7 tips for choosing an ondulin for a roof

The usual roofing materials are replaced by more modern analogues. Not so long ago, the ondulin appeared on the domestic construction market, which is often called the euro slate. He immediately bribed with a low price, presentable appearance, record moisture resistance and other positive qualities. The popularity of the material has grown so much that its even began to fake. Let's focus on how to choose the ondulin for the roofso that it is of proper quality and fully complies with future operating conditions.

No. 1. How is ondulin produced?

Wavy bitumen sheets, called today Ondulin, were produced and patented. French company Onduline, whose name subsequently gave the name to the material. The first production facilities for its manufacture began to operate near Paris back in 1944. In the 60s, the company already had several factories, and a new roofing material began to be widely used in European countries. Ondulin came to Russia only in 1994, and since then the material has been in ever-increasing demand.

Wavy bitumen sheets, called today Ondulin, were produced and patented. French company Onduline, whose name subsequently gave the name to the material. The first production facilities for its manufacture began to operate near Paris back in 1944. In the 60s, the company already had several factories, and a new roofing material began to be widely used in European countries. Ondulin came to Russia only in 1994, and since then the material has been in ever-increasing demand.

For the production of ondulin use cellulose fiberwhich is crushed together with mineral components and rolls into sheets of a given shape. Further, in several stages, impregnation with purified bitumenwhich provides high waterproofing material properties. At this stage, the material is also impregnated mineral additives and curing resins. Painting can be carried out on one or both sides. The color palette is the widest, the surface can be matte or glossy depending on the composition used: to obtain a matte surface, acrylic paint is used, a glossy surface is obtained by adding silicone.

For the production of ondulin use cellulose fiberwhich is crushed together with mineral components and rolls into sheets of a given shape. Further, in several stages, impregnation with purified bitumenwhich provides high waterproofing material properties. At this stage, the material is also impregnated mineral additives and curing resins. Painting can be carried out on one or both sides. The color palette is the widest, the surface can be matte or glossy depending on the composition used: to obtain a matte surface, acrylic paint is used, a glossy surface is obtained by adding silicone.

After completion of all processing processes, the material is cut into sheets of the required size. As a rule, an ondulin sheet has 10 waves, the height of which is 36 mm. The sheet size is 2000 * 950 mm, the wave step is 95 mm, the sheet thickness is 3 mm.

No. 2. Advantages and disadvantages of ondulin

The production method and the materials used made it possible to achieve excellent performance. Among the main The advantages of ondulin are worth highlighting:

water resistance. Ondulin surpasses all other roofing materials in this parameter. Waterproofing properties provided by impregnation with special compounds. Moreover, cellulose fibers when heated by sunlight are more tightly connected to each other, further increasing the moisture resistance of the material;

water resistance. Ondulin surpasses all other roofing materials in this parameter. Waterproofing properties provided by impregnation with special compounds. Moreover, cellulose fibers when heated by sunlight are more tightly connected to each other, further increasing the moisture resistance of the material;- environmental friendliness and hygiene;

