14 tips for choosing plastic windows

Plastic windows have long and solidly replaced old wooden structures. Newspapers and bulletin boards today are literally full of offers from different manufacturers. In such a crowded market it’s difficult make an informed choice, and often consumers are guided by the lowest prices and attractiveness of advertising. The fallacy of this approach makes itself felt already in the first winter, when drafts, frosts appear, and the glasses begin to sweat. Do not repeat the mistakes of thousands of users - the choice of plastic windows must be done deliberately. A little knowledge of the theory will help to understand which design will be preferable in a particular house or apartment.

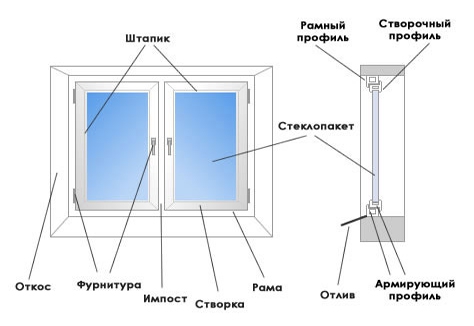

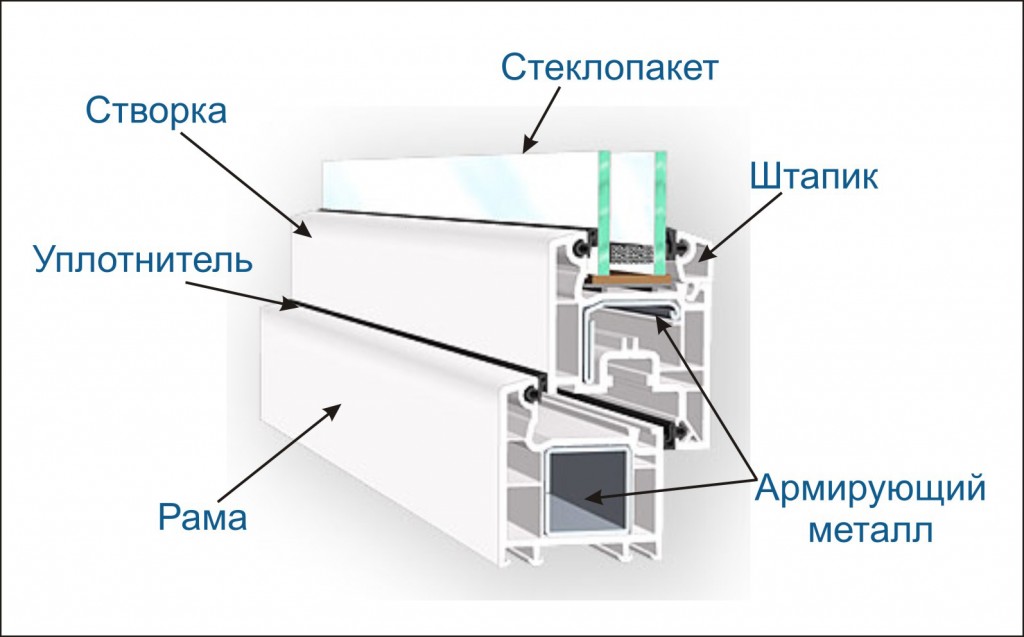

No. 1. Plastic window construction

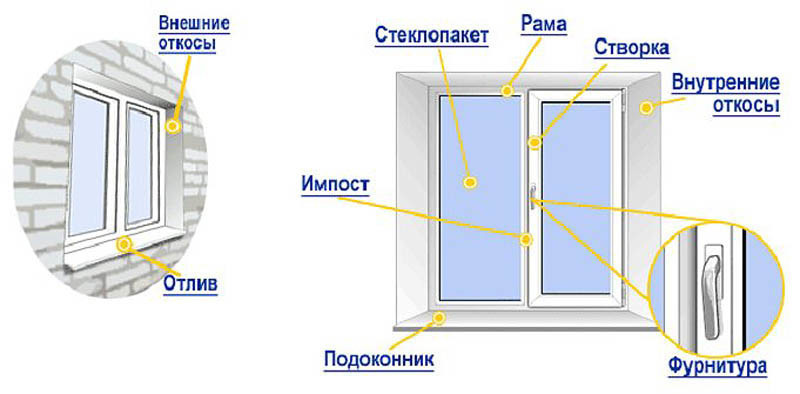

To properly navigate the market for a particular product, you need to know what it is made of and how. The main structural elements of the plastic window are frame, sash, double-glazed window, fittings, gasket and glazing bead. The frame and sash consist of a plastic profile reinforced with a steel profile.

