9 tips for choosing a manipulator: rent or purchase

Cranes-cranes are a kind of hybrid of cargo vehicles and familiar truck cranes. With their help, you can perform a wide range of installation, excavation and construction works. Such a versatile technique is very expensive, and to manage it you need to hire specially trained people. In some cases, these expenses are more than paid off, but sometimes it's easier to just rent equipment with the necessary characteristics. What is more profitable, buying or renting, and what must be taken into account when choosing a manipulator?

No. 1. What functions are assigned to the manipulator?

Modern manipulators, which are a truck with a crane installation, are used in construction, agriculture and utilities, freight. Using the manipulator, you can perform the following tasks:

- loading, unloading and transportation of various goods (building materials, industrial equipment, containers, cars, change houses, machines, bulk materials, etc.);

- lifting goods to a height;

- lifting workers to a height if the manipulator is equipped with a cradle;

- installation of structures (using a vacuum suction cup, you can safely install double-glazed windows);

- drilling of wells, if the manipulator is equipped with auger drill.

No. 2. The nuances of renting and buying a manipulator

The answer to the question which is better, renting or buying a manipulatorworth looking in the field of the company. Simple calculations will help to understand what is more profitable: buy a manipulator of a certain model with clearly necessary parameters, provide it with proper maintenance, regularly refuel and pay to a qualified crane driver, or pay for the rental time and not know the hassle of servicing. At first glance, it might seem that the second option is much simpler and easier, and in most cases this is really so.

Many medium-sized business owners conclude that it’s better to take manipulator for rent, especially if you need a similar technique only from case to case, and sometimes manipulators with completely different parameters are needed. Even in Moscow, renting a manipulator will cost inexpensively, and serious companies offer a decent fleet of equipment of domestic and European production to choose from, carrying out its timely maintenance and repair. The rental period can be any, and the price already, as a rule, includes the remuneration of the driver.

The purchase is justified in the event that the company specializes in strictly defined types of work, and a substantial part is assigned to the manipulator. Of course, a transport or large construction company is unlikely to rent such equipment. Of course, you will have to look after the manipulator, but it will always be available at the facility.

The quality of the work performed will directly depend on the correct choice of the manipulator, whether it is bought or rented. Its characteristics will greatly depend on the type of work performed and the specifics of the area.Companies that sell or rent manipulator cranes for rent can give tips and give useful advice, but this does not eliminate the need to know the purpose of various crane manipulation equipment.

Definitely necessary determine the volume of cargo, type and mass will be transported, which directly depends on parameters such as load capacity, body volume, manipulator type, boom reach and its load capacity. The type of chassis, manipulator and boom characteristics depend on the specifics of the area where the work will be carried out.

No. 3. Types of manipulators: crane and hydraulic manipulator

Under the general name of manipulators usually mean such devices:

- crane arm;

- hydraulic manipulator;

They differ in their scope, load capacity and cycle time.

Hydraulic manipulators They work with hydraulic tools, are equipped, as a rule, with an L-shaped boom and are used to perform work with high intensity, for example, for overloading logs or scrap metal. Such installations are subject to increased reliability requirements, since the working cycle time is short and the operations are uniform. The installation is usually mounted behind the cab, sometimes closer to the rear of the truck. Not so long ago, hydraulic manipulators began to appear in which the boom has a reverse Z-shaped folding scheme, but the scope of such devices is limited.

Truck mounted cranes in the classic version they do not have a hydraulic drive and transport goods using a hook suspension. Like technique use less intensively, usually for loading and subsequent transportation to the object. Such manipulators have a higher carrying capacity and a longer working cycle time, which is what distinguishes them from hydraulic manipulators. Truck mounted cranes are more popular.

Number 4. Type of crane arm

One of the fundamentally important characteristics of the crane is the type of boom, or rather the type of its folding. There are two main options:

- Z-shaped, or an arrow without a winch. It has an articulated design that folds in a Z-shaped way. It has a higher carrying capacity and range, is easy to operate, reliable, compact and can bypass some obstacles. The hook attaches to the end of the boom end section. Sections can rotate and change the angle, but the angle of inclination is limited, and there are certain dead zones;

- L-shaped, or an arrow with a winch, to which the hook is attached. Among the advantages are the ability to move the load at any angle, use high sides, lower the load below the base of the frame, as well as complete control over the speed of rotation and the position of the load. Of the minuses, bulkyness and the need to often change the winch cable are noted.

Today you can also find manipulators in which the boom combines the advantages of both types, which is achieved through the use of articulated joints in the first two sections and telescoping of the remaining sections from the second.

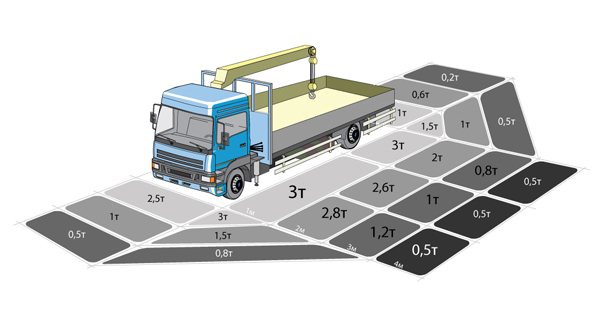

No. 5. Boom reach and load

Departure and carrying capacity of the boom, as well as the loading capacity of the sides, are selected depending on the type of cargo transported. All these characteristics are interconnected.. Note that the crane still inferior to full-fledged truck cranes in terms of capabilities, and its load capacity is usually lower, but progress does not stand still, and on the roads you can see impressive sizes of manipulators that are already almost the length of the boom and the total load capacity step on the heels of truck cranes.

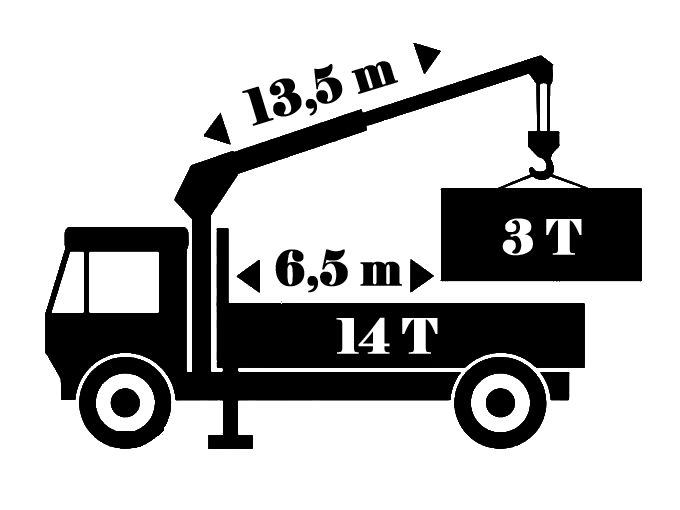

The higher the load capacity of the device, the higher its price both when buying and when renting. As a rule, the loading capacity of the sides and the boom are in direct proportion to each other.. Boom capacity varies widely, from 2 to 10 tons, and her length may be from 6-7 to 23 m, but manipulators are most popular in the domestic space with a departure of an arrow of 8-12 m. It is advisable that the boom be at least 1-2 m longer than the body, but this advice is not always true. For example, if the car body is long, and it is planned to transport long pipes, then it is enough that the arrow reaches at least the middle of the body.

Take into account that the farther the load is from the manipulator, the lower the load capacity of the boom. In other words, you should not expect that a manipulator with a boom lifting capacity of 8 tons will be able to lift a load of 8 tons at full reach. The crane can handle the maximum weight when the load is located very close to it. This must be taken into account when choosing a manipulator.

To assess the actual capacity of the boom of the manipulator, use the concept freight moment. This is the product of the mass of the cargo and the length of the boom at which this load can be raised, measured in tons per meter. For example, if during the work you have to lift a load weighing 3 tons, which will be located at a distance of 4 m from the manipulator, then the load moment should be 12 t.m. But here one should not forget about common sense: if the load moment is 16 tons, this does not mean that it will be possible to lift a load of 16 tons located at a distance of 1 m - it is unlikely that such a compact and heavy object can be found.

