5 tips for grouting tiles

Process laying ceramic tiles quite laborious and complicated, but even if all the work was carried out flawlessly, it’s too early to talk about the result, because the final stage is ahead grouting, or jointing. Grouting takes on a ton of functions and sometimes allows you to not only achieve a complete and harmonious appearance of the tiled surface, but also significantly transform it or even mask laying defects. All this is quite possible if you know which grout for the tile to choose and what to look for in the store.

No. 1. The main functions and types of grout

Grouting is as much a must when laying karmic tiles as door handle- It’s completely impossible to do without it, but they are assigned to the grout immediately several functions:

- protection of tile joints from moisture and dirt;

- development prevention mold;

- reinforcement of masonry;

- improving the appearance of the masonry and giving it an additional decorative effect, because often the successfully selected grout color is able to transform the tiled section of the wall or floor.

Currently the most popular such trowels:

- cement based - the cheapest and most popular grouts, characterized by simplicity in operation;

- epoxy based - These are already more durable grouts that perfectly tolerate any negative effects, but their application requires great skill.

To grouts are sometimes referred silicone sealants, which are sometimes called even silicone grout, although this is not true if only because the joints between the tiles are not treated with such compounds - they designed for insulation of masonry from bathtubs, sinks, toilet bowl and other surrounding objects. Over time, such a sealant under the influence of moisture begins to darken and become covered with a fungus, therefore, experts recommend using instead of humidity silicone sealant epoxy grout.

Also for grouting can be used furan mixtures, but due to their dark, almost black color, they are almost never used in apartments, but they have found application in industrial premises.

No. 2. Cement grout: properties and application

Even the most experienced builder will be able to prepare cement grout and apply it to tile seams, which is the main reason for its popularity. IN cement grout composition includes Portland cement, colored pigments, as well as various plasticizers and other additives to give specific qualities. When water or water-based latex is added, the grouting powder turns into a very plastic material resembling putty. Latex plasticizer also allows you to change the color of the grout after drying in a more saturated direction.

Depending on the type of tile joints, slightly different compositions:

- for narrow seams thickness up to 5 mm use grouts, the composition of which is indicated above;

- for wide seams (more than 5 mm) use grouts with sand, which will help to keep the composition in a given shape and will not allow it to spread excessively.The wider the seam, the larger fractions of sand should be added, but note that large grains of sand can scratch the tiles when grouting, so work will have to be carried out with extreme caution.

A wide range of cement grouts are presented in the store, and can be sold:

- as a ready-to-use grout;

- in the form of a dry powder, which is pre-diluted with water.

Main advantage finished compounds - the ability to use them immediately after purchase and not waste time mixing powder with water. Such compounds are sold in plastic buckets, and after opening the lid, it is better to use the grout all at once, otherwise it will dry out.

Much more practical to use are dry powders. To get the grout, the composition must be filled with the amount of water or latex specified in the instructions, and if you need a small amount of fugue, you can prepare it without problems - the rest of the powder in a dry room can be stored for a long time.

The main advantages of cement grouts:

- cheapness;

- simplicity in preparation and use;

- good strength;

- maintainability. Over time, small cracks will appear in the seams, which are filled with dirt, and scrub her already impossible. In this case, remove the old grout with a spatula or screwdriver, and the seams are overwritten again - such an update will cost inexpensively.

Cons of cement grout:

- lack of moisture resistance;

- low resistance to household chemicals.

In view of these shortcomings, in particularly humid places, it is still recommended to use epoxy grout, the main competitor of cement compositions.

In view of these shortcomings, in particularly humid places, it is still recommended to use epoxy grout, the main competitor of cement compositions.