The frame is the basis of the design, is installed in the window opening. Frame profile consists of several chambers, each of which has its own purpose: for drainage of condensate, placement of a reinforcing strip, fixing accessories, etc. Double-glazed window It occupies the main part of the plastic window construction, is held thanks to hidden glazing beads. To make the structure airtight, seals. An important role is played by accessories, on the quality of which durability and reliability largely depend.

Due to the design features, the plastic window receives several advantagesamong which it is worth noting increased level of heat saving compared to ordinary wooden windows, high level soundproofing and protection from unauthorized entry.

No. 2. What should be the profile?

A profile made of PVC is harmless, attractive and resistant to various chemicals, but the plastic would not withstand serious deformations and temperature extremes, therefore, additionally steel reinforced profile. Metal thickness should not be less than 1.4 mm: the thicker the metal insert, the heavier the double-glazed window can be installed. The profile should only be reinforced with galvanized steel.

High quality plastic It has a uniform color, a smooth and grain-free surface, and has no odors. Pay attention to the type of surface: matte plastic will literally absorb impurities, which subsequently will be almost impossible to remove from the surface. Glossy plastic, even the most inexpensive, will be much more convenient to use. A high-quality profile is quite durable and should easily withstand 50-60 years of operation.

No. 3. Profile Thickness and Width

Profile thickness is usually understood as plastic profile thickness. First of all, the strength and mechanical resistance of the material depend on this parameter. IN depending on the thickness of the external and internal walls of the profile It is divided into three classes:

- class A assumes an external wall thickness of 2.8 mm and an internal wall thickness of 2.5 mm or more. The European standard is those windows in which the thickness of the external walls of the profile exceeds 3 mm. Exactly such structures can be installed in residential premises;

- the class B. Such a profile has outer walls with a thickness of 2.5 mm and inner walls with a thickness of 2 mm. Such designs are not so durable, they hold heat worse and do not protect well enough from noise, therefore they can be installed only in non-residential premises;

- class C. This includes profiles that do not meet the requirements of previous classes. Today, such designs are practically not used.

Another important design profile parameter is width, or installation depth. This parameter does not cannot be less than 50 mm, and for normal operation of the window should be 58-70 mm, because then the requirements for heat and sound insulation of the room will be met. For the noisiest and coldest areas, profiles with a larger thickness, which can reach even 130 mm, are suitable.

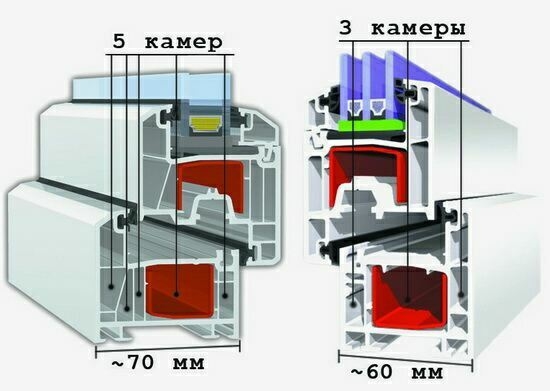

Number 4. Number of air chambers profile

The profile inside consists of several cavities, the so-called cameras, which should not be confused with double-glazed cameras. A profile chamber is a cavity elongated over its entire length and filled with air or reinforcing material. By the number of such cavities, 2-, 3-, 4 and even 8-chamber profiles are distinguishedbut got the most popularity 3- and 5-chamber constructions. As a rule, manufacturers allow you to look inside the profile, demonstrating their products in the context and showing the design features of the cameras.

As the number of cameras increases heat insulating profile material characteristics. If the 3-chamber profile is perfect for windows that face south on a quiet courtyard, then the 5-chamber profile is indispensable for windows that face north or on a noisy road.

No. 5. Number of double-glazed cameras

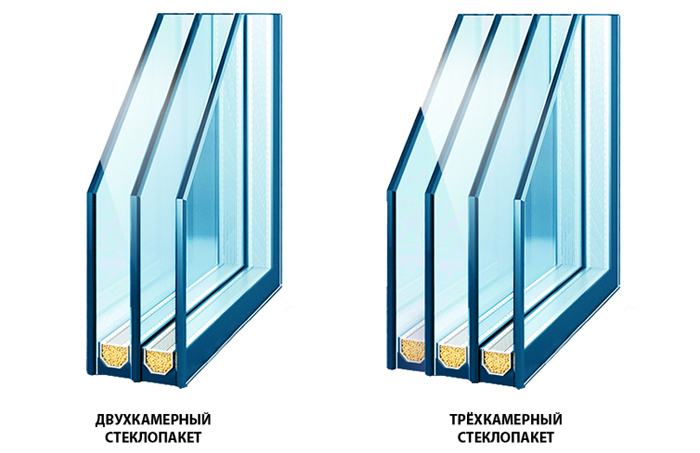

The double-glazed window, the light-transmitting part of the window, consists of two or more glasses, the space between which is filled with air or inert gas. A camera is the space between two glasses.

