6 tips for choosing foam blocks

Foam blocks allow build a warm strong house as soon as possible. This material conquered domestic builders with its operational qualities, so its range and number of manufacturers is constantly growing. Unfortunately, the percentage of foam blocks produced by the artisanal method without taking into account any standards is also increasing, so it becomes more and more difficult to choose high-quality material. What foam blocks are suitable in each case and what to look for when buyingto get really high-quality, strong and durable material?

No. 1. Features of the production of foam blocks

The basis of the foam block is cement, sand and water. To carefully mixed mixture add special foam, which is usually obtained on the basis of a surfactant or foam concentrate. A homogeneous mass is cut or laid out in a mold, leaving to harden in the open air or in an autoclave.

The basis of the foam block is cement, sand and water. To carefully mixed mixture add special foam, which is usually obtained on the basis of a surfactant or foam concentrate. A homogeneous mass is cut or laid out in a mold, leaving to harden in the open air or in an autoclave.

Not the most difficult production process allows the manufacture of foam blocks to questionable companies, which led to the flooding of the market with products that do not comply with GOST. Factory packaging in plastic wrap, availability pallets and labeling indicating the density, purpose and permissible errors in size indirectly indicates the integrity of the manufacturer.

In the general scheme for the production of foam blocks, there are some differences that mostly relate to the formation of individual blocks, which determines the quality and geometry of the product. According to the manufacturing technology, foam blocks are divided into the following types:

molded block. The wet mass is poured into the prepared form cells of a given size. Hardening takes about 10 hours. This is the most economical way, but the accuracy is not the highest. Now more and more often they use a more modernized version, when the blocks pass automatic stripping. In this case, a special machine with partitions is used, where the mass is poured, and after it hardens, the finished blocks are extruded, which allows to obtain products with better geometry;

molded block. The wet mass is poured into the prepared form cells of a given size. Hardening takes about 10 hours. This is the most economical way, but the accuracy is not the highest. Now more and more often they use a more modernized version, when the blocks pass automatic stripping. In this case, a special machine with partitions is used, where the mass is poured, and after it hardens, the finished blocks are extruded, which allows to obtain products with better geometry;- threaded block. Such products are obtained by cutting the wet mass with a steel string or by cutting one large frozen foam block into elements with the desired parameters. Thus, it is possible to achieve more accurate dimensions of the product;

- reinforced block. For its manufacture, polypropylene fiber is added to the mixture, which increases the strength of the finished product.

Foam blocks are often confused with aerated concrete. What are the differences? The main one is hiding in the composition. For the manufacture of foam block and aerated concrete they use a mixture of cement, sand and water, and gas blowers are different. Instead of special foam, lime and aluminum dust are added to the aerated concrete, as a result of the interaction of which hydrogen is released, which foams the mass. The internal structure also differs: in aerated concrete, the pores are continuous. In addition, it must undergo heat treatment, and therefore it costs more.

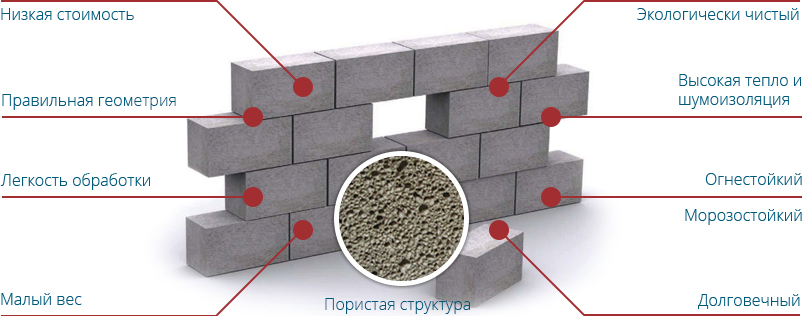

No. 2. Advantages and disadvantages of foam blocks

If the foam block is made efficiently and in compliance with all requirements, then it gets a lot of excellent performance, for which it has gained such significant popularity.

The main advantages of foam blocks:

- high compressive strength. This indicator reaches 3-5 MPa and grows with time. Comparison of the newly made foam block and foam block, which has been in operation for 50 years, showed that the density of the latter is 3 times higher;

- low density. For blocks of different brands, this figure is 400-1200 kg / m3;

- light weight, which allows to simplify the transportation of material, construction work and reduce the load on the foundation;

- convenience in work. Large and light blocks allow you to build a house easy and fast. Processing material is simple, so you can give it any shape;

- thermal insulation properties. Due to the porous structure and a large amount of air inside the material (up to 40-80%), the thermal insulation qualities of the material increase. Compared to brick, the thermal conductivity coefficient of the D700 foam block is 3.5 times lower. In practice, this means that it is possible to make masonry of smaller thickness, reducing the load on the foundation, and in areas with a warm climate, provided that the masonry is of good quality, you can do without additional thermal insulation;

