Decorative plaster: types, application, painting

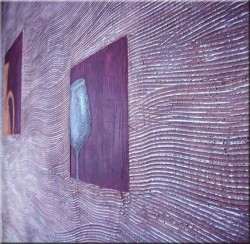

The days when at the peak of popularity were long gone wallpaperMoreover, those wallpapers that were able to get out, and decorated the room for the next decades. Today, the market for building materials is full of different types of wall finishes, among them there is decorative plaster.

What are the main advantages of this material, which decorative plaster is better to choose and how to apply?

Advantages of decorative plaster

The first and most important advantage is uniqueness. Indeed, even if the coating in two identical rooms is applied by the same person with the same tool, it will still result in a different pattern, so this type of decoration is a great chance to make your room unique. In addition, with the help of decorative plaster it is possible to achieve an imitation of a coating under marble, metal, granite, silk, etc.

The first and most important advantage is uniqueness. Indeed, even if the coating in two identical rooms is applied by the same person with the same tool, it will still result in a different pattern, so this type of decoration is a great chance to make your room unique. In addition, with the help of decorative plaster it is possible to achieve an imitation of a coating under marble, metal, granite, silk, etc.

She comes to any type of interior, although many people think that it fits most precisely into the classic interior. With a competent selection of colors and textures, it will be an excellent addition to the interior in the style of hi-tech, modern, minimalism.

It is not difficult to apply decorative plaster - it is rather a pleasant creative process, however, you will have to try to prepare the surface, because the cleaner and it will be more eventhe better the result.

Such plaster is capable of hide some wall flaws, small cracks and bumps, especially if it contains cellulose fibers. In addition, it is able to add warmth to the room, since high-quality plaster together with a good primer are good heat insulators.

Such plaster is capable of hide some wall flaws, small cracks and bumps, especially if it contains cellulose fibers. In addition, it is able to add warmth to the room, since high-quality plaster together with a good primer are good heat insulators.

Sustainability and safety - one more pluses. So, decorative plaster is made of natural materials, and the finished coating does not absorb odors, does not emit harmful substances, therefore it is not able to cause any inconvenience or harm to health.

Such a coating will not cause trouble in operation: it is durable, resistant to temperature extremes, practically does not need care. Moreover, as a result of application on the surface there are no seams, joints and other defects.

Of course, one cannot pay attention to such a direct drawback as the high cost of the material. But if you consider that such a coating will last long enough, will be unique, easy to care for and repair, then its cost is quite justified.

Classification of decorative plasters

The whole variety of different types of surfaces obtained using decorative plaster is formed due to the fact that the compositions can be different: in some there are elements thanks to which you can get a certain relief, and for others there must be a special approach and ability to create the desired surface.

What does decorative plaster consist of? In most cases, the composition includes a water base, binders, additives and fillers, such as thickeners, antiseptics, etc. Fillers can be completely different, but in addition to filler, plasters can differ in their basic composition. And it is precisely this characteristic that makes this or that material applicable in specific conditions.

So, Among the interior decorative plasters distinguish the following main types:

- Mineral plaster It is made on the basis of cement and is sold dry, therefore, immediately before use, it must be mixed with water and turned into a homogeneous mass using a construction mixer at low speeds. This type of finish is perfect for mineral substrates, but the use of a quartz primer is necessary, it has good indicators of strength, durability and vapor permeability. But, as you might guess, mineral plaster cannot be painted in bulk, so be prepared for the fact that after applying it will have to be painted additionally. Another advantage of this type of plaster is its low price, although there are more expensive options that include glitter, marble chips and other elements that are designed to enhance the aesthetics of the finished coating.

Acrylic plaster - This is a synthetic material, which includes acrylic resin. It gives the material properties such as ductility, the ability to repel water, and excellent adhesion to the mineral base. But the material is able to burn, therefore, for example, next to mineral wool insulation it is better not to use it. But working with it is not difficult: it is easy to apply, it is easy to form a texture either with a filler, or with a roller and spatula. True, such a finish requires high-quality preparation of the base and primerswhat we talk about next. Acrylic plaster is sold ready-made, i.e. you don’t have to dilute the dry mixture, but pay attention to the expiration date: if the date is close to the final date of operation, then even at a reduced price it is better not to take such material, since it will be difficult to work with it.