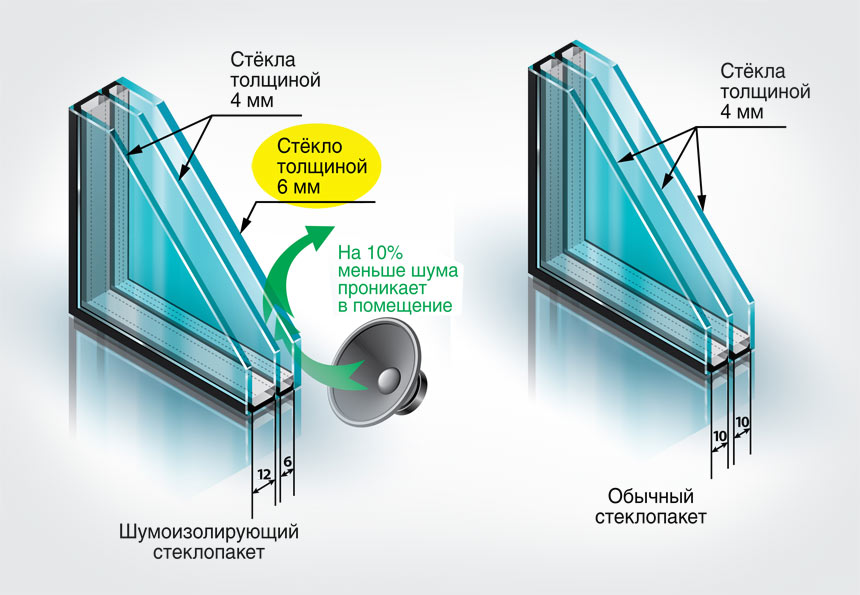

Single chamber double-glazed windows find application in quiet areas with a mild climate. Most in demand double-glazed windowswhich perfectly suppress street noise and allow you to maintain the optimum temperature in the room. For maximum protection against noise, it is recommended to choose double-glazed windows in which the space between the glasses has a different thickness. Even better, if the inner glass is thinner than the rest, which will provide maximum sound insulation.

On sale can be found double-glazed windows and with a large number of cameras - 3 and even 4. But it should be borne in mind that the more double-glazed windows in the design, the greater its total weight, and the more reliable and strong the fittings should be.

No. 6. Type of glass in a double-glazed window

The quality of the glass matters no less important than the number of glass panes. Today, manufacturers can use these types of glasses., as:

- float glass. The technology of its manufacture allows to obtain glass that is exceptionally even and completely identical in thickness, with increased transparency;

- triplex or laminated glass. Such glasses consist of several layers of glasses, each of which is laminated with a film or a special liquid. Due to this, the material gains additional strength and burglar resistance, it is difficult to break, and even with damage, such glass does not leave sharp fragments. Moreover, triplex will more reliably protect the apartment from noise;

- selective glasses covered during the manufacturing process or after it in a vacuum with special substances that transmit long-wave radiation, but delay the short-wave, allowing the maximum to keep warm air in the apartment in winter and not to let the heat in in summer. Selective glasses can be of two types: i-glass they are sprayed with silver ions, have high efficiency and excellent translucency, but are afraid of atmospheric influences, therefore they can be used only from the inside. In contrast to them, k-glass more resistant to external negative influences, but have slightly lower efficiency;

- colored float glass has the ability to reduce the transmission of solar thermal energy. Such glasses are stained in bulk and can have almost any shade. Of course, the transparency of the material is lower, but along with the protection against heat, you also get a pleasant cozy atmosphere;

- reinforced glass characterized by the presence of a reinforced mesh, making it safer and fireproof;

- strained glass it resembles triplex in properties, but is made by special chemical or heat treatment. Upon destruction, such material forms a mass of small, safe fragments.

Number 7. Which seal is better?

A sealant is another important part of a plastic window that provides it proper tightness, protects the room from external noise, cold, dirt, etc. Today, the following materials are used as sealants:

- rubber. This material is obtained by vulcanization of rubber with sulfur. Among all possible sealants, this the cheapestTherefore, it is used in most plastic windows. It perfectly seals all cracks, but has one serious drawback - it “dubs” at low temperatures, and constant temperature changes can lead to cracking;

- silicone - An excellent safe and durable material that boasts high durability. Throughout the life of the silicone does not change its original properties, and temperature differences do not affect it in any way. The material calmly tolerates temperatures from -40 to +1500C. Moreover, moisture and sunlight are also not able to spoil such a seal. Among the disadvantages of the material is the high cost, due to which the seal is not so common;

- EPDM sealant, or ethylene propylene rubber. The material is used quite often, since with good performance it boasts a fairly reasonable price. This sealant is not afraid of the effects of precipitation, sunlight, high and low temperatures, mechanical influences;

- TPE sealant (thermoplastic elastomer). Under normal temperature conditions, the material behaves like rubber, and as the temperature rises, the material softens like a thermoplastic.