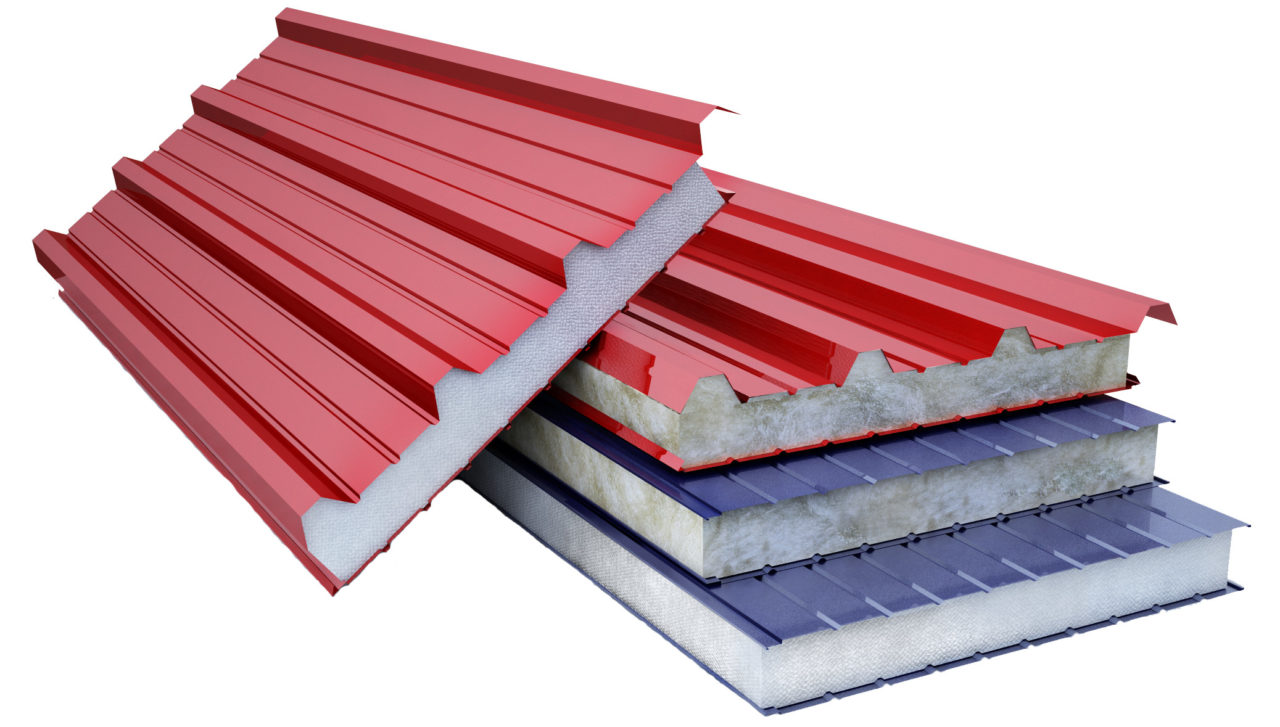

- a light weight. A sheet of ondulin in standard sizes weighs only 6.5 kg, which is almost 4 times less than slate similar area, and this means easier transportation and installation of the material;

- ease of processing. To cut sheets, you can use a hacksaw on a tree;

flexibility. It’s easy to give the material the most bizarre shape, so it can be used to equip roofing complex forms;

flexibility. It’s easy to give the material the most bizarre shape, so it can be used to equip roofing complex forms;- low cost. Ondulin, of course, is slightly more expensive than ordinary slate, but much cheaper than other roofing materials, including and metal tiles;

- noise insulation qualities. The material allows you to do without additional soundproofingsince falling raindrops and gusts of wind will not be heard indoors;

- ondulin not subject to corrosionexposed to aggressive environments, does not rot and does not grow moldy.

Despite the huge number of advantages, the scope of use of ondulin is limited due to some of its shortcomings:

low strength. It is this minus that is often noted by those who performed the installation of ondulin in violation of the rules. The material is flexible and lightweight, so errors in arranging the rafter system and fixing the material may result in the roof not withstanding heavy snowfall. The solution is simple - fully comply with the installation rules, and the strength of the roof will be at its best. One sheet of ondulin must be attached at least 20 nails, the step of the crate is not less than 0.6 m. Nevertheless, in summer heat it is better not to go ondulin from the roof, since bitumen is very softened. Also, unpleasant odor can be released into the heat;

low strength. It is this minus that is often noted by those who performed the installation of ondulin in violation of the rules. The material is flexible and lightweight, so errors in arranging the rafter system and fixing the material may result in the roof not withstanding heavy snowfall. The solution is simple - fully comply with the installation rules, and the strength of the roof will be at its best. One sheet of ondulin must be attached at least 20 nails, the step of the crate is not less than 0.6 m. Nevertheless, in summer heat it is better not to go ondulin from the roof, since bitumen is very softened. Also, unpleasant odor can be released into the heat;- flammability. Ondulin is susceptible to combustion, ignites at temperatures above 2500FROM;

- fading. Under the influence of sunlight, the color of the coating will gradually fade, which is typical even for high-quality material.

As for durability, then it is average. Subject to all the nuances of installation and operation, ondulin will last 15-20 years.

No. 3. Ondulin Slate and Ondulin Tile

Ondulin appeared as an analogue of slate, but later sheets of reduced size, which were called ondulinova, began to be produced. roof tiles. Ondulin Slate has the dimensions described above: 200 * 95 cm, a thickness of 3 mm and a weight of 6.5 kg. It is used for arrangement of roofs of simple form. Please note that if the number of waves on the sheet is not 10, but 9, and the material itself is thinner than necessary, then we are talking about non-original and low-quality products.

