7 Tips for Choosing a Vinyl Laminate

A floor covering that is a cross between laminate flooring and linoleum, appeared on the domestic market relatively recently and became known as a vinyl laminate. Immediately, the material became an object of increased attention, because with an excellent appearance the coating has an exclusive set of performance, is not afraid of fire and demonstrates record durability. Due to the novelty of the coating, a lot of myths have developed around it, and many still do not understand what the material consists of. We figure out how to choose a vinyl laminate, which manufacturer to prefer, what types and sizes of material.

No. 1. What is a vinyl laminate made of?

The modern vinyl laminate is an improved analogue of the good old PVC tile, which appeared in the 30s of the last century. The production technology has since improved significantly, operational and decorative qualities have improved significantly, which makes the two materials completely different, but there is still a kinship between them.

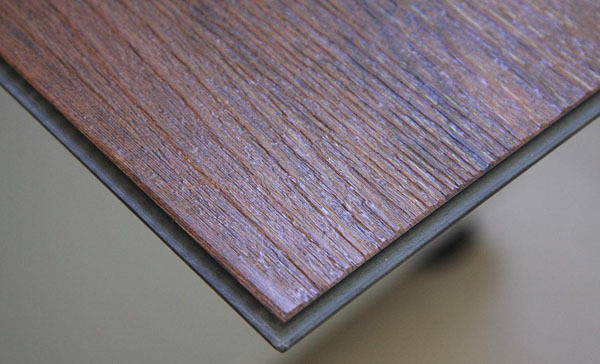

Vinyl laminate structure multilayer. The basis is a layer durable balance polyvinyl chloride layer with mineral additives (usually quartz sand), which provides the material with the necessary rigidity and flexibility. Bottom and top of it are another layers of PVC reinforced fiberglass. Next comes base layerproviding the material with proper durability and additional sound insulation. Glued on top patterned paper layer, which is protected from external influences by a layer of polyurethane and can be covered with an additional layer of transparent polyvinyl chloride. The composition of quartz vinyl tiles may include up to 60-80% quartz sand, which provides the material with proper strength, resistance to abrasion and moisture.

No. 2. Pros and cons of vinyl laminate

The multilayer structure of the coating allows us to talk about the mass of positive qualities of the material. TO main advantages should include:

- moisture resistance and hygiene. The material does not absorb moisture, does not swell, it can be washed with water, use all kinds of detergents, it does not slip. Largely due to this, vinyl laminate gained popularity in the arrangement bathrooms, pools and kitchens;

- durability and wear resistance. Manufacturers claim that the material can easily withstand heavy furniture items and even simulators, it is steady against damages, and confirm words with a long-term guarantee. Such strength is ensured by the presence of fiberglass and quartz in the composition of the material and its multilayer structure, which brings the material closer to the quartz agglomerate;

- relative ease of installation. Most will be able to independently cope with all the installation of the coating, because it can even be laid on top of the old linoleum or tilesThe main thing is that the surface is clean, dry and even. Many companies are convinced that the material can be mounted even with a height difference of up to 3 cm, and a preliminary screed is not needed, but it is better not to mount the material on a completely uneven surface.When working with an adhesive vinyl laminate, you must be extremely careful, because it will be impossible to remove and move the element, unlike a castle laminate;

- easy care;

- security. It is allowed to use coverage in child care facilities;

- durability. A number of manufacturers speak of a coating life of 40 years. This, according to professional builders, is overestimated, but until 15-20 years the coating can last;

- not bad heat and sound insulating qualities;

- design and variety. The material can repeat the pattern and color of any species of wood or stone. Moreover, even the corresponding roughness can be simulated;

- ability to use with underfloor heating, Besides infrared film. The material can be heated up to a maximum of 300FROM;

- fire resistance and inability to maintain burning, but when the material temperature rises to extreme values, harmful substances can be released, therefore, the coating is not used near the stoves.