Number 8. Ventilation of plastic windows

Plastic windows, if they are made efficiently and installed correctly, differ high tightness of a designtherefore external air currents will not penetrate inside the apartment. Basically, The absence of drafts is one of the main advantages of designs, but what to do with ventilation? In houses of the old construction, as a rule, there is no supply ventilationas fresh air penetrated through the cracks in windows and doors. New owners of plastic windows after installing them may notice that the air in the apartment has become stuffy, musty, and condensation is collecting on the windows. All this is evidence that normal ventilation is not provided.

Plastic window manufacturers offer to solve the problem of ventilation in several ways:

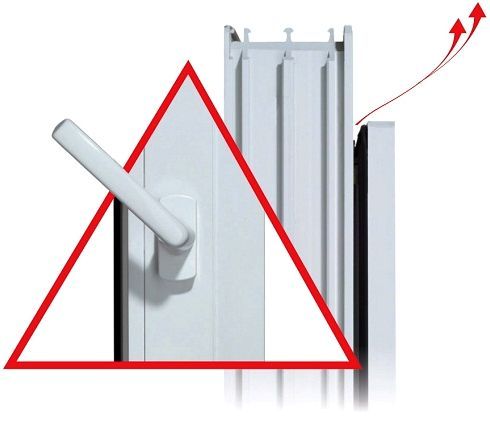

- micro-slot ventilation mode. With a certain rotation of the handle, a small gap forms between the frame and the window sash, which is not able to greatly reduce the heat and noise insulation characteristics of the structure, but provides an influx of fresh air;

- use of a window. Since plastic windows are made to order according to individual parameters, you can get a design not only with any number of double-glazed windows and any profile width, but also with the required number of partitions. The window allows you to let in fresh street air under the very ceiling of the room, where it mixes with room air. As a result, it becomes easier to breathe in the room, and there are no direct flows of cold air per person. The disadvantage of this long-standing and proven method of ventilation is that the design of the plastic window is complicated, becomes more expensive and heavier, and less sunlight will enter the apartment;

- combs on the windows - A simple, convenient, cheap and effective way of ventilation. In this case, the design of the window includes a special regulator, which allows you to fix the sash in the required position. As a rule, 4-5 modes are provided, allowing you to leave both a micro-gap between the frame and the sash, and a fairly impressive space;

- ventilation valves - The most effective and convenient option, providing the necessary level of ventilation in the room. Since today several types of valves are presented by manufacturers, this issue requires separate consideration.

No. 9. What are the ventilation valves?

Plastic windows are most often used. these types of ventilation valves:

- slotted valves. May be automatic or mechanical execution. This is a system consisting of an external lower intake valve and an upper internal exhaust valve, which are open-hole profiles. Fresh air enters the lower valve, heats up and exits through the upper valve at room temperature. Thus, it is possible to achieve the preservation of the optimum temperature in the room and ensure the flow of fresh air;

- seam valves provide an influx of fresh air due to the presence of seam folds. Dismantling the window is not required, the cost of the copan is small, the sound insulation will remain at the proper level, but the throughput is not the highest;

- overhead valves practically not used in residential premises - they found distribution only at production facilities. It is necessary to install such valves during the installation of plastic windows, otherwise then the dismantling of the structure will be required. The valve of the laid on type differs in big capacity, worsens heat and sound insulation of the room.

When choosing a ventilation valve, it is worth considering some of its parameters, the most important of which is bandwidth: it is necessary to start from 30 m3/ hour for 1 person. It is important to pay attention to the peculiarities of winter operation, so that once it just does not icy. That is why the valve must have quality thermal insulation.

It is also worth paying attention to ventilation adjustment methodwhich can be automatic, manual or mixed. Automatic regulation the ventilation valve is ensured by the presence of a hygro-regulation sensor, which is responsible for monitoring the humidity level in the room. The ventilation control process itself is ensured by changing the cross-section of the check valve, which in certain cases can even be completely closed. Similarly, you can minimize the heat loss of the room, because the air from the street will be let in only when the humidity in the room rises, for example, with a large number of people. At manual setting the user will have to decide when to ventilate and when not. This setting is coarser.

It is worth noting that sometimes ventilation valves are not installed in the window structure itself, but in the wall near the window. This option will require much more serious investment of time and effort.