Ondulin appeared as an analogue of slate, but later sheets of reduced size, which were called ondulinova, began to be produced. roof tiles. Ondulin Slate has the dimensions described above: 200 * 95 cm, a thickness of 3 mm and a weight of 6.5 kg. It is used for arrangement of roofs of simple form. Please note that if the number of waves on the sheet is not 10, but 9, and the material itself is thinner than necessary, then we are talking about non-original and low-quality products.

Ondulin tile It has parameters 1 * 0.35 m. These are flexible tiles that can be used to equip complex roofs, and there will be less waste using such material. The main difference is the use of fiberglass in the production.

Number 4. The main types of ondulin

Demand for material has led to the emergence of new varieties of it. Currently ondulin of these types:

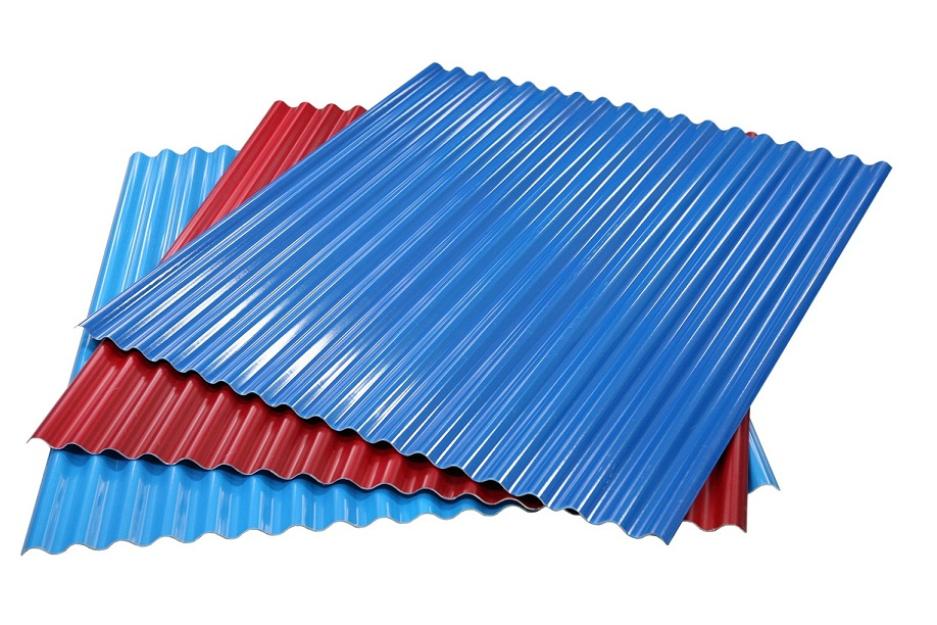

- classical. Used on flat and vaulted roofs, has dimensions 200 * 95 cm, thickness 3 mm;

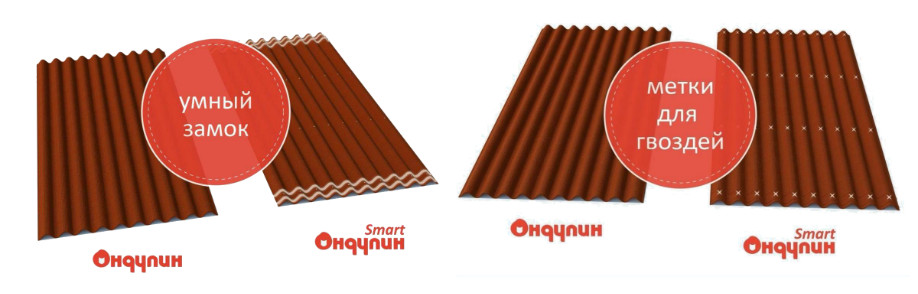

- ondulin smart. A more modern and perfect coating, which differs from the classic one in lower parameters and weight, caused by the attachment points and the presence of a hydro-barrier lock. Options sheets 195 * 95 cm, thickness 3 mm, the number of waves - 10, weight 6.3 kg. Thanks to the availability Smart Lock melt water and slanting rain will not fall into the places of overlapping sheets. Installation of such material is simplified by marked markings. Such an ondulin can be used for roofing. public and residential buildings;

