Types of dry plaster mixes: composition and functional features

Anyone who has ever encountered repair workknows what stucco is and why it is needed. This is a compound that aligns the walls inside or outside the premises, prevents the appearance of cracks, improves the microclimate, serves as the basis for decoration or as a finishing layer for both facades and rooms. Depending on which function of these is preferable, slightly different compositions are chosen. Today on the construction market there are quite a lot of types of dry plaster mixes, the properties and characteristics of which are worth dwelling in more detail.

The concept dry plaster mix often confused with dry plaster. The latter is the usual sheets of drywall and is designed to simplify, speed up repair and construction work. Dry mixes must be diluted with water in the specified proportion before application. Of course, you can prepare the mixture with your own hands, but then its quality and the desired properties will be under big question. That's why it is better to purchase the finished mixture.

The concept dry plaster mix often confused with dry plaster. The latter is the usual sheets of drywall and is designed to simplify, speed up repair and construction work. Dry mixes must be diluted with water in the specified proportion before application. Of course, you can prepare the mixture with your own hands, but then its quality and the desired properties will be under big question. That's why it is better to purchase the finished mixture.

A lot of companies producing stucco mixes appear on the modern market, but if quality is really important, then it’s better not to risk it and buy material from trusted manufacturers. The company Lentekhstrom specializes in the production of various building materials, among which dry stucco mixes play a key role. For a long time, the company has already established itself always with quality products manufactured according to European standards. Quality control is carried out at each stage, and production is carried out using the most modern technology. In addition, the company also boasts the presence of its own laboratory, which not only tests and analyzes manufactured products, but also constantly works to improve it and develops new types of plaster mixes. Permanent sanitary control is also carried out, so only buyers get into the hands of safe and environmentally friendly materials. The choice of mixes for plaster from Lentekhstrom is able to satisfy any requirements, and the range is constantly updated. With all these advantages, the company also has a well-thought-out pricing policy with a flexible discount system, and experts are always ready to give practical advice and advice.

A lot of companies producing stucco mixes appear on the modern market, but if quality is really important, then it’s better not to risk it and buy material from trusted manufacturers. The company Lentekhstrom specializes in the production of various building materials, among which dry stucco mixes play a key role. For a long time, the company has already established itself always with quality products manufactured according to European standards. Quality control is carried out at each stage, and production is carried out using the most modern technology. In addition, the company also boasts the presence of its own laboratory, which not only tests and analyzes manufactured products, but also constantly works to improve it and develops new types of plaster mixes. Permanent sanitary control is also carried out, so only buyers get into the hands of safe and environmentally friendly materials. The choice of mixes for plaster from Lentekhstrom is able to satisfy any requirements, and the range is constantly updated. With all these advantages, the company also has a well-thought-out pricing policy with a flexible discount system, and experts are always ready to give practical advice and advice.

The composition of the plaster mixes

In order not to get confused at the sight of a significant choice of plasters, it is important to know which and what is intended. So, if facade work is ahead, then the choice is limited to cement or cement-sand dry mixes. But if work is carried out indoors, then gypsum plasters are also added to the listed list. What do these materials represent themselves?

All dry mixes for plaster are divided into several types depending on the binding agent.

Cement plaster

One of the most popular and sought after formulations. Here as an astringent is used cement, and as a filler - sand, but sometimes additives that improve ductility or adhesion may be present in the composition.This is a universal plaster, which can easily be used both for external and internal works, while ensuring durability and resistance to external negative factors. TO merits such mixtures should also include their long-term viability: you can immediately knead a sufficiently large amount of plaster, for example, in a concrete mixer, and be completely sure that it will not freeze in the tank during operation. The strength of the finished surface and the low cost of the mixtures themselves complements the list of advantages.

One of the most popular and sought after formulations. Here as an astringent is used cement, and as a filler - sand, but sometimes additives that improve ductility or adhesion may be present in the composition.This is a universal plaster, which can easily be used both for external and internal works, while ensuring durability and resistance to external negative factors. TO merits such mixtures should also include their long-term viability: you can immediately knead a sufficiently large amount of plaster, for example, in a concrete mixer, and be completely sure that it will not freeze in the tank during operation. The strength of the finished surface and the low cost of the mixtures themselves complements the list of advantages.