No. 10. The method of opening a plastic window

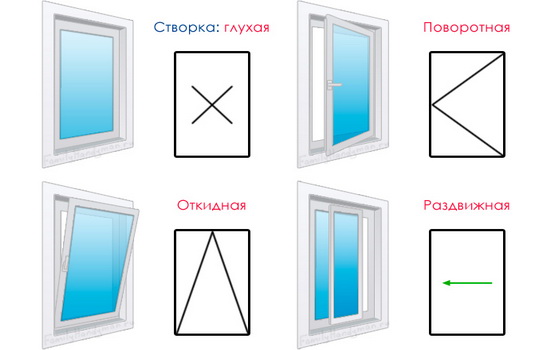

There are several basic options for opening a window structure:

- turning, the most familiar to us;

- folding;

- Fold-up;

- movable. It is used when there is no room for a swivel and tilt option, or the design is too heavy.

No. 11. Accessories for a plastic window

Whatever the quality of glass or window profiles, when using cheap, unreliable hardware, the entire structure will lose its previous characteristics within a few months after use. To withstand the heavy weight of the double-glazed window, window sangs must be very strong and reliable.

Pens - Another weak point, and often they go awry. Owners of plastic windows can name a lot of problems that they encountered during the operation of these structures, and many of them are associated with hardware. From all this we conclude that even such trifles, which at first glance are handles and loops, you need to pay maximum attention.

Today, window manufacturers offer a lot of different options for the performance of hardware elements. Window fittings are handles, locks, locks, latches. People like to consider even ventilation valves to fittings, Mosquito nets, window sills and low tidesbut they are not hardware.

Pens

Window handles They are used several times a day, so they must be especially durable. Handles differ not only in material and color, but also in function:

- standard. Allow you to open and close the window, leave it in the ajar position. They do not have any bells and whistles, therefore they are cheap and are most widespread;

- burglar-proof. Outwardly identical to standard handles, but they do not allow to open the window from the outside thanks to a special mechanism that blocks the window when exposed from the outside;

- pens with the castle will be by the way in those apartments where there are small children. It will be impossible to open the window if you do not insert a key, but you can even fold it out without a key;

- removable handles parents of young children who can inadvertently open a window will also save nerves, which can cause disastrous consequences.

Hinges

The main thing is that the hinges are made of durable material and withstand the weight of the glass. By the method of installing the loop can be of the following types:

- standard invoices. They consist of two metal cards, can be rotary or tilt-turn. After installation, they can be closed with decorative overlays for beauty;

- screw loops previously used only for wooden windows, today they are beginning to be used for plastic structures. They are attached to the sash and frame by threaded pins, and on one loop there can be 2-6 of these pins: the more they are, the more reliable the structure will be;

- mortise hinges - One of the best and most common solutions for plastic windows. They are not visible, they provide a large opening angle for the sash, and there will be no blowing through these hinges;

- burglar-proof hinges, the name of which speaks for itself, will provide the user with maximum security, because they cannot be dismantled with the windows closed.

Locks and locks

All kinds of locks and locks are an optional element in the design of windows, but if you live on the ground floor and are afraid of breaking in, or are afraid that a child may open the window and fall out of it, then it is worth installing additional accessories on the window:

- a lock with one or more constipations;

- latches;

- children's locks that block the opening of the sash, but do not prevent it from folding.

No. 12. The necessary little things for the window

When installing a plastic window, you should not save on trifles - this will not bring much benefit.It will be much more reasonable to equip the structure with everything necessary so that its operation is as durable and comfortable as possible.

What are the necessary elements to complement the plastic window? Among the most important:

- mosquito net. Everyone is convinced of its necessity with the advent of spring and summer, because this simple detail protects the house from poplar fluff, leaves, insects, particles of dirt, without interfering with the free circulation of air. Usually the grid is inserted into the frame and can be easily removed from it, but you can equip it with your own hinges - this is an option for large windows;

- window sills play a decorative and functional role;

- platbands - patch strips for the design of the window opening, made of the same material as the window sill;

- slopes - These are the slats that are inserted between the window profile and the walls. It is important that these elements are made as high quality as possible, otherwise they will be moldy due to increased humidity;

- low tide It is installed from the outside and is designed for quick removal of precipitation. It may seem that this part is not so necessary, but without it the waterproofing of the window is gradually disrupted.

