12 Tips for Laying DIY Concrete Garden Paths

What garden plot or country house does without paths? First of all, they serve for the movement of the owners, therefore they must be durable and properly located. They are also a decoration of the territory, with the help of paths you can not only create an interesting decor, but also visually increase the area if you make the paths longer. Tracks today create from a mass of a variety of materials: tiles, crushed stoneartificial stone but remains the most popular concrete, because it is optimal for value for money. Moreover, garden paths concrete easy to do with your own hands.

No. 1. What are concrete tracks good for?

Before you equip concrete walkways on your site, you need to know about all the advantages and disadvantages. To the mainmerits paths made concretemay include:

- ease of installation, everything can be done independently without the help of specialists;

- low price (compared to other options);

- the possibility of manufacturing any forms and sizes when appropriate formwork is available;

- extensive decoration options (adding pigment to the solution, using stone, mosaics and other decorations);

- strength and durability;

- resistance to the harmful effects of the environment (moisture, frost, etc.).

Among the disadvantages can be called:

- lack of the possibility of redevelopment. Since this is a capital structure and changing direction after completion of work will be practically impossible, it is necessary to plan in advance both the structure itself and the entire surrounding territory;

- the complexity of the preparatory work. In order for the design to be really high-quality and reliable, you will need to make enough efforts and spend a lot of time on the preparation of materials;

- the occurrence of cracks. Sometimes in the off-season, soil shifts can occur, as a result of which the concrete structure can gradually deteriorate, including from temperature changes.

If we compare concrete tracks with other options in terms of advantages and simplicity of arrangement, then they win in many respects. Related to this is the desire to independently organize such trails on the site. To start with it and what to consider?

No. 2. What are the steps for creating concrete tracks?

The whole process of creating concrete tracks can be divided into the following stages:

- soil design and marking;

- soil preparation;

- formwork installation;

- pillow formation;

- installation of reinforcing elements and concrete pouring.

No. 3. What tools and materials will be needed?

Before starting work, it is worth stocking up on everything you need, namely:

- cement not lower than grade 300;

- sand;

- crushed stone;

- waterproofing additives in concrete;

- pieces of plywood, boards or metal to create formwork;

- wooden or steel pegs;

- a sledgehammer or hammer to hammer pegs;

- a container for mixing the solution;

- a pair of shovels;

- steel construction mesh;

- trowel for leveling the surface of the track;

- trowels and spatulas.

Number 4. How to design a track?

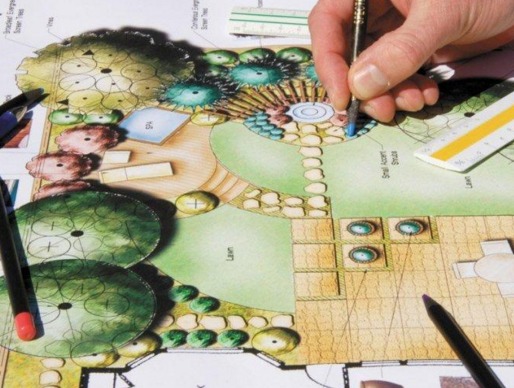

The first thing to think about where the tracks will be located, who and when will move along them, why their width and shape depends. On paper, you can draw a plan of the site, indicate on it the location of all buildings and important areas, connect them with straight lines, which will be the axes for future tracks. Trails can remain even and straight only between huge beds, in other cases it is better to make them slightly curved in order to give the area an interesting look and make moving more comfortable and convenient.

Track width, which leads from the gate to the main entrance of the house, should be about 2 m, 0.8-1 m wide will be enough for auxiliary paths, paths about 0.5 m wide can be arranged between the beds. Those paths along which the car will move should to be wider than the machine itself.

No. 5. How to calculate the weight of building materials?

So that in the process of construction work there is no need to urgently buy cement or sand, it is better to estimate at least approximately the amount of materials that will be needed. The concrete layer may vary in different conditions.: for heavy clay soil - 5-7 cm, for sandy and light loamy soil - 10 cm. In addition, if the soil is marshy, then you need to provide a layer of gravel 5 cm thick. In any case, the so-called sand pillow and has a thickness of 10-15 cm.

The calculation of all the necessary materials is quite simple. Suppose you want to build a track with a width of W = 1 m, a length of D = 10 m and a thickness of T = 10 cm (0.1 m), and the underlying layer of sand will be P = 0.1 m:

- to organize a sand pillow, the amount of sand needed is calculated as W * D * P. In our case, it turns out 1m * 10m * 0.1m = 1m3. According to the reference information, the weight of a cubic meter of sand is 2400 kg, therefore, 2400 kg is necessary to perform the underlying layer;

- concrete can be prepared in a proportion of 3 parts of sand and 1 part of crushed stone, cement and water, but there are other options, about which later. It is more convenient to first calculate the volume of necessary concrete according to the formula W * D * T, it turns out 1m * 10m * 0.1m = 1m3. According to the reference information, the average weight of a cubic meter of concrete is 2800 kg. The resulting weight of the concrete volume can be divided into 5 parts, excluding water: 2800/5 = 560 kg - the weight of one part, i.e. cement. The remaining 2240 kg is the weight of sand, gravel and water. Dyes, plasticizers, water-repellent additives, etc. may also be needed.

Of course, this calculation does not pretend to strict mathematical accuracy, but allows you to approximately understand how much and what is needed.

No. 6. How to do markup?