As for loading capacity, then manipulators are usually divided into:

- small tonnage (1-3 tons);

- medium tonnage (5-10 t);

- heavy (more than 10 tons).

Better to choose a manipulator with low margin, which will extend its life and become a safety net in case of errors in the calculations for the mass and dimensions of the cargo. The length and height of the sides are selected depending on what will be transported.

No. 6. Arrow Cross Section Shape

Boom profile may be rectangular, five-, six- or octagonal. In theory, the more faces, the better, because then the voltage will be distributed more uniformly along the profile, and the boom will be more reliable and more durable in operation. On the other hand, the more complex the profile, the more expensive the arrow and the entire manipulator. For devices with low load capacity, a rectangular profile will be sufficient.

Number 7. Manipulator rotation angle

The angle of rotation of the manipulator is determined by the type of construction, but, as a rule, is 360 degrees, i.e. full circle. In practice, it is limited, since the area above the cabin is considered unstable, and if the manipulator brings a heavy load there, then the machine may roll over. Usually in manufacturer's instructions hazardous areas indicated, and the rotation angle can be limited mechanically or electronically.

The manipulator can have manual control of levers, manual control from the platform, from a chair on the column of the manipulator or remote control.

Number 8. Choosing a car chassis

Depending on the conditions under which the manipulator will work, the basis for it can serve:

- on-board vehicle;

- truck tractor;

- tractor;

- trailer.

The first two options are the most common. Experts advise that the weight of the manipulator should be no more than 20-25% of the carrying capacity of the chassis, which is true when goods will be transported using similar equipment. If the crane is used as an analogue of a truck crane and serves simply for lifting goods, then the mass of equipment can take away almost the entire load capacity of the base.

No. 9. Manipulator Manufacturers

On domestic open spaces manipulators are often used today. Korean madewho have proven themselves to be a great choice, with normal prices and good quality. Japanese manipulators are much more expensive, but they are considered one of the best in quality of performance and functionality. Main plus Russian technology - maintainability, since spare parts can be obtained without problems, so if you are considering the purchase of a manipulator, then you should pay attention to domestic products. On the other hand, those who rent a manipulator do not want to waste time and wait until they find the necessary part for repair, so the availability of spare parts for the manipulator becomes another important issue when choosing. Chinese manipulators, for example, are not very expensive, but consumables will not be easy to find. Equipment European and American production high-quality, expensive and presented in our small assortment.

As for the specific names of manufacturers, it is worth highlighting such large companies that produce manipulators:

- Palfinger - Austrian company operating since 1931. In Europe today, every third manipulator relates to the production of this company; they are also represented in Russia;

- Unic - A major Japanese manufacturer, exports products to 120 countries. In Russia, for a long time, all manipulators were called "Yuniks" regardless of the name of the manufacturer;

- Tadano - Another Japanese company whose products are widely represented in the domestic market;

- Fassi - Italian-made manipulators, characterized by high performance and safety;

- Kanglim - A Korean company, whose significant advantage is the low prices of high-capacity manipulators compared to competitors' proposals;

- Hiab - A large Swedish company whose products are characterized by consistently high quality and performance;

- Velmash - A leading domestic manufacturer of mobile lifting equipment, admits, among other things, cranes;

- BAKM (Balashikhinsky automobile cranes and manipulators) has been operating since 1948 and has recently been manufacturing cranes with manipulators with a load moment of 4.6-21 tons.

In conclusion

For efficient and quick execution of the planned work, it is necessary to choose a manipulator with the characteristics completely corresponding to the task, but in rent or ownership is a matter of regular use of the manipulator. Here we could talk about another possibility of acquiring a manipulator - used purchase, but since we use a similar technique, which is called, until the end, the market for used manipulators has not yet formed.

CMU is really convenient. But if the work in which the crane is involved is a one-time operation or is rarely carried out, then it is economically more profitable to rent a CMU with a driver.