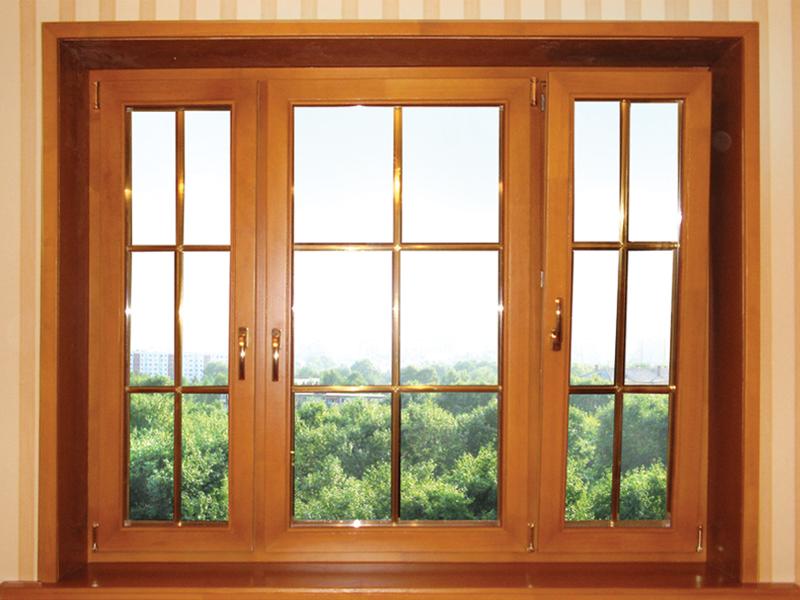

No. 13. Plastic window design

We are used to standard plastic windows in white frames, but there are much, much more design options. Here are just the basic techniques that are used to give the window an individual style:

- film frame lamination allows you to issue a profile for wood of any breed;

- decorative layout - dividing the window into zones, often rectangular, but can be triangular and rounded. They not only decorate the structure, but also make it stronger;

- tinted glass will give the room a unique shade, reduce the effect of ultraviolet rays, and it will be difficult for outsiders to consider what is happening outside the window;

- stained glass drawing on glass;

- smart glass changes the degree of transparency depending on the light. This happens under the influence of electric current. This solution is rarely used so far, but it’s a great alternative to the familiar jalousie;

- decorative triplex - This is not only protection and additional security, but also the opportunity to make the interior unique. Through the use of layers of glass of different transparency and with a specific pattern, you can achieve the most incredible results;

- mirror glass protect from prying eyes and sunlight.

It is worth noting that plastic windows can be not only rectangular, but also oval, arched, etc.

No. 14. Which manufacturers can be trusted?

Today, dozens and even hundreds of firms are engaged in the production of plastic windows, but not all do their work in good faith. Let us dwell on the largest manufacturers who have established themselves in the domestic market with high-quality, strong and durable products.

KBE

German company, which has become not just an industry leader, but a synonym for quality. The first production appeared in Berlin in 1980, and even then the company was a pioneer in the field of high-performance extrusion. In a very short time, the manufacturer gained confidence both in Germany and throughout Europe, and in 1995 it entered the domestic market. The demand for the manufacturer’s plastic windows was so high that it was decided to open two plants in Russia: one in Khabarovsk, the other in Voskresensk near Moscow. At Russian plants, German technology and quality control are fully observed, so the windows come out identical in all respects, which is confirmed by various tests.

German company, which has become not just an industry leader, but a synonym for quality. The first production appeared in Berlin in 1980, and even then the company was a pioneer in the field of high-performance extrusion. In a very short time, the manufacturer gained confidence both in Germany and throughout Europe, and in 1995 it entered the domestic market. The demand for the manufacturer’s plastic windows was so high that it was decided to open two plants in Russia: one in Khabarovsk, the other in Voskresensk near Moscow. At Russian plants, German technology and quality control are fully observed, so the windows come out identical in all respects, which is confirmed by various tests.

Moreover, the company's engineers participated in the preparation of GOSTs for plastic windows, and these documents are accompanied by drawings of the KBE windows, which means that the manufacturer’s windows have become the domestic standard. The designs are really very high quality, durable and thoughtful in all respects, but they are also expensive.

Rehau

Swiss company Since 1948, has been faithful to its philosophy of creating solutions for minimum energy consumption. The production of windows and doors is the basis of the company. Here they are trying to constantly improve designs in order to achieve ever higher levels of heat and sound insulation. Today the windows of Rehau are some of the best in Europe and the world. They are able to withstand even the most severe frosts, winds and heavy rainfall, being a defense no worse than a brick wall. For example, a window with a 6-chamber profile and a depth of 86 mm replaces a brick wall 1.3 m thick. The company's products are characterized by a wide range, frost resistance and environmental friendliness. An excellent choice for harsh domestic climatic conditions! True, and have to pay a lot.

