12 tips for choosing a brick for building and cladding

It is hard to imagine a more popular and versatile building material than brick. Private and high-rise buildings are built from it, fences and outbuildings, it is used to organize the foundation and construction of partitions, they are faced building facades and lay out the stove. Brick has gained such widespread use due to its exceptional performance and variety. The latter, by the way, can lead to a dead end, because right away to say which brick to choose for the construction of the house, its cladding, arrangement fireplace or an interior partition, it’s not so simple - before you buy, you will need a little theoretical preparation.

No. 1. Types of bricks by material

For the production of bricks, various raw materials can be used. Manufacturing technology can also vary significantly, which explains the differences in the properties of different types of bricks. At the moment, we can distinguish such types of bricks:

- ceramic;

- silicate;

- hyperpressed;

- clinker;

- fireclay.

The first two are divided into ordinary and facing depending on the appearance, as well as corpulent and hollow depending on the structure. Brick also differs in size, color, strength, frost resistance and other parameters.

No. 2. Ceramic brick: pros, cons, production

Ceramic brick produced by burning clay in furnaces at a temperature of about 1000 0C. Since red clay is often used, the brick gets a characteristic shade, so its second name is Red brick. Grades of clay with a different shade can be used or pigments can simply be added, and then the color of the product will be completely different.

As raw materials, high-quality clay with a minimal admixture of sulfates and marl is taken. After molding, the product is sent for firing in the oven: properly burnt brick will have red-brown hue and ring when struck. The unfinished material has a mustard color and a dull sound upon impact, it is afraid of moisture, does not retain heat. Burnt brick has a dark core and fused edges, it is not used in the construction of walls.

In the manufacture of ceramic bricks, one of the following is used. formation methods:

- plastic. The original clay mass has a moisture content of 15-21%, the brick is made by extrusion. Hollow bricks are made in vacuum installations. The brick of plastic formation is more resistant to frost and is great for building a house;

- semi-dry and dry. Clay has a lower moisture content (7-12%, depending on the characteristics of production), it is crushed into powder, from which raw bricks are formed in presses without drying or with reduced drying, which is then fired. The main advantage is the accuracy of the geometry.

Ceramic brick applied everywhere: when bookmarking foundation, the construction of load-bearing walls and partitions, cladding of buildings, to perform interior decoration. To the main the benefits include a variety of colors, sizes, shapes, ease of installation, long service life, environmental cleanliness, good indicators of heat and sound insulation and reasonable price. Minuses due to improper production, which may result in products with low durability and incorrect geometry, so trust only products responsible manufacturers.

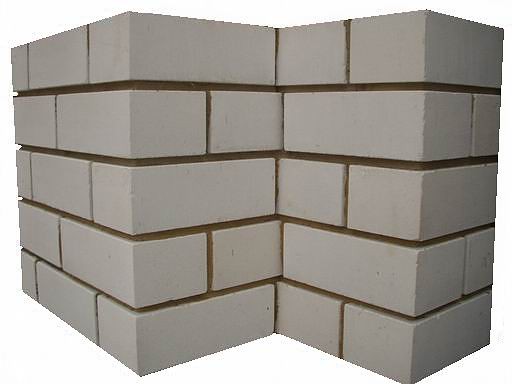

No. 3. Silicate brick: pros and cons

Silicate brick received the greatest distribution in the domestic space, and the main reason for its popularity is its low price. It is made from a mixture of quartz sand (90%), lime (about 10%) and additives. White color, but by adding coloring pigments, other shades can be achieved. The brick is formed by dry pressing, and the setting is obtained due to the chemical reaction of slaking lime. The reaction is accelerated in autoclaves at elevated temperature and pressure.

Among the main the benefits silicate brick:

- low cost;

- environmental friendliness;

- excellent geometry and good aesthetic qualities. Facing silicate brick is widely used for decorating building facades;

- good durability and sound insulation;

- sufficient level of frost resistance.

Minuses:

- large weight and fragility, therefore it is difficult to handle the material;

- high level of thermal conductivity - thorough wall insulation;

- low moisture resistance and the ability to collapse under the influence of moisture and chemicals, therefore, for the construction of foundations and socles the material does not fit at all;

- instability to high temperatures - silicate brick is not used in the arrangement of furnaces and chimneys;

- little variety. Silicate bricks are always rectangular blocks with precise straight lines, without roundness and complex elements.

