How to choose mineral wool for insulation

Today, mineral wool is considered one of the most popular materials that are used. for warming rooms. Under the concept of "mineral wool" on the market there are different types of materials, which combine a similar method of production. So it could be glass wool, slag or stone woolproduced in the form of rolls or mats. What material is more preferable in a particular situation, we will try to figure it out.

Mineral wool - a generalized concept of all those heat-insulating materials, which are obtained by blowing fibers from a hot mineral material. Depending on the source material, mineral wool is divided into three different types. All of them have such properties as high degree of thermal insulation, good sound insulation, high fire resistance and vapor permeability. The remaining characteristics and the severity of the listed advantages differ depending on the type of mineral wool. Choosing is the one that will best meet your requirements.

Mineral wool - a generalized concept of all those heat-insulating materials, which are obtained by blowing fibers from a hot mineral material. Depending on the source material, mineral wool is divided into three different types. All of them have such properties as high degree of thermal insulation, good sound insulation, high fire resistance and vapor permeability. The remaining characteristics and the severity of the listed advantages differ depending on the type of mineral wool. Choosing is the one that will best meet your requirements.

Type of mineral wool

So, it has already been mentioned that different materials can be used for the manufacture of mineral wool, depending on what the finished product receives certain properties.

Slaggy produced from blast furnace wastes, which explains such a small particle size. As a result, the resulting mats and boards have little rigidity, but they are not inferior to other types of mineral wool in thermal conductivity. It is not very convenient to work with this material, which limits the circle of its consumers, since private developers who carry out all or almost all of their work on their own prefer to choose those materials that are as easy to work with. Due to all this, slag wool is most often used in industrial facilities, when warming pipes, etc., when it is possible to resort to the services of specialists and provide them with the proper level of protection, since small particles of this material can penetrate both the skin and respiratory ways, and into clothes.

Slaggy produced from blast furnace wastes, which explains such a small particle size. As a result, the resulting mats and boards have little rigidity, but they are not inferior to other types of mineral wool in thermal conductivity. It is not very convenient to work with this material, which limits the circle of its consumers, since private developers who carry out all or almost all of their work on their own prefer to choose those materials that are as easy to work with. Due to all this, slag wool is most often used in industrial facilities, when warming pipes, etc., when it is possible to resort to the services of specialists and provide them with the proper level of protection, since small particles of this material can penetrate both the skin and respiratory ways, and into clothes.

Glass wool has become more widespread, but working with it is still difficult. This material is produced from molten glass waste or rocks that contain a lot of silicon. Glass wool is characterized by the longest particle length, which can even reach 3 mm, which means that the material has high rigidity even at low density, and, accordingly, light weight. But, on the other hand, these long pointed particles can easily hit a person: when working with mineral wool, they pierce the skin, respiratory tract, causing discomfort and irritation.

Glass wool has become more widespread, but working with it is still difficult. This material is produced from molten glass waste or rocks that contain a lot of silicon. Glass wool is characterized by the longest particle length, which can even reach 3 mm, which means that the material has high rigidity even at low density, and, accordingly, light weight. But, on the other hand, these long pointed particles can easily hit a person: when working with mineral wool, they pierce the skin, respiratory tract, causing discomfort and irritation.

Mineral wool has properties such as elasticity and vibration resistance (due to its structure), so it is easy to transport: no matter how the roll is folded or the plate is twisted, the weight will be equal to the material then it will take the necessary form. Among other things, glass wool boasts excellent indicators of thermal insulation and sound insulation, fire resistance. It is often used in private construction, which is explained by a relatively low price, but it is worth considering the need for serious personal protection when working with similar material.

Stone wool often also called mountain, since it is made of rocks, or basalt, since most often it is based on it basalt. Less often, this insulation is produced from mining waste, but in any case, material comes out that differs in the best, in comparison with "classmates", operational properties. Stone wool is absolutely non-combustible: it can be heated up to 10,0000C, and at the same time it will not melt and will not even begin to emit any smoke. This is an absolutely natural material that holds heat well, and due to its structure, it also acts as a good noise insulator. To all this, you can add excellent vapor permeability, lack of shrinkage, density and ease of installation: it is enough to cut the necessary piece and insert it into the opening intended for this. At the same time, the structural features of the material allow you to work with it without additional protection, which means that the entire process of insulation is simplified, therefore this material still remains the most appropriate in private construction. But you have to pay for all these advantages: stone wool costs much more than glass wool, and in the process of working with it you will notice that it is also not very elastic.