Swiss company Since 1948, has been faithful to its philosophy of creating solutions for minimum energy consumption. The production of windows and doors is the basis of the company. Here they are trying to constantly improve designs in order to achieve ever higher levels of heat and sound insulation. Today the windows of Rehau are some of the best in Europe and the world. They are able to withstand even the most severe frosts, winds and heavy rainfall, being a defense no worse than a brick wall. For example, a window with a 6-chamber profile and a depth of 86 mm replaces a brick wall 1.3 m thick. The company's products are characterized by a wide range, frost resistance and environmental friendliness. An excellent choice for harsh domestic climatic conditions! True, and have to pay a lot.

Veka

it German companyexisting since 1969. Today she is one of the world leaders in the production of plastic windows and doors. The manufacturer has a huge research center, whose employees are constantly working on improving window designs and manufacturing techniques.

it German companyexisting since 1969. Today she is one of the world leaders in the production of plastic windows and doors. The manufacturer has a huge research center, whose employees are constantly working on improving window designs and manufacturing techniques.

Today, dozens of factories of the company operate in different countries on almost all continents, but everywhere the activity is carried out under the close supervision of employees of the main office of the enterprise. Veka windows are also being manufactured in Russia., which allows domestic buyers to receive quality goods at a better price. The manufacturer’s windows survive any climatic conditions and loads: from winter in the Far North to high humidity and strong wind loads.

Trocal

This company the first in the world introduced plastic windows, invented multi-chamber profiles, coextruded acrylic coatings, offered a lot of unique ways to decorate the profile. It all started in 1895 with the creation of Dynamit Nobel. The concern produced explosives and artificial materials. After numerous transformations in 1954 Trocal appeared, which introduced the world the first plastic window. All subsequent years were marked by constant new developments, the introduction of innovative technologies. The result was the popularity of the company's products around the world.

This company the first in the world introduced plastic windows, invented multi-chamber profiles, coextruded acrylic coatings, offered a lot of unique ways to decorate the profile. It all started in 1895 with the creation of Dynamit Nobel. The concern produced explosives and artificial materials. After numerous transformations in 1954 Trocal appeared, which introduced the world the first plastic window. All subsequent years were marked by constant new developments, the introduction of innovative technologies. The result was the popularity of the company's products around the world.

Today, the company attaches great importance to the production of not only high-quality and durable windows, but also completely safe for health. The range of different designs is huge, production in Russia is operating, made several valuable developments for the production of windows specifically for our market.

LG Chem

History South Korean company LG Chem begins in 1947, but came to the production of plastic windows in the 80s. Today, the company's windows have established themselves with a sleek design, high quality, excellent value for money and performance.

History South Korean company LG Chem begins in 1947, but came to the production of plastic windows in the 80s. Today, the company's windows have established themselves with a sleek design, high quality, excellent value for money and performance.

SALAMANDER Industrie-Produkte GmbH

This German company It was formed in 2002 as a result of the merger of two well-known manufacturers of PVC profiles: SALAMANDER and BRÜGMANN. SALAMANDER is known as the largest manufacturer shoes. The search for new materials for its production eventually resulted in the creation of PVC profiles. Since then, many innovative ideas have been born within the walls of the company that have conquered the whole world. Products are manufactured in many countries today, including and in Russia. At the domestic plants modern German equipment is used, strict quality control is in place.

This German company It was formed in 2002 as a result of the merger of two well-known manufacturers of PVC profiles: SALAMANDER and BRÜGMANN. SALAMANDER is known as the largest manufacturer shoes. The search for new materials for its production eventually resulted in the creation of PVC profiles. Since then, many innovative ideas have been born within the walls of the company that have conquered the whole world. Products are manufactured in many countries today, including and in Russia. At the domestic plants modern German equipment is used, strict quality control is in place.

SCHÜCO

The company operates since 1951 in Germany. Today, the company's factories and representative offices are located around the world, and the products have become a symbol of high quality, because it meets the most stringent requirements in terms of design, safety, comfort and energy efficiency. Products are developed taking into account the characteristics of various climatic zones, which is why it has gained wide popularity in different countries of the world. The company's products are valued for its perfect performance, the highest quality and record durability.

The company operates since 1951 in Germany. Today, the company's factories and representative offices are located around the world, and the products have become a symbol of high quality, because it meets the most stringent requirements in terms of design, safety, comfort and energy efficiency. Products are developed taking into account the characteristics of various climatic zones, which is why it has gained wide popularity in different countries of the world. The company's products are valued for its perfect performance, the highest quality and record durability.

The deceuninck group

Another one German companyengaged in the production of PVC systems for windows. She regularly is included in the world rankings of the best in its field. For more than 75 years of existence, the company has conquered more than 90 countries, its plants are located in 19 countries. In Russia there is a wide network of company representative offices. The manufacturer offers several types of profile systems with different widths and design features, which allows you to find the perfect solution for a home located in any climatic conditions.

