Which is better to choose polypropylene pipes for heating and water supply

The key element in the water supply and heating system is precisely pipes. It depends on them how high-quality heating will be, and how durable it will be water supply system. That is why today cast-iron pipes are no longer in such demand as before, because they are heavy, difficult to install and susceptible to corrosion. Newer option plastic pipes, devoid of all these shortcomings, but during their installation a huge number of joints are formed, which can negatively affect the performance of the heating system or water supply. The most modern and reliable option at the moment is polypropylene pipes, but in order to get the maximum benefit from their use, you need to choose the appropriate option.

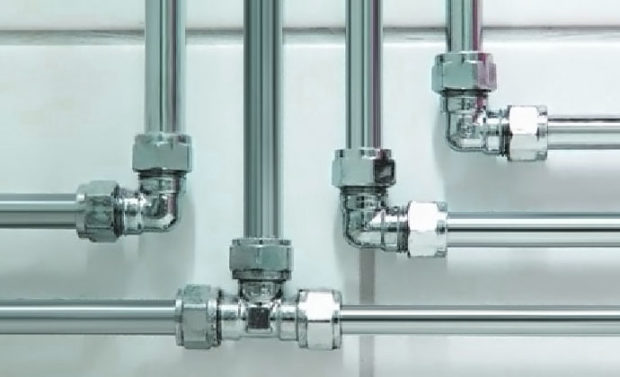

Polypropylene pipes confidently push metal pipes out of the market and become one of the most demanded materials today heating systems or heat supply. All this is due to the combination of their positive qualities. So, they are not afraid of corrosion, easily withstand high pressure, are easy to install, are lightweight. In addition, they are durable, practically do not wear out, and due to their smooth surface they are not able to accumulate scale. Also, such pipes can withstand negative temperatures, and at the same time they are relatively inexpensive, which provided the material with the widest popularity among buyers with completely different budgets. When choosing pipes, it is worth starting from future operating conditions, stopping at those that are most suitable for a particular room. It is also worth noting that pipes along with everything necessary are better to buy from reliable manufacturers and in trusted locations: a vivid example is the products presented by AquaLend.

Polypropylene pipes confidently push metal pipes out of the market and become one of the most demanded materials today heating systems or heat supply. All this is due to the combination of their positive qualities. So, they are not afraid of corrosion, easily withstand high pressure, are easy to install, are lightweight. In addition, they are durable, practically do not wear out, and due to their smooth surface they are not able to accumulate scale. Also, such pipes can withstand negative temperatures, and at the same time they are relatively inexpensive, which provided the material with the widest popularity among buyers with completely different budgets. When choosing pipes, it is worth starting from future operating conditions, stopping at those that are most suitable for a particular room. It is also worth noting that pipes along with everything necessary are better to buy from reliable manufacturers and in trusted locations: a vivid example is the products presented by AquaLend.

Now let’s dwell on what polypropylene pipes are, and which ones are best suited to specific conditions.

Types of Polypropylene Pipes

The properties of pipes directly depend on the structure of the material:

The properties of pipes directly depend on the structure of the material:

- PPH (polypropylene homopolymer) - solid material, the disadvantage of which is the inability to withstand low temperatures. That is why such pipes are most often used in the arrangement of industrial pipelines for supplying cold water, or in the organization of ventilation ducts;

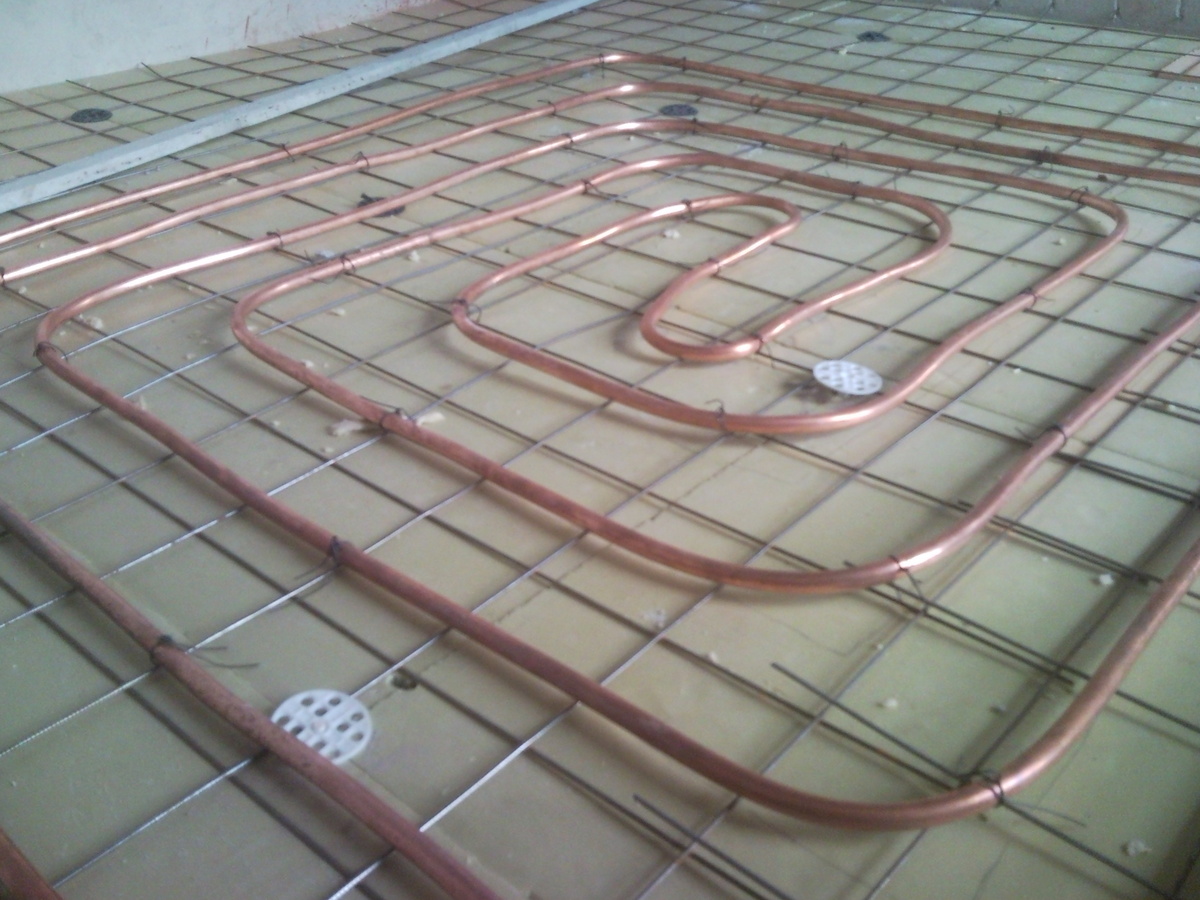

- PPB (block copolymer) - excellent wear-resistant material, in which up to 30% of polyethylene is present. It is he who gives the finished product the ability to withstand low temperatures, as well as the necessary flexibility. Due to all these advantages, these pipes are often used not only for supplying cold water, but also for transporting aggressive substances. In addition, this type of pipe is used in the arrangement of internal sewerage and floor heating. Impact resistant pipes and fittings are also made from this material, which once again confirms their excellent operational properties;

PPR, PPRC (copolymer of propylene and ethylene). Such pipes are widely used in the arrangement of cold and hot water supply, heating systems, including and floor, but it should be borne in mind that the temperature of the coolant should not exceed 70 0C;

PPR, PPRC (copolymer of propylene and ethylene). Such pipes are widely used in the arrangement of cold and hot water supply, heating systems, including and floor, but it should be borne in mind that the temperature of the coolant should not exceed 70 0C;- PPs (special propylene) - This is the most popular material for today, which is worth choosing for equipping a reliable heating and heat supply system at home.Such pipes have incredible operational properties: they withstand high pressure, low temperatures, and the coolant can be supplied to them with a temperature of up to 95 ° C, and you can be absolutely sure that nothing will happen to the pipe material.

What are reinforced pipes?

For all its merits propylene pipes have one drawback - with increasing temperature, they are able to expand, lengthen. To neutralize this feature, manufacturers have long been accustomed to reinforcing pipes. If you need to purchase a product for arranging hot heat supply or heatingthen reinforcement becomes a prerequisite. It is worth considering that the reinforcing layer is made of different materials:

aluminium foil, which is located in the walls of the pipe, gives the product the necessary strength, but at the same time complicates the installation;

aluminium foil, which is located in the walls of the pipe, gives the product the necessary strength, but at the same time complicates the installation;- polyethylene layer, which is applied to the inner walls of the pipe. This type of pipe is actually metal-plastic pipes, the outer layer of which is made of polypropylene. The main advantage of this solution is that the pipes can withstand a higher temperature, but can not do without a number of disadvantages. Again, this is some difficulties during installation, as well as the layering of the product, which cannot but affect the reliability and durability, because the different layers are connected by glue;

- reinforcement fiberglass It is considered the most reliable solution to date. Such products have a monolithic design, have high rigidity, almost do not change when exposed to high temperatures. In addition, such products are simpler during installation, since it will not be necessary to perform special cleaning before welding, as is the case with the two previous types of pipes.