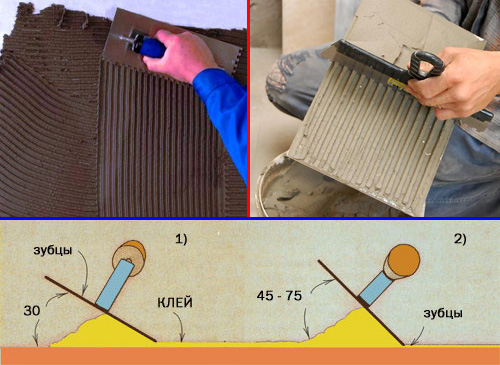

You can proceed to grouting only after tile adhesive completely dry. A prepared solution with a spatula is applied to the seams and carefully leveled and compacted. Surplus on the tile can be carefully removed first with a spatula, and then with a damp cloth. There is nothing complicated in this process.

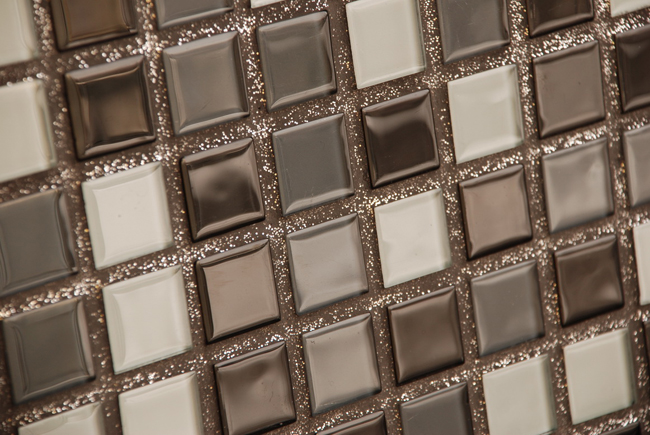

No. 3. Epoxy grouts: advantages and features

Part epoxy grouting includes epoxy resins, modifying additives, a filler (usually quartz sand of different fractions), as well as a hardener. It is indispensable in those conditions that can become a real test for cement grout: poolsbaths, laboratories, kitchen apron and other places where the tiles are exposed to high humidity and aggressive chemicals can get into it.

The benefits of epoxy grout:

- highest strength and ability to withstand the influence of any negative factors;

- durability. The color, strength and other high performance qualities of the joints will be unchanged for 40-50 years;

- high level of resistance to mold, fungal infections, pollution;

- waterproof and resistant to detergents;

- excellent decorative qualities. Epoxy grout can be of almost any shade, and sometimes even shiny elements are added to the composition, so the seams made with such a fugue become the decoration of the tile masonry.

The disadvantages of epoxy grout:

- the complexity of the work, which is explained by too viscous consistency, so even for professionals working with such formulations requires a decent investment of time and effort. Everything is complicated by the fact that if such a grout gets on the tile, it will be difficult to clean it. Today, for a more accurate and simple application of epoxy grout, special bags are used that resemble confectionery bags, with their help the composition is squeezed exactly into the seam;

- high price.

