5 tips for choosing a primer for walls

Flaking wallpaper, cracked paint or stucco, falling tiles - these are all problems that may be encountered by those who decided to save money and refuse from priming the walls. The application of the primer will not take much time and will not hit your pocket, but it will provide better grip finishing material with the wall surface, and in some cases even save the expense of materials for the finish coating. Not so long ago, a primer mixture was prepared by spreading glue with water, but now there are many ready-made products on sale that allow you to choose the optimal composition for any type of surface, finishing material and room conditions, for example, Knauf primer. We will determine which primer to choose for the walls in each particular case, and how not to make a mistake when buying.

No. 1. What is a primer for?

This question is asked by everyone who is engaged in repair, doubting that soil is generally necessary. So why do we need a primer and what does it consist of? The composition of primers includes film-forming polymer materials (resins, oils, glues), pigments, drying accelerators and various additives to give the necessary qualities. Primers do not have decorative properties, are used under finishing coating, but if necessary, can be tinted to simplify the process of applying the cladding.

Primers are available in the form of ready-to-use formulations or powders on the wall, which must be prepared according to the instructions. The composition may vary significantly depending on what surface the primer is intended for and what conditions will be in the room where it is used. Regardless of composition primer functions remain unchanged:

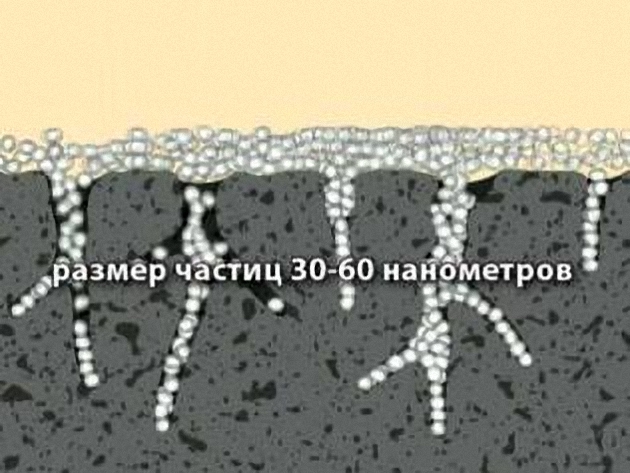

- surface hardening, therefore, for loose, porous, uneven and weak substrates, the use of a primer is strictly necessary. For the most fragile surfaces, primers of deep penetration are used, which are "climbed" into the thickness of the material by 8-10 cm, while conventional compounds penetrate only by 2-3 cm;

- improved adhesion with the finishing material, which is the main function of the primer. With its help, roughnesses are removed, and absorbent surface properties are reduced, What allow save material consumption for finishing up to 30%. Theoretically, some surfaces do not need priming, but in practice such a solution brings additional costs. On any surface that has undergone a primer treatment, paint, plaster, glue, mastic and others materials are easier to apply, lie better and are stronger;

- special substances that make up primers, increase the moisture resistance of the wallprotect against occurrence mold, fungus, rust.

Manufacturers today offer a huge variety of compounds that can confuse an unprepared person and make them buy not entirely suitable material from despair. To determine which primer is best to choose, you should clearly understand what surface will the composition be applied to, consider features of the room and type of future decoration material. On sale you can find special compounds for metal, wood, bricks, drywall or for places with high humidity. It is worth paying attention to the information indicated by the manufacturer, but it is better when you can double-check it, knowing the features of a particular composition, therefore it is worth studying the properties of the main types of primers before buying.

No. 2. Types of primers for walls by composition

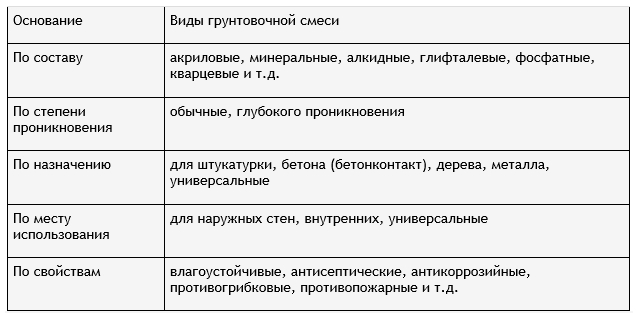

Depending on the characteristics of the composition, such main types of primers:

- acrylic primer - most universal compositionthat you can cover the tree with concrete, Chipboard, brick, old and fresh plaster. Acrylic primer can be used to treat porous substrates, it is odorless, dries quickly (about 5 hours), forms a “breathing” surface. The only negative is not suitable for priming metal surfaces;

- alkyd primer - ideal for processing wooden surfaceswhich, under the action of such a primer, acquire a slightly expanded structure, due to which excellent adhesion with any finishing materials: from wallpaper and painting to cement-sand coatings. One coat of such a primer dries for about 15 hours. Substances that inhibit corrosion and mold may be added to the composition;

