8 tips for choosing a slate for roofing

The most popular roofing material in the domestic space is slate. This is a collective concept under which mean materials different in manufacturing technology. What unites them is that they are leafy and, as a rule, have a profiled shape. To choose the right slate for the roof, it is necessary to analyze the features of the roof, the loads placed on it, environmental factors, and also know the basic properties of each type of slate and the scope of use of each of them.

No. 1. The main types of slate

Due to the widespread use of asbestos slate, many still refer to it as “slate”. Nonetheless, slate can be made of different materials and using various technologies. Depending on this, today they allocate these kinds of slate:

Each of them requires detailed consideration, because it has its own sphere of use.

No. 2. Natural slate slate

The progenitor of all known types of slate - shale, because the word "slate" itself is of German origin and translates as "slate". The material is a slate plate of various shapes and sizes, the color is usually gray and blue gray, greenish and brown shades are less common. The length of the elements usually varies from 25 to 60 cm, width - from 15 to 35 cm, height - from 0.4 to 0.9 cm. Due to its unique appearance and high price, the material is used to equip elite roofs.

The progenitor of all known types of slate - shale, because the word "slate" itself is of German origin and translates as "slate". The material is a slate plate of various shapes and sizes, the color is usually gray and blue gray, greenish and brown shades are less common. The length of the elements usually varies from 25 to 60 cm, width - from 15 to 35 cm, height - from 0.4 to 0.9 cm. Due to its unique appearance and high price, the material is used to equip elite roofs.

The main advantages of slate slate:

- unique structure and appearance, due to which unusual roofs can be formed with the help of material;

low thermal conductivity;

low thermal conductivity;- resistance to sunlight, low and high temperatures, moisture, which allows the use of the material in any climatic conditions;

- great soundproofing;

- resistance to fire;

- durability.

With such high operational and decorative qualities, slate slate is not widely used due to its shortcomings:

- high weight and brittleness of the material, which complicates the work with it and requires the formation of reinforced truss structures;

- high price.

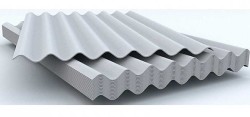

No. 3. Asbestos cement slate

Asbestos-cement corrugated sheets received most common among all kinds of slate. The material is made on the basis of cement, water and asbestos, therefore, the color turns light gray. Asbestos, evenly distributed, reinforces the cement mortar, while increasing the strength of the material. Today we managed to get rid of the boring gray shade by staining finished slate sheets. Thanks to the layer paints the material receives additional protective and strength properties.

Asbestos-cement corrugated sheets received most common among all kinds of slate. The material is made on the basis of cement, water and asbestos, therefore, the color turns light gray. Asbestos, evenly distributed, reinforces the cement mortar, while increasing the strength of the material. Today we managed to get rid of the boring gray shade by staining finished slate sheets. Thanks to the layer paints the material receives additional protective and strength properties.

The popularity of this type of slate is ensured by the combination its advantages:

simplicity of laying;

simplicity of laying;- low price;

- long service life, up to 40 years;

- low thermal conductivity;

- resistance to frost and fire;

- strength;

- choice of colors.

Among the main disadvantages:

- high weight of the material, so it is imperative to equip a powerful crate;

- fragility.Transporting and handling material will not be easy

The strength of asbestos-cement slate upon purchase can be checked in an old and well-established way. It is enough to put the sheet on a flat, straight surface and stand on it - a durable material must support the weight of a person without cracking or breaking.

It is believed that asbestos-cement slate is harmful to health, since it contains asbestos, which has a carcinogenic effect when it enters the respiratory tract. This statement is only partially true. The fact is that asbestos is the name of a whole group of natural minerals. there is chrysolite asbestosobtained from the mineral serpentite, it is resistant to alkali, but dissolves in an acidic environment. Amphiol Asbestosobtained from actinolite and anthophyllite, on the contrary, is resistant to acids. This is a key difference and causes a danger to humans of amphiol asbestos. In Europe, asbestos slate was banned precisely because amphiol asbestos was used there. Only chrysolite asbestos is mined in Russia, the harm from which is incomparable with amphiol asbestos, so domestic slate can be safely used.

It is believed that asbestos-cement slate is harmful to health, since it contains asbestos, which has a carcinogenic effect when it enters the respiratory tract. This statement is only partially true. The fact is that asbestos is the name of a whole group of natural minerals. there is chrysolite asbestosobtained from the mineral serpentite, it is resistant to alkali, but dissolves in an acidic environment. Amphiol Asbestosobtained from actinolite and anthophyllite, on the contrary, is resistant to acids. This is a key difference and causes a danger to humans of amphiol asbestos. In Europe, asbestos slate was banned precisely because amphiol asbestos was used there. Only chrysolite asbestos is mined in Russia, the harm from which is incomparable with amphiol asbestos, so domestic slate can be safely used.

