9 tips for choosing a film for a greenhouse

Until recently, film was the most popular material for arranging greenhouses. Today it is being replaced by glass and polycarbonate, which surpass it in many respects, but do not differ in low price. If the budget is limited, then you can grow a crop in a greenhouse covered with a film, but you still need to be able to choose it. Film clash: manufacturers offer both the simplest polyethylene and more practical options, such as reinforced, polyvinyl chloride and stabilized. Sellers strive to give out cheap material for a more expensive analogue, because outwardly some species are very similar. How, then, to choose a film for a greenhouse under these conditions, not to overpay and be sure of its quality?

No. 1. Advantages and disadvantages of a film for a greenhouse

Previously, only plastic wrap was used to shelter the greenhouses. At the moment, summer residents are offered more advanced analogues of it, in which some of the disadvantages are less pronounced. In general, for all types of films that are used for arrangement of greenhouses and greenhouses are characteristic common pros and cons.

Main advantages:

- low price. There are differences in price between different types of film, but compared to glass and polycarbonate it's still a budget option;

- high elasticity and plasticity, so with the help of a film you can equip a greenhouse of any shape;

- moisture resistance;

- high light transmission and the ability to diffuse sunlight;

- low weight and ease of installation.

The main disadvantages:

- low durability. When choosing a plastic film, you should be prepared that it will need to be changed for the next season. More expensive analogues will have to be changed after 2-3 seasons;

- low resistance to sunlight, which leads to rapid destruction of the material, but in some films this disadvantage is not so pronounced;

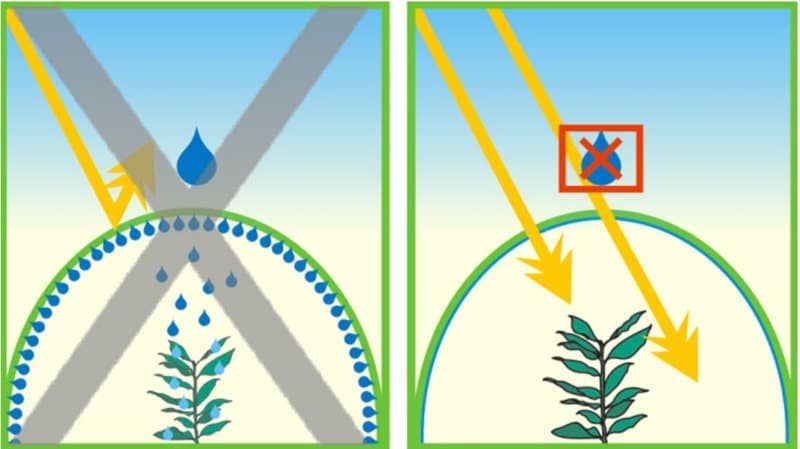

- condensation accumulates on the surface of the film, which harms most of the crops grown in the body. This disadvantage was avoided by hydrophilic films, the production of which use special additives;

- the accumulation of electrostatic charge, which contributes to the attraction of dust, and this, in turn, reduces transparency. Manufacturers are also trying to deal with this minus by introducing special additives.

Many summer residents also complain that the film is stretched and sagging, so you have to constantly tighten it. But the presence of so many significant minuses still does not make the material less popular, because it the cheapest way to equip a greenhouse in the country, and many believe that it is more profitable to change coverage once a year than to immediately spend money on buying expensive polycarbonate.

No. 2. The main types of films for greenhouses

The whole variety of films for greenhouses can be divided into the following types:

- polyethylene (the most common and inexpensive);

- reinforced;

- polyvinyl chloride;

- films with additives (light stabilizing, antistatic, thermostabilizing, foamed and others).

No. 3. Polyethylene film

The main advantage is low cost. The film transmits about 80% of thermal radiation, so daytime heat is poorly conserved at night. Properly mounted high-quality plastic film will last no more than a season, and it’s unlikely to survive the winter, as temperature changes, wind and snow will destroy the material. Even the thickest films are not particularly durable.

Polyethylene film very tender, therefore, it must be transported and mounted very carefully. Even the smallest cut will soon “grow”, which will negate all efforts to equip the greenhouse.

They sell the material in rolls with a width of 1.2-3 m, it can be a single-layer canvas or sleeve. In the second case, the material can be cut along the seam and get a wider canvas, or you can cover the greenhouse with a sleeve, although you should not count on a significant increase in durability. The bend of the sleeve is considered the weakest point and collapses in the first place, so it is better to immediately strengthen it with tape.