There are no ideal finishing materials, so when choosing a vinyl laminate, you should be prepared for such disadvantages:

- the material is not resistant to solvents, and when it comes into contact with rubber, discolored spots may appear on it, so rubber mats will have to be discarded;

- a cigarette butt or hot object may leave a mark on the surface;

- the ability to gradually fade under prolonged direct exposure to sunlight;

- relatively high price for really high-quality products. The low-cost vinyl laminate on the market is rarely of high quality;

- low maintainability. If a lock connection was used, then the damaged lamella can be changed, and with glue mounting it will be more difficult to do.

No. 3. Vinyl Laminate Size and Design

Coating can be issued directly in laminate format and have dimensions of about 100 * 920 or 180 * 920 mm, fully simulating lamellas. Another variation is square tile with side from 300 to 600 mm. The thickness of the material, as a rule, is from 1.5 to 3.5 mm, sometimes more, but not more than 5 mm. Such a small thickness with high strength and wear resistance allows the use of a vinyl laminate on top of an old floor covering, reducing repair time and not reducing the height of the room. The forcing of the material is not more than 0.08 mm.

Assortment of colors and textures material is so wide that it allows you to choose a coating to any interior style. Modern technology is not only capable of coloring any shade, creating the most intricate designs, imitations of wood and stone, but also fully repeating tactile sensations from touching a tree or stone. In appearance and to the touch, a material is obtained that is indistinguishable from natural.

Number 4. Durability classes of vinyl laminate

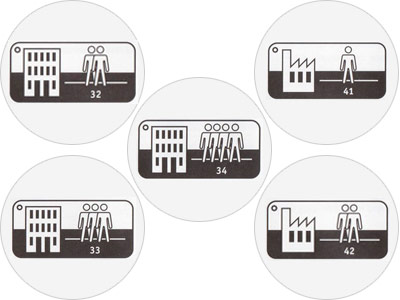

About strength and ability to withstand loads and deformations, the material is usually divided into three classes for various purposes:

- household coverage, which includes vinyl laminate 23 and 31 classes, is a material with a small thickness of the protective coating, the greatest variety and low durability (5-6 years, up to a maximum of 10);

- semi-commercial and commercial vinyl laminate Class 32-42 is designed for public buildings, offices and places where there are a lot of people. It is more durable, its durability is up to 15 years, so many prefer use it at home;

- special coating 43 classes possesses the increased durability and is intended for use in production or gyms.

How is this two-digit number representing the class of material obtained? The first figure determines what type of premises the cover is intended for: 2 - apartments, 3 - public buildings, 4 - production. The second figure determines the degree of possible load, from 1 to 3, sometimes up to 4.

No. 5. Thickness and type of protective layer

A lot depends on the main vinyl layer, but it takes a lot of loads protective layer. It is he who makes up up to 60% of the cost of the final product, and it is on it that unscrupulous manufacturers try to save. Its thickness varies within from 0.1 to 0.5 mm: the larger this parameter, the higher the strength and wear resistance. Material with a protective layer thickness of 0.1 mm is suitable only for home use, and it is better to move on it barefoot or in soft socks. With a protective layer thickness of 0.5 mm, a vinyl laminate can be used in public buildings with a large flow of people.

To save on production, some companies reduce the thickness of the protective layer, and often this nameless Chinese manufacturers sin. In most cases, with a specified layer thickness of 0.4 mm, the real parameter will be 0.3 or even 0.25 mm - this is difficult to determine by eye, therefore Better trust products of trusted and reputable manufacturers, which will be discussed later.

The protective layer can be made of different materials, but today the following types of coating are most popular:

- polyurethane with the addition of aluminum oxide, or the so-called 4th generation. This is a good, but not the most modern and durable option;

- polyurethane with ceramic chips and ultra-component (UV), it 5 and the last generation, which has the highest rates of wear resistance and strength.