When choosing asbestos-cement slate, you should pay attention the number of waves on the sheet. This parameter ranges from 5 to 8:

- 5-wave slate It is the least demanded due to its low profitability;

- 6-wave slate with dimensions 2 * 1.125 m has the largest thickness, which reaches 7.5 mm. The material is widely used in industrial and residential construction;

- 7-wave slate received the most popularity, especially often used for roofing country houses. With sheet parameters of 1.75 * 0.98 m, the thickness is 5.8 mm;

- 8-wave slate is less commonly used due to its heavy weight.

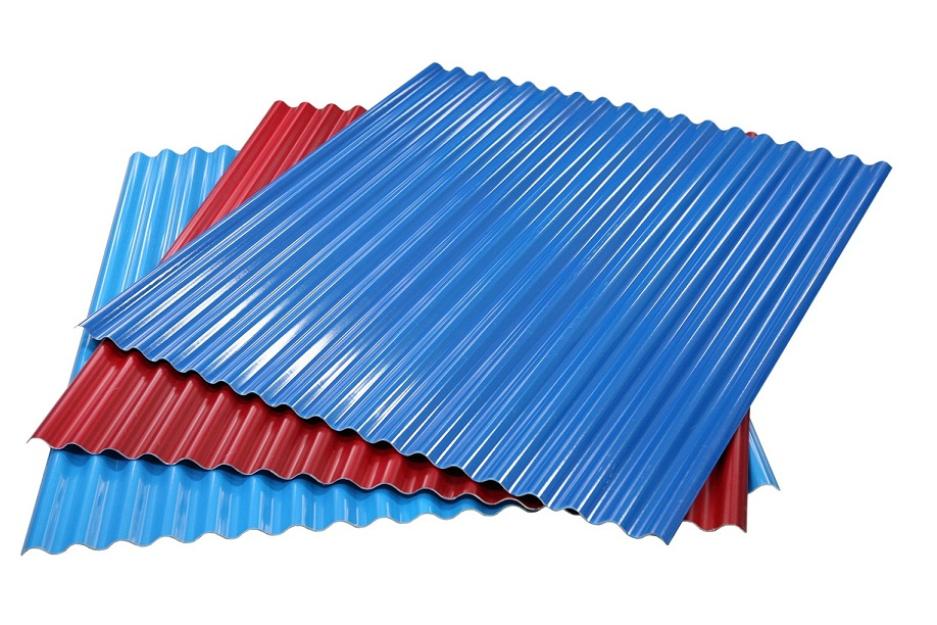

Number 4. Euroslate

Having abandoned the asbestos-cement slate, European states switched to the use of the euro-slate. It is also called bituminous or soft slate. Material appeared in our construction stores not so long ago, but buyers have already managed to appreciate its merits. Euro slate is produced based on cellulose fiberswhich are impregnated with special polymer substances, after which the material is pressed under the influence of bitumen vapor at high pressure and temperature, and after drying it is painted in the desired color. Bitumen allows you to create a completely waterproof material.

Having abandoned the asbestos-cement slate, European states switched to the use of the euro-slate. It is also called bituminous or soft slate. Material appeared in our construction stores not so long ago, but buyers have already managed to appreciate its merits. Euro slate is produced based on cellulose fiberswhich are impregnated with special polymer substances, after which the material is pressed under the influence of bitumen vapor at high pressure and temperature, and after drying it is painted in the desired color. Bitumen allows you to create a completely waterproof material.

Euroslate is represented by the following species:

ondulin It is made on the basis of cellulose, rubber, bitumen, dyes and mineral components. The result is light, soft and plastic sheets;

ondulin It is made on the basis of cellulose, rubber, bitumen, dyes and mineral components. The result is light, soft and plastic sheets;- nullin also plastic, durable and with a wave profile, but slightly heavier than ondulin, and its service life is longer;

- gutta dramatically different from other types of bitumen slate. In its manufacture, organic fibers are used that reinforce the sheets of material. Special impregnations are applied to increase rigidity and strength. Gutta is usually used for the roof of industrial buildings, this material is cheaper than other types of bitumen slate, but its basic properties are not inferior to them.