But not without disadvantages: Long-term vitality also results in a long drying period of the stucco layer, therefore, the next stage of wall decoration can only be started after a couple of weeks, and further work will require puttying. Cement-sand plaster is not very good adhesion to smooth concrete surfaces, and the process of applying it is not the easiest. In addition, you need to be prepared that a lot of dirt is formed, and dust particles from cement and sand can fly in the air.

But not without disadvantages: Long-term vitality also results in a long drying period of the stucco layer, therefore, the next stage of wall decoration can only be started after a couple of weeks, and further work will require puttying. Cement-sand plaster is not very good adhesion to smooth concrete surfaces, and the process of applying it is not the easiest. In addition, you need to be prepared that a lot of dirt is formed, and dust particles from cement and sand can fly in the air.

Lime plaster

Such a mixture consists mainly of lime and sandbut there are a small proportion of cement, as well as a variety of additives that give certain properties. Such plaster is best used indoors, but, in principle, it is suitable for outdoor use. Its advantages include ease of installation, as well as relatively quick solidification. Moreover, it does not require any additional processing, has excellent antibacterial properties, therefore it protects the walls from the appearance and development of the fungus. One more bonus - excellent adhesion with almost any type of surface. In terms of price, this is one of the most profitable options, since lime is cheaper than cement when it is used as a binder.

Lime plaster boasts also nearby other benefits: it has excellent thermal insulation properties, which are several times higher than that of analogues - gypsum and cement plasters. It also has a higher ability to vapor permeability, so the right microclimate is then created in the room, which is pleasant to be in and easy to breathe. In addition, the finished surface is resistant to heat and remains in its original form for a long time when exposed to high temperatures. In the list of pluses you can add more elasticity and environmental friendliness, but to cons non-record strength, which is much inferior to the same cement plasters, as well as poor resistance to moisture.

Lime plaster boasts also nearby other benefits: it has excellent thermal insulation properties, which are several times higher than that of analogues - gypsum and cement plasters. It also has a higher ability to vapor permeability, so the right microclimate is then created in the room, which is pleasant to be in and easy to breathe. In addition, the finished surface is resistant to heat and remains in its original form for a long time when exposed to high temperatures. In the list of pluses you can add more elasticity and environmental friendliness, but to cons non-record strength, which is much inferior to the same cement plasters, as well as poor resistance to moisture.

Gypsum plaster

The composition of gypsum plaster mixes includes gypsum and various mineral additives. They are used only for internal work, due to a number of properties. So, such plaster is unstable to moisture, which limits its scope. Continuing the theme of her disadvantagesIt is worth noting that it is not very viable, and the finished solution hardens very quickly, so you will have to prepare it in portions. The resulting surface is very weakly resistant to mechanical influences, and according to this indicator gypsum plaster greatly loses cement and even lime.

The composition of gypsum plaster mixes includes gypsum and various mineral additives. They are used only for internal work, due to a number of properties. So, such plaster is unstable to moisture, which limits its scope. Continuing the theme of her disadvantagesIt is worth noting that it is not very viable, and the finished solution hardens very quickly, so you will have to prepare it in portions. The resulting surface is very weakly resistant to mechanical influences, and according to this indicator gypsum plaster greatly loses cement and even lime.

But list of advantages able to cover all the shortcomings of such compositions. So, gypsum plaster hardens very quickly and does not require further processing, so the duration of repair work can be minimized. The application process is also as simple as possible, and one person can plaster about 30-40 m per day2, and at the same time, the layer does not slip, lies flat on the surface, has a high plasticity, does not shrink and does not crack after drying, and the application process is not so dirty and dusty.

But list of advantages able to cover all the shortcomings of such compositions. So, gypsum plaster hardens very quickly and does not require further processing, so the duration of repair work can be minimized. The application process is also as simple as possible, and one person can plaster about 30-40 m per day2, and at the same time, the layer does not slip, lies flat on the surface, has a high plasticity, does not shrink and does not crack after drying, and the application process is not so dirty and dusty.

