8 tips for choosing paint for the facade of the house: types, color, manufacturer

Facade paint is both protection and decoration of the building. Everyone who is engaged in the construction or restoration of a house sooner or later faces the question of choosing a facade paint, and here he will find a big surprise in the form of a huge variety of its types, colors and manufacturers. As a rule, plastered facades are painted, less often - brick, concrete and wooden, and in each of these cases a certain type of paint will be needed. If you add that it is also worth considering the features of the area where the house is located, as well as the name of the manufacturer, then your head can go around. Do not panic - calmly deal with the existing assortment and make the right choice.

No. 1. Types of paints for facade work

Common sense suggests that paint for facade should have such properties as:

- resistance to ultraviolet radiation;

- resistance to moisture;

- resistance to temperature extremes;

- resistance to aggressive chemicals, especially if the house is located near a busy road or in an industrial area;

- antiseptic properties;

- high decorative qualities.

Naturally, not every one of them is now existing paints can withstand intense outdoor conditions - specific performance is determined by its composition, in which the binder plays a crucial role. After drying or evaporation of the solvent, the binder forms a film with protective characteristics and high adhesion to the base.

According to the type of solvent, paints are divided into two groups:

- on organic solventsincluding on the basis of white spirit, form a dense weather-resistant film, but somewhat toxic and fire hazardous;

- water soluble paints are more environmentally friendly, because instead of toxic organics, water is used here.

Depending on the type of binder paint there are:

- on synthetic resins (acrylic, silicone, vinyl);

- based on minerals (cement, lime, liquid glass).

The amount of binders - an indicator of the quality of the paint. In the cheapest materials, there are few binders, and instead of them, the bulk are fillers, which do not affect the quality of the finished coating. Checking the amount of filler in the paint is not easy - the manufacturer must notify about it, and the reliability of this information depends on the name of the company.

No. 2. Synthetic Resin Paints

Acrylic, vinyl and silicone paints are usually water-based, and the result is an environmentally friendly and completely non-toxic coating. Much less often, but still on sale, are organically soluble options.

Vinyl paints

Polyvinyl acetate or vinyl acetate copolymers are used here as a binder. The main advantage is low pricebut in terms of vapor permeability, resistance to moisture, resistance to chemical pollution and color fastness, vinyl paints are inferior to acrylic paints, therefore, recently they are less and less used for finishing facades.

Acrylic paints

Among water emulsion are most popular. They are resistant to various atmospheric influences, moisture, ultraviolet, “breathe” and differ in durability at the level of 10-15 years and more. To others the benefits include the ability to dry quickly and low price. Acrylic paints are alkali resistant and have good adhesion to many substrates. Thanks to tinting You can get absolutely any color you want. Coating is suitable for coloring. concrete surfaces and facades made of cement-sand plastersand preliminary priming is not required. For silicate and lime facades is not suitable.

Silicone paints

Silicone paints are made on the basis of silicone resins and have excellent hydrophobic properties, they do not soften under the influence of high temperatures, have a neutral electric charge, and therefore almost do not attract dust and dirt, which ensures long preservation of the original appearance of the facade. Silicone paints resistant to sunlight, mechanical stress, durable, elastic, have biological resistance, and are also resistant to fading and are available in a variety of color palettes. Silicone paints are suitable for almost all substrates: concrete, cement-fiber boards, as well as cement, lime and cement-lime plasters. TO cons include only cost.

Acrylic silicone paints

It is easy to guess that the composition of such paints includes acrylic and silicone resins, so the coating has the advantages of the two paints described above. They are resistant to moisture, have high moisture permeability, are resistant to abrasion, practically do not get dirty.

Oil paintsmade on the basis of natural or artificial drying oils, have recently been less and less used for arranging facades, as they dry for a long time, have a specific smell and quickly fade. However, due to the low price, the coating is still used for wooden painting facades.

No. 3. Mineral paints for facades

Mineral ones include lime, cement and silicate paints.

Lime paint

Calcareous paints are based on slaked lime. It can be ready to apply coatings or pastes, which are diluted with water and pigment directly at the construction site. The pigment must necessarily be resistant to alkaline conditions, which greatly limits the possible color palette, but this is not the only one disadvantage lime paint for the facade. It has low moisture resistance, low durability, gets dirty relatively quickly and can be washed off by heavy rain.