Common to all types of euro slate are such advantages:

lightness, sheets of bitumen slate can even be put on top of the old roof;

lightness, sheets of bitumen slate can even be put on top of the old roof;- flexibility;

- strength. The material easily withstands significant wind and snow loads;

- durability. Service life reaches 50 years;

- excellent waterproofing properties. Material does not pass and does not absorb moisture;

- high level of sound insulation. When raindrops hit the roof, this noise will not be heard in the house.

Without disadvantages not done:

- insufficient resistance to low and high temperatures. In summer, the material can soften, and in winter it becomes too fragile;

- low resistance to ultraviolet rays, therefore, the appearance of faded spots on the surface of the slate;

- relatively high price.

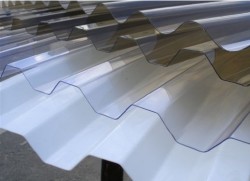

Number 4.Plastic slate

Plastic colored translucent slate compares favorably with its appearance and is used for roofing pools, pavilions, greenhouses, atticscreating garage awnings etc. Material produced from polycarbonate or polyvinyl chloride.

Plastic colored translucent slate compares favorably with its appearance and is used for roofing pools, pavilions, greenhouses, atticscreating garage awnings etc. Material produced from polycarbonate or polyvinyl chloride.

The main advantages plastic slate:

- translucency;

- moisture resistance;

- frost resistance;

- ability to withstand significant wind and snow loads;

fire resistance, self-extinguishing ability;

fire resistance, self-extinguishing ability;- light weight, which greatly facilitates both the direct roofing and preparation for them, because the reinforcement of the crate is not needed;

- high strength. Sheet polycarbonateFor example, it is very difficult to break.

Of course, a plastic translucent roof is not an option for every building. The main disadvantage of the material can be considered the ability to expand under the influence of high temperatures, which must be taken into account when arranging such a roof.

No. 5. Rubber slate

Rubber Slate Produce fiberglass and rubber waste. As a result, sheets with a wave height of 2-3 cm are obtained. The material is not widely used, it is used mainly for roofing small buildings. By some characteristics, rubber slate resembles asbestos-cement.

Rubber Slate Produce fiberglass and rubber waste. As a result, sheets with a wave height of 2-3 cm are obtained. The material is not widely used, it is used mainly for roofing small buildings. By some characteristics, rubber slate resembles asbestos-cement.

The main advantages of the material:

- light weight;

- ease of processing. Rubber slate is easily cut with a knife, it can be bent, so the material can be used for roofing complex curved roofs;

strength. Such slate is often used for roofing gently sloping roofs, on which it is necessary to walk for snow removal.

strength. Such slate is often used for roofing gently sloping roofs, on which it is necessary to walk for snow removal.

The main limitations material:

- low frost resistance;

- flammability.

These two minuses limit the scope of use of rubber slate.

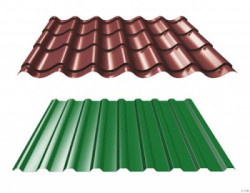

No. 6. Metal slate

Metal slate or profiled flooring made of galvanized steel. Sheets can have waves of different shapes and sizes (wave height from 8 to 50 cm), the material is covered with a protective layer of polymers on top. Previously, metal slate was used only to equip the roofs of industrial buildings, but when manufacturers learned to give the material different shades, such slate began to be used in residential construction.

Metal slate or profiled flooring made of galvanized steel. Sheets can have waves of different shapes and sizes (wave height from 8 to 50 cm), the material is covered with a protective layer of polymers on top. Previously, metal slate was used only to equip the roofs of industrial buildings, but when manufacturers learned to give the material different shades, such slate began to be used in residential construction.

In terms of mass of parameters, metal slate is not inferior to other types of slate, and in some it even surpasses them. The main advantages of the material:

- high strength and rigidity due to the presence of a profile;

- ability to withstand high temperatures, as well as temperature extremes;

- several protective layers make the material resistant to ultraviolet rays, moisture and mechanical damage;

durability. Subject to proper installation and proper maintenance of the roof, metal slate will last about 50 years. Moreover, due to the use of special substances, the material retains an attractive appearance for a long time;

durability. Subject to proper installation and proper maintenance of the roof, metal slate will last about 50 years. Moreover, due to the use of special substances, the material retains an attractive appearance for a long time;- light weight, which greatly simplifies the installation of the roof;

- fire safety and full environmental friendliness.