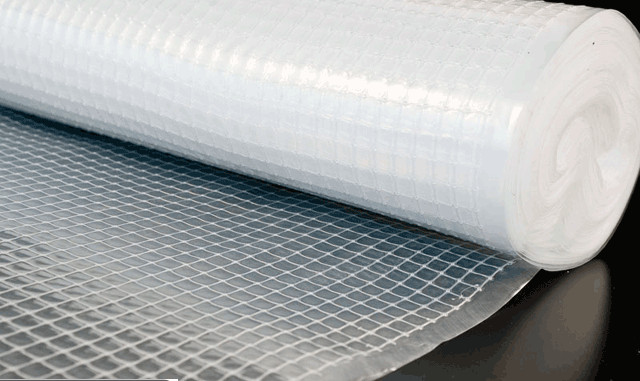

Number 4. Reinforced film

Reinforced film differs from ordinary polyethylene in the presence of a peculiar framemade of fiberglass, extruded, twisted or stretched polyethylene or polypropylene, the thickness of the filament yarn 0.29-0.32 mm Polyethylene is usually used more durable, sometimes with additives for greater resistance to sunlight. The frame takes up the main load, so a greenhouse with such a coating gets resistance to winds, snow and even degrees. The film can protect seedlings even when frozen to -50FROM.

The material will last in the greenhouse for more than a year, usually enough for three seasons, but some manufacturers say about a life of 5 or even 7 years, but much depends on the characteristics of the film and the climatic conditions of the region. Reinforced film more maintainable: holes can be sealed with tape, they do not have the property to spread over the entire canvas. The main characteristic of the material is not thickness, but density. The most common material is considered to be with a density of 120-200 g / m2. On sale there is a film with holes in the cells, which provides the greenhouse with proper tightness, but at the same time does not allow “preserving” the air in it.

The durability and strength of the reinforced film turns over high price. In addition, the light transmission of this material is slightly lower than that of a conventional stabilized film, and the dust is washed off very difficult due to the relief, which also harms transparency.

No. 5. PVC films for greenhouses

Polyvinyl chloride films are one of the best options for arranging greenhouses. It is a flexible and durable material that can last.from 2-3 seasons up to 6-7 depending on operating conditions, care and climate. As a rule, light-converting and stabilizing additives are introduced into the composition.

Material skips up to 90% light, 80% ultraviolet radiation and retains up to 95% of infrared radiation, which means that at night and during frosts in the greenhouse will be warmer than in the same from a plastic film. This is a very significant advantage of the material.

The disadvantage of the material is the price, which is 2-3 times higher than the cost of a polyethylene analogue, but taking into account the fact that there is no need to buy a new film and mount it every season, this minus can not be called too significant. Another nuance is polyvinyl chloride. attracts dust, but also to wash off it is simple. Frost resistance of the material is low, at temperatures below -150With the film becomes too fragile, therefore for winter greenhouses heating will be required.

No. 6. Plastic films with special additives

If specific substances are introduced into polyethylene, then its operational qualities can be somewhat improved. Depending on the additives, the following types of material are distinguished:

- stabilized film made with the addition of substances that increase resistance to sunlight. The service life increases by 2-3 times, and the price increases. The material may have an orange or pinkish tint, but this is optional.Externally stabilized and ordinary plastic films are the same, so you need to carefully look at the packaging and labeling;

- light conversion film "Knows how" to turn hard ultraviolet, harmful to plants, into infrared and red radiation, which increase productivity. All this is possible thanks to the phosphor additive, but for the material to last for a long time, it is necessary that stabilizing substances be included in the composition. To make sure that you really have a light-converting film, you need to shine it with an ultraviolet lamp, while the light from the lamp should change to red;

- heat holding film Differs in a dull whitish shade. It weakly transmits thermal radiation, so the temperature in the greenhouse will be 1-30C is higher than in the similar of other types of film. Due to this, early crops can be increased by 10-30%, saving on heating. The service life of the film is about 9 months, the material has antistatic and hydrophilic properties;

- stabilized hydrophilic film allows you to solve the problem of "drops", characteristic of other types of material. A flat-drop condensate is formed on this film in the form of a continuous layer, therefore there is no negative effect on the plants. Light transmission is high, the ability to transmit thermal radiation is 30-35%, so it will be warm in such greenhouses;

- bubble wrap strongly reminiscent of the one that packs fragile goods. It has good light transmission, and in terms of thermal insulation it can be compared with polycarbonate. Strength is low, with the exception of special types of film, but for growing early crops in a small greenhouse, the material will fit;

- foamed film consists of a monolithic and foamed layer of polyethylene, transmits 70% of the light, holds heat well, is suitable for the construction of greenhouses intended for vegetative propagation of plants;

- copolymer ethylene vinyl acetate It has a decent level of strength, it retains heat well, it is resistant to punctures, wind loads, frost, hydrophilic. High light transmission (up to 92%) on hot summer days can cause overheating. Durability - up to 3 years;

- photodegradable film collapses after a certain period (20, 45 and 60 days). It is used for frameless shelters and mulching.