If you do not know which brick to choose for the construction of partitions and walls, and the budget is limited, then you can stay on silicate. It still remains the most popular in private construction, but for the foundation it is better not to use it.

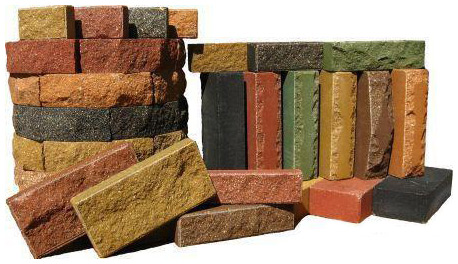

Number 4. Hyperpressed brick: production technology and features

Hyperpressed brick, if you look, is more like fake diamond. It is based on screenings of calcareous rocks, shell rock, dolomite, marble, the proportion of which reaches 90%. Cement is used to bind limestone, and iron oxides or other natural components are used to color the material. The solvent is plain water. The mixture, uniform in structure, is sent under a press, and under the influence of high temperatures, individual particles are fused together, which makes it possible to obtain the strongest material with precise geometry. After that, the brick is steamed and sent for rusting.

Benefits:

- high strength, durability, environmental friendliness;

- aesthetic appearance, a variety of shapes, colors, sizes;

- frost resistance, the brick can withstand up to 150 freezing / thawing cycles;

- low moisture absorption.

Minuses:

- high price;

- heavy weight;

- high thermal conductivity.

Hyper pressed brick used exclusively for cladding facades and soclescan be used for facing of fireplaces and for interior decoration.

No. 5. Fireclay refractory brick

Fireclay bricks are made of chamotte clay (about 70%), which is burned until plasticity is lost, then crushed and the product is formed. In fact, this is the same ceramic brick, but due to the unique properties of the clay included in its composition, it receives resistance to temperatures up to 1700 0FROM. Fireclay brick is characterized by a straw color, it can have brown and reddish blotches, it is produced both in the correct form and in wedge-shaped, angular and other forms for the convenience of masonry.

Despite the fact that ordinary ceramic bricks can easily withstand temperatures up to 800 0FROM, for furnishing furnaces usually chamotte bricks are used, since it accumulates and slowly gives off heat. It is used not only for the internal arrangement of furnaces, but also for chimney masonry.

No. 6. Brick brick

Clinker brick is made from special refractory grades of clay, including shale clay. In the production of material, the temperature rises to 1100 0C, therefore, individual particles are sintered, and all voids are filled. They carefully approach the choice of raw materials, so in the end it turns out solid monolithic brickpossessing resistance to freezing temperatures, environmental friendliness, heat resistance and high durability. The variety of shapes, colors and surface types is huge, which allows the use of clinker brick for cladding facades, for paving garden paths and furnishing furnaces and chimneys. Among cons material high cost and thermal conductivity.

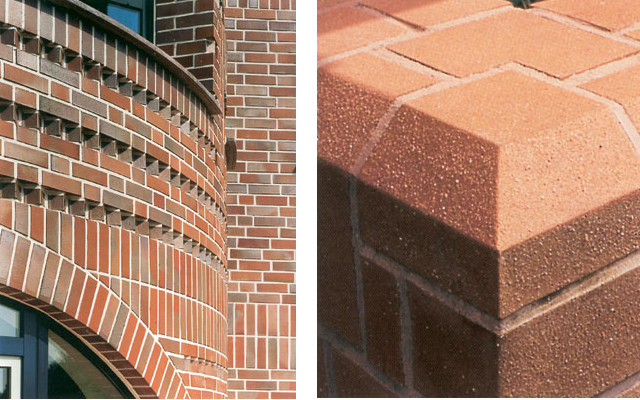

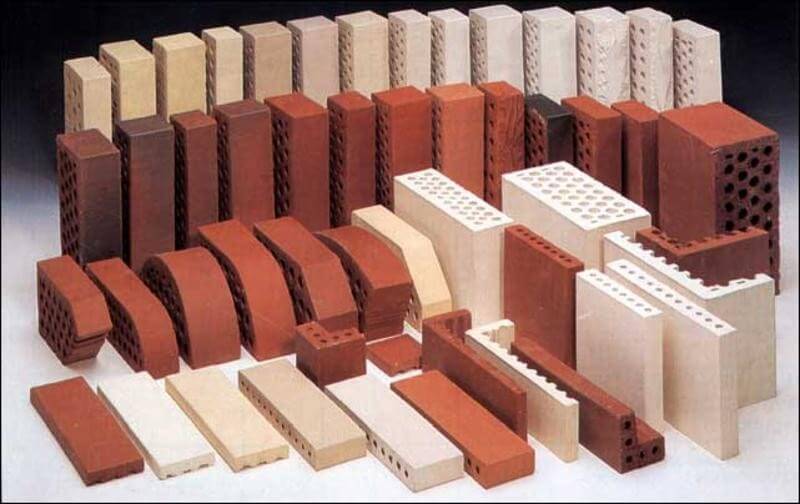

Number 7. Building and facing brick

According to from the field of application, the brick is divided into:

- construction or ordinary;

- facing or front, front.