- soundproof qualities. The porous structure of the foam block allows you to largely dampen external noise, especially low frequencies. A wall 30 cm thick absorbs 60 dB noise;

- environmental friendliness. Foam blocks are absolutely harmless to human health, are made from environmentally friendly materials, and the blowing agent used in the production does not form harmful gases. Foam blocks do not rot and do not decompose;

- high fire resistance, moisture resistance and frost resistance. The material almost does not absorb moisture, and thanks to this and the closed pore structure, foam blocks easily withstand dozens of freezing and thawing cycles without losing strength and integrity;

- reasonable cost. 1m3 the foam block is several times cheaper than solid wood, timber and much cheaper than brick, so building a house from a foam block will be more economical.

The main disadvantages of the foam block:

low bending strength. According to this indicator, the material is significantly inferior to concrete and reinforced concrete, however, with an increase in density, the strength of the products also increases, but at the same time the thermal insulation properties decrease. Remember that foam concrete increases strength over time and reaches the required levels for building buildings by 28 days. A newly made foam block is not recommended, and it is such a material that is often present on the market in the midst of construction work, therefore it does not interfere with building up for 3-4 weeks after purchase;

low bending strength. According to this indicator, the material is significantly inferior to concrete and reinforced concrete, however, with an increase in density, the strength of the products also increases, but at the same time the thermal insulation properties decrease. Remember that foam concrete increases strength over time and reaches the required levels for building buildings by 28 days. A newly made foam block is not recommended, and it is such a material that is often present on the market in the midst of construction work, therefore it does not interfere with building up for 3-4 weeks after purchase;- often block geometry far from ideal, which complicates installation. It is better to buy a foam block from trusted manufacturers who offer quality products with the most accurate dimensions;

natural shrinkage. Within two months after completion of construction, the foam block shrinks, which is associated with a set of strength. Shrinkage reaches 2-4 mm per linear meter. Since it is uniform, the structure is not in danger, but finishing work will be delayed for several months;

natural shrinkage. Within two months after completion of construction, the foam block shrinks, which is associated with a set of strength. Shrinkage reaches 2-4 mm per linear meter. Since it is uniform, the structure is not in danger, but finishing work will be delayed for several months;- not the best appearance, therefore, houses built from a foam block are additionally finished, for example, with decorative or ordinary brick, equipped with ventilated facades, etc.

Foams have more advantages than disadvantages, and if you choose the right material, the construction will be durable and reliable. From foam blocks you can build houses up to three floors. To increase strength, it is recommended to reinforce the walls.

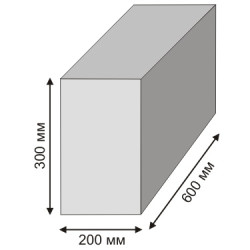

No. 3. The size of the foam blocks

The first thing that is taken into account when buying a foam block is its size. Today, almost all manufacturers make foam blocks of this size:

20 * 40 * 60 cm (height / depth / length) for load-bearing external walls;

20 * 40 * 60 cm (height / depth / length) for load-bearing external walls;- 30 * 20 * 60 cm for load-bearing internal walls;

- 10 * 30 * 60 cm for curtain walls and partitions.

All foam blocks in the batch must be exactly the same size. - This is a guarantee that they will fit snugly together. Verification before purchase can be done by measuring the parameters of the blocks and comparing them, or by installing the blocks on a flat surface, so you can compare the dimensions of the products and see how tight they fit together. The presence of gaps and steps on the surface of the blocks is not allowed - this will not only increase construction costs, but can also lead to the formation of cold bridges.