TO the benefits material include low cost, high vapor permeability and excellent antiseptic properties. Today, coating is used less and less, but in some cases it is indispensable. Lime paint is still used for the restoration of architectural monuments.

Cement paint

Cement paints are available in the form of powders, which are diluted in place with water or special preparations. The base of the paint is white or colored Portland cement, to which hydrated lime (about 15%) is added to improve water retention capacity and water repellents (about 1%) to increase weather resistance. Such coatings have high vapor permeability, are inexpensive, endure exposure to sunlight, but not very resistant to moisture and tend to exfoliate.

Silicate paint

Silicate paints are produced on the basis of potassium water glass with the addition of ethyl silicate. The composition is resistant to sunlight, temperature extremes, aggressive atmospheric influences (acid rain), has biological resistance, and due to the presence of water repellents, moisture resistance is added to the benefits. The color palette of silicate paints is limited, it is impossible to use them over acrylic and silicone paints, and work must be done in personal protective equipment.

Polysilicon paints

Polysilicon paints are also called silicate ash. In fact, it is a more perfect analogue of silicate paint. The coating is moisture resistant, vapor permeable, suitable for painting facades plastered with cement and cement-lime compounds.

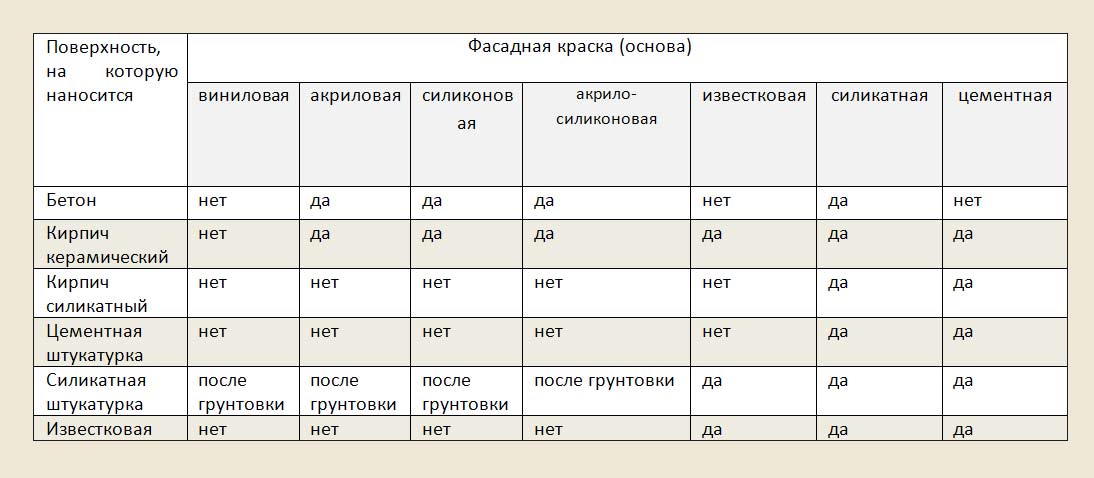

Number 4. Facade paint and base type

The manufacturer, as a rule, indicates on the packaging what type of surface this or that material is intended. To simplify your choice, here is the so-called ideal base-paint pairs:

- for cement and cement-lime plasters suitable vinyl, silicone, acrylic, acrylic-silicone, cement, lime, silicate and polysilicon paints. In general, almost everything;

- for silicate plastersas well as for facades, previously silicate paintedsilicate, calcareous, cement and polysilicon paints are suitable, which can be applied even without primers. If you complicate your task a little and pre-primed the surface, then you can also use vinyl, acrylic, acrylic-silicone and silicone paints;

- facades made using lime plasters, and lime paintedcan be finished with lime, silicate, cement and polysilicon paints. Also suitable are some silicone paints that have a high ability to pass carbon dioxide;

- if the facade was used organic plastersit is best to use silicone, acrylic and polysilicon paints;

- concrete base can be painted with acrylic, silicone, silicate and polysilicon paints;

- brick facades rarely painted, but if the need for this nevertheless arose, then you can use a number of suitable paints. For ceramic bricks suitable silicone, acrylic, acrylic-silicone paints, as well as silicate, cement and lime compounds. For coloring silicate bricks polysilicon, cement and silicate compositions can be used;

- for metal suitable compounds with high anti-corrosion properties;

- for coloring wooden facades it is better to take acrylic or alkyd enamel, primer on an acrylic base or colorless varnisheswhich protect the tree and emphasize its natural beauty.

