6 tips for choosing plastic panels for walls and ceilings

Looking for a lightweight, hygienic, moisture resistant and cheap wall covering or the ceiling? Then you should definitely pay attention to the plastic panels, which, plus everything else, also differ in their excellent appearance. They are often used. for facing walls in the kitchen, in bath and on balcony, for ceiling finishes in the bathroom and other rooms, often plastic panels are used in non-residential premises. For each of these applications, panels of a certain size, color, and relief will be appropriate. With a variety of material and features of the choice of plastic panels, we will try to figure it out.

No. 1. What are the pros and cons of plastic panels?

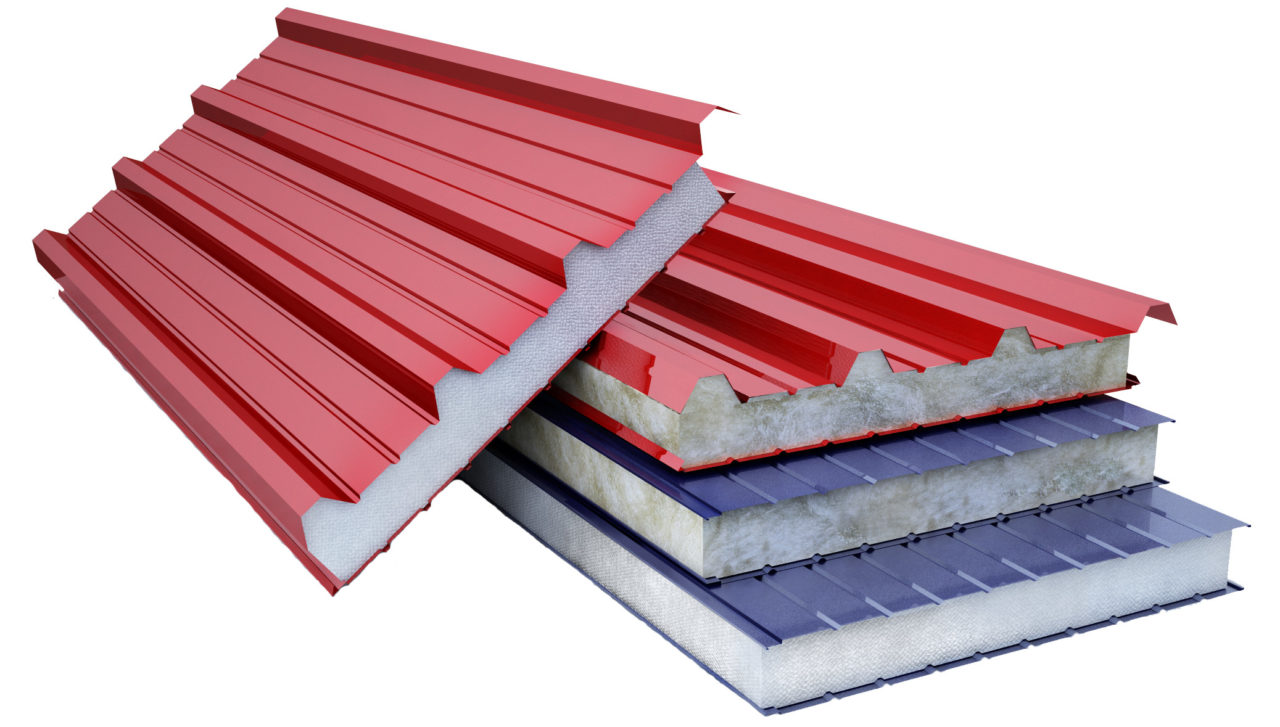

Basis for the production of plastic panels - solid polyvinyl chloride, which is characterized by maximum resistance to fire. The material is made by extrusion; between two painted or varnished surfaces there is a space consisting of numerous longitudinal honeycombs formed stiffeners.

The main advantages of PVC panels:

- light weight;

- moisture resistance, hygiene, antistatic, easy care;

- environmental friendliness;

- fire resistance and resistance to temperature extremes;

- not bad soundproof quality;

- a huge selection of drawings and textures, which allows you to organize the interior in any style;

- simple installation, which almost anyone can handle;

- low price.

Considering plastic panels as a material for facing ceilings or walls, you need to be aware that it It has some disadvantages:

- low strength. It is easy to leave a scratch, dent, or other type of damage on the surface of the material;

- at first the panels may emit a specific smell;

- the material has a limited scope and is suitable for those rooms where strength is not as important as moisture resistance, fire resistance and decorativeness.

No. 2. Types of wall panels by purpose

The most important and, at the same time, conditional division of wall panels is division into ceiling and wall. No one forbids the use of wall panels to decorate the ceiling and vice versa. The difference between these types of panels is found only in the difference between the main parameters.