Number 4. Density and frost resistance of foam blocks

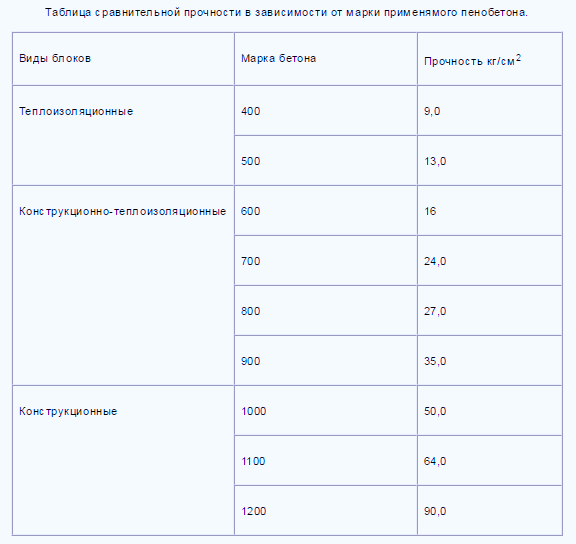

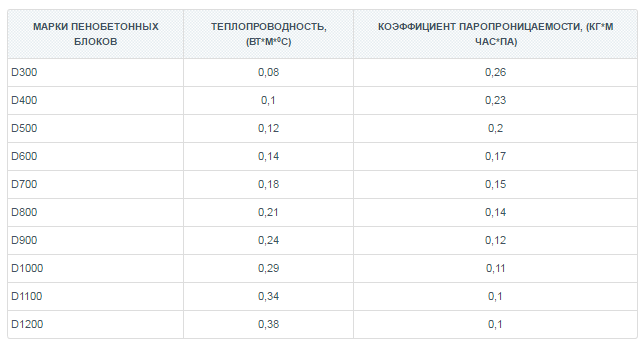

Density is a key characteristic of foam blocks. According to this parameter, one or another brand is assigned to the material. Density is indicated by the letter D, foam blocks of brands are presented on the market from D400 to D1200. For different purposes, foam blocks with different densities are used:

heat-insulating foam blocks of brands D400 and D500 have a coefficient of thermal conductivity of about 0.12 W / m º C, weigh 11-19 kg, highly porous, used for wall insulation;

heat-insulating foam blocks of brands D400 and D500 have a coefficient of thermal conductivity of about 0.12 W / m º C, weigh 11-19 kg, highly porous, used for wall insulation;- structural and heat-insulating blocks of grades D600-D900 have a coefficient of thermal conductivity in the range of 0.14-0.29 W / m º C and a weight of 23-35 kg. Can be used for the construction of load-bearing walls in houses of small floors;

- brand building blocks D1000-D1200 with a coefficient of thermal conductivity of 0.36 W / m º C and a weight of 39-47 kg are used for the construction of load-bearing walls and ceilings.

With increasing density, the thermal insulation characteristics of the blocks fall, since the amount of air trapped in its structure decreases.

Another characteristic of foam blocks is frost resistance, i.e. the number of freezing and thawing cycles that the material can withstand without changing its properties. This indicator is indicated. the letter Ffollowed by a number showing the number of permissible freezing and thawing cycles. This indicator ranges from 15 to 75. The highest level of frost resistance is suitable for areas with extremely harsh climates.

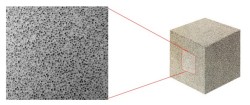

No. 5. Foam block structure

Foam blocks must be durable. If you managed to grind a piece of material between your fingers, then the manufacturer saves on cement or violates technology. In any case, such material cannot be used for the construction of load-bearing walls. Between the fingers, only heat-insulating foam blocks with a density of up to 15 kg / cm can be rubbed2.

Foam blocks must be durable. If you managed to grind a piece of material between your fingers, then the manufacturer saves on cement or violates technology. In any case, such material cannot be used for the construction of load-bearing walls. Between the fingers, only heat-insulating foam blocks with a density of up to 15 kg / cm can be rubbed2.

Block should not contain cracks - their presence indicates the existing internal stress as a result of the improper drying process. The structure of the block should be uniform throughout the mass, and the bubbles should be small (no more than 1 mm) and spherical in shape - oval-shaped bubbles indicate fragility of the product. The uneven color of the block and the presence of stains should also be cautious.

No. 6. What else to consider when examining a foam block?

Since the production of foam concrete blocks does not require special equipment, today the number of unscrupulous entrepreneurs offering products that do not comply with GOST is growing, so it is becoming increasingly difficult to choose a really durable and high-quality material. With an external inspection of the foam block, you should focus on such signs of quality material:

- color should be from light gray to dark gray. The whitish color indicates that lime was used in the production, which negatively affects the strength characteristics and environmental friendliness;

no black grease, since their presence will not allow normal plastering of the wall surface. The fact is that responsible manufacturers use high-quality self-decomposing mold grease that does not leave marks on the block. To save money, used machine oil can be used, which creates a film on the product, and in this place the plaster will simply peel off;

no black grease, since their presence will not allow normal plastering of the wall surface. The fact is that responsible manufacturers use high-quality self-decomposing mold grease that does not leave marks on the block. To save money, used machine oil can be used, which creates a film on the product, and in this place the plaster will simply peel off;- good foam block does not sink in water;

- quality products must be packed in filmotherwise, excessive drying of the block will lead to the formation of a network of microcracks;

- foam blocks must have quality certificates, and a normal manufacturer is ready to provide complete information about its products, so hiding some data should alert;

- too low price It is also an indirect sign that the manufacturer saved and violated production technology.

And finally, better trust proven large manufacturersthat have been on the market for a long time - so the guarantee is higher that the constructed structure will be durable, and the foam block will meet your expectations.