No. 5. What paint properties should I pay attention to?

Despite the fact that the requirements for resistance to moisture, sunlight, are put forward for facade paints, mold, fungus, abrasion and other factors, in different compositions these properties are expressed differently. When choosing a facade paint, you must pay attention to such properties:

- water resistant. One of the main requirements for facade paint is the ability to withstand the effects of atmospheric moisture and not absorb it. Otherwise, the finish layer will become dirty, be affected by the fungus, lose its integrity and even fall off. The manufacturer must indicate on the packaging water absorption coefficient w, which ideally should not be higher than 0.05 kg / (m² • h0.5). Sometimes, percentages are also given. The lower this figure, the better;

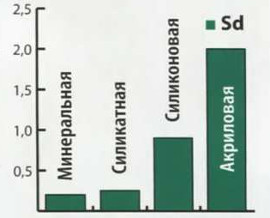

- vapor permeability paint indicates its ability to pass moisture coming out of the house, and this indicator determines how healthy the microclimate in the room will be. If the walls of the house are made of vapor-permeable material, and the paint has low vapor permeability, then moisture will condense inside the wall, which will not lead to anything good. On the packaging of the paint, you should definitely look for information and vapor permeability. Define it in many ways. It can be specified as the amount of water that passes through 1 m per day2 painted surface. In vapor-permeable paints, this value starts from 130 g / m2 per day. Sometimes vapor permeability is indicated by the coefficient Sd, which means air permeability with the same vapor permeabilitylike a layer of facade paint. The lower this indicator, the better, and ideally it should be at the level of 0.05-0.11 m. Much less often, vapor permeability is determined through diffusion coefficientwhich, with good “breathing” paints, approaches 1400-1500;

- UV resistance it is not measured by any indicators, but if the region is southern and sunny, then it is better to take polysilicon, acrylic-silicone and acrylic paints - they are most resistant to sunlight and retain their original color for a long time;

- abrasion resistance - an indicator that largely determines the durability of the coating and the safety of its original appearance. During operation, the facade will need to be washed, which will certainly lead to abrasion. Moreover, some places of the facade, in particular near front doorwill be subjected to increased loads. So that after a couple of years the paint does not fade and does not lose its color, pay attention to number of dry and wet cleaning cycles. The responsible manufacturer always indicates this information on the package, and an indicator of 5000 cycles will be quite sufficient;

- the ability to stain and self-clean paint. It often happens that a painted facade literally a couple of months after painting acquires a grayish tint, this is especially typical for areas located near roads and industrial enterprises. Just note that there are no paints that do not get dirty at all, but there are compounds in which the dirt is not absorbed, i.e. does not penetrate into its structure, and dust is easily washed off from the surface layer even during rain. This is called self cleaning ability. Hydrophobic properties begin to unfold on a full scale 3-4 weeks after application of the paint. Silicone paints, as well as acrylic and silicate compositions, are best manifested in this regard. Do not forget about tricks: dirt is washed off much better from a glossy surface, and on a dark background it is less noticeable;

- resistance to fungus. Houses built near water in places with a high level of underground water, as well as buildings located in dense shade, are most susceptible to mold. The easiest way to avoid its appearance is to use lime paints, which have excellent antiseptic properties, but this is far from a universal option, and they cannot boast of a wide palette of colors. An alternative to them is bioprotective compounds on an acrylic basis. Another solution is to apply antiseptic primers to the base, after which any paint can be used;

- paint consumption The manufacturer must honestly indicate the packaging. It is approximately 5-12 l / m2 and depends not only on the type of paint, but also on the characteristics of the substrate, including absorbent properties and surface type. Less paint consumption when processing smooth surfaces. If the paint will be applied in two layers, then the indicated flow rate is multiplied by two and another 10-15% of the reserve is added;

- drying time it differs for different compositions, and on the packaging indicate the time after which a second coat of paint can be applied (this is about 2-5 hours) and the time after which the paint fully acquires all of its operational qualities.