- Ondulin DiY It has all the properties and advantages of ordinary ondulin, but at the same time it is smaller, which greatly simplifies its installation. Sheet sizes 200 * 75 cm, thickness 3 mm, weight 5.2 kg, number of waves - 8. Due to the reduced width of the sheets, the number of overlaps increases, which makes the roof more durable. Such sheets found distribution in areas with difficult climatic conditions;

- ondulin compact used for arrangement small or complex roofs, ease of transportation and installation is due to reduced size. Parameter Sheet 100 * 75 cm has a thickness of 2.6 mm, weight 2.5 kg, number of waves - 8. Due to the large number of overlaps, high roof strength is ensured, even with a smaller thickness of the material. The material used is mainly for arrangement of roofs of small buildings, in including garages, sheds.

Although the number of waves on different types of ondulin is different, their size is the same, therefore different types of material can be combined. This is an additional advantage of ondulin, which concerns roofs of complex shapes.

No. 5. Ondulin analogs

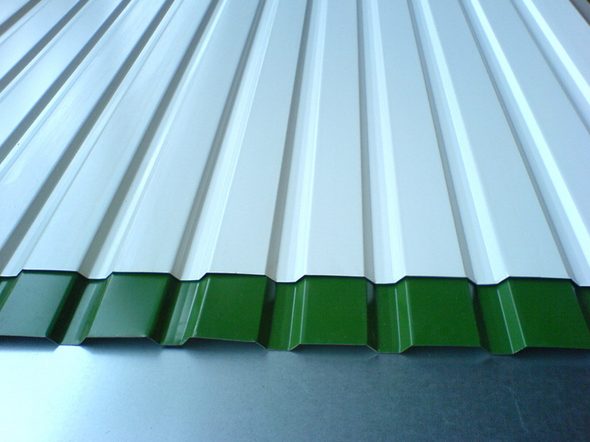

On sale you can find materials very similar to ondulin, with similar properties, but produced using slightly different technologies. The main analogues of ondulin are as follows:

- Ondura and Ondalux - products of the French company Onduline. The material has a thickness of 2.6 mm, a wave height of 34 mm and a weight of 6 kg;

- nullin - A material developed by the American company Nuline Corporation, which, by the way, since 2010 passed into the possession of Onduline. In terms of characteristics and quality, nulin resembles ondulin, but has slightly different sizes. The weight of one 10-wave sheet with dimensions of 200 * 122 cm is 10 kg, and an 8-wave sheet with dimensions of 200 * 102 cm weighs 6.8 kg. The material is more durable and durable, therefore, the guarantee for it is higher - 25 years;

- onduville differs from ondulin in profile and size. Its dimensions are 106 * 40 cm, sheet thickness 3 mm, weight 1.2 kg. A special profile and method of painting creates a 3D effect. According to a number of parameters, Onduville refers to soft tiles.

No. 6. What to consider when buying ondulin?

When it is decided that ondulin is ideal for the roof of a particular building, it is important to choose a quality material that will fully meet all the expectations assigned to it. When buying, pay attention to the following points:

- the dimensions of the sheet must correspond to the declared type of ondulin, all sheets must be the same among themselves;

- the number of waves on standard sheets is always 10, on compact sheets - 8, and on fake sheets it can be 9;

- It does not hurt to selectively compare several sheets so that they are exactly the same shade;

- on the sheets, the presence of bituminous spots is undesirable;

- Feel free to look at the quality certificates and study the conditions of the guarantee;

- it is better to make a purchase from reliable sellers and official dealers of large manufacturers. It is better to refuse the goods at too low a price.

Number 7. Ondulin Production

The main producer of ondulin is the French company Onduline SA. Actually, this is the enterprise where this roofing was developed and patented. Production has expanded so much that plants are located today in many countries of Europe, as well as in Brazil, the USA, and Malaysia. In 2008 was opened branch in Nizhny Novgorod, and in 2012 the second line was launched. it the only ondulin company in Russia. Onduline SA occupies 75% of the European market for the production of corrugated cellulose-bitumen roofing materials.

Unduline-like undulating cellulose-bitumen sheets some other European companies also produce, including a Belgian company Aqualine, German company BitwellTurkish Corrubit and american Nuline.

In conclusion

Due to its low cost and good performance, ondulin is now used to cover the roofs of farm buildings, and in the construction of houses. The right choice of ondulin and installation complying with all the rules is the key to the long service of this roofing material.

Great! Thank you!