10 tips for choosing a sealant: types, types, properties and applications

Replacing a sink in the kitchen, installing a faucet, bathtub, door and window frames is not complete without the use of sealants. These are special compositions based on polymers that can reliably fill gaps, cracks and voids, isolating them from external negative effects. Since there are a lot of uses for such substances, formulations have been developed that are optimally suited to particular conditions. Before going to the store and buying, it does not hurt to decide which sealant to choose, and what types of sealants generally exist. So you protect yourself from the advice of consultants that is not always correct and beneficial for you.

No. 1. Types of sealants

Sealants are a whole group of materials that are polymer-based compounds that have a pasty, viscous, or ribbon consistency and are designed to protect and waterproofing joints. The remaining properties are highly dependent on composition. Sealants are used for sealing joints between plumbing products and the wall, during installation windows and doors, for closing cracks between logs, concrete and reinforced concrete structures - and this is far from all areas of application.

Sealants can be divided into:

- one-component;

- with two or more components.

One component formulations more convenient, as they are immediately ready for use, and sealants with several components will first require mixing all the components in the required proportions.

According to the type of hardening, sealants are divided into:

- drying formulations acquire the necessary properties only after the water or solvent has evaporated. Differ in significant shrinkage;

- curing compounds acquire a working state under the influence of moisture or air, or, if it is a multicomponent composition, after mixing all the components. From a pasty mass such compounds become like rubber;

- non-hardening compounds made in the form of mastics, outwardly similar to plasticine.

Most important is chemical classification:

No. 2. Acrylic sealants: properties and scope

Acrylic sealants are a mixture of acrylate polymers used mainly for internal work. Can be painted acrylic paints or varnishes in any color.

Acrylic sealants are:

- non-water resistant. They are odorless, have complete environmental safety, hardly tolerate deformation, therefore they are best used on surfaces that are not subject to thermal expansion. It is applied at repair of furniture, window framesas well as when working with dry walls from drywall and concrete. Moisture on such compounds will lead to rapid damage to the sealant;

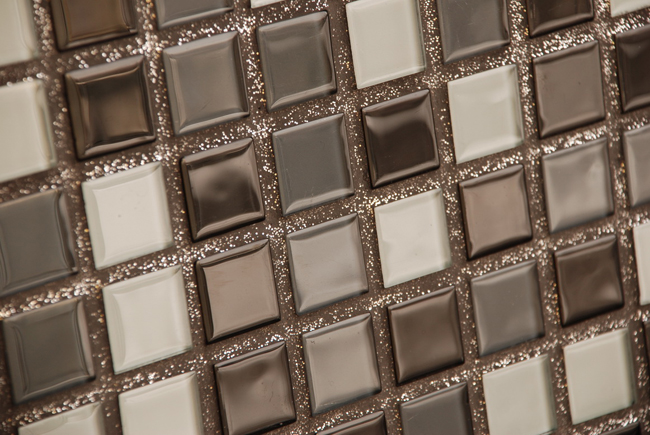

- waterproof compounds have high adhesion to almost all types of surfaces, including brickconcrete, tile, PVC and drywall. Can be used in bathrooms and kitchens, but not in basins. If sealant will be used in the bathroom, it is desirable that in the composition were antifungal components.

All types of acrylic sealants are characteristic such benefits:

- good adhesion with brick, concrete, stucco, wood, tile and other surfaces;

- ability to maintain initial properties in a wide temperature range (from -20 to +600FROM);

- environmental friendliness and the absence of harmful fumes, so you can work with such sealants without personal protective equipment;

- resistance to ultraviolet rays;

- simplicity of work;

- price. It costs 1.5-2 times lower than silicone sealants. The most expensive are transparent acrylic sealants.

disadvantages:

- with prolonged exposure to low temperatures, elasticity is lost;

- Acrylic sealants are inferior to their peers in terms of moisture resistance, therefore it is better to choose other compounds for rooms with a steadily increased humidity level.

Acrylic sealants, as a rule, are sold in tubes of 300-500 ml, applied directly from the tube or using a special gun. Already 15 minutes after application they form a film, and finally freeze after 24 hours.

Scope of application: filling joints and cracks in stone and concrete surfaces, boards, window and door frames, filling voids around communication pipes, sealing joints in bathrooms and kitchensless often in bathrooms.

No. 3. Silicone Sealants

Siliconized sealants largely repeat the properties of acrylic, but due to the presence of silicone, they are more durable, flexible and resistant to temperature extremes. In addition, they are more resistant to moisture, can be used even for outdoor use.

Siliconized sealants largely repeat the properties of acrylic, but due to the presence of silicone, they are more durable, flexible and resistant to temperature extremes. In addition, they are more resistant to moisture, can be used even for outdoor use.