Stone wool often also called mountain, since it is made of rocks, or basalt, since most often it is based on it basalt. Less often, this insulation is produced from mining waste, but in any case, material comes out that differs in the best, in comparison with "classmates", operational properties. Stone wool is absolutely non-combustible: it can be heated up to 10,0000C, and at the same time it will not melt and will not even begin to emit any smoke. This is an absolutely natural material that holds heat well, and due to its structure, it also acts as a good noise insulator. To all this, you can add excellent vapor permeability, lack of shrinkage, density and ease of installation: it is enough to cut the necessary piece and insert it into the opening intended for this. At the same time, the structural features of the material allow you to work with it without additional protection, which means that the entire process of insulation is simplified, therefore this material still remains the most appropriate in private construction. But you have to pay for all these advantages: stone wool costs much more than glass wool, and in the process of working with it you will notice that it is also not very elastic.

Plate or roll?

Since slag is not used in private construction and is produced mainly on the order of enterprises, then we will only talk about glass wool and stone wool. Depending on where and how the insulation will be used, choose one or another form of its release.

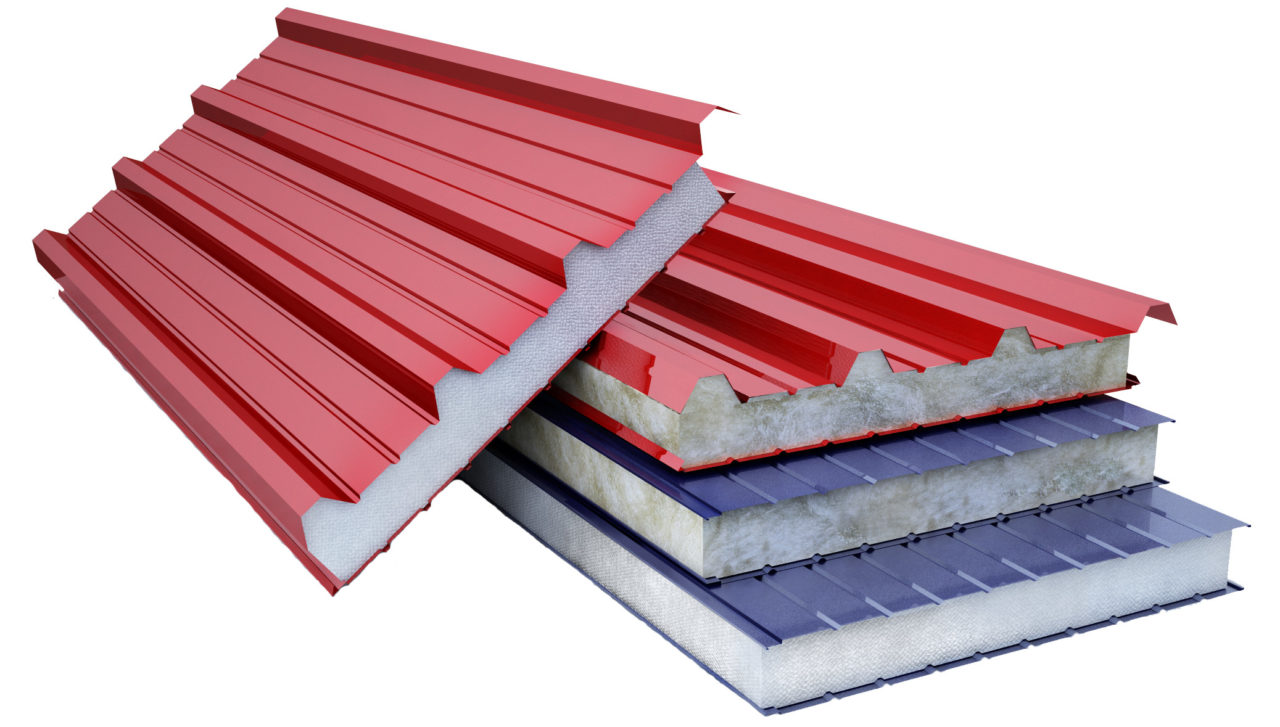

Glass wool Available in the form of plates and rolls. Slabs they are usually pasted over with fiberglass, non-woven material or aluminum foil during the production process, and each of the options, due to the obtained properties, is better used in clearly defined situations. For example, glass wool, fiberglass coated, used for ventilated hinged facades, in order to ultimately get maximum wind protection. Glass wool with foil great for insulation of the roof, insulation of the floors of attics and basements. Glass wool in a roll more suitable for insulating horizontal surfaces, and its advantage is that you can reduce the number of joints to a minimum.

Glass wool Available in the form of plates and rolls. Slabs they are usually pasted over with fiberglass, non-woven material or aluminum foil during the production process, and each of the options, due to the obtained properties, is better used in clearly defined situations. For example, glass wool, fiberglass coated, used for ventilated hinged facades, in order to ultimately get maximum wind protection. Glass wool with foil great for insulation of the roof, insulation of the floors of attics and basements. Glass wool in a roll more suitable for insulating horizontal surfaces, and its advantage is that you can reduce the number of joints to a minimum.

Basalt wool also available in plates and rolls, maybe reinforced with foil or fiberglass, and the scope is about the same as glass wool. The only thing to note is that stone wool can also be produced in several other forms. That's it granulated cotton wool, which, with the help of a special installation, is blown up to where other insulation cannot get, thus covering the most inaccessible places. Mineral plates covered with a bitumen layer, which makes them an ideal material for roof insulation, but lamella plates differ in a special structure. In them, all the fibers are located perpendicular to the surface: the heat-insulating properties do not increase from this, but the elasticity increases, which means that they can be insulated with curved surfaces.