- glyphtal primer - one of the few compounds that can be processed metal surfaces. It is also sometimes used for application on wooden walls. The primer dries up during the day, but has a limitation - it is suitable only for relatively dry rooms, as with constant exposure to high humidity it loses its properties;

- vinyl chloride primer - a universal composition with which it is possible to process wood, brick, plaster and even metal. It dries quickly, and in summer at high temperatures one layer dries in 1 hour. Inside the premises, this primer is not used due to its toxicity, but for external work she may come up;

- polyvinyl acetate primer consists of a polyvinyl acetate dispersion and latex, can be applied to any surface and is used only as a base under polyvinyl acetate paint. Dries quickly, up to 30 minutes;

- phenolic primer used as the first layer in the processing of metal and wooden structures. The composition dries up to 15 hours, is used to hold only outdoor work;

- polystyrene primer also cannot be used for internal work, it processes plastered and wooden surfaces;

- aluminum plasters, as a rule, they are used for processing wooden surfaces and can additionally protect them from damage by fungus;

- epoxy primers Suitable for metal and concrete. They protect metal from corrosion, and concrete allow better adhesion to the finish;

- shellac primers used for processing wooden surfaces and prevent the release of resins;

- mineral primers are based on gypsum, lime and cementused for surface treatment of concrete and brick walls. Such soil dries from 3 to 24 hours, which depends on the thickness of the layer and the nature of the surface material.

You can also find on sale universal primers. The very name of these compounds suggests that they can be used for application on any surface. They are used to carry out minor construction and repair work when the right composition with specific qualities was not at hand, and sometimes also for surface treatment, consisting of different materials.

No. 3. Properties and purpose of the primer

Depending on the room in which the primer will be used, for surface treatment, you can choose compositions with specific properties:

- deep penetration primer - an option for loose and not strong enough surfaces. The composition is able to perfectly strengthen such a wall and significantly reduce paint consumption.Often, such compounds are used to impregnate a surface finished with plaster, but this does not interfere with the use of a primer for applying to drywall, brick, foam concrete and aerated concrete. If necessary reliable primer for wallpaper, especially for their heavy species, you can safely opt for such compositions. It is not recommended to use a deep penetration primer for surface treatment with poor ability to absorb moisture;

- antiseptic primer for wet rooms (bathroom and kitchen) in the composition has special substances that prevent the appearance and development of the fungus, has water-repellent properties and can even reduce the ability to ignite the base. Such compositions provide such high adhesion that the surface of the material and finish adhere very strongly, and no microorganisms can seep into the joint. In the bathroom, it is recommended to apply a primer in three layers;

- anticorrosive compounds indispensable when processing metal surfaces, prevent the formation of rust, increase the service life;

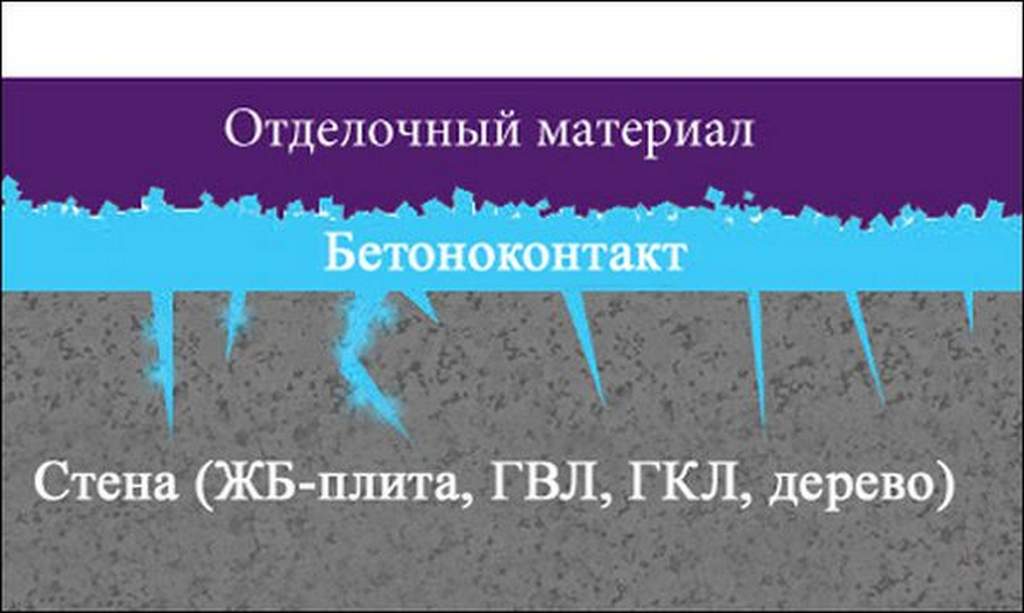

- adhesive compounds and non-contact primers use when it is important to achieve the maximum level of adhesion with a smooth and completely non-absorbing surface (concrete, previously painted walls). They include sand or needle quartz particles that increase adhesion. Such primers can be used to treat the substrate before sticking heavy wallpaper.