Another one German companyengaged in the production of PVC systems for windows. She regularly is included in the world rankings of the best in its field. For more than 75 years of existence, the company has conquered more than 90 countries, its plants are located in 19 countries. In Russia there is a wide network of company representative offices. The manufacturer offers several types of profile systems with different widths and design features, which allows you to find the perfect solution for a home located in any climatic conditions.

Proplex

This is the lead domestic manufacturer of plastic windows, which has been operating since 1999 and uses Austrian technology. The company is constantly expanding production, introducing new technologies, introducing new models and designs. Since the manufacturer uses the best world experience and adapts designs to domestic conditions, plastic windows come out reliable, durable, they have excellent performance and are inexpensive. The network of representative offices throughout the country is very wide, special training centers operate where they teach the correct installation of structures, which is no less important than high-quality production.

This is the lead domestic manufacturer of plastic windows, which has been operating since 1999 and uses Austrian technology. The company is constantly expanding production, introducing new technologies, introducing new models and designs. Since the manufacturer uses the best world experience and adapts designs to domestic conditions, plastic windows come out reliable, durable, they have excellent performance and are inexpensive. The network of representative offices throughout the country is very wide, special training centers operate where they teach the correct installation of structures, which is no less important than high-quality production.

Montblanc

Domestic manufacturer plastic windows that have been on the market since 2000. Immediately, modern Austrian equipment was purchased, thanks to which the company was able to produce high-quality products and sell them at low prices, since there were no transportation costs. Today throughout the country there are 4 manufacturer's factories that produce windows in a large assortment.

Domestic manufacturer plastic windows that have been on the market since 2000. Immediately, modern Austrian equipment was purchased, thanks to which the company was able to produce high-quality products and sell them at low prices, since there were no transportation costs. Today throughout the country there are 4 manufacturer's factories that produce windows in a large assortment.

In conclusion

Since the plastic window is installed for a sufficiently long period of time, it makes sense to take time to study the design features, familiarize yourself with the products of different manufacturers in order to choose the window that is ideal for specific conditions.

My husband and I were choosing which windows to install for a long time. We stopped at 70 kb, on the advice of friends. The windows pleased us. Good design, a wide selection of colors. Noise and thermal insulation are good. Quality fittings. That's what we were looking for.

It seems to me that you need to order windows from the manufacturer, it’s more reliable.

Victoria, in any case, you will order windows from the manufacturer, because all dealers and intermediaries will still order from the manufacturer. You just need to clarify the prices and conditions of the guarantee.

Before installing the windows, we heard and read stories about the nerves with which people change windows. Either the installers will tear off all the wallpaper and get it dirty with foam, then the low-quality windows themselves will come across. We are lucky with everything. They asked a friend what windows to install; he works in construction and knows everything about it. On his advice, they put KBE.

Thanks for the interesting article. I can say that each buyer will have his own factor in choosing the windows he needs. For some, the main thing is thermal insulation, someone is noise insulation, someone is committed to design. We live in the Far East, so it was important for us that the windows could withstand low temperatures and temperature extremes ... We searched for a long time, bought kbe88 and still have no problems. We have a very severe winter and nothing, despite this, the house is warm and comfortable. So I think, in addition to the quality of the goods, the consumer will look for what is right for him

We also have kbe 88. For such a period, and they have been standing for 4 years already, you are convinced that the windows are of high quality.You don’t even need to read any reviews. They still look like completely new, there have never been any blows, the noise insulation is 100 percent excellent, we can say this with confidence, because our windows open onto the tram tracks — you can imagine what it is. In general, I would undoubtedly put five for this manufacturer for quality and reliability.

I am very glad that KBE was put in the first place, they really deserve it. We are also fans of this manufacturer) We set kbe76 a few years ago, of course, a little time, but the obvious pluses are already visible - the houses are warm, comfortable both in winter and in summer, and for us it was the most important thing ... for a long time we searched for this. It’s good that our acquaintances helped with the choice)

Good tips, thanks a lot to the author. We ourselves recently literally dealt with this issue. They installed new windows for themselves in the fall and are already very pleased that in winter they showed their best. From the cold and weather changes were protected just fine. So the purchase was a success, not lost)

And we have a KBE expert, we are also very pleased with the purchase. Very warm windows Before that, they were always tormented ... there were old wooden ones. Draft, cold, and wash some problems ... Now everything is just fine!)

We chose the windows of Rehau and are quite satisfied. Although the neighbors have KBE installed and they also have not complained for several years. As I understand it, Rehau and KBE are the most reliable manufacturers, and this was the basis for our choice. But, of course, it is equally important - to correctly install the windows, otherwise there will be no sense from them.