10 tips for which brick for the furnace is better to choose

Despite the wide existing opportunities to organize a system heating a country house, many still stop at the brick kiln. It would seem that this is a conservative and very outdated method, but in a house with stove heating in the cold season, the optimal level of humidity is maintained. In addition, the brick oven is a special cosiness and expressive detail. of interior, and in some cases the only way to organize home heating. Creating a brick kiln is a whole science, the cornerstone of which is the right choice of material. Which brick for the furnace is better to use, what are the requirements for it, and what material should not be used in any case?

No. 1. Basic brick requirements for masonry furnaces

The stove must cope with the mass of complex negative factors affecting it, among which there is a very high temperature and sharp temperature drops up to negative values, if only occasionally in a country house in the winter. The chimney, which is in direct contact with the environment, also experiences the effects of sudden temperature changes. Therefore, the brick that is used to equip the stove in the house, must meet the following general requirements:

- resistance to high temperatures and an open flame;

- high mechanical strength;

- resistance to temperature fluctuations;

- ability to accumulate heat and keep it.

For laying one furnace use different types of bricks, and each is used in arranging a specific part of it.

No. 2. Furnace elements and suitable brick

A solid fuel furnace is a complex structure, each element of which operates under different conditions, so it is unlikely that it will be possible to lay out all its components with one brick. Conventionally, in the design of the furnace, one can distinguish the following parts:

- foundation;

- firebox;

- smoke channels;

- chimney;

- facing.

Brick for the foundation of the furnace

Natural brick requirements for foundation - strength, moisture resistance and frost resistance, since part of it can cool to freezing temperatures. To equip the furnace foundation, use ceramic or brick brick. Universal option - ceramic brick first grade, which can even be used for the construction of massive two-story furnaces. Ceramics of lower quality may be used if the load on the furnace foundation is low. Clinker brick is used in regions with harsh climates, as it shows exceptional frost resistance.

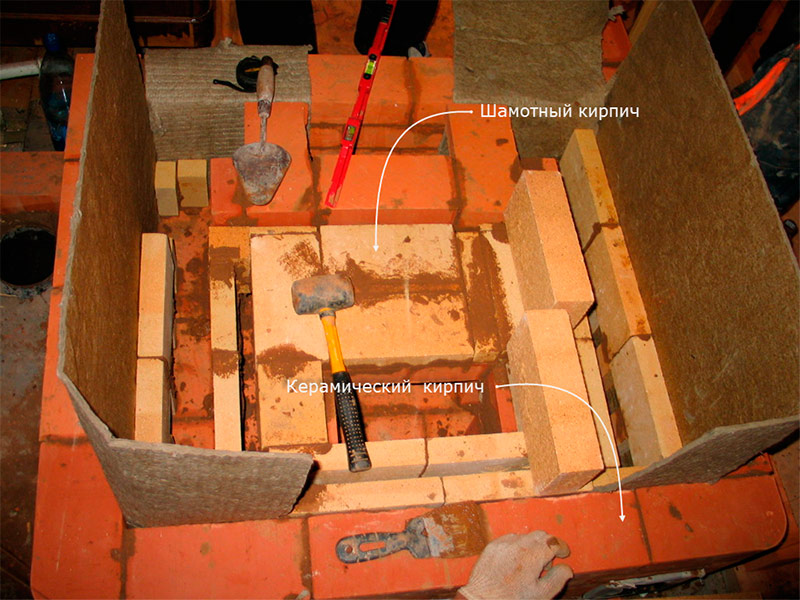

Brick for the furnace

The solid fuel combustion chamber typically has two-layer walls: the inside is being built from fireclay bricksand the outer (facing) - from ceramic. The temperature in the furnace reaches 1100 0C, and ceramic brick at a temperature of 1150 0C begins to melt, so the inside of the stove is laid out with fireclay bricks, for which such temperatures are not destructive. Moreover, the material copes well with heat storage. It is worth noting that sometimes the firebox is laid out from heat resistant ceramic brick, but it is possible only for furnaces with an unstressed thermal regime (for example, a Russian stove). Since on exterior finish such high temperatures do not affect, it can be arranged from facing ceramic bricks.

Chimney brick

Smoke ducts are a large furnace heat exchanger. The temperature in it, although lower than in the furnace, is still high and it is better to use for laying its elements fireclay brick. Outside, smoke ducts can be lined with ceramic bricks.

