How to choose a countertop made of artificial stone: 7 useful tips

A universal option for arranging kitchens and bathrooms - countertops made of artificial stone. They are durable, practical, look great, can be integrated with the sink. The similarity of artificial stone to natural is striking, and the price difference is significant, so organizing a stylish and functional interior is becoming cheaper. How to choose an artificial stone countertop so that it meets all expectations and becomes a practical and durable decoration of the apartment? We deal with the main existing production technologies and the secrets of a successful purchase.

No. 1. The advantages of artificial stone countertops

The secret to the popularity of artificial stone countertops lies in their numerous benefits:

- high strength and the ability to withstand decent mechanical loads, which is important for the arrangement countertop in the kitchen;

- moisture resistance, hygiene, resistance to aggressive environments, temperature extremes and mold, therefore, artificial stone can be considered one of the best and most suitable materials for kitchens and bathrooms. Often, by the way, made of artificial stone bar counterstables in restaurants, fast foods and beauty salons;

- complete environmental Safety;

- durability;

- a huge variety of colors and shapes. The technology for the production of artificial stone allows you to simulate any natural rocks, and at the same time create countertops of any shape and size;

- cost, which in relation to natural stone is many times more affordable. In fairness, we note that it is impossible to call tabletops made of artificial stone cheap (although the variation in prices is sufficient), they are more expensive than their counterparts from MDF, steel, and even more so, particleboard. On the other hand, given the durability and unique performance, the price can be called more than justified.

Disadvantages this kind of countertops is small, and each technology for the production of artificial stone has its own. Acrylic stone, for example, does not respond very well to contact with hot objects, and quartz agglomerate cannot boast of good maintainability. These shortcomings seem completely insignificant in comparison with the ability to create an elegant interior that fully meets the requirements that are put forward to rooms with high humidity and temperature extremes. The artificial stone countertop is easy to care for, which is especially important for the kitchen: drops of grease, dirt, water and food debris will not eat up, leave traces, and you can wash the surface with almost any detergent, except for abrasive ones.

No. 2. Types of artificial stone for countertops

Artificial stone produce from mineral filler, polymer binder, dyes and modifying additives. Different technologies provide a different ratio of these components, the use of different types of filler and binder, hence the differences in the types of artificial stone from which tabletops are made today. The main ones are:

- acrylic stone;

- quartz agglomerate;

- polyester stone;

- cast marble.

The first two types of artificial stone have found the greatest distribution today: most of the countertops that are on the modern market are made of acrylic stone or agglomerate.

No. 3. Acrylic stone countertops

The technology for manufacturing acrylic stone appeared the first among all the currently known methods for the production of artificial stone. Composite material is made based on acrylic resins, mineral filler (stone chips, its share 60-70%), dye and aluminum hydroxide. All components are thoroughly mixed until a homogeneous viscous mixture is obtained, which is poured into a mold where the cooling and formation of the material takes place. The technology allows you to create countertops almost any shapes and sizes, but the advantages of acrylic stone do not end there. The pluses also include:

- the ability to create enough large seamless countertops, and this is, firstly, aesthetically pleasing, and, secondly, reliable, because moisture does not leak into the seam;

- high strength and impact resistance, and in these parameters, acrylic stone surpasses a number of natural analogues;

- absolute moisture resistance and impermeability to bacteria, which is explained by the lack of micropores in the structure of the material characteristic of natural stone. Acrylic stone can be used in rooms where it will be constantly in contact with water, suitable for use in public catering and medical facilities;

- ease of cleaning. Contamination can be washed with soapy water;

- pleasant to the touch and not cold surface. An acrylic stone worktop will not cause discomfort with its cold - it acquires an ambient temperature;

- high maintainability. Scratches on acrylic stone are easy to sand;

- wide variety of options. The countertop can be any color, repeat the texture of natural stones, have decorative inclusions.

There are acrylic stone worktops and some disadvantages:

- fear of very high temperatures. If you put a hot frying pan or pan just removed from the fire on the countertop, then a trace will remain on the surface - to ensure the safety of the original appearance of the countertop, it is better to use special hot stands;

- from washing with abrasive products and moving dishes may form scratches. However, it is not difficult to get rid of them by grinding.

The technology for the production of acrylic stone in 1968 was patented by the company Dupont, which produced the product under the brand name "Korian". For a long time, only she could produce acrylic stone, but after the patent expired, other companies also got access to the technology, therefore, the production of acrylic stone is now established in many countries. In Moscow, products from artificial stone are offered by Enot`s Stone, which has its own production and uses raw materials from large trusted suppliers, which allows it to provide customers with the best prices and a 5-year warranty, as well as offer exclusive countertops made on an individual order.

Number 4. Agglomerate quartz countertops

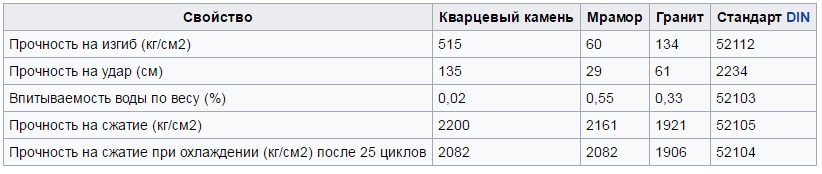

Quartz agglomerate even more resembles a natural stone, but at the same time significantly surpasses it in basic physical properties (see table). The material is based on a mineral filler, which is often used as crumbs and even pieces of natural quartz, less often marble or granite. Mass fraction of mineral filler in the total mixture is 91-93%, which explains the unique properties of the material. As a binder use polyester resins, also coloring pigments are added to the mixture.