Wall panel thickness 8-10 mm, and the length can be 2.7 m, 3 m or even 6 m. Length ceiling panels starts from 6 m and can reach 12 m, and their thickness is less than 8 mm: if earlier most of the ceiling panels had a thickness of 8 mm, now manufacturers are constantly reducing it, so it’s easy to find panels with a thickness of 7 mm and even 4-5 mm.

No. 3. Joint of plastic panels

Depending on the type of joint, plastic panels are:

- seamless

- suture.

Seamless PVC panels can be called very conditionally, since the joint will still be noticeable, but the surface itself will be smooth, because the visibility of the joint between the panels is not provided for by the decor. Of course, you should not expect that the ceiling trimmed with such panels will be as smooth as traction or drywall, but when using special sealants You can achieve very good results in terms of aesthetics.

Suture panels They are distinguished by a special embossed joint to give the surface an interesting decorative effect. Often such plastic panels imitate wooden lining. On sale there are also panels under tile: experts recommend using square elements with a side of 30-98 cm. In addition, on sale you can find plastic panels with rust, they are a cross between seam and seamless panels, but are not very common.

Number 4. Surface type

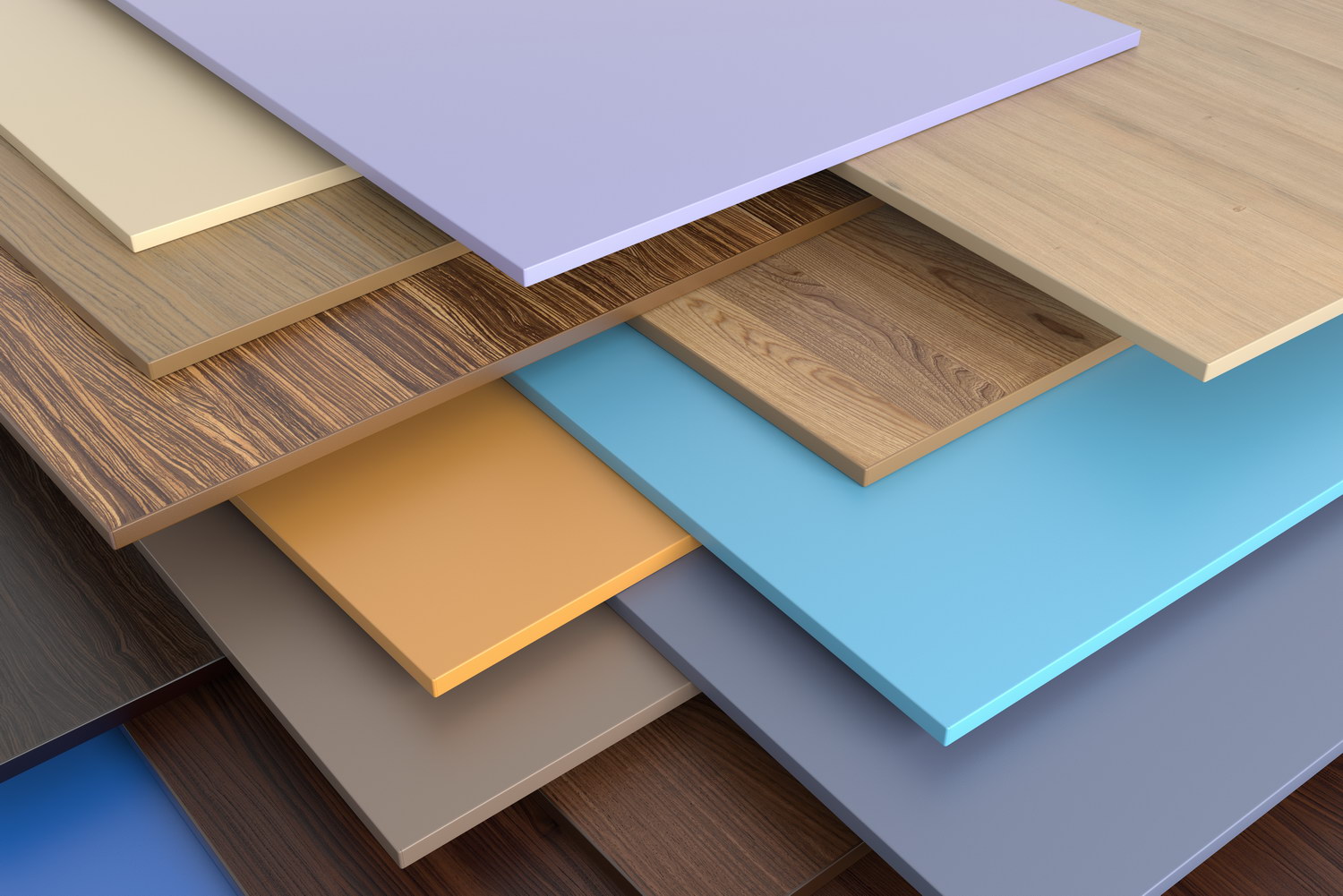

One of the main advantages of plastic panels is variety of design. On sale you can find both the simplest and cheapest white panels, and material painted in any color, but the most interesting options are those that have some kind of pattern or imitate wood, stone or other noble surfaces.