Manufacturers must indicate on the package what type of surface the primer is intended for, where it is recommended to be used, and what approximate material consumption will be for different types of surface. When choosing a primer, experts advise paying attention to the products of those manufacturers whose finishing materials you use - as a rule, the products of one company are perfectly combined.

Number 4. Top Primer Manufacturers

It is unlikely that one can argue that the primer from a major eminent manufacturer is of high quality. Buying a compound from a little-known company is always a risk: maybe you are lucky and the material will meet expectations, or maybe it will not have the declared properties or, worse, spoil the surface. If you do not want to risk the quality of repairs, it is better to go to the shelves with products immediately in the store well-known manufacturers of primers:

- Ceresit - A leader in the production of building mixtures, exists for more than 100 years and always focuses on advanced technologies, quality control and expanding the range. Due to the fact that today the company's factories are located in Russia, the cost of production was reduced without loss of quality. The assortment includes a primer and a primer-concentrate of deep penetration, a primer for absorbent mineral substrates, a primer for decorative plaster and a non-contact primer for processing smooth substrates;

- Knauf - A German company, exists since the 30s, has been represented on the domestic market since 1993. They pay great attention to innovation, continuous improvement and implementation of integrated solutions for repair work. The assortment is represented by primers of deep penetration, universal compositions for absorbent substrates, primers for cement plaster;

- Tikkurila - A Finnish company that has been operating since 1862. Factories are located in 7 countries of the world, they produce paints and other finishing and construction materials. Primers are represented by acrylic compositions, universal, waterproofing and adhesive compositions;

- Caparol - A brand known throughout the world. The history of the company began back in 1885 in Germany, and today its products are used in hundreds of countries. It produces primers for indoor and outdoor use, including frost-resistant and antiseptic compounds;

- Weber - A company that is now part of the Saint-Gobain group and produces construction mixtures under the Vetonit brand name. In assortment there are primers for external and internal works, if necessary they can be tinted;

- Ivsil - A domestic company, operating since 1997, has been constantly evolving and today has grown into a major manufacturer of building mixtures. Produces a universal primer and primer deep penetration;

- "Prospectors" - A domestic company, founded in 1992. At first only putties were produced here, then they began to establish the production of other mortars and mixes, improved formulations, purchased raw materials from leading manufacturers, introduced innovations, and now it is one of the largest Russian manufacturers of primers. The range includes universal compounds, primers for highly absorbent surfaces, and primer concrete contact.

No. 5. How to apply a primer?

The process of applying a primer is not more complicated than wall painting. Experts recommend priming the wall not only for the finishing material, but also before it alignment (by applying plaster or putties) Before applying a primer under the facing layer, make sure that the surface is even, smooth and has no noticeable defects.

For work, you need the selected primer, bath and tools for applying the composition: soft roller and brush for handling hard to reach places. Some use a spray gun, but its use is not always justified. The consumption of the composition depends on many factors and averages 100-200 ml per 1 m2. The main surface is treated with a roller, the corners and the most difficult places are primed with a brush. When the first layer has dried up, they begin to apply the second, if there is a need for it (when the wall structure is fragile). After the primer has completely dried, you can proceed to the finishing work.

It is not difficult to cope with the priming of the walls yourself, and when choosing a primer, carefully study the information indicated on the package: this will save you from a wrong purchase and tell you how to work with the composition correctly.

after primed walls is it possible to work in 4-5 days

Yes, the primer dries in a day or two.

What primer is better to use for an external slag-filling wall before its insulation with foam

A deep penetration primer is suitable for outdoor use. The composition will take a lot, but the event will allow you to well strengthen the surface. Good Primer - Knauf Grundirmittel

The porch is lined with natural stone, flagstone. Seams are covered with sand cement. I want to prime the surface to strengthen the sand cement, before coating the stone with alkyd varnish. Variants - either alkyd primer on wood, pinotex base or acrylic primer like Cerezit C 17. The first option is suitable for varnish based on white spirit, the second is suitable for the base. What to choose?

And if you try to use acrylic varnish for stone? It is also suitable for outdoor use. Then a primer ceres will do.

So you need to buy it) and I have two halons of fine American varnish

Hello. The wall is painted with Tex interior paint.Do I need special wall preparation before sticking ceramic tiles in the kitchen? Which primer is suitable? Thanks.

Should concrete contact be used under ceramic tiles on a poorly absorbing wall in the bathroom?

absorbent concrete wall