The advantages of quartz agglomerate countertops:

- the highest strength and impact resistance. It is safe to say that such a countertop will withstand any load and will serve faithfully for a very long time;

- water resistant, because the material also lacks micropores. Mold will not start on it;

- resistance to temperature extremes and ability to withstand very high temperatures, therefore, hot dishes on such a countertop can be placed without using any supports and without fear of damaging the surface;

- resistance to washing with aggressive detergents, incl. with abrasive particles - it is very difficult to leave scratches on a quartz agglomerate, so you can not stand on ceremony with the surface;

- a great appearance and a wide variety of different options. Such countertops are as similar to natural stone as possible.

Minuses:

- the technology provides for the creation of quartz agglomerate slabs with a length of not more than 3 m, therefore, if the countertop parameters are greater, no seams to do. On the other hand, they close up very well, and they will be almost invisible;

- quartz agglomerate impossible to restore;

- the surface of the material is cold. On the one hand, this allows you to create the maximum resemblance to natural stone, but a cold surface is not always comfortable.

No. 5. Countertops made of polyester stone and cast marble

Polyester stone and cast marble much less commonly used in the manufacture of countertops, but since some manufacturers still have similar offers in their assortment, let us dwell on the basic properties of these materials.

Polyester stone they are produced according to technology similar to acrylic stone, only polyester is used instead of acrylic resins. They are cheaper, which allows you to get much more affordable countertops. In terms of strength, durability and moisture resistance it is impossible to find fault with them, but there are some nuances that explain the reduced demand for material. Firstly, a specific smell emanates from it, however, with time it disappears. Secondly, the features of production do not allow the creation of bent forms, therefore, countertops are obtained only in traditional strictly sealed forms.

Cast marble produced on the basis of marble chips (about 80% of the total mass), polyester resins and pigments. The material significantly exceeds the strength and moisture resistance of natural marble, looks great, can be used in kitchens and bathrooms as countertops.

No. 6. Parameters of Artificial Stone Countertops

The first thing you should pay attention to when choosing is countertop thickness. Acrylic stone is usually glued to the frame, which is used as plywood (the best option), MDF or chipboard. It is important that the frame is strong and strong, and the bonding quality is reliable. The thickness of the stone itself can fluctuate from 3 to 12 mm and more, but this does not affect the performance of the countertop. Thickness affects how many times you can grind its surface, which means it is directly related to durability. If you are not a fan frequent repairs and global change of scenery, it is best to choose a thicker countertop.

Quartz agglomerate usually does not have a substrate, which positively affects its operation, because for rooms such as the kitchen and bathroom, the absence of a moisture-resistant substrate means less problems. If the agglomerate countertop is without a substrate, then it will weigh more, and the more weight, the more difficult the transportation and the greater the load on the supporting elements. By the way, some manufacturers offer gluing to the countertop 1-1.5 cm thick (the most common option) a side with a larger thickness, but this is purely for the visual effect.

It is worth remembering that installing a countertop made of quartz agglomerate, which involves gluing several parts and processing joints, will cost more than installing a similar acrylic stone countertop.On the other hand, the cost of acrylic stone countertops is higher, and their color palette is wider. It is possible to create countertops of more complex shapes from acrylic stone.

Width countertops corresponds to the depth of the cabinet on which it will be installed. For kitchens, the standard is considered to be 60 cm, in bathrooms this parameter can vary significantly. Sometimes the width of the countertop may exceed the depth of the cabinet, but this is in cases where it is necessary that it protrudes slightly.

Number 7. What else to consider when choosing?

Acrylic stone countertops may scratch and are best seen on a dark surface. If you do not want to make frequent repairs, give preference light shades and non-gloss surfaces, and it is desirable that the material has small inclusions, since on a plain surface all scratches and dirt can be seen much better. Also, light countertop suitable for decoration small rooms. There are countertops with a large number of inclusions: they are the least visible damage, so this is ideal for arranging a kitchen where a lot of cook.

Color of artificial stone can be almost anything, and in addition to the classic light and dark shades, you can also find bright countertops, which will become an integral part modern interiors. When choosing the color of the countertops, one should be guided not only by the size of the room, but also by the color of other pieces of furniture, including kitchen unit or cupboards under the sinkwhen it comes to the bathroom. If furniture facade white, then the countertop can be black, light and even bright - here the greatest scope for imagination. For beige furniture facades, worktops in warm saturated shades are perfect, for facades of black color and “wood-like” you can choose white and light worktops.

Finally, we note that if the design idea involves the use of large bent-shaped countertops, it is better to give preference to acrylic stone, which will allow installation without seams. An artificial stone countertop is a durable product that, with minimal care, will serve faithfully for many years.