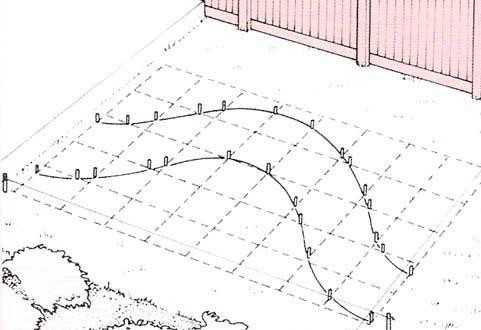

According to a pre-prepared plan for the location of garden paths, it is already necessary to determine where the trails will pass directly on the ground. Their location is indicated by wooden pegswhich drive at the same distance from each other and stretch a rope between them. This is the simplest and most time-consuming stage of work.

Number 7. How to prepare the ground?

At this stage, they begin to select the topsoil at the location of the trail. They remove the earth along with small roots, which can begin to rot, form voids in which water can accumulate, and when it freezes and the volume increases, additional pressure will be applied to the track.

If the “pillow” layer of sand will be 10 cm, and concrete - 10 cm, then when you consider that it is better to the path was 3-5 cm above the ground, you will need to choose 10cm + 10cm-3cm = 17 cm of soil. If a drainage layer of gravel is needed, then add another 5-10 cm to the obtained value. A soil layer is selected with a shovel.

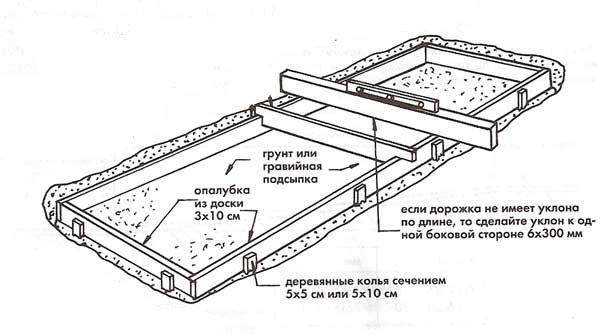

Number 8. How to mount formwork?

Formwork - construction for pouring concrete. It is made of wood. If you want to make smooth lines or bends, you can always use plywood or other flexible material. The formwork is mounted immediately or in parts, since concrete is poured gradually.The second option will also save on material costs.

The formwork should project 5-10 cm above the ground. At the bottom of the prepared trench, it is necessary to lay the building grid, and every 5-6 m of the future path, install across the boards, which play a role expansion joints. Thanks to them, the concrete path will not crack when temperature changes, placing a load on the boards. The height of the expansion joints must match the height of the track.

No. 9. How to equip a pillow?

The so-called pillow under a concrete walkway performs several functions, the main of them:

- load distribution of concrete;

- drainage.

The sandy base passes water well, which means that the soil under the path will not freeze, causing the path to deform. Under the sand, many experts advise organizing a layer of compacted gravel, but this is not always necessary. Over time, sand can go into the ground along with water passing through it, so it’s better to lay under it waterproofing layer of roofing material, geotextile or agrofibre. The last two manifest themselves very well, as they do not rot and pass moisture well.

A layer of sand must be well compacted. Perhaps for this it will have to be wetted, since there should not be voids inside. The surface must be level so that the concrete layer is evenly distributed. It is worth noting that alternative to sand concrete screed or flat stones may become, but their thickness must be taken into account when deepening the trench.

No. 10. Concrete preparation and mixing

The only correct proportions in the ratio of sand, cement, gravel, water and other concrete components are not. Concerning amount of water, then the best option is 1 part water to 4 parts cement, but as the composition is prepared, water can be added to improve ductility.

For tracks with light loads, you can choose a ratio of cement, sand and gravel, as 0.5: 5: 4. For automobile tracks, a ratio of 1: 1.5: 2.5 is suitable. Many experts use universal composition of durable concretewhere cement, sand and crushed stone are correlated in a ratio of 1: 3: 1. Additives are also used that give concrete the necessary qualities.

It is better to choose cement not lower than M300, sand can be taken in river, gravel 10-20 mm in size. Granite is ideal. If the load on the trails is large, then you can take a larger fraction of crushed stone at 40 mm. Mix all ingredients conveniently in a concrete mixer., but in its absence, any capacity such as a trough or just a large steel sheet will do. First, sand and gravel are mixed, then cement is added, a gray mass is obtained. After that, add half of the required amount of water, mix, and then gradually add the rest of the water to make the composition the desired consistency.

In theory, the thicker the concrete, the stronger it is, but it’s easier to work with more liquid and evenly distribute it. To simplify your task, you can add a little plasticizer, which makes concrete more plastic and fluid without excess water.

No. 11. Reinforcement and filling

On a sand pillow fittings fit or a reinforcing mesh over which concrete is poured. The bottom of the trench can be additionally poured with water so that it does not sink under the weight of concrete. The layer is leveled and compacted until the appearance of the so-called cement milk, which gives concrete excellent strength characteristics and allows it to harden rather than dry out. So that the concrete hardens, not cox, recommend periodically wetting the surface with water or covering it with polyethylene. Some even lay a plastic film for concrete, but this is not the best way.

So that in the future water does not accumulate on the tracks and puddles do not form, make its central part a little higherthan the side. The next day, when the solution is slightly hardened, but still soft, you can decorate the surface.For example, you can make furrows in a chaotic manner, simulating a stone surface. The next day, cement mortar painted in white or red is poured into the furrows.

No. 12. Final work

2-3 days after pouring concrete, you can remove the formwork and pull out the pegs. The places deformed by the pegs are treated with a solution with a waterproofing additive. The edges of the track are cleaned of debris, covered with remaining soil and rammed. After a few days, you can walk on the track.

Since the garden path also has a decorative shape, it can be given interesting appearance. This is either an imitation of natural stone, as mentioned above, or giving a characteristic texture, coloring, or indenting pebbles, buttons, tile fragments at the stage of solidification. In places where there are not so many, you can do not a monolithic concrete path, but mold slabs of a certain shape. Cheapness and simplicity made concrete the most popular option for creating a variety of garden paths.