Chimney brick

Chimney temperature can range from -400C to +4000C, i.e. the material should be frost resistant and withstand temperature extremes. In addition, the pipe should warm up quickly enough so that the furnace can increase traction - if this happens slowly, we will deal with excessive consumption of fuel and increased deposition of soot. It is also worth considering mechanical loads, which, mainly, are the impact of wind of any direction. Therefore, for the arrangement of the chimney of the furnace is suitable ceramic brick with maximum frost resistance. In regions with a harsh climate, you can lay pipes with two layers of brick: the first is clinker, the second is hollow ceramic. By the way, this is the only case that allows the use of hollow bricks in the arrangement of the furnace.

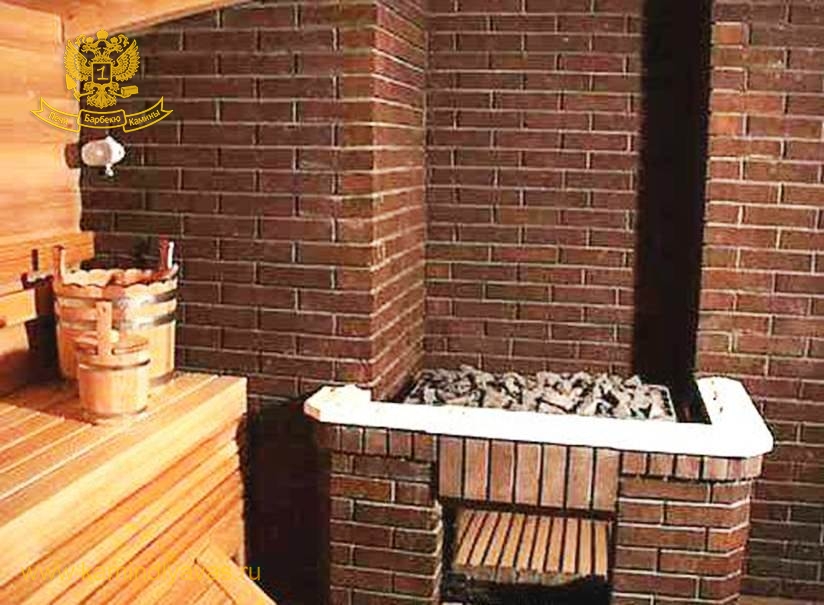

Brick for facing the furnace

Depending on the idea and design solution, the facing of the furnace is carried out in one of the following ways:

- building ceramic brick second grade, which is characterized by the presence of a sufficient number of pores that ensure the respiration of the furnace. Its rough surface will become a good basis for the facing material;

- facing ceramic brick plastic molding provides the necessary breath of the furnace, gives it an aesthetic appearance, turning it into an interior decoration, and the whole structure comes out as strong as possible due to the dressing of the seams;

- clinker cladding tiles Meets the requirements put forward for home stoves, it looks great, but is not cheap, so it is rarely used.

No. 3. What should be a ceramic brick for a furnace

Ceramic brick actually underlies the construction of the furnace and also serves for its lining. It is easy to guess that the durability, safety and proper functioning of the furnace depend on its quality and compliance with the requirements. Better for masonry choose a brick with such characteristics:

- strength grade indicates the compression load the material can withstand (kg / cm2) Brick from M75 to M300 and even higher grades is available on the market. The denser the brick, the slower it cools down, but at the same time, it heats up more slowly, so here it is necessary to adhere to the middle ground. Better stay at brand brick not lower than M150 and not higher than M250, and for a two-story oven, it is better to use M200-250. Brick M100 and below is not suitable, since it does not have sufficient strength and heat engineering properties, and brick above the M300 grade cannot be obtained from natural raw materials - additives are used for its production, which justify themselves in housing construction, but are harmful to stoves;

- frost resistance is indicated by the letter F and the number following it, indicating the number of freezing and thawing cycles that a brick can withstand. This parameter is especially important when arranging a chimney, which will constantly be in a temperature differential. It is better to choose a brick with frost resistance no less F75;

- full body. For masonry and cladding use only corpulent ceramic brick (with the exception of the above-described case of pipe arrangement in cold regions);

- preparation method. Ceramic brick is suitable for masonry and cladding. plastic molding, which involves extruding a clay mass with a moisture content of about 20% through a die and further cutting the formation into modules of the desired size. Semi-dry and dry bricks are made of pre-dried clay, which allows you to get the product with the most accurate dimensions, but the strength of such a brick is inferior to plastic. You can recognize a brick of dry and semi-dry formation by an even cut on all sides.

