8 tips for choosing and installing decorative concrete blocks for the fence

Question arrangement of the fence sooner or later it becomes in front of every owner of a private house or suburban real estate. There are many options: from classic brick and forged fences to wicker and even plastic, but Concrete fences always remain among the leaders. Today it’s not gray dull monolithic sections - it’s decorative concrete blocks for a fence of different sizes, colors and textures, from which you can easily and quickly build a reliable, durable and, most importantly, pretty fence. What are the blocks and sections, and how to install them with your own hands?

No. 1. Pros and Cons of Concrete Fences

The great popularity of fences from concrete blocks and sections due a lot of their advantages:

- strength;

- longevity, which reaches 100 years;

- resistance to fire, corrosion, negative temperatures and other negative external influences;

- installation of concrete blocks can be done with your own hands, but some skills will be required;

- appearance. The aesthetics of concrete fences always suffered, so the appearance was considered a minus, but it's all about monolithic sections. They were replaced by decorative concrete blocks and sections, sometimes called Euro-fences. They quite accurately imitate the texture of natural stone and wood, can be any shades, solid or with decorative holes.

Among the main disadvantages:

- the need to build a solid foundation;

- relative high cost, but given longevity, the price cannot be considered too high.

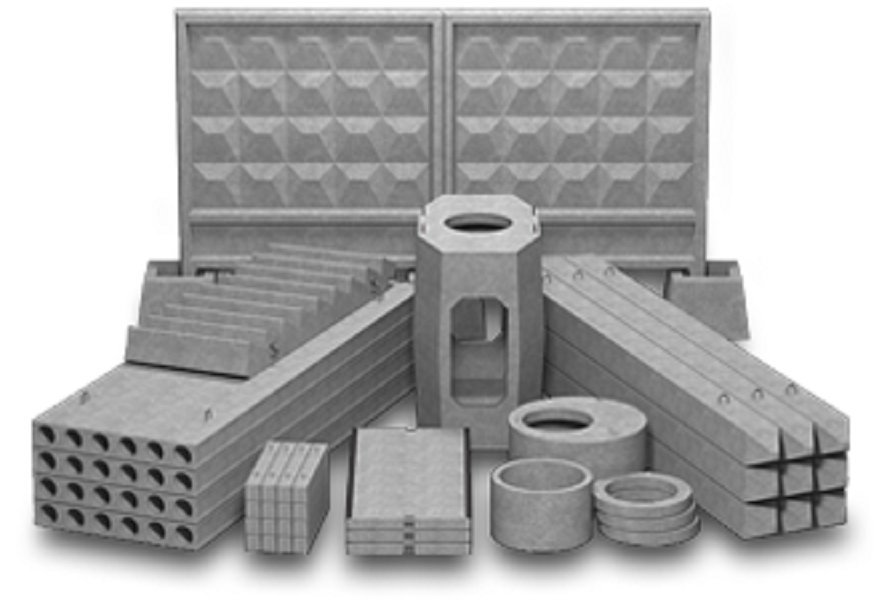

No. 2. Types of structures for creating concrete fences

To avoid confusion, we will deal with classification of concrete elements that are used to create fences:

- monolithic reinforced concrete sections of decent length and height, with a smooth, rarely embossed (robotic) surface. Such sections weigh several tons, are mounted with special equipment, are used to protect industrial enterprises - are not used in private construction;

- decorative concrete slabs (eurofence) are wide variety; they are used to fence summer cottages, country and private houses;

- decorative concrete blocks in size similar to gas blocks and foam blocks, allow you to build a fence as quickly and easily as possible, are distinguished by the greatest variety of colors and textures.

The last two versions of concrete blocks found distribution in private construction, and they will be discussed further.

No. 3. Decorative concrete slabs

Decorative concrete slabs are released 2 m long and 55 cm high, thanks to which the height of the fence can be adjusted at your discretion. As a rule, fences are built of 2-4 sections stacked on top of each other. Such modules are produced by concrete pouring in forms whose diversity is quite large. Sections can be deaf and laced, imitate sandstone, slate, brick, tile, tree, have various patterns and ornaments. There are even samples where concrete is combined with forged elements and wood. Fences built from such slabs are called eurofence.

Concrete can be painted after being molded, but it is better to choose products painted in the mass - they retain their original appearance for much longer, do not scratch and do not fade. Different decorative concrete slabs can be combined with each other, getting exclusive combinations. In addition, plates with a bilateral decorative coating are also available - they are useful when it is important that the fence from two sides looks attractive.