Acrylic plaster - This is a synthetic material, which includes acrylic resin. It gives the material properties such as ductility, the ability to repel water, and excellent adhesion to the mineral base. But the material is able to burn, therefore, for example, next to mineral wool insulation it is better not to use it. But working with it is not difficult: it is easy to apply, it is easy to form a texture either with a filler, or with a roller and spatula. True, such a finish requires high-quality preparation of the base and primerswhat we talk about next. Acrylic plaster is sold ready-made, i.e. you don’t have to dilute the dry mixture, but pay attention to the expiration date: if the date is close to the final date of operation, then even at a reduced price it is better not to take such material, since it will be difficult to work with it.- Silicone plaster It is considered the most modern and universal: high elasticity, durability, adhesion to any type of base, vapor permeability and aesthetic effect favor the use of this type of finish. This plaster is very easy to clean, even self-cleaning, so it is often used for decoration facades. It is sold ready-made, with a certain color, and the color scheme is quite rich, which allows you to choose the most suitable option, eliminates the need staining, creates excellent color transitions, and even a beginner in the construction industry can work with such material. As you might have guessed, all this durability and high aesthetics cost a lot of money, and a special primer is needed - silicone, but the result will definitely please you, and it will please you for a very long time.

- But silicate plaster, which is made on the basis of potassium glass, is rarely used for interior wall decoration, which is in question. Most often, silicate plaster is used for facade work, since during operation it can emit harmful substances. In addition, it is not very easy to apply it: it quickly sets, therefore, some skill is needed to manage to distribute it and create a pattern.

In addition, all decorative plasters differ in the type of finished surface: bark beetle, with marble chips, with imitation of granite, rain, under the roller, under the rust, Venetian, etc. They can also use graters, putty knives, fabrics and other materials to give texture - all this in order to move away from typical factory solutions with a filler, but about the technique of creating a relief a little later.

To better understand what will be discussed below, it is worthwhile also to give a classification of decorative plasters by type of filler:

- textured plaster - the most popular and relatively inexpensive type of plaster, here the filler is wood fibers, small pebbles, mica, etc. Thanks to this inclusion, the surface becomes truly three-dimensional, which is not within the scope of any wallpaper or painting.To enhance the effect, various rollers and dies are often additionally used;

- structural plaster as fillers, it uses small grains of quartz, grains of other minerals, and as a result, the finished surface is homogeneous in contrast to the previous type. Often, it is with this type of plaster that the famous “bark beetle” surface is prepared, which resembles the surface of a tree bark. If the size of the filler is slightly larger than the standard, then you can get a good mosaic effect on the walls;

- Venetian plaster It is made on the basis of marble chips, it is very uniform and as a result a smooth shiny marble coating is obtained;

- flocking - A more modern development, the result of which is a rather interesting appearance. Such a coating is applied in several layers: the adhesive base, the flocks themselves, i.e. colored insoluble particles, and varnish coating.

Surface preparation

Like any other coating, decorative plaster requires a certain surface preparation. Naturally, the very first step is to completely remove the old coating: wallpaper must be carefully removed, you can use a spatula, slightly moisten them with water. All paint residues are also removed: a spatula will also come to the rescue, building hair dryer or even special solvents.

When the surface is completely cleaned, it is necessary to wash it from all traces of work: use a cloth and detergent. If there are obvious defects and large cracks on the surface, then, of course, it is better to align them. Small irregularities even out, depending on the situation: for example, Venetian plaster and some other types require a perfectly flat surface, so it’s useful putty.

But the primer is needed in any case - it closes microcracks, prevents absorption, improves adhesion. For each type of decorative plaster, a different type of primer is suitable, and manufacturers often indicate the recommended composition. If the wall surface has metal surfaces, then it is better to treat them with a protective composition, otherwise it is highly likely that they will begin to rust, and brown spots will appear through the plaster.

But the primer is needed in any case - it closes microcracks, prevents absorption, improves adhesion. For each type of decorative plaster, a different type of primer is suitable, and manufacturers often indicate the recommended composition. If the wall surface has metal surfaces, then it is better to treat them with a protective composition, otherwise it is highly likely that they will begin to rust, and brown spots will appear through the plaster.

If the walls have never been finished before, i.e. the building is completely new, then it will be quite enough to cover the surface with lime mortar, although many professionals still advise using appropriate primers.

Essential Tools for Application

In order to apply decorative plaster, you may need a different set of tools, but the minimum required is:

In order to apply decorative plaster, you may need a different set of tools, but the minimum required is:

- spatulas;

- graters;

- metal iron;

- container for the plaster itself;

- rollers or dies for textured plaster;

- paint will also be needed if the plaster is not painted in bulk;

- water-based varnish for fixing a layer of paint and a primer for paint.

Application of decorative plaster

So, the application of decorative plaster begins with the fact that it is necessary to prepare the material itself. If the plaster was sold ready-made, then you just need to make sure that the expiration dates and storage conditions were not violated, open to mix again and start working - such compounds usually harden longer, so rush as with the plasters that need to be prepared yourself, not worth it.