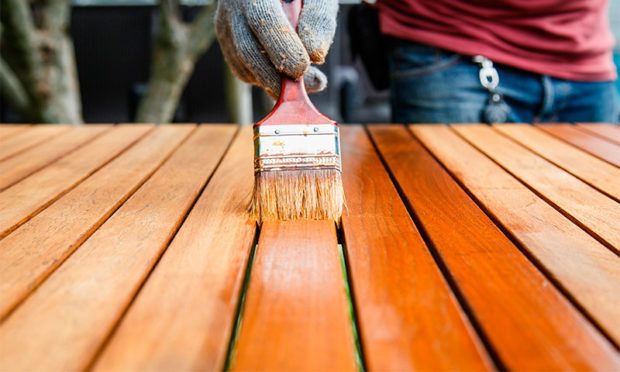

The compositions have good adhesion to wood, plaster, particleboard, glass, can also be used to seal window and door frames. After drying, they, like acrylic sealants, can be coated with paints, they are usually used oil and latex formulations.

Number 4. Silicone sealants: types and properties

Silicone sealants are universal compoundsthat can be used in external and internal works, have excellent adhesion to almost all materials. In terms of performance, silicone sealant can be called a leader among analogues. The basis of such compositions is an organosilicon polymer (silicone rubber, up to 45%). Also may include dyesthat give the sealant a specific shade fungicidesimpeding development mold, and mechanical fillersthat contribute to better adhesion to different types of surfaces. Organic extenders that reduce the viscosity of silicone are often included in the composition.

Silicone sealants are divided into:

- single component. Cured by air moisture. It is these compounds that are used in domestic conditions;

- two-component. The basis of such sealants is cured under the influence of special compositions when mixed. Found application in the industry.

One-component silicone sealants, depending on the chemical composition, are divided into the following groups:

- acidic. The composition contains acetic acid, as evidenced by the characteristic odor that is released during hardening. Acidic silicone sealants can be used for wood, plastic, and ceramic products, but not suitable for processing metal, glass, marble, granite and cement compositions. In most non-ferrous metals, such a sealant causes accelerated corrosion rates. The main advantage is a lower price;

- neutral sealants instead of acetic acid, they contain alcohol or ketoxime, which ensures the universality of their use. They can be used both for working with metal surfaces and with sanitary ceramics;

- alkaline sealants, produced on the basis of amines, are used infrequently in everyday life and relate to special materials.

All types of silicone sealants are characterized by such advantages:

- high elasticity, which allows the use of similar compositions for sealing movable joints. The sealant will not collapse under the influence of mechanical vibrations;

- tensile strength;

- wide range of operating temperatures (from -50 to +2000FROM);

- adhesion to the mass of materials (wood, ceramics, metal, glass, concrete, plastic, etc.);

- resistance to negative environmental influences. Silicone sealant perfectly tolerates the effects of ultraviolet radiation, high humidity, temperature extremes and aggressive environments;

- safety for health. Since there are no harmful fumes, it is possible to apply sealant without special protective agents;

- durability, service life of 15-20 years.

disadvantages:

- seams created with silicone sealant cannot be painted, but manufacturers offer compositions with ready-made shades, the range is sufficient;

- acid compounds cause corrosion of metals, but there is only one way out - use neutral compounds to work with metal surfaces;

- poor adhesion to the old layer of silicone sealant, so it will have to be dismantled, which can cause some difficulties.

Silicone sealants are used for indoor and outdoor use. Can be used when installing doors, window frames, metal structures. Plumbing Silicone Sealant indispensable for sealing baths and showerssealing threaded water connections. Special adhesive sealant can be used to work with glass products. Silicone compounds provide a high level of tightness against odors, water and noise.

Using such a sealant is no more difficult than using acrylic. The surface must be clean, dry and fat free. The composition is applied using special pistols, it sets in 30 minutes, hardens in 24 hours. Wipe excess off the surface with a damp cloth, and wash it off with soap and water.

It is not easy to remove the old silicone sealant: you will either have to gradually cut it with a sharp knife, or use special chemicals that dissolve the sealant.

No. 5. Polyurethane Sealants: Benefits and Uses

Polyurethane sealants are very flexible and resistant to deformation, therefore they are often used to seal the foundation and the roof. May be one-component and two-component. The latter are used primarily in industry.

The main advantages:

- high elasticity and ability to withstand significant deformations;

- excellent adhesion to materials such as reinforced concrete, aluminum, wood, stone, ceramics, plastic. The composition glues the surfaces so firmly that even an earthquake of 5 points will not destroy the seam;

- resistance to moisture, temperature extremes, ultraviolet, corrosion;

- composition withstands temperatures from -60 to +800C, it can be applied in cold weather -100FROM;

- durability. Service life is 20 years or more;

- the possibility of staining the frozen seam.

Minuses:

- when applied, emits corrosive toxic substances, therefore, when working with such a sealant, safety measures must be observed;

- insufficient resistance to high temperatures (above +1200FROM).

Polyurethane sealants harden under the influence of water, quickly set, but you can talk about complete solidification only after 7-10 hours. Apply the composition from a tube or when using a gun, it does not drain from vertical surfaces, gives zero shrinkage.