Higher plates are also produced, which in themselves are already a full section of the fence. They are not so diverse in terms of design and color, but still prettier than industrial monolithic sections, and weigh less.

Number 4. Decorative concrete blocks for the fence

Decorative concrete blocks are made by spillage or vibrocompression in forms. The blocks are small in size, due to which their installation is greatly simplified in comparison with large sections and even slabs and is somewhat reminiscent of ordinary brickwork. Length such items is about 30-50 cm, width - 15-25 cm, and height - 14-25 mm, the weight of not one block is about 10-25 kg depending on size and hollowness. Such elements are several times larger than the dimensions of the brick, which means that the installation of the fence will be much faster.

External parties can accurately repeat the structure of brick, slate, natural stone, tiles and other noble materials, therefore, a fence made of such blocks cannot be distinguished from what is built of brick or stone, but it is much cheaper, and in terms of durability it is not inferior to them. The surface can be smooth - such fences also look good. Blocks are painted in bulk or after installation.

Concrete blocks are predominantly hollow, which facilitates their transportation and installation, but this is not the main purpose of the voids. When mounting, the holes in the blocks are filled with cement mortar and reinforced with reinforcement, allowing you to get a reliable and extremely durable design. In fact, the blocks become fixed formwork.

As fillers for decorative fence blocks use crushed stone or gravel, but can be used expanded clay or granite screenings.

No. 5. Decorative concrete blocks for fence posts

Theoretically, support columns for a concrete fence can be made of brick or other suitable materials, but it is much easier and faster to build fence posts made of special blocksthat are made in exactly the same way as the elements of the fence. Pillar blocks can also boast a variety of textures and colors, they are easy to match to the selected fence elements, especially since in the collections of manufacturers, as a rule, there are blocks for different purposes, but of a similar design. Concrete pillar blocks today are used in the construction of fences from corrugated board, wood, forging, picket fence and other materials, therefore, have become fully universal.

With concrete blocks for the fence, it is the most reasonable to use concrete poles. They may vary in size, most often they are a square with a side of 25-37 cm, but there are also rectangular blocks. Empty interior space is used to place reinforcement elements.

To protect the fence and its decor are also available concrete pillar and fence covers, although they are sometimes replaced or supplemented with metal covers.

No. 6. Concrete block manufacturers

When buying concrete blocks for a fence, you need to pay attention to the size and appearance - it all depends on the taste, dimensions of the fence and the style of the site, advising something inappropriate. Blocks that are almost identical in appearance can vary greatly in quality, and much depends on the integrity of the manufacturer, whose name is a kind of guarantee of reliability.

One of The largest manufacturers of decorative concrete blocks for fences are:

- LLC 4th Bastion - A company from St. Petersburg, working since 2001 and producing concrete blocks for fences and poles, pillar covers in a wide assortment. The company's products are sold outside the region;

- Eurozone - Another St. Petersburg company that manufactures blocks using the "washed concrete" technology, which involves the addition of granite, marble, quartz, and pebbles to the solution. The result is blocks that are indistinguishable in appearance from natural stone, as strong and durable as possible. Thus, all the necessary elements for the fence are produced. Delivery nationwide;

- Smik House LLC - A Moscow company that provides a 3-year warranty on its products. Delivery is carried out in all regions, if necessary, installation is carried out. The products are of high quality, as evidenced by the relevant test reports. The assortment is wide;

- ConstantaZabor company, which is part of the MidGard group of companies, has been operating since 2009, and provides a 5-year product warranty. Makes various types of fences, including and concrete blocks. The range is small, but includes all the most popular options;

- LLC Fortis relies on the quality of raw materials, therefore, concrete elements are strong and durable. If necessary, the company produces individual elements for the fence according to customer designs.

When buying does not interfere with personal inspection of blocks. They should have the most accurate geometry, a flat surface without chips, foreign inclusions and cracks, uniform color.

Number 7. Installation of concrete blocks

In principle, it is possible to carry out the installation of a fence of concrete blocks independently, but for this it is better to have experience in arranging the foundation and laying walls. The main difficulty lies in preparing a solid foundation.

Foundation workflow such is:

- territory marking with pegs and rope. It is necessary to outline exactly where the fence will be located. It may be necessary to coordinate this issue with neighbors and relevant authorities. To simplify the work and get a perfectly even fence around the perimeter of the future fence, pegs are driven in and the rope is pulled along them;

- digging trenches. Its width should be twice the width of the future masonry, plus another 40 cm. The depth depends on the type of soil: for non-porous, you can dig a ditch 70 cm deep, in other cases it is better to make a trench 20 cm deeper than the freezing level of the soil;

- the bottom of the trench is well compacted, poured 10 cm sand and gravelEach layer is watered and rammed. After that, you can equip waterproofing - will do roofing material. They are lined with the walls and bottom of the trench;

- concrete mortar preparation from cement, crushed stone and sand in a ratio of 1: 5: 3 and water. Since concrete will need a lot, it is better to use concrete mixer;

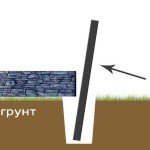

- concrete is poured onto a drainage with a waterproofing layer with a layer of about 10 cm and, after hardening, it is installed formwork from boards, it is advisable to provide spacers. A reinforcement frame is laid in the formwork, which is knitted by welding or knitting wire. For reinforcement, steel rods with a diameter of 12 mm are best suited. About 4 longitudinal rods are used (depending on the width of the block), they are connected by transverse rods and they make vertical rods, a step of 10-20 cm. Vertical rods are let out by 15 cm - they will enter the voids of concrete blocks and will serve to better bond the foundation with the fence;

- at the locations of the posts to the reinforcing cage strictly vertically attached pipes. If earlier post arrangement was not clearly defined, it can be done now. The first rack will be located at the very beginning of the frame. Now parallel to the trench lay out the pillar and fence blocks, taking into account the thickness of the seam. The length of the span of the fence is usually 3-4 m. The middle of the next pillar will indicate the location of the rack;

- concrete pouring into formwork and thorough ramming. Periodically, the solution can be moistened with water, the formwork is removed after a week;

- parts of roofing material coming to the surface are glued to the foundation with bituminous mastic;

- the distance between the walls of the trench and the concrete foundation is covered with earth.

On this the preparation of the foundation ends and begins construction of the fence:

- start work with installation pillar elements, ordinary masonry mortar is used for masonry, the thickness of the seam is 1-1.5 cm. Every 2-4 rows, a reinforcing masonry mesh is laid with an outlet that will enter the fence masonry;

- concrete mortar is poured into the voids of the first blocks of the fence. Each new row is laid with a shift in relation to the previous one by a third or half - as with bricklaying. Verticality and horizontalness are constantly checked by level. It is advisable to stack every two rows. mesh for greater structural strength. Masonry mortar is applied to the ends, bypassing the voids, do not forget about vertical seams;

- when laying, it is better to take blocks from different lots and pallets to get the same appearance of the fence along its entire perimeter;

- excess solution must be removed promptly, avoiding the appearance of smudges and dirt on the blocks;

- if the fence has not yet been completed, then it does not interfere with protecting it in case of rain with plastic wrap. If water gets into a still fresh masonry mortar, efflorescence cannot be avoided;

- after installation is complete, the masonry can be treated with protective hydrophobic agents;

- it remains only to install covers for the pillar and fences.

When it comes to installing concrete slabs, then the sequence of work is the same except that they use special posts with grooves in which the plates are mounted. First, the first pole is mounted, the lower section is inserted, and only then the second pole is mounted so that the plate fits snugly into the grooves.

Number 8. DIY concrete blocks

This lesson is not for the faint of heart, since a lot of blocks will be needed to build a fence. Self-made concrete blocks for the fence will be appropriate in cases where it is necessary to build a small fence or when you want to feel like a real builder.

To make blocks you need the form appropriate size. It can be made of wood, but it will work better with a metal mold - they are sold ready-made.

The sequence of work is as follows:

- preparation of concrete mortar in a concrete mixer;

- filling out a mold with voids and constant ramming with a vibrating table;

- the mold is lubricated with oil before each use so that the block can be removed from it;

- a well-packed product is removed from the mold and dried for several days. The entire process is presented in detail in the video.

Concrete fence care is minimal, it can stand for 80-100 years, and in case of damage it must be repaired. For the sake of this, it is worth making an effort to create the foundation and laying the blocks.

Thanks, good article. It is useful for those who have not yet decided what kind of fence to choose.