Despite the declared service life, some experts recommend changing the film every three years, since it still becomes cloudy. If the material has retained its integrity, it can be used for other purposes.

You can also find films, in the production of which several additives were used at once - this is the best option. But often, under the guise of special films, they give out ordinary polyethylene, so it does not interfere look at certificates and markings.

According to GOST 10354-82, a stabilized film for greenhouses and greenhouses is labeled ST, a stabilized light-converting film - SIK. Also, for greenhouses, you can use a film in the labeling of which is the letter H: this is a stabilized or unstabilized film for the manufacture of household products.

Number 7. Density and film thickness

The thicker and thicker the film, the better it will cope with negative environmental factors. In the case of ordinary plastic film, the thickness has little effect on durability, and when it comes to stabilized materials, this factor is of greater importance.

Externally, a film with a thickness of 200 and 100 μm cannot be distinguished, which is used by unscrupulous sellers. To protect yourself from a disadvantageous purchase, it is worth remembering that a thicker film weighs more:a linear meter of a film of 200 microns weighs 530 g, 150 microns - 400 g, 120 microns - 320 g, 100 microns - 260 g and 80 microns - 210 g. For greenhouses, it is better to choose a film with a thickness of 150-200 microns.

Number 8. Film color

Better to choose a transparent film - she lets in more light.To obtain a material of different shades, a food coloring is usually introduced into the composition, which tends to fade under the sun, so there is no point in it. If the paint is resistant, then less light will enter the greenhouse, which will entail a decrease in yields and the need to use additional lighting.

No. 9. Film manufacturers

If the choice is stopped on ordinary plastic film, then the risk of running into low-quality goods is reduced. More fakes are found in the category of more expensive types of films: for example, they can be issued for a stabilized film as ordinary. In any case, it is better to trust trusted manufacturers, it is good to look at the accompanying documentation and labeling.

The film of such manufacturers has sufficient quality:

- NPF "Shar" - A company from St. Petersburg, founded in 1991 and specializing in the development of composite polymer materials. For agriculture, films of various types are produced, including Svetlitsa, Rostock, and Yuzhanka use their own developments, all materials are durable, and Svetlitsa, according to the manufacturer, lasts up to 7 years;

- Agrokhoztorg - one of the leading domestic enterprises in the field of polymer production. The manufacturer has a wide range of products, and Vural Plastik with reinforcement is produced for greenhouses;

"Agrotema A" - A domestic company that has been operating since 1993. The main activity is the production of plastic film for various fields of use. For the equipment of greenhouses, ordinary polyethylene and reinforced film are offered;

"Agrotema A" - A domestic company that has been operating since 1993. The main activity is the production of plastic film for various fields of use. For the equipment of greenhouses, ordinary polyethylene and reinforced film are offered;- "Stable" - A company that produces film under the brand name Stabilen. In its manufacture, the patented unique Fitistab additive is used, which allows to obtain durable material suitable for year-round use in almost all climatic zones. Several types of films are produced, differing in thickness and basic properties, all have the highest quality, are exported to neighboring countries;

- "Odysseus" works since 2005, specializes in the production of polyethylene. For greenhouses, ordinary polyethylene and reinforced films of different thicknesses and widths are produced;

- "Polymer" - Kemerovo factory with 30 years of experience in the production of films. The greenhouse films of the company are considered one of the best among domestic ones, their assortment is the widest, constantly replenished with new types;

- ORA - St. Petersburg company, equipped with modern imported equipment and producing film of various brands, including "Polysvetan" and "Anti-mold". The quality is high, the price is affordable;

- Richel serres de france - A French company that offers comprehensive solutions for equipping greenhouses. The official dealer for us is the Greenhouse Technologies company, which offers Richel film. She, according to reviews, keeps even in winter greenhouses for a long time.

Despite the fact that the film is not the most durable and durable material for creating greenhouses, with a competent approach to its selection, it will be possible at a minimum cost to equip the greenhouse according to all the rules and get good yields.