9 tips for choosing a cork floor: pros, cons, types, manufacturers

Until recently, cork was used only to seal bottles, but the unique properties of this natural material have greatly expanded its scope. Today, cork oak bark is used in the manufacture of sports goods, furniture, shoes, of wallpaper and even in the space industry. Not so long ago, flooring began to be made of it, which is still perceived ambiguously: some are in real delight, others are more skeptical. Stores and manufacturers, while promoting products, sometimes mislead the buyer, so before you make any decision, you need to know well what the material is. We deal with all aspects of the choice of cork flooring: the pros and cons of the material, its types, installation options and major manufacturers.

No. 1. Cork flooring

For the production of cork, cork oak wood is used, which grows mainly in the Mediterranean. Large areas are covered in Portugal, so the bulk of the cork flooring comes to our stores from there. A cork is a dead section of the bark of a tree, which is removed from time to time (no more than once every 9 years) by making longitudinal cuts. After removing the bark, its new growth begins, and with each cut the quality improves.

It is not always possible to remove whole layers of cork, so often the flooring is made of crumbs, called agglomerate. Cork is a unique material, which consists of a mass of small airtight chambers filled with oxygen and nitrogen, which gives special properties to coatings and objects made from it. The cork contains about 30% ligninswhich are responsible for density, about 40% suberinresponsible for elasticity and adhesive properties, as well as about 10% of oligosaccharides, due to which a unique relief and structure are formed. In addition, there are tannins in the cork, which determine the color of the material, and some ceroids responsible for water resistance.

Short the cork floor production scheme can be described as follows:

- the production of veneers from natural, stabilized or pressed bark;

- drying and sorting cork chips (granulate). High-density granulate is used for the manufacture of warp, with a lower density for finishing;

- production of granulate blocks that will serve as the basis for gluing veneers. Binders are added to the crumbs, the finished mass is placed in the molds and exposed to temperature and high pressure. After cooling and stabilization, cutting and grinding take place;

- bonding the base and veneer. At this stage, varnishing and gluing of the resulting tile to HDF boards may occur if the cork floor is intended for laying by means of a lock connection;

- varnishing, cutting locks, packaging.

The structure of the coating differs slightly depending on the method of installation provided: it is only a granulate base and veneer, if we are talking about adhesive material, or a more complex structure with an HDF plate and an additional cork substrate, if we are talking about a castle cork field.

No. 2. Cork flooring: pluses

Cork today is credited with a set of unique properties. Sorted out what are the benefits of a cork floor?, and which are somewhat exaggerated:

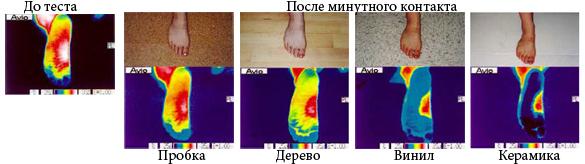

- thermal insulation properties. The thermal conductivity of the cork is not much higher than the corresponding indicator for air, which allows you to do without the use of an additional heat insulator when installing the floor. The surface of the material is pleasant to the touch and warm, you can walk on it barefoot, so the material gained popularity in the arrangement bedrooms and children's rooms. The thicker the floor, the higher its thermal insulation properties, but the higher the price. Glue floors have a thickness of 2-6 mm, castle - 9-12 mm;

- soundproof properties. Due to its porous structure, cork is capable of absorb noise, but the coating will cope well with this task if the thickness of the cork layer is more than 3 mm;

- environmental friendliness. The level of naturalness largely depends on the characteristics of production. If we are talking about whole veneer, then its naturalness is at the highest level. If cork agglomerate was used for the manufacture, environmental friendliness is somewhat reduced, because the natural material was compressed using adhesives and plasticizers. Responsible manufacturers, which will be discussed below, use non-toxic and absolutely safe additives, so there is no question of harm to health. Since a layer of natural cork veneer is used on top, the material retains hypoallergenicity and a unique pattern. This coating can be put on one step with parquet board. In terms of environmental friendliness, the castle cork floor based on an HDF board is inferior to the first two coating options, but still retains naturalness and safety for health;