So, the application of decorative plaster begins with the fact that it is necessary to prepare the material itself. If the plaster was sold ready-made, then you just need to make sure that the expiration dates and storage conditions were not violated, open to mix again and start working - such compounds usually harden longer, so rush as with the plasters that need to be prepared yourself, not worth it.

If you chose the dry option, then the package should contain instructions for preparing the mixture with an exact indication of the proportions. Such material sets quickly enough, so it needs to be prepared in the volume that can be used at one time, otherwise it runs the risk of freezing directly in the working tank, and it will be necessary to work quickly.

The prepared solution is applied to the wall with a spatula in an even layer, and when it sets a little bit, they begin to create a relief: grater, stamps, rollers, brushes, own hands and even plastic bags, leaves and feathers can come to the rescue, everything that is under your hands, can be used to create unique patterns. They work a little differently, but tools for creating relief are applied, they are drawn along the surface, they draw some patterns, etc. The thickness of the layer will depend on which pattern you want to create and what effect you want to get.

The prepared solution is applied to the wall with a spatula in an even layer, and when it sets a little bit, they begin to create a relief: grater, stamps, rollers, brushes, own hands and even plastic bags, leaves and feathers can come to the rescue, everything that is under your hands, can be used to create unique patterns. They work a little differently, but tools for creating relief are applied, they are drawn along the surface, they draw some patterns, etc. The thickness of the layer will depend on which pattern you want to create and what effect you want to get.

Most often, when self-applying plaster, they create a pattern in the form of rain, horizontal or vertical stripes, circles and other similar simple patterns. Usually they start from the angles at which they train - they are not so noticeable if suddenly your technique is not perfect from the very beginning. You need to work at a pace, and pay special attention to the joints so that there are no inflows, and that they are generally imperceptible.

Most often, when self-applying plaster, they create a pattern in the form of rain, horizontal or vertical stripes, circles and other similar simple patterns. Usually they start from the angles at which they train - they are not so noticeable if suddenly your technique is not perfect from the very beginning. You need to work at a pace, and pay special attention to the joints so that there are no inflows, and that they are generally imperceptible.

When the plastered surface loses its wet sheen, and this happens after about 15-20 minutes, it is necessary to walk with a wet trowel along the surface and slightly smooth the resulting relief. The ironer should be washed as often as possible in water so that particles of plaster do not accumulate.

When the layer is completely dry - after about 24 hours - you need to walk along the surface with a fine sandpaper to smooth out possible irregularities.

When the layer is completely dry - after about 24 hours - you need to walk along the surface with a fine sandpaper to smooth out possible irregularities.

Separately, it is worth highlighting the Venetian plaster: it requires a very responsible approach, so it is not always possible to cope independently. Here you need a perfectly flat and smooth surface, even tools, attention to the application and compacting of all layers of plaster, the correct application of the pattern and skillful polishing to get a glossy or matte surface.

By the way, if you have a penchant for creating drawings, then you can try in the center of the wall, for example, create a small bas-relief depicting some simple object, landscape, or maybe even people or animals - it will look very stylish and harmonious, especially if you emphasize all this with paint.

Decorative plaster painting

If you used mineral plaster, then after drying it must be painted in the desired shade. Before painting, the plaster layer is recommended to be primed so that the coating lasts longer.

You can paint in any chosen color, it is better to choose a waterproof paint that is resistant to mechanical damage and sunlight. Staining is carried out with a long-nap roller, but often monophonic coloring does not give the desired effect, therefore, after the wall is painted, protruding relief parts are shaded. Tint them, as a rule, in a more saturated or even contrasting shade. There is also the application of a second layer of paint by washing - this is a more complicated option, since here a darker paint is applied to the surface, and then without letting it dry, they wipe the surface, removing the paint layer, while it remains only in the recesses. For washing, it is better to use non-moisture resistant paint - this will even save money.

You can paint in any chosen color, it is better to choose a waterproof paint that is resistant to mechanical damage and sunlight. Staining is carried out with a long-nap roller, but often monophonic coloring does not give the desired effect, therefore, after the wall is painted, protruding relief parts are shaded. Tint them, as a rule, in a more saturated or even contrasting shade. There is also the application of a second layer of paint by washing - this is a more complicated option, since here a darker paint is applied to the surface, and then without letting it dry, they wipe the surface, removing the paint layer, while it remains only in the recesses. For washing, it is better to use non-moisture resistant paint - this will even save money.

If the surface of the plaster was additionally painted, then this layer must be fixed with water-based varnish. It is better to dilute it with water in a ratio of 1: 1, so that it penetrates better into the structure of the plaster. The varnish is applied with a brush in 2-3 layers: carefully with drips, you need to squeