Floor board: types, size, manufacturing method

Diversity various flooring today it’s simply amazing, but still the tree is considered the most universal, environmentally friendly and durable material. Boards have never lost popularity, but now the demand for them is constantly growing.At first, this material will last a very long time, and, SecondlyHe fits into absolutely any interior style: from classic to hi-tech. The choice of floor boards is wide enough today, which allows you to purchase a material that is suitable for width, thickness, length and appearance.

What is a floor board?

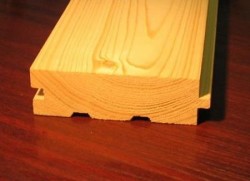

Floor board (floor board) - floor covering material, which is made from a massive piece of wood, which determines the main advantages and properties, because a parquet board, for example, is obtained by gluing several layers of wood. Most often, the boards are equipped with a groove and a comb from different sides, so that the installation process is much easier.

Floor board (floor board) - floor covering material, which is made from a massive piece of wood, which determines the main advantages and properties, because a parquet board, for example, is obtained by gluing several layers of wood. Most often, the boards are equipped with a groove and a comb from different sides, so that the installation process is much easier.

Naturally, the boards are made only from natural, and high-quality wood, which should be free from such defects as knots, blackening, cracks, etc. Boards can be of different thicknesses and widths, most often made from larch, pine, ash or oak. But such breeds as linden and poplar are extremely undesirable for creating flooring.

Advantages and disadvantages

Floorboards - a unique floor covering that has many advantages. So, the key ones are:

Floorboards - a unique floor covering that has many advantages. So, the key ones are:

- durability and high reliabilitythat is especially important for a floor covering on which big load and pressure is regularly carried out;

- durability: boards are not material for several years. Such flooring with minimal care can last from several tens of years or more, depending on the type of wood selected;

- environmental friendliness of material - an important indicator for those who want to create the safest possible housing, building materials in which will not be a direct threat to the health and life of inhabitants;

antiallergic properties - an advantage that flows smoothly from the naturalness of the material;

antiallergic properties - an advantage that flows smoothly from the naturalness of the material;- thermal insulation - This is an important bonus for those who want to always maintain comfort and a wonderful microclimate in their home. Wood is a warm coating, so it will be much more comfortable with it in winter;

- nice appearancewhich is able to decorate any room and fit into any style of interior.

Deciding on the use of boards as a floor covering, you need to be prepared that they also have some disadvantageswhich include the following:

regarding considerable cost;

regarding considerable cost;- necessity observe some rules in careso that the coating lasts as long as possible;

- rot susceptibility to wood, wiping, scratching;

- wood flammable, and over time, it can deform and slightly change its shape.

But even despite many of these disadvantages, wood remains one of the best options for arranging flooring, so let's consider which floorboards are currently on the market, and which ones are better to choose in each case.

Wood species

In many respects, the properties of the floorboard depend on what kind of wood it is made of.So, appearance, color, texture, strength, moisture resistance, resistance to deformation, price - those are the parameters that can vary greatly between boards made from different breeds.

In many respects, the properties of the floorboard depend on what kind of wood it is made of.So, appearance, color, texture, strength, moisture resistance, resistance to deformation, price - those are the parameters that can vary greatly between boards made from different breeds.

The board is in greatest demand today. from larch, spruce, pine, maple and beech. These are strong breeds that hardly change their color over time. More expensive options that can be used in the most luxurious interiors are considered cherry, wenge, pear and teak. All of them are distinguished by their original color and texture, capable of giving the interior a special cosiness combined with chic and elegance.

It is worth noting that hardwoods are denser than conifers, and therefore pine and spruce are in great demand. All this is due to the fact that they are much easier, and therefore easier to work with, the requirements for fasteners are much lower. If you have to lay the coating yourself, it is better to opt for coniferous species. By the way, in this case, it will be possible to save a little more.

It is worth noting that hardwoods are denser than conifers, and therefore pine and spruce are in great demand. All this is due to the fact that they are much easier, and therefore easier to work with, the requirements for fasteners are much lower. If you have to lay the coating yourself, it is better to opt for coniferous species. By the way, in this case, it will be possible to save a little more.

As for the appearance, each breed is unique and gives itself away with a peculiar shade or texture. When choosing, you can also build on what visual effect you need to get. For example, cedarhas a pinkish tint with a reddish tint, and the remaining conifers are light wood. Larch It has a pleasant golden hue, and it is also the most resistant to decay, durable, compares favorably with all conifers. Birch pleases with a very fine-fiber structure, which allows to achieve the effect of monolithic coating. Such material is very durable and incredibly aesthetic. Oak It belongs to a special price category and is appreciated for its original texture with streaks, a special color and incredible durability. It is worth noting that the shade of any wood can be slightly changed with special impregnation.

As for the appearance, each breed is unique and gives itself away with a peculiar shade or texture. When choosing, you can also build on what visual effect you need to get. For example, cedarhas a pinkish tint with a reddish tint, and the remaining conifers are light wood. Larch It has a pleasant golden hue, and it is also the most resistant to decay, durable, compares favorably with all conifers. Birch pleases with a very fine-fiber structure, which allows to achieve the effect of monolithic coating. Such material is very durable and incredibly aesthetic. Oak It belongs to a special price category and is appreciated for its original texture with streaks, a special color and incredible durability. It is worth noting that the shade of any wood can be slightly changed with special impregnation.

Board size

In terms of length, width and thickness, floorboards can be completely different. Which parameters are considered ideal? This question cannot be answered unambiguously, because depending on the totality of external factors and conditions, the choice can radically differ.

Width - a key parameter of the floorboard. Today you can find products with a width from 80 to 135 mm, but the most popular and universal are boards with a width of 100-105 mm. In this case, the choice should be based on the parameters of the room and the interior solution, because, for example, in a large space, an overly narrow board will not look appropriate. A wider board eventually forms a smaller number of joints, can fit faster, and, in general, looks more respectable and expensive. Nevertheless, the narrow one is excellent for rooms with a small area, as well as where the floor is under increased load, as this option boasts increased strength.

Width - a key parameter of the floorboard. Today you can find products with a width from 80 to 135 mm, but the most popular and universal are boards with a width of 100-105 mm. In this case, the choice should be based on the parameters of the room and the interior solution, because, for example, in a large space, an overly narrow board will not look appropriate. A wider board eventually forms a smaller number of joints, can fit faster, and, in general, looks more respectable and expensive. Nevertheless, the narrow one is excellent for rooms with a small area, as well as where the floor is under increased load, as this option boasts increased strength.

As for thickness, then on sale there are boards from 28 to 40 mm. The choice should be based on the distance between the logs of the floor. So, if it is about 60 cm, then boards with a thickness of 30-35 mm are quite suitable, if the distance is 80 cm, then you will have to use boards 40-45 mm in thickness. Also, you need to take into account the intensity of movement on the floor, i.e. Board load: the higher it is, the thicker the boards should be.

Preparation method

Floor board can massive and spliced, or glued. The first is made of solid wood, the second, respectively, is assembled from separate pieces of wood, equal in length. The junction of such boards is somewhat similar to a gear, they are almost invisible, but it is almost impossible to perfectly match the texture of the tree. Glued board is not inferior to solid in strength, but both types can boast of their advantages.

Floor board can massive and spliced, or glued. The first is made of solid wood, the second, respectively, is assembled from separate pieces of wood, equal in length. The junction of such boards is somewhat similar to a gear, they are almost invisible, but it is almost impossible to perfectly match the texture of the tree. Glued board is not inferior to solid in strength, but both types can boast of their advantages.

So, massive board It is distinguished by its naturalness, but knots and resin pockets may be present on it, which, one way or another, reduce the quality of the material. It has no such disadvantages glued board, which, plus everything, has perfect geometry and high strength. But in terms of naturalness, such material is inferior to a massive board, because there is glue in the composition, with which the individual parts are connected. In addition, such boards can not be installed if the step lag is more than 40 cm.

So, massive board It is distinguished by its naturalness, but knots and resin pockets may be present on it, which, one way or another, reduce the quality of the material. It has no such disadvantages glued board, which, plus everything, has perfect geometry and high strength. But in terms of naturalness, such material is inferior to a massive board, because there is glue in the composition, with which the individual parts are connected. In addition, such boards can not be installed if the step lag is more than 40 cm.

The length of the boards is mainly 3-6 meters. Some experts say that working with shorter and narrower boards is much easier, but with wide and long boards you can achieve the most aesthetic result.

Other differences

In addition, the floorboard may be sheet pile and non-sheet pile. The first one has grooves on one side, and protrusions on the other, which simplify the installation of such a board, and in the future allow you to get a more durable and durable result. On the modern market, mainly boards of this type are represented.

Today's selection also offers us whiteboard and euroboard. The latter is distinguished by improved properties, since higher quality raw materials and modern technologies are used in the production, which ultimately allows you to get a board with perfect geometry, low humidity, without defects in the form of knots, blue, holes, etc. Euroboard is also distinguished by the presence of ventilation grooves, which allow better to distribute the load on each individual element, inhibit fungus formation. As a result, such a board is able to serve much longer without changing its qualities.

I want to make repairs at home with my parents. Here, too, stopped at the floorboards. It seems to me much better than plywood and lay laminate flooring over old boards.