- cork flooring is good for your health (in particular for the spine and joints) due to the elasticity, elasticity and ability of the material to spring slightly. This is confirmed by relevant studies carried out by the Biomechanical Institute of Valencia in 2005;

- resistance to mechanical stress. The fall of a heavy non-sharp object and the prolonged exposure to massive objects of furniture not able to damage the coating. After the heavy bed, for example, has been moved away from its original place, the depressions from the legs will soon disappear. At least that's what cork floor manufacturers say, drawing an analogy with a cork in a bottle that instantly takes its original shape. In principle, the way it is, but if the impact was strong and lasting, then residual deformation can be present, however, its depth will be no more than 0.2 mm;

- moisture resistance. The coating is not as afraid of moisture as parquet, for example, but resistance to it is different for different variations of the cork floor. Absolutely water-resistant coating from whole veneer, and if the structure has an HDF panel, it is not recommended to use the floor in rooms with high humidity;

- resistance to most detergents, but with abrasive cleaners and those compounds where the level of alkali is elevated, you must be extremely careful - they can damage the surface.

The surface of the cork floor is rough, but thanks to modern processing and application of several layers of varnish Absolute smoothness can be achieved.

No. 3. Cork Floor: Cons

There are enough advantages and a cork floor, but it’s difficult to call it a universal coating for any room in the apartment, since it has some disadvantages:

- sharp object instability, and this means that the heel, the falling object with sharp edges and even the claws of animals can be dangerous for such a gender;

- complexity of repair. Theoretically cork flooring can to grind, but in practice grinding is rarely carried out, since for this it is necessary to observe a number of conditions.Damage should not be too deep, and the room should maintain approximately the same temperature and humidity level throughout the life of the coating. But it is not all that bad. If only certain parts of the floor are deformed, then damaged elements can be replaced with new ones. To make this possible, professionals are advised to purchase material with a margin;

- castle cork floor is not very resistant moisture. When water gets in, it behaves better than a parquet floor, but use it in bathrooms and on kitchens, especially in the cooking area, is not recommended;

- a few years ago, a small assortment of colors and patterns could be written down as flaws, because the cork has approximately the same shade in tan, so manufacturers have learned how to make a cork floor with a wood pattern. Thus it turned out cork laminate.

As for longevity, then a lot depends on the structure of the coating, the varnish used and the responsibility of the manufacturer. Adhesive cork floors withstand about 10 years of operation.

Number 4. Types of cork flooring

The following types of flooring are made from cork:

- solid veneer - the most expensive, high-quality and environmentally friendly material. Floorboards for one collection and a batch of color are selected manually;

- roll coating Do not use as a decorative finish - it plays the role of a heat and sound insulating substrate;

- adhesive cork floor - these are interconnected cork agglomerate and veneer;

- castle cork floor performed on the basis of HDF or MDF boards.

The last two types of coverage are most common.

No. 5. Adhesive cork floor

Adhesive cork is sometimes called cork flooring. These are rectangular or square plates made of pressed cork. 2-6 mm thick and veneer 1 mm thick. The dimensions of such tiles are usually 30 * 30, 45 * 45, 45 * 15 cm, but most often found 60 * 30 cm. Tiles with a thickness of 3 mm are considered the most wear-resistant and can be used even in offices, but in a residential apartment it’s better a coating with a thickness of 6 mm behaves: it is softer and better protects against cold, especially when it comes to the ground floor.

Normal manufacturers use safe glueodorless, and unscrupulous sin using toxic compounds with a characteristic suffocating odor. Top veneer can be protected three layers of varnish - this is the best option. Only one coat can be applied, then after laying it will be necessary to apply the finish coating. There is a glue plug and without varnish - in this case, all three layers are applied after installation independently without fail.

Normal manufacturers use safe glueodorless, and unscrupulous sin using toxic compounds with a characteristic suffocating odor. Top veneer can be protected three layers of varnish - this is the best option. Only one coat can be applied, then after laying it will be necessary to apply the finish coating. There is a glue plug and without varnish - in this case, all three layers are applied after installation independently without fail.