Operating pressure

The working pressure for which specific pipes are designed is another important parameter that must be considered when choosing. It is worth starting from what exactly these pipes are necessary for: hot or cold water supply, and maybe a heating system.

The working pressure for which specific pipes are designed is another important parameter that must be considered when choosing. It is worth starting from what exactly these pipes are necessary for: hot or cold water supply, and maybe a heating system.

So, the products must be marked accordingly: after the letters PN there is a number corresponding to the amount of fluid pressure for which specific pipes are designed. So, for example, PN10 pipes withstand pressure of 1 MPa, PN20 - 2 MPa, PN25 - 2.5 MPa, etc. Depending on a number of other characteristics of pipes with different working pressures, in each case it is necessary to choose the most suitable product:

- pipes PN10 - one of the cheapest options, they have a thin wall and can withstand temperatures up to 20 0С, therefore they are recommended for use only in cold water supply systems;

- PN 16 withstand temperatures already up to 60 0С, therefore they can be used both in cold and in hot water supply;

- pipes PN20 perfectly tolerate temperatures up to 80 0С; therefore, they are excellent for hot water supply;

- pipes PN25 with reinforcement are used in the heating system, but may be applicable for water supply.

Pipe diameter

Pipe diameter is another parameter that needs careful consideration. So, before designing a water supply or heating system, it is better to calculate what pipe diameter is needed. For large private houses or for apartment buildings it is better to use a special calculation, and for a small house you can take pipes with a diameter of 20 mm (for heating) or even 16 mm (for water supply). If the pipe diameter is larger than necessary, there will be little harm from this, but it is difficult to call such a solution economical. If too small a section is selected, then there will be problems with pressure.

Pipe diameter is another parameter that needs careful consideration. So, before designing a water supply or heating system, it is better to calculate what pipe diameter is needed. For large private houses or for apartment buildings it is better to use a special calculation, and for a small house you can take pipes with a diameter of 20 mm (for heating) or even 16 mm (for water supply). If the pipe diameter is larger than necessary, there will be little harm from this, but it is difficult to call such a solution economical. If too small a section is selected, then there will be problems with pressure.

In the modern construction market, pipes with a diameter of from 16 mm up to 1200 mm, but such huge products are used more often in industry and manufacturing. For a home heating system, pipes with a diameter of 16-32 mm are quite suitable, for sewage - from 40 to 110 mm.We are talking about the inner diameter of the pipes, since the outer one has nothing to do with it and can only indicate the wall thickness, which determines the rigidity of a particular product.

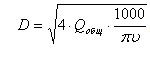

there is formulaallowing a rough calculation the required diameter of the polypropylene pipe for water supply, and it looks like this:

where Qtotal is the peak water flow rate, v is the water velocity (1.5-2 m / s for thick pipes and 0.7-1.2 m / s for thin pipes).

When calculating, it is better to use the maximum speed values for this type of pipe, since the smooth surface of polypropylene practically does not resist the movement of water.

Substituting specific values, you can derive the value of the diameter of the pipes needed to organize water supply in the house. More accurate hydraulic calculations will be needed to organize water supply for an apartment building, but even here there are already their own time-tested solutions: for five-story buildings pipes with a diameter of 25 mm are used, and for nine-story houses - 32 mm pipes. Larger diameter pipes are used to supply water to apartment buildings, but polypropylene is not applicable for heating pipelines, since the temperature of the water supply pipe is often so high that even reinforced reliable products can not cope with such an effect.

Substituting specific values, you can derive the value of the diameter of the pipes needed to organize water supply in the house. More accurate hydraulic calculations will be needed to organize water supply for an apartment building, but even here there are already their own time-tested solutions: for five-story buildings pipes with a diameter of 25 mm are used, and for nine-story houses - 32 mm pipes. Larger diameter pipes are used to supply water to apartment buildings, but polypropylene is not applicable for heating pipelines, since the temperature of the water supply pipe is often so high that even reinforced reliable products can not cope with such an effect.

Naturally better do not take pipes with a diameter less than necessaryotherwise there is a risk during peak hours to stay with poor water pressure or without it at all. But, on the other hand, it is tempting to take a pipe with a diameter much larger than necessary, because in this case it is unnecessary to count, check, etc. Such a rash decision will not only require more money for the purchase of products, but will not save in the future.

To find out the inner diameter of the polypropylene pipe, if it is not indicated on the package, you can use the ratio of external and internal diameter. So, with an outer diameter of 16 mm, the inner will be 10 mm, with 20 mm - 15, with 63 mm - 50, with 125 mm - 100, etc.

When organizing a heating or water supply system for an apartment or a small house, exact calculations in most cases are not needed, since there are not so many water points. Most often, 20 mm pipes are used for heating and 16 mm for water supply.