Ceramic brick is divided into grades, and each of the three grades has the right to be used in the construction of the furnace, but only for certain works:

- first grade - it is a brick with exact geometry, moderately burnt, of uniform bright color, when tapped it gives a clear metallic sound, the edges do not crumble, the cut marks have no burrs, the strength and pore size are sufficient. Such bricks are used for building and facing the furnace;

- second grade - this is a slightly unfinished brick with a light shade, when tapped it gives a clear but dull sound, can be used for cladding;

- third grade - this is a burnt brick, in which the indicators of frost resistance and heat capacity do not meet the requirements for laying and facing the furnace, but the foundation for it can be made of such material.

Number 4. Refractory brick for the furnace

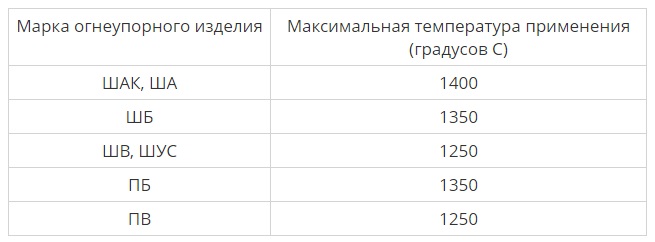

The furnace furnace is laid out with special refractory bricks, allowed the use of its types:

- quartz brick made of sandstone with the addition of a small amount of clay. The result is a durable glazed brick, a bit like chamotte. He is exclusively heat resistantbut expensive, does not withstand the effects of aggressive chemicals and metal oxides. Its use is justified when laying heat-reflecting arches of stoves and fireplaces. Often quartz bricks are laid out the so-called tooth fireplace - a curly masonry element that reflects infrared rays into the room. For chimney fittings not suitable as condensate can easily destroy the material. Apply only solid brick;

- fireclay brick received a higher popularity than quartz, since it is much cheaper and more resistant to negative influences. It is made in the same way as ceramic, but refractory grades of clay are used, and firing takes place at a temperature of 15000C, so temperatures up to 13000They’re not afraid of him.

In view of the features described the most common when laying the firebox was fireclay brick, they lay out the combustion chamber of the furnace and the initial parts of the chimney channels, where burnout processes are still possible. Fireclay brick is suitable for creating all elements of the furnace, but its use is limited by its high price and specific appearance.

When choosing fireclay bricks for the furnace, pay attention to the following points:

- products must be durable, with a small porosity, have a uniform color;

- sizes presented in a wide variety and may correspond or differ from the typical dimensions of ceramic bricks. With narrowed, shortened, elongated, shaped bricks and bricks with a reduced block width and complex configuration, it is easier to lay out the firebox;

- so that test for strengthIt’s enough to throw a brick from a height of about 1 m onto a stone floor. If the product breaks into large parts, then it is of high quality, and bad brick crumbles into a bunch of small elements. In this way, quality is checked in production. It is clear that not every seller will agree to such experiments, so you can rub the edge of the brick, and if there is no dust and crumbs, then the product can be used for masonry. Continuous sound when tapping is a sign of quality first-class fireclay brickswhich can be used in furnaces with intense thermal conditions. Second grade gives a mellow, but clear sound when tapped, it is suitable for all other fireboxes. A dull sound is a sign of marriage, such a brick is not recommended.

No. 5. Clinker brick for the furnace

In the arrangement of the furnace, it is allowed to use clinker brick. It is produced on the basis of special refractory grades of clay (clinker), which are fired at temperatures up to 1300-15000C. With this temperature effect, the clay is sintered with mineral additives in the vitreous mass, and traces of sagging are even visible on the spoons. Clinker brick is different highest durability (M300 and even higher), frost resistance (F100 and above) temperature exposure up to 12000FROM and not afraid of aggressive substances.

So why are such products not so often used in furnishing furnaces? It's all about high price, because there are almost no deposits of suitable raw materials in Russia, and big weight a brick. In addition, brick brick it is not capable of ensuring the correct “breathing” of the furnace, and is inferior to chamotte in heat resistance.