It is difficult to say unequivocally which cork floor is better, adhesive or castle. Everyone will make a conclusion himself, depending on the purpose of use and means, but for now, let's focus on Advantages of the glue option:

- more moisture resistant compared to the castle, but the flood will still leave noticeable marks on it;

- the ability to perform artistic styling and create a single coverage throughout the apartment without thresholds;

- higher durability.

Minuses:

- higher price, incl. through the use of expensive adhesives and varnishes. Saving on varnish during production or installation leads to the fact that it soon begins to exfoliate, depriving the coating of protection;

- need carefully level the floor, as small differences can be noticeable after installation;

- complexity and high cost of laying, but repairs can be made by replacing one tile with another.

Before styling the material is allowed to lie down in the room for several days. The surface of the floor is pre-carefully leveled. It is recommended to start laying from the center of the room and run it parallel to the wall. Glue is applied both to the floor and to the material. After the glue has completely dried, the first coat of varnish can be applied; it dries for about 5 hours.Before applying the last layer, intermediate grinding is performed. The first 8 days, it is better not to expose the floor to serious loads.

No. 6. Castle cork floor

A cork floor with a locking connection is actually the same adhesive option, only mounted on an HDF or MDF board. The structure of the castle cork floor is as follows: the bottom layer is a cork substrate with a thickness of 1-2 mm for sound insulation, then an HDF board with a density of 380-880 kg / m3 (the higher the density, the better), then a cork agglomerate 3 mm thick with cork veneer and a three-layer varnish coating. Often the advantages of a castle cork floor include the presence of a protective layer of varnish, which does not have to be applied manually, but sometimes there is a coating on sale with a complete lack of varnish. As for the underlying plate, it is made from sawdust by pressing: HDF boards have a higher density than MDF. The top layer can be made not of cork veneer, but of wood.

Elements generally have the size 90 * 18.5 and 90 * 30 cm, are connected due to the presence of a lock connection at the ends, their thickness is 9-12 mm. Mounting such a finish is quite simple, and this material compares favorably with the adhesive analogue. To others the benefits It is worthwhile to include the affordable price and speed of work performed. Among disadvantages the inability to perform artistic styling of the material and sensitivity to moisture. The material is great for living roomsbedrooms and even hallways when combined with other finishing materials.

Castle floor can to mount even on the existing old finish, pre-laying the substrate from cork or polyurethane. Lay the elements from left to right, from window to door, inserting one into another at an angle of 30 degrees and fixing the lock, if necessary, use a rubber mallet. When installing a cork floor (both types), a clearance of about 1 cm is left near the walls for expansion due to changes in temperature and humidity. This gap can be hidden behind skirting board. When the element of the castle cork floor is deformed, you have to disassemble all the flooring from the wall to the damaged area.

Number 7. Cork flooring rolls

Cork roll only as a substrate when laying laminate flooring, parquet and cork floor. The material is made of pressed crumbs, so it retains all the exclusive heat and sound insulation characteristics of the cork. Available in a thickness of 1.5 to 10 mm, the width of the roll is usually 1 m, the length ranges from 5 to 12.5 m. There is also a sale rubber-cork roll coatingswhich differ in record soundproofing and shock-absorbing qualities.

Number 8. What else to consider when choosing a cork floor?

When buying cork, it is worth checking the quality of the material in the package:

- slices should be smooth, free from burrs and nicks;

- in different packages, the elements must have the same color gamut, the cuts at the slabs must be the same, so that during the laying no cracks form;

- the wrong side should be dense, even and uniform;

- carefully examine the material sections: the presence of foreign inclusions is unacceptable. Sometimes manufacturers, wanting to reduce the cost of production, add cheap sawdust to the mass with expensive cork. Naturally, the quality of such a coating is reduced.

Sometimes the cork coating is almost the same in appearance or with the same performance, but with a different veneer, the prices vary greatly. The final cost dependsfirst of all, from the veneer used, its type (natural - the most expensive, stabilization cheaper, pressed - the cheapest), the method of applying it to the substrate, as well as the type of MDF board: the higher its density, the more expensive the material.

Attention should be paid and choice of varnish, because the durability of the coating largely depends on its quality.If you choose the right varnish and timely update the coating, then the service life of the cork floor can be significantly increased. At the moment, you can recommend such varnish brands as Natural Shield, Hotcoating, PU-Varnish, WRT, Lobadur 2K Supra Cork.