Among the shortcomings of the metal slate note:

- the material perfectly conducts acoustic noise, so the sound of falling rain will be very well audible. The way out is the use of a layer of vapor barrier or insulation materials under the roof, which will absorb sounds;

- metal slate is not suitable for arranging roofs of complex shapes.

Number 7. Calculation of the required amount of slate

The selection and purchase of a certain type and quantity of slate should be preceded by work on measuring roof area. It is important to analyze the features of the roof and environmental conditions, to assess the installation costs and the specifics of the installation of a material.

To calculate the approximate amount of material required, you need to know the area of the roof slopes. It’s easy to make a calculation, knowing the parameters of the roof and applying simple mathematical calculations. After that it is calculated effective area of slate by a simple formula: SP = S * k, where S is the slate sheet area, and k is the usable area coefficient. With an overlap of one wave k = 0.8, two waves - 0.7.

To calculate the approximate amount of material required, you need to know the area of the roof slopes. It’s easy to make a calculation, knowing the parameters of the roof and applying simple mathematical calculations. After that it is calculated effective area of slate by a simple formula: SP = S * k, where S is the slate sheet area, and k is the usable area coefficient. With an overlap of one wave k = 0.8, two waves - 0.7.

For example, a slate sheet with parameters of 1.75 * 1.125 will have an area S = 1.97 m2, and with an overlap of one wave, the usable area will be Sп = 1.97 * 0.8 = 1.379 m2. It remains to divide the area of the roof slopes into the usable area of one slate sheet to get an approximate number of sheets of material. It is better to add to the result 10% on waste during cutting and combat.

Number 8. Major Slate Manufacturers

At the moment, the slate market 80% represented by domestic products, and these are mainly asbestos-cement sheets. The largest domestic manufacturers of slate:

Belgorodasbestotsement OJSC has been operating since 1953, it produces flat and wave asbestos cement sheets, as well as special fasteners. Production is carried out on 10 high-tech lines, products meet domestic standards;

Belgorodasbestotsement OJSC has been operating since 1953, it produces flat and wave asbestos cement sheets, as well as special fasteners. Production is carried out on 10 high-tech lines, products meet domestic standards;- Bryansk Asbestos-Cement Plant LLC has been operating since 1908, when the First Russian plant of artificial slate was opened in Bryansk Uyezd. Today, the production is equipped with modern technologies and a quality control system. Flat and wavy slate is produced, as well as painted in several shades;

- LLC Combine Volna is the largest Siberian enterprise that has existed for more than 60 years. For the production of asbestos-cement slate it uses high-tech equipment, produces sheets with different numbers of waves, painted and unpainted;

- Lato OJSC, one of the leading enterprises in the field, specializes in the production of chrysolite cement products, produces slate and components for roofing;

Orenburg Minerals JSC was established on the basis of the chrysolite fiber deposit. Today, they produce, among other things, chrysolite cement slate wavy and flat, painted and unpainted;

Orenburg Minerals JSC was established on the basis of the chrysolite fiber deposit. Today, they produce, among other things, chrysolite cement slate wavy and flat, painted and unpainted;- Sebryakovsky Plant of Asbestos-Cement Products OJSC is one of the largest domestic manufacturers of roofing and asbestos-cement slate roofing, located in the Volgograd Region, supplies its products to all regions of the country, as well as to several CIS countries;

- LLC Timlyuisky Zavod has been producing slate for 55 years. Products always undergo serious control, therefore they are characterized by consistently high quality;

- Fibratek LLC is a young Ryazan company equipped with the most modern technological lines. A wavy and flat slate is produced.

With the advent of new types of slate in the domestic market products of foreign manufacturers:

ONDULINE is a French company engaged in the production of bitumen slate. The material manufactured here using its own technology has become one of the varieties of bitumen slate;

ONDULINE is a French company engaged in the production of bitumen slate. The material manufactured here using its own technology has become one of the varieties of bitumen slate;- GUTTA - a Swiss company that manufactures gutta type euro slate;

- ONDURA - American manufacturer of bitumen slate;

- ONDEX - a French company for the production of translucent PVC slate;

- SALUX is a German manufacturer of transparent polycarbonate roofing sheets.

Finally

When inspecting and buying slate, you can safely require quality certificates to be sure that the material is fully consistent with the qualities declared by the seller. Some types of slate should be transported with extreme caution.

strength. Such slate is often used for roofing gently sloping roofs, on which it is necessary to walk for snow removal.

strength. Such slate is often used for roofing gently sloping roofs, on which it is necessary to walk for snow removal.

Oh, I didn’t even know that so many varieties of slate happen! Thanks, very interesting article.