefully.We are recommended to insulate the base with extruded polystyrene foam. Tell me, what is more profitable to insulate, so that price and quality? You understand construction is not a cheap thing, I want to at least save a little.

The best option for price / quality is extruded polystyrene foam. Polyurethane foam, of course, is better, but also more expensive.

Is it possible to insulate the base of a wooden house with extruded polystyrene foam from the outside? After all, it does not allow air to pass through. will condensation appear?