No. 9. Top cork flooring manufacturers

Cork flooring leader Portugal, because here the cork oak most suitable for use for these purposes is growing. Its bark has a high density, and it contains a lot of suberin, the very substance that is responsible for elasticity and stickiness. Due to this, in the production process glue, you need to add a minimum, and this reduces the cost of production and makes the finished product more environmentally friendly. Chinese companies use the bark of the local balsa wood, which is inferior in density and composition to the Mediterranean, so you have to add a lot of glue. To make the product cheaper than competitors, low-quality glue is often used.

The best manufacturers of cork floors have recommended themselves:

Wicanders - One of the largest Portuguese cork coating companies. The company is actually a trendsetter in this area, regularly updates collections, offers adhesive and castle floors of different thicknesses and a wide range of shades. HDF boards are used high-quality and dense (not less than 860 kg / m3), therefore, the company's products are considered a model of quality. Cost from 20 to 50 $ per sq. m .;

Wicanders - One of the largest Portuguese cork coating companies. The company is actually a trendsetter in this area, regularly updates collections, offers adhesive and castle floors of different thicknesses and a wide range of shades. HDF boards are used high-quality and dense (not less than 860 kg / m3), therefore, the company's products are considered a model of quality. Cost from 20 to 50 $ per sq. m .; Corkstyle - Swiss brand, existing since 1998. Products appeared in the domestic space in 2006 and today is considered the most popular among competitors. The company cooperates only with the best manufacturers of raw materials and equipment: it purchases cork in Portugal and Sardinia, varnishes from Kleiberit and Loba, an HDF base from Kronospan. The range of adhesive and castle floors is huge, there is cork floors with photo printing (the picture can be absolutely anything). Cost from 24 to 80 $ per sq. m .;

Corkstyle - Swiss brand, existing since 1998. Products appeared in the domestic space in 2006 and today is considered the most popular among competitors. The company cooperates only with the best manufacturers of raw materials and equipment: it purchases cork in Portugal and Sardinia, varnishes from Kleiberit and Loba, an HDF base from Kronospan. The range of adhesive and castle floors is huge, there is cork floors with photo printing (the picture can be absolutely anything). Cost from 24 to 80 $ per sq. m .; Corkart - Portuguese company whose products are always of the highest quality. The manufacturer cooperates with the best suppliers of equipment and components of products, striking a huge assortment and the availability of affordable options. There is a cork floor and for $ 20 per sq. m. (without varnish), and for $ 60 per sq. m. (with a unique pattern and increased thickness);

Corkart - Portuguese company whose products are always of the highest quality. The manufacturer cooperates with the best suppliers of equipment and components of products, striking a huge assortment and the availability of affordable options. There is a cork floor and for $ 20 per sq. m. (without varnish), and for $ 60 per sq. m. (with a unique pattern and increased thickness); Mjo - Portuguese manufacturer, presented in all price categories. The range of coatings is wide, there are always several collections on sale, the cheapest of them use HDF boards with a low density of 400 kg / cm3, prices start at $ 25 per sq. m .;

Mjo - Portuguese manufacturer, presented in all price categories. The range of coatings is wide, there are always several collections on sale, the cheapest of them use HDF boards with a low density of 400 kg / cm3, prices start at $ 25 per sq. m .;- Maestro club - a brand of cork coating, which is manufactured at the Portuguese concern Amorim (where the well-known cork Wicanders) by domestic order. The quality is European, and the price is many times more affordable, because there is no overpayment for the brand. The average cost is $ 30 per sq. m .;

- Corksribas Is a Portuguese company that produces commercial cork. Strength, wear resistance and durability is ensured through the use of a special varnish, which gives the material a roughness, so it is better to walk on it only in shoes.

Cork Floor Care simple. It can be kept clean with a vacuum cleaner and wet cleaning; most detergents can be used with the exception of strongly alkaline and abrasive ones. Metal brushes are also better not to use. To exclude the appearance of scratches, it is better to attach pieces of felt or felt to the furniture legs. The right choice of cork flooring and appropriate care for it is a guarantee that it will last for many years.