No. 6. Bituminous and rubber sealants

Bitumen sealant - this is a paste-like material made on the basis of a modified bitumen binder with the addition of special fillers that provide resistance to negative environmental factors.Rubber compositions are prepared on the basis of synthetic rubber

Bituminous and rubber sealants are indispensable when carrying out roofing worksare used for mounting roofing material and other bitumen coatings, for fixing polystyrene foam, polyurethane and other insulating materials are also used to repair cracks in the foundation and drainage system. In addition, both compounds can be used to seal joints in rooms with high humidity and even to repair rubber products.

In most properties, these two types of sealants are similar, which gives the right to talk about common the benefits:

high elasticity;

high elasticity;- resistance to high humidity, sun rays, mechanical damage;

- high adhesive properties, which allow not to clean the initial surface before applying a layer of sealant;

- simplicity in work.

Minuses:

- it is impossible to carry out work on applying sealant at subzero temperatures;

- Bituminous sealant cannot be painted, but rubber can be painted.

Number 7. Butyl rubber sealants

Butyl rubber sealants are obtained by copolymerization of isoprene and isobutylene. As a result, an uncured material is formed, supplied in the form of mounting tapes and gaskets of various thicknesses and widths. Such tapes are used in the installation of subroofing materials, for sealing interpanel seams, as well as in the installation of roof windows.

Benefits:

- elasticity that does not get lost over time;

- adhesion to concrete, metal, wood, glass, plastics;

- wide range of operating temperatures, from -45 to +1500FROM;

- the ability to repeat the deformation distortion of roofing materials.

disadvantages:

Number 8. Thiokol Sealants

Thiokol (polysulfide) sealants are considered one of the most durable, durable and expensive formulations. Typically, such sealants consist of 2-3 components (base, curing paste and vulcanization accelerator), which are mixed in predetermined proportions before use. The resulting composition must be used within two hours, complete solidification occurs from several hours to a couple of days.

Benefits:

- high elasticity;

- highest resistance to aggressive substances, gasoline, kerosene, oils, which allows the use of sealant in garages, gas stations, laboratories, etc .;

- resistance to precipitation, UV rays, as well as to a wide range of temperatures (from -50 to +1300FROM);

- high adhesion to concrete, reinforced concrete and metal, which makes it possible to use sealant in the repair of metal roofs;

- durability.

disadvantages:

- high price;

- the need to use protective equipment when working;

- the need to perform all work on applying sealant is very quick.

No. 9. What must be considered when choosing a sealant?

Naturally, before you go to the store, you must clearly understand where and under what conditions the sealant will be used. If this is a bath, then a moisture-proof composition is necessary, if there is a wooden floor, then the sealant must be flexible and not contain solvents. Moreover, Pay attention to what is indicated on the package:

- area of application of the composition (external or internal work);

- type of work performed (roofing, window, plumbing, etc.);

- the manufacturer must indicate for what types of surfaces the sealant is intended, as well as whether it is elastic or not;

- color composition. If the sealant cannot be painted or simply will not be painted, its color is important so that aesthetics do not suffer;

- sealants can be household and professional, the latter are more difficult to use;

- pay attention to the indicated operating temperatures of the composition, comparing them with the existing climate features in the region.

No. 10. Sealant manufacturers

Manufacturer Name - sealant quality guarantee.To be 100% sure of the high quality of the purchased composition, trust the products of large companies. Very well established sealants of such manufacturers:

Ceresit - A true giant in the field of construction materials, part of Henkel Corporation. Among other things, it produces silicone and acrylic sealants. The highest quality;

Ceresit - A true giant in the field of construction materials, part of Henkel Corporation. Among other things, it produces silicone and acrylic sealants. The highest quality;- "Moment" - One of the trademarks of the German corporation Henkel, whose plants are located in 70 countries, and products are sold in 125 countries. Under the trademark "Moment" in the domestic market are silicone, polyurethane, acrylic and bitumen sealants in a wide range;

- CIKI FIX - Turkish company producing silicone sealants. Decent quality, reasonable prices;

- Belinka belles - Slovenian manufacturer specializing in the manufacture of paints and protective coatings for wood, but the range also includes silicone sealants;

Selena - an international corporation with Polish capital. The group includes 30 companies around the world; a wide range of products is produced. Sealants are manufactured under the TYTAN trademark, specialized professional compounds, silicone, acrylic, bituminous and rubber sealants are offered;

Selena - an international corporation with Polish capital. The group includes 30 companies around the world; a wide range of products is produced. Sealants are manufactured under the TYTAN trademark, specialized professional compounds, silicone, acrylic, bituminous and rubber sealants are offered;- Krass - A group of companies whose factories are located in the Netherlands, Switzerland and Poland. Among the sealants are silicone, siliconized and acrylic compounds.

Carefully study the descriptions from the manufacturer on the packaging - it is worth spending a little time studying all the characteristics in order to avoid unnecessary expenses and unnecessary purchases or, even worse, a bad result.

high elasticity;

high elasticity;