No. 6. Vinyl Laminate Manufacturers

From all the above, it is easy to understand that the name of the manufacturer is a guarantee of quality, especially in those conditions when the construction market is flooded with vinyl laminate of not the best quality. To the most large and trusted manufacturers vinyl laminate should include:

- Allure floor - one of the leaders in the field. The material is produced using technology patented in 2005 by American scientists. The variety of colors and sizes is huge, the material also differs in the way of installation, but the popularity of the brand and the location of production overseas played a cruel joke - prices on the domestic market are high;

- Quick step - A leading European manufacturer from Belgium, which since 1960 specializes in the manufacture of only floor coverings. It was here that they suggested using the world-famous Uniclic castle, which facilitates the installation of the laminate. Today, the company also offers certified vinyl laminate Livyn. The prices for this durable coating of the highest quality, presented in three extensive collections, are surprisingly affordable. In St. Petersburg and the region, Quick Step vinyl and ordinary laminate are sold by the Skill retail and wholesale company, which is a certified point of sale, has several stores, delivers all over Russia and, if necessary, can easily cope with the installation of any finishing material. The range of flooring and wall coverings is expanding day by day, but the most interesting is the constant availability of promotional offers that help to save additional money;

- Tarkett - Another major producer of the field, which has factories on different continents. Not so long ago, the range of flooring replenished with a vinyl laminate ART VINYL. Today it is available in the format of planks and tiles of different sizes, in three collections, the range of colors is huge. Company opened two plants in Russia, which allowed us to make high quality more affordable to domestic customers. A separate brand has even been created for our market. POLYSTYL - this is the same vinyl laminate, but a little cheaper and limited in variety;

- IVC - Belgian company, which gained fame in the domestic market thanks to vinyl laminate Moduleo. The company offers customers a constantly expanding range of coatings with a castle connection, there are both expensive offers and affordable options. Wear resistance class 32 and 42, the manufacturer gives a guarantee of up to 20 years;

- Vinilam - A Belgian company, which, incidentally, was one of the first in the world to produce vinyl laminate. Since then, many innovations come from this manufacturer. The company's collections are among the most extensive, and the products are able to satisfy any request. What can I say, if many still call vinyl laminate vinyl from the name of this company. The prices here are average, and the quality is always up to standard;

- Allur - One of the few decent Chinese companies that produces coatings imitating a wood structure, tile, stone and even zebra skin. The quality is not bad, wear resistance up to 43 classes, but also the prices are on the same level with European ones;

- Haro - vinyl laminate, which is made by the German company Hamberger Flooring. The manufacturer uses its own innovative solutions that can significantly increase wear resistance, without losing environmental friendliness. Increased strength turns into a double price, and the range includes only basic shades.

These are not all large and reliable companies. The products of Belgian companies AquaFloor (brand Dumafloor) and Fine Floor, as well as German Holzplast and EGGER, the Swedish company Pergo and the Portuguese Barco are not so widely represented, but still presented on the domestic market.

Number 7. The method of mounting a vinyl laminate

At the moment, there are several options for installing a vinyl laminate. It depends on the structural features of the material and must be specified by the manufacturer.

By the method of installation, there are such types of material:

- with a lock. This is the simplest and most suitable for self-assembly coating. The lock device and assembly principle are not much different from ordinary laminate. Installation is quick and easy;

- glue laying used in self-construction infrequently. For work, special adhesive compounds are needed;

- self-adhesive coating characterized by the presence on the wrong side of the adhesive layer protected by paper. For installation, it is enough to carefully remove the paper and lay the lamella in the designated place. Such material can even be mounted on an old one on tiles and linoleum, but it is necessary to act with extreme caution, because in case of an error it will be impossible to peel and reposition the lamella;

- with adhesive tape. The adhesive coating in this case is located at the ends of the lamellas and is also covered with paper. The locking connection is not performed mechanically, but thanks to glue.

Vinyl laminate has gained fame and popularity due to a combination of high strength, ease of installation, excellent appearance and excellent performance, but all these advantages can be fully used if the products are really high-quality, so do not flatter yourself with too cheap offers.