Sometimes still the use of clinker brick for laying the furnace is justified:

- during the construction of a large heavy furnace, the starting rows of the foundation can be made of durable clinker;

- for the internal channel of the chimney with its temperature differences and a high concentration of combustion products;

- to create compact stoves, such as bourgeois, especially for a bath.

No. 6. Which brick can not be used for the furnace?

It is not superfluous to list which brick for the furnace can not be used, since this is a responsible construction and requiring safety precautions. So, completely unsuitable:

- silicate brickwhich is afraid of high temperatures and moisture. In frequency construction, unfortunately, they still use it at their own peril and risk;

- raw brick;

- brick slip castingwhich may crumble from temperature extremes;

- hyper pressed brick also can not withstand temperature jumps.

Number 7. The size and shape of the brick for the furnace

When laying a stove today, as a rule, they use standard single brick with dimensions 250 * 120 * 65 mm, but some masonry schemes are designed for so-called furnace module dimensions 230 * 125 * 65 mm. This is an outdated format, but manufacturers, as a rule, have a whole line of products oriented specifically to the furnace module, so before buying a brick you need to understand exactly what type of furnace was designed.

For the construction of the furnace, you may need a brick non-standard form - shaped. It is necessary for more simple and high-quality formation of the furnace, as well as for external decoration. To create decorative arches, vaults and other curly elements, you can use wedge-shaped bricks with end or rib narrowing. Parameters in this case are recorded in this way 230 * 114 * 64/45 mm. Bricks with rounded corners, arcuate and others can also be used.

Number 8. Brick for the furnace in the bath

Stove in the bath It works at high humidity, so the general principles of arrangement here can not be used. Best for arranging a small bath stove clinker brick, but chamotte and quartz are not suitable, since their use at a humidity of more than 60% is not allowed. Another option is to create a firebox from ceramic refractory brickand make the lining of ceramic bricks of the first grade.

No. 9. External inspection of a brick

When choosing a brick for the furnace, you must definitely look certificate of conformity, where the basic properties of the material should be indicated and the fact that this brick can be used in the construction of the furnace must be emphasized. In addition, a visual inspection is of utmost importance:

- the brick must have exact geometry with a maximum deviation of 2 mm;

- if you take a brick in your hand and, while holding its canopy, apply a weak blow with a hammer, then the tool should bounce off the surface with a jingle. This indicates the absence of cracks inside the brick;

- crush test It’s not always possible to perform, but how the brick breaks, and what its internal structure is, can say a lot. Unacceptable crumbling and uneven coloring of the slice;

- fireclay brick should contain a minimum of shells formed during the evolution of gases during firing. There should be no more than 4, and on different faces.

No. 10. Oven Brick Manufacturers

The best quality guarantee for bricks is manufacturer name. Refractory brick is represented by the products of foreign and domestic enterprises, among which the largest and recommended ones are:

- LODE - Latvian company, which specializes in the production of a wide range of bricks. Kiln brick is an important part of production and is widely distributed in the domestic market;

- Wienerberger ag - a huge concern that grew from a small Austrian company. Now it is a world leader in the production of bricks and tiles, which has 230 factories in 30 countries, including and in Russia. For the construction of furnaces, the company offers heat-resistant front brick of the Terca trademark;

- JSC "Ceramics" – Belarusian company, produces stove bricks under the trademark "Vitebsk brick". This is a ceramic brick, which is suitable for facing a stove or fireplace, and there is a large selection of shaped products. The manufacturer indicates that its brick can also be used to equip the furnace;

- BKSM CJSC (Borovichi brick factory) - an enterprise with a long tradition, its products are represented in all regions of the country by ceramic refractory and fireclay bricks;

- OJSC "BKO" (Borovichi Refractory Plant ") specializes in the production of refractory materials, including produces fireclay bricks.

Of course, the quality of the furnace also depends on the project, solution, erection techniques, but what brick is chosen for the masonry of the furnace is of decisive importance, so you should be extremely careful about this issue.

Only fireproof brick is needed in the furnace, the kiln brick will be destroyed!

Brick is ordinary and front. The higher the density, the faster the brick heats up and cools down. The full-bodied LODE has the M-500 brand, which is used only for chimneys.

Tell me please, I bought a brick front M-150 brown single, can I build a galanka from it?