No. 6. Textured facade paint

Textured facade paints differ from usual granular consistencydue to which it is possible to form a relief surface. Such compounds are also called structural and texture paints, but they always mean the same thing - acrylic paint, which includes granular granulate. Less commonly, a different base may be used instead of acrylic.

Textured paint is applied to the facade with a sufficiently thick layer, about 10 mm, so its consumption is higher than the compositions that form a smooth surface. This is more than compensated by the ability of the composition to hide cracks and chips on the wall surface, therefore, in preliminary preparation and thorough alignment there is no need. The resulting texture resembles decorative plaster, but the pattern largely depends not on the composition of the paint, but on the way it is applied and used tools.

Number 7. Choose the color of the facade paint

In order for a house to please even with just one glance at it, it is necessary to choose the right color of facade paint. It is important that the shade is in harmony with the environment, neighboring buildings, color the roof, windows, doors and stairs. Manufacturers, as luck would have it, offer such a wide range of shades that you can get confused very easily. When it seems that you can’t do without professional help, use simple rules that experts apply in their practice:

- it is best to use natural colors in the decoration;

- facade color should be lighter than the color of the roof. Opposite combinations are the place to be, but choosing the right combination is likely to require designer intervention;

- a house with a bright roof is better to paint in light shades;

- in facade decoration it is better to use not one but 2-3 matching shades. One can be the main one, and the second will emphasize window and doorways, interesting architectural elements. Using more than three colors is not recommended;

- buildings located in warm regions, it is better to paint in light shades, so that in the summer it was not so hot in the room;

- paint color is better to evaluate not by catalog, not on the pages of an online store, or even in the store itself, looking into a jar. To understand how the color will look in real conditions, it is better to go out with a can of paint to the street, and even better - put it on the most inconspicuous part of the facade to make a final decision;

- if you don’t know which shade to dwell on, choose pastel colors;

- a painted house should be in harmony with the surrounding landscape, and this applies not only to nature, but also to existing buildings nearby, so even the color of the facade of neighboring houses will have to be taken into account, otherwise your home will fall out of the general context;

- for houses of complex configuration, it is better not to use bright colors;

- for buildings located in the sun, suitable matte paints - Glossy will give too much glare.

The assortment of various shades is large, and given the possibility of tinting some compositions, it is generally endless.

Number 8. Facade paint manufacturers

The quality of the paint and the correspondence of its real properties to the declared largely depends on the name of the manufacturer. On the shelves of stores you can find the products of dozens of companies, both foreign and domestic. One of the largest and best-known manufacturers are:

- Tikkurila - A major Finnish manufacturer that does not need a special introduction. The assortment contains paints intended for painting wooden and stone facades, metal surfaces, concrete plinths. Silicone, silicate, calcareous and acrylic compositions are presented, exemplary quality;

- Dulux - one of the largest paint coating companies in the world. Factories are located in 26 countries. For exterior work, paints with a matte, glossy and textured surface are presented. All formulations have antiseptic properties, a guarantee for them - 15 years;

- Dufa - A large German company operating since 1955. It produces paints for all occasions, for all surfaces and conditions of use. For facades, water-dispersion compounds are produced, there are especially strong and especially elastic compositions;

- Marshall - Turkish company, which today is part of the world's largest concern AkzoNobel. Products are in great demand in the domestic market; there is a development of a network of points of sale. For the facade, only acrylic paint is produced, which can be tinted in any shade;

- Caparol offers almost the largest selection of facade paints. The assortment includes mineral and dispersion-based paints, paints intended for concrete, cement and lime plasters;

- Eurolux - a domestic manufacturer whose products are much cheaper than foreign analogues, but at the same time they are not inferior in quality to them. For facades there is acrylic and latex paint;

- "Optimist" - Another domestic manufacturer offering a decent assortment of facade paints, including silicone, acrylic and latex. The quality is not bad, the price is affordable;

- paints OLIMP are made by the company Descartes CJSC. Products fully meet all international requirements and can safely compete with foreign counterparts. For the facade, matte acrylic paint is produced, which can be tinted in any color.

It is better not to save on facade paint - not only the appearance of the house depends on it, but also largely its durability and strength.