All plastic panels by surface type can be divided into:

From the point of view of technical characteristics, all these panels are exactly the same, and depending on your own preferences, you can choose a panel with the necessary surface.

When it comes to material with a specific pattern, it can be applied in one of the following ways:

- varnishing. First, the necessary pattern is applied to the surface of the panel thermal transfer or offset printing, and for fixing it from above, the panel is covered with a layer of varnish - it protects the pattern from moisture, sunlight, friction, etc. Using different processing methods, the varnished surface can be either glossy or matte;

- lamination. In this case, the surface of the panel is covered with a thin strong film, on which a pattern is applied that repeats the texture of wood or stone. Such panels can imitate any kind of wood and almost any kind of stone, sometimes manufacturers thus apply an abstract pattern to the surface of the material.

No. 5. What else to look for when choosing?

Undoubtedly, everyone wants to get the highest quality material that can serve faithfully for as long as possible. To choose strong and durable plastic panels, we recommend pay attention to such parameters:

- front panel thickness: the more, the better, because strength, durability, resistance to mechanical damage, etc. If the panel can easily be damaged, then moisture will begin to penetrate into the gap over time, causing mold to develop. It is clear that hardly any plastic panel is able to withstand a strong blow, but it should cope with a number of less serious loads. Ideally, the thickness of the front panel should be 2.5 mm, and the same indicator in low-cost products rarely exceeds 1.5 mm;

- number of stiffeners. Here the same rule works as with the thickness: the more, the better, and the stronger and less susceptible to deformations the panel will be. The panel should have at least 20 stiffeners, ideally 29. All ribs should be flat, have the same thickness and be strictly perpendicular to the two panels that they connect;

- appearance. The panel should be uniformly painted and even, stiffeners should not appear on it, there should be dents. Also, before buying, it is better to check how firmly the panels are connected to each other;

- an indirect sign that quality material is in front of you is weight. The thicker the front panel and the more stiffening ribs, the greater the weight of the panel. This indicator is useful when comparing two panels with the same dimensions;

- better to get material from one batch - This is a guarantee that the color and features of the picture will be the same. Even with one article, but from different parties, the material may differ in shade, which will be clearly visible after installation.

No. 6. Top Plastic Panel Manufacturers

When buying any product, we are used to paying attention to the manufacturer.The reputation that has developed around his name allows us to judge the quality of products. No exception and plastic panels. Today, hundreds of manufacturers of plastic panels appear on the market: both foreign and domestic. Let us dwell on the best.

Venta

This Belgian company is one of the leading European manufacturers of decorative panels, and the range is constantly growing. The manufacturer’s products are in great demand around the world, so the company is constantly opening new plants. So, in 2003, production was opened in Russia, so today domestic buyers have the opportunity to buy plastic panels of European quality, manufactured using the most modern technologies, but at the same time pay a low price for these products.

This Belgian company is one of the leading European manufacturers of decorative panels, and the range is constantly growing. The manufacturer’s products are in great demand around the world, so the company is constantly opening new plants. So, in 2003, production was opened in Russia, so today domestic buyers have the opportunity to buy plastic panels of European quality, manufactured using the most modern technologies, but at the same time pay a low price for these products.

The assortment of the company includes panels with different parameters and different designs. There are even rugged material with tile effect, which will be most welcome when decorating walls. Most recently, production was launched. panels with digital printingthat can become a real decoration of the interior.

Forte

Italian company Forte has been operating since 1969, and has already established itself as one of the world's largest manufacturers of PVC products. The company's products are now successfully sold in more than 50 countries. Production is carried out on the most modern equipment with the introduction of innovative technologies. The company's specialists constantly monitor the requirements of customers, quickly responding to them with new offers.

Italian company Forte has been operating since 1969, and has already established itself as one of the world's largest manufacturers of PVC products. The company's products are now successfully sold in more than 50 countries. Production is carried out on the most modern equipment with the introduction of innovative technologies. The company's specialists constantly monitor the requirements of customers, quickly responding to them with new offers.

Among other things, the company produces decorative plastic panels and exclusive decorative wall panels Le MURINO. For the production of the latter is used stone crumbwhich is sprayed onto the front panel. In two collections, more than 20 different colors and shades are presented, which allows you to choose the right finish for any room.