Adhesive stucco

This is not a very popular type of mixture, which is notable for its high price. Includes sand, cement, polymer additives and fibers that give the composition certain properties. Usually, such plasters are used during the installation of insulation, or for leveling wallswhen stacking the net.

Plaster mixes by functional features

Although the composition of the stucco mixtures is relatively simple, still additives to them can slightly change their properties and areas of use.

Plaster mix may be ordinarywhen its composition includes only an astringent and a filler. Such compositions are used to level the surface and prepare it for subsequent finishing. She may be simple, superior and high quality. If the first two types are used for work in utility and technical rooms, for facades, the latter applies only to the decoration of residential premises.

Decorative plastersIn addition to the main components, they also include coloring mattergiving the composition a certain color, or stone crumb a certain breed, which allows you to get a surface with a characteristic pattern. There are also plasters sgraffitothat allow you to create an interesting surface based on the two colors that make up the composition. Such plasters are used for finishing and can decorate both the facade and the walls in the room.

Decorative plastersIn addition to the main components, they also include coloring mattergiving the composition a certain color, or stone crumb a certain breed, which allows you to get a surface with a characteristic pattern. There are also plasters sgraffitothat allow you to create an interesting surface based on the two colors that make up the composition. Such plasters are used for finishing and can decorate both the facade and the walls in the room.

There are also specialized plasters, which include such components that give the finished surface additional properties:

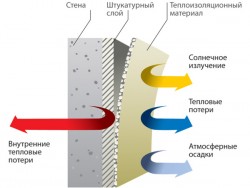

- heat insulating or “Warm” plaster able to create the optimal microclimate in the room and even allows you to do without additional insulation. It consists of special substances, such as polystyrene foam, hydromica, foam glass or perlite: as a result, the composition has an increased volume with less weight, which contribute to thermal insulation;

sound absorbing plaster due to its properties it is indispensable for the construction of stadiums, concert halls and production halls, and in ordinary apartments it brings a lot of benefits. With it, you can protect yourself from extraneous noise, making your stay more comfortable. Special properties are explained by the presence of pumice, slag, expanded clay or perlite;

sound absorbing plaster due to its properties it is indispensable for the construction of stadiums, concert halls and production halls, and in ordinary apartments it brings a lot of benefits. With it, you can protect yourself from extraneous noise, making your stay more comfortable. Special properties are explained by the presence of pumice, slag, expanded clay or perlite;- X-ray protective plaster based on the use of barite concentrate. This is an excellent alternative to lead screens, and excellent protection can already be obtained with a layer of 50 mm. Application conditions: temperature above 15 degrees and the need to plaster the entire surface at once;

- waterproofing plaster indispensable in rooms with high humidity: bathroom, kitchen, pools;

- fire resistant plaster excellent resistance to high temperatures, can maintain its original state for a long time and not ignite;

- acid resistant composition It is used in industrial plants and laboratories where exposure to aggressive vapors is possible. The composition of such plasters usually includes liquid potassium glass.

Use plasters

It has been repeatedly mentioned above that for facade and interior work slightly different formulations are required. Many manufacturers indicate on their dry plaster mixes, for what conditions this or that product is suitable. So, facade plasters must be durable and strong, resist such effects as precipitation, humidity, wind, mechanical damage, sun rays, frost, temperature changes.

It has been repeatedly mentioned above that for facade and interior work slightly different formulations are required. Many manufacturers indicate on their dry plaster mixes, for what conditions this or that product is suitable. So, facade plasters must be durable and strong, resist such effects as precipitation, humidity, wind, mechanical damage, sun rays, frost, temperature changes.

For interior work such qualities of plaster as environmental friendliness and decorativeness come first. In both cases, it is also necessary to take into account the material of the walls. But in most cases this is a purely conditional division, since a significant part of the compositions can be used in both cases.

I understand that the mixture needs to be selected for its intended purpose and composition. And which manufacturers are considered the leading, the best and highest quality?