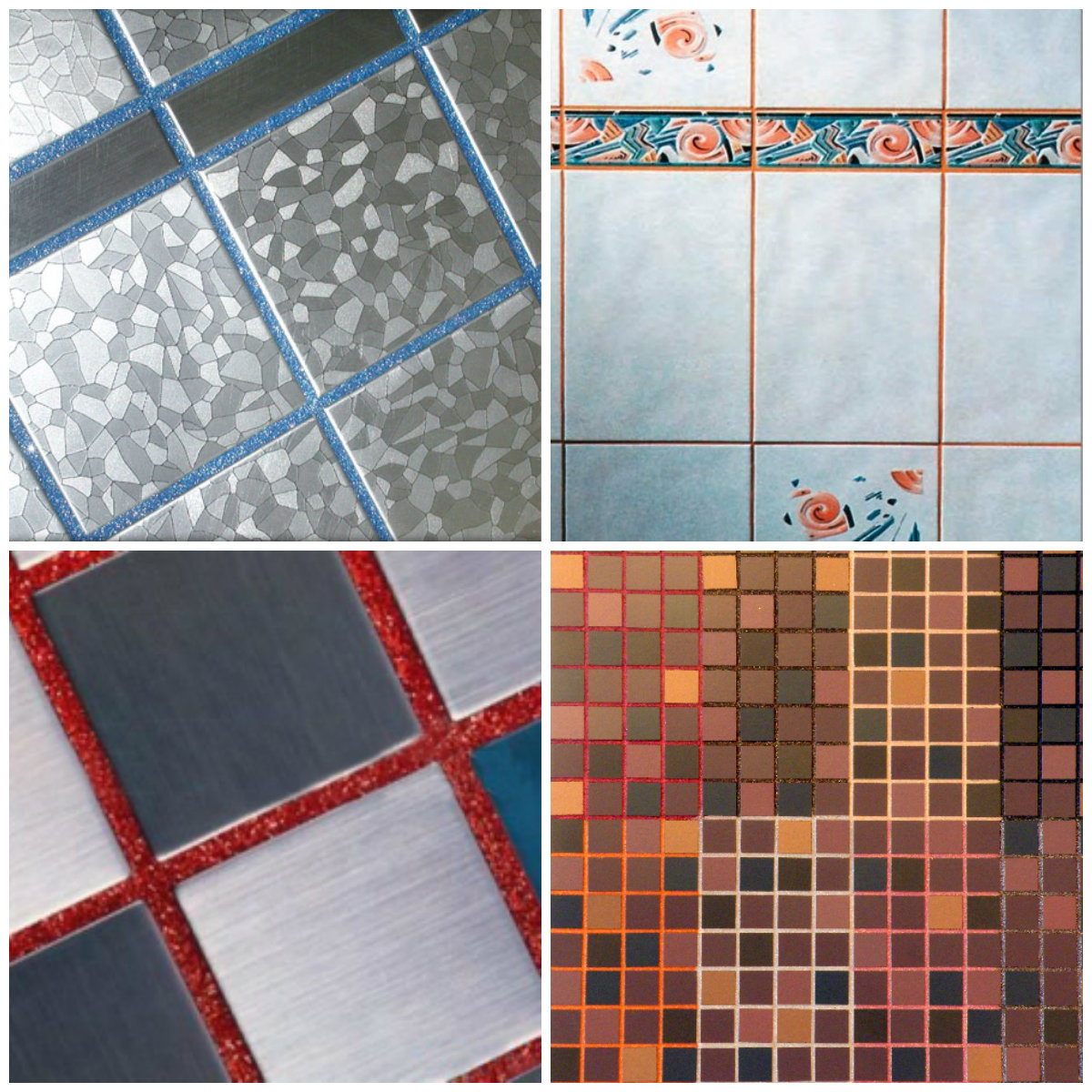

Number 4. Tile grout color

The color of the grout for the tile is no less important than its properties, because you should not guess with a shade, and you can spoil the impression of the most expensive and beautiful tile. Part cement grout coloring pigments should already come in, although sometimes it is difficult to select the necessary color, and then the craftsmen advise adding a little color to the white mixture, which can even be used with gouache. Color selection epoxy grout much more, so finding the right shade is not difficult. Moreover, epoxy grout may be transparent - It will be a great addition to mosaic tiles. The presence of shiny components in gold, silver or bronze can make the tile joint very original.

As for the issue of choosing the color of the grout, there are several basic principles:

- grout in tile color - The easiest option, which will turn the tiled surface into a single and harmonious one. A similar option to select the shade of the grout will be appropriate for any color of the tile;

- grout of contrasting color. In this case, choosing the right shade is more difficult, because you will need an exceptional sense of taste. You can dwell on quiet options and use light beige grout under the brown tile, or you can go the bolder way and rub the seams of the yellow tile with red grout. It is important that there are no other such bright elements around, and that such a solution fits well into the interior. If the wall is finished in this way, the grout for the floor tiles should be of a neutral color, so that the room does not look clumsy;

- white grout - universal optionwhen you can’t decide which color to choose. However, it is better to use a white puffer only for walls, because on the floor it will instantly get dirty. An alternative universal option for floor tiles is gray or any other dark shade that will blend in with the tile.