Deceuninck

it international company, which began production in France and the UK, and today the manufacturer's plants are located in different countries. In total, the company has 14 factories, and products are represented in 91 countries. A large representative office of the company operates in Russia, therefore the manufacturer's plastic panels are widely represented in the domestic market.

it international company, which began production in France and the UK, and today the manufacturer's plants are located in different countries. In total, the company has 14 factories, and products are represented in 91 countries. A large representative office of the company operates in Russia, therefore the manufacturer's plastic panels are widely represented in the domestic market.

Shanghai Zhuan

Lately Chinese companies begin to offer increasingly better products. Of course, not all plastic panels marked “made in China” should be trusted, but Shanghai Zhuan Qin Co. Ltd is a prime example of a conscientious responsible manufacturer. The company specializes in the production of wall panels from various materials, including and plastic panels. In the assortment there are materials of different sizes, with different types of jointing joints, and there is no need to talk about the number of colors and shades. With high quality prices are acceptable.

Lately Chinese companies begin to offer increasingly better products. Of course, not all plastic panels marked “made in China” should be trusted, but Shanghai Zhuan Qin Co. Ltd is a prime example of a conscientious responsible manufacturer. The company specializes in the production of wall panels from various materials, including and plastic panels. In the assortment there are materials of different sizes, with different types of jointing joints, and there is no need to talk about the number of colors and shades. With high quality prices are acceptable.

Green Line LLC

One of the leading domestic manufacturers PVC panels. Production facilities are located in Vladimir region, deliveries are made throughout the country and abroad. The main thing for the manufacturer is the high quality and safety of the panels, so the raw materials are supplied from Europe. Great importance is given to the strength of the joints, because it depends on them how much the panel will be resistant to moisture. The company's assortment includes several hundred panel options with different parameters and patterns, which opens up wide opportunities for customers in design. With all this, the price remains acceptable.

One of the leading domestic manufacturers PVC panels. Production facilities are located in Vladimir region, deliveries are made throughout the country and abroad. The main thing for the manufacturer is the high quality and safety of the panels, so the raw materials are supplied from Europe. Great importance is given to the strength of the joints, because it depends on them how much the panel will be resistant to moisture. The company's assortment includes several hundred panel options with different parameters and patterns, which opens up wide opportunities for customers in design. With all this, the price remains acceptable.

Planet Plastic LLC

It's big Moscow enterprise It has been on the market since 2001. Foreign equipment is used for the production of plastic panels, raw materials are also supplied from abroad, which allows us to talk about high quality products and an ever-expanding assortment. PVC panels are the main activity of the company.The drawing is applied by offset and thermal transfer printing, the length, thickness and width of the panels varies widely, the surface can be matte and glossy - in total more than 150 different options.

EVROPLAST service

The company has existed since 2005, equipped with modern equipment of European production, the products are manufactured taking into account strict international quality standards. The company's assortment has a wide selection of plastic panels of different thickness and relief, there is all the necessary accessories for them. Production is underway in Samara regionbut products are widely represented throughout the country.

The company has existed since 2005, equipped with modern equipment of European production, the products are manufactured taking into account strict international quality standards. The company's assortment has a wide selection of plastic panels of different thickness and relief, there is all the necessary accessories for them. Production is underway in Samara regionbut products are widely represented throughout the country.

Ural-Plast LLC

It is a major manufacturer of Magnitogorskwhose high quality products are also explained by the use of imported equipment. The company's products are captivating with its variety, because in addition to quite standard and common options, there are panels with a unique design. The thickness of all panels is 9 mm.

It is a major manufacturer of Magnitogorskwhose high quality products are also explained by the use of imported equipment. The company's products are captivating with its variety, because in addition to quite standard and common options, there are panels with a unique design. The thickness of all panels is 9 mm.

Pareti

This is a young company from Volgogradwhose assortment is constantly expanding. Employees of the enterprise responsibly approach each type of product, trying to make each material so that it can be combined with other finishing materials of the manufacturer. The assortment includes varnished panels with thermal transfer and laminated panels.

This is a young company from Volgogradwhose assortment is constantly expanding. Employees of the enterprise responsibly approach each type of product, trying to make each material so that it can be combined with other finishing materials of the manufacturer. The assortment includes varnished panels with thermal transfer and laminated panels.

LLC "AnV-plast"

This Krasnodar company started its activities in 2001. Today, the products of the manufacturer are widely known throughout the country. The company actively cooperates with domestic enterprises, buying raw materials from them, is focused on wholesale sales and attracts buyers with low prices. The assortment has panels with thermal printing, offset printing, matte white, all of them are presented in different sizes.