Building brick, as the name implies, is used for the construction of foundations, walls and partitions. After the construction of the outer walls, they must be protected and insulated. Such a brick may contain small chips, but it must have accurate geometry. Construction can be ceramic and silicate brick.

Facing brick differs in precise geometry and interesting appearance; it is used for decoration of facades, basement, and can be used in interior decoration. Facing can be ceramic and silicate bricks, as well as hyper-pressed and clinker. Appearance may vary significantly. It is customary to divide the facing brick into textured and shaped. The first differs in a standard form, but has a decorative surface, the second has complex profile configurations and is used to equip arches, windows and other non-standard architectural forms.

Type of surface of facing brick:

- smooth matte or glossy;

- rusticated when convex irregularities are created on the surface;

- grooved with indented type irregularities;

- broken when the surface has chips or breaks (often this is found in hyper-pressed brick).

As for shades, then each manufacturer offers its own set of colors, and bricks with an interesting color transition are also found. Gamma is represented by almost all colors of the spectrum: from light shades to almost black.

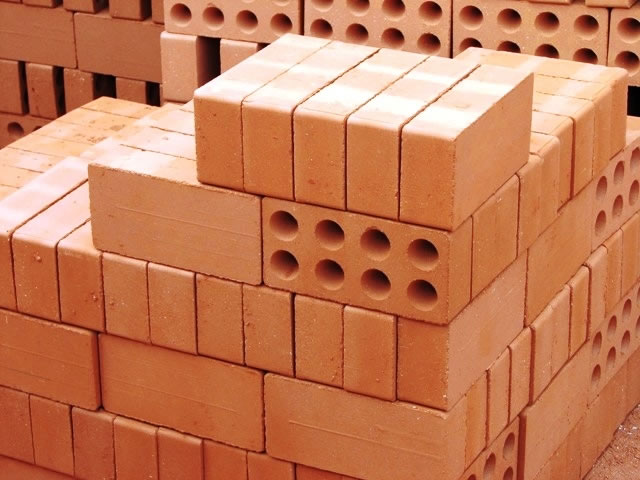

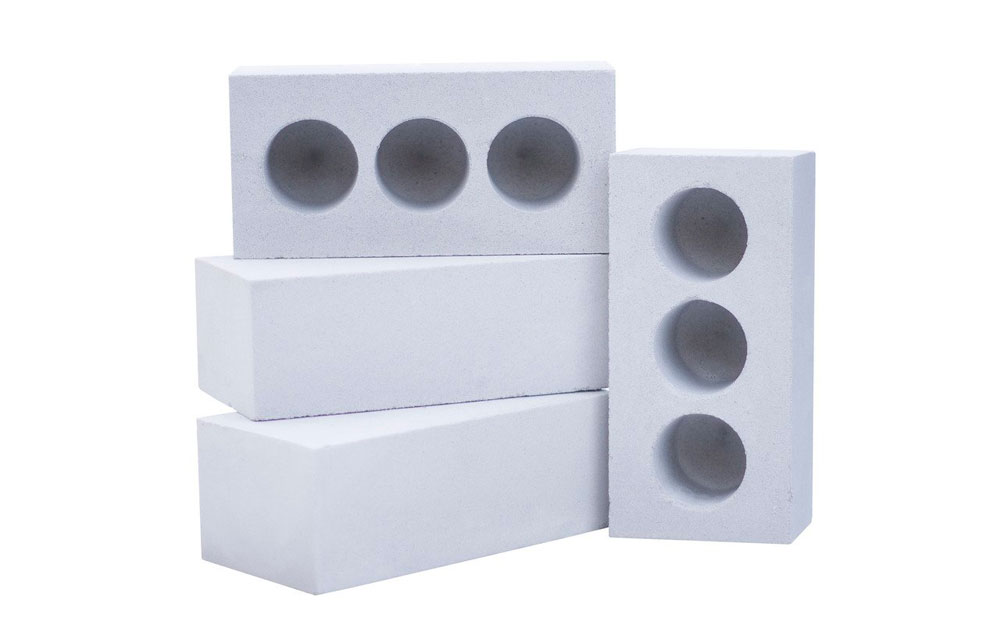

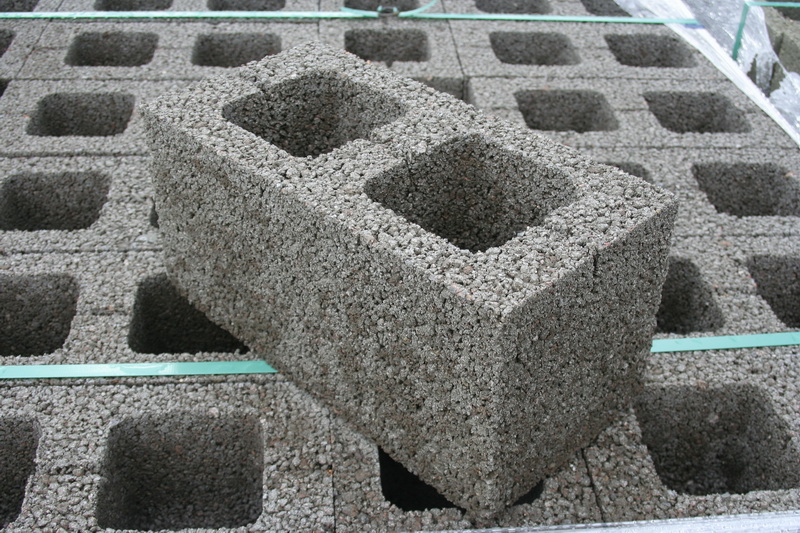

Number 8. Brick filling character

Depending on the filling, a brick can be:

- full-bodied;

- hollow;

- porous - a separate type of brick.

Solid bricks Do not have holes or chambers. They are more durable, therefore they are used for the construction of the foundation, walls, columns and other responsible designs. Such a material has high bending strength, frost resistance, but has high thermal conductivity, so the walls need to warming.