What to do if a couple of types of ceramic tiles of different colors are used in the decoration right away? You do not need to choose a separate grout for each - it is better to choose a single option that would be combined with all shades of tile, or for one color of the tile would be in tone, and for the other - in contrast. For example, if you used dark chocolate and beige shades for wall cladding, the grout can be light: it will fit both colors of the tile and combine different elements together. With a combination of white and black tiles, the grout can be either black or white.

If you opted for white tile, then either a snow-white grout or a completely contrasting shade is used with it: all light gray and beige colors will look dirty. Practical Scandinavian interiors suggest the use of dark gray grout together with white tiles, especially this concerns bathrooms, where the white grout can quickly turn yellow, and the gray will remain in its original form for a very long time.

If both light and dark shades of the grout are equally suitable, then decide what you want to achieve: visually combine all the elements of the tile into one panel or divide them into sections. Light shades of grout will serve as a unifier, dark - on the contrary, will disconnect.

In cases where the tile is decorated colorful ornament, grout can be selected for any color that is used on the tile, while if the room is small, it is better to select the puffer for the lightest elements. If multi-colored mosaic tiles are chosen for wall decoration, then let the grout be better in a neutral color.

Another question - how much the actual color of the grout will meet the expected, since often the final result is very different from the sample presented in the store or indicated on the package. If the final shade is critical, you will have to incur additional costs and purchase a small package of grout to test it on the site, which will be hidden behind furniture or appliances. You can judge the color after the grout has dried.In cases where the grout is already fully applied, but in the end its tint does not meet expectations, some craftsmen recommend carefully walking along the seams with moisture-resistant paint necessary color. In order not to stain the tile, you can seal it with masking tape.

No. 5. Tile Grout Manufacturers

To be sure of the quality of the grout, it is better to give preference to products of well-known and reputable manufacturers. Among the largest companies producing grout for tiles and presented on the domestic market, it is worth highlighting:

Ceresit - company number 1 in the market of building materials. It exists since 1898, today it is part of the Henkel concern, products are presented in almost all countries of the world, and has established itself with the highest quality. The assortment includes grouts for narrow and wide joints, hydrophobic compounds, as well as two-component, antifungal and water-repellent grouts;

Ceresit - company number 1 in the market of building materials. It exists since 1898, today it is part of the Henkel concern, products are presented in almost all countries of the world, and has established itself with the highest quality. The assortment includes grouts for narrow and wide joints, hydrophobic compounds, as well as two-component, antifungal and water-repellent grouts;- Atlas - One of the largest European companies for the production of building and finishing materials and mixtures. The company appeared in Poland in 1991, and today its products are widely represented in many countries of Europe and Asia. Grouts are available in a sufficient assortment, there are epoxy compositions in different colors and with the inclusion of sparkles. Own developments allow us to produce frost-resistant compounds, and the addition of silver ions allows us to talk about the antibacterial effect;

Mapei - A large Italian company, existing since 1937 and today is actively conquering the world market. The company's epoxy grouts are known under the trademarks Kerapoxy, Ultracolor Plus and are of the highest quality;

Mapei - A large Italian company, existing since 1937 and today is actively conquering the world market. The company's epoxy grouts are known under the trademarks Kerapoxy, Ultracolor Plus and are of the highest quality;- Sopro - A German company with more than a century of history. Her range of grouts is the highest, there are both cement and epoxy compositions, shades of mass, there are grouts with sparkles. Separately, it is worth highlighting quick-drying compositions, as well as special compositions for the effective removal of residues of epoxy fugue.

In conclusion

Even after you have decided which grout to choose for the tile, and what shade it should be, do not be too lazy to carefully read the manufacturer's instructions on the packaging, for what size of the joints the concrete composition is intended for and what additional properties it has. If there is sand in the composition, then it will be necessary to rub the seams of marble and glazed tiles very carefully so as not to scratch the surface.