When is mineral wool used?

From the combination of the described properties, it can be understood that mineral wool is an excellent heater, which suitable in most situations. And the fact that its composition is completely free of organic components means that the material will be as durable as possible. In addition, the fibrous structure allows air from the room to freely enter the street, so that as a result, excess moisture does not stagnate in the house. Such a "breathing" effect will be most welcome, when you need to insulate a wooden or stone house.

From the combination of the described properties, it can be understood that mineral wool is an excellent heater, which suitable in most situations. And the fact that its composition is completely free of organic components means that the material will be as durable as possible. In addition, the fibrous structure allows air from the room to freely enter the street, so that as a result, excess moisture does not stagnate in the house. Such a "breathing" effect will be most welcome, when you need to insulate a wooden or stone house.

Many users fear that mineral wool may clump, losing its properties. This, indeed, can take place, but this process is very long in time, and it is facilitated by a change in humidity, temperature, strong vibration, etc.It is worth noting that such deformations often occur with less dense mats than with hard plates, so you may have to look at the latter.

Some nuances of choice

When planning to buy insulation, pay attention to some other nuances in order to choose a quality material that has the maximum set of positive qualities and durability. So, it is important that the mineral wool is properly stored: it is better that it be factory packaging, shrink film and a canopy from the rain. If the material is packed in cardboard boxes, and special types of mineral wool are often sold, it is important that they are stored in a dry place. Buying at least a little wet cotton wool is a waste of money, because after it dries it becomes unusable. The name of the manufacturer also means a lot, like reviews about a particular brand, so before buying it is better not to be too lazy and find out the opinion of those who have already encountered a specific type of product.

When planning to buy insulation, pay attention to some other nuances in order to choose a quality material that has the maximum set of positive qualities and durability. So, it is important that the mineral wool is properly stored: it is better that it be factory packaging, shrink film and a canopy from the rain. If the material is packed in cardboard boxes, and special types of mineral wool are often sold, it is important that they are stored in a dry place. Buying at least a little wet cotton wool is a waste of money, because after it dries it becomes unusable. The name of the manufacturer also means a lot, like reviews about a particular brand, so before buying it is better not to be too lazy and find out the opinion of those who have already encountered a specific type of product.