Hollow brick characterized by the presence of chambers or holes of round, rectangular or square shape, they can be through or closed on one side, horizontal or vertical. The hollow core of silicate brick can reach 30%, ceramic - up to 45%. Due to the voids, raw materials are saved, so such a brick costs less, and due to its low weight it is more convenient to work with it. But its main advantage is thermal insulation properties, because air is enclosed inside the voids. Usually they use such a brick for the construction of interior partitions and cladding of facades, rarely - for laying lightweight external walls and never when equipping furnaces and chimneys. It is worth remembering that this is a rather fragile material, and the masonry mortar should be thick so as not to flow into voids.

Separately worth mentioning porous brick. These are blocks of rather large sizes, whose thermal conductivity is 0.14-0.26 W / m0C, and the larger the block, the lower its thermal conductivity. Similar indicators bring the brick closer to foam concrete, a tree and even gas silicate, and record values are achieved due to special production technology. Porized brick differs from ordinary ceramic brick in that wood sawdust is added to the clay, which burns out during the firing process, forming voids, and they, in turn, contribute to thermal insulation. Depending on the desired thermal conductivity and strength grade, one or another number of sawdust is added.

It’s not very convenient to work with porous bricks, but the walls are erected very quickly. Moreover, there are special channels in such products where vertical reinforcement can be poured, and this is an excellent solution for the construction of warm houses in earthquake-prone areas. At first glance, it may seem that porous brick is too expensive, but if you calculate the price per cubic meter, you can find that it is not much higher than a conventional ceramic brick.

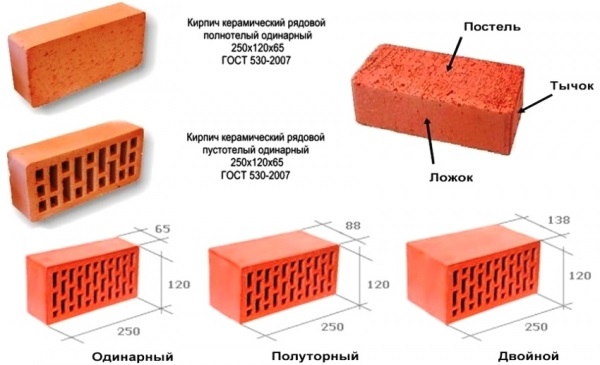

No. 9. Brick size

After the color, type and nature of the filling is determined, the following question arises - what size brick is needed. According to GOST 530-2007, standard brick has dimensions 250 * 120 * 65 mm, and with respect to it all sizes are determined:

- single brick - this is the same standard, it is the most versatile, it is used both for masonry and for facing, it is convenient to work with it, since it fully corresponds to the hands of a person;

- one and a half 250 * 120 * 88 mm in size is used when laying massive structures and can significantly save time;

- double size 250 * 120 * 138 is rarely found full-bodied, and hollow is used in lightweight masonry;

- narrow size 250 * 60 * 65 is used only for decorative purposes;

- thin 250 * 22 * 65 mm in size - this is, in fact, a tile, the scope of which is facing work;

- there is still a brick "Euro"(0.7 of the standard thickness), modular (1.3 of standard thickness) incomplete bricks and other exotic sizes, which are rarely used in construction.

Historically, that brick facets They call it a bed (the working largest part of the product), a spoon part (long side face) and a stick (the smallest face). Some manufacturers and stores operate with precisely these concepts, so it will not be superfluous to remember them.

Knowing what structure (or decoration) to be completed, given its size and the dimensions of the most suitable type of brick, it is possible to calculate without difficulty how much material is required, but it is still better to take with a margin.

No. 10. Brick grade for strength

When it comes to the construction of foundations and walls of buildings, such a brick indicator as strength, which is determined by the brand, comes first. By strength is meant the ability of a material to withstand a load, or in other words weight that can withstand 1 cm2 bricks without deforming. This parameter is reflected in the brand. For example, a brick that can withstand a load of 100 kg / cm2 - this is the M100. Today, brick is produced from M75 to M300:

- M75, M100 and M125 suitable for walls of small private houses up to 3 floors;

- M150 can be used to build walls of multi-storey buildings and foundations of country houses;

- M200-M300 suitable for the construction of foundations of apartment buildings.

Strength data should be indicated in the technical data sheet of the product. It’s difficult to identify the brand, and if possible, only approximately. So, for example, if a brick, when struck with a hammer, splits into particles the size of rubble, then this is a low-quality product. If it takes several strokes to break a brick, then this is a medium-strength product.When hit with a hammer on a brick of M150 grade and above, it will sparkle, a maximum of several small pieces will be able to be repelled. To surely choose high-quality, strong and durable brick, it is better to turn to products reputed manufacturerswhich indicate honest information about the product and produce bricks in accordance with all requirements. It is also worth noting that the final strength of the wall being built will also depend on the masonry mortar.

No. 11. Brick frost resistance

Since the climate in most regions of the country is harsh, when choosing a brick, the frost resistance indicator should be taken into account, it is designated as Мрз and measured in successive freezing and thawing cycles, which in no way affect the basic properties of the material. For central Russia, it is better to take a brick with an indicator of frost resistance not less than 30-50 cycles, for the harshest areas with a cold climate and changeable winter weather, there is a brick with Mrz 100. If the winters in the region are mild, then you can stop at the minimum indicators.

No. 12. What else to consider when choosing a brick?

When buying a brick, take enough time to inspect it and study the accompanying documentation:

- high-quality ceramic brick publishes upon impact sonorous soundand unburnt - deaf;

- large chips, cracks and bumps should not be on the surface. Building bricks with a spall depth of more than 6 mm are not suitable for use, and the facing brick should not have defects at all;

- small whitish calcareous inclusions may destroy brick in the future. They fall into it as an inclusion in clay, and if they were not sufficiently crushed, they become a hotbed of moisture absorption. Lime begins to increase in size and deform the brick;

- brick samples are best viewed not in the room, but on the street, it is advisable to generally see a sample of the use of the material (house, fence, facade, etc.)

- for facade cladding it is better to take a brick from one batch, since then it can be difficult to choose exactly the same shade;

- All important technical specifications are indicated in the product passport.

With such a variety of products and a huge number of possible areas of its use, it is difficult to derive the only correct formula for the ideal material and clearly answer the question of which brick is better to choose. The main thing is that the products should be of high quality and meet the declared characteristics, which largely depends on the honesty of the manufacturer (large companies value their name), and the necessary strength, fullness, color, shape and size can be easily determined independently, based on the purpose of use and the advice given.

Is it possible to use double hollow bricks for multi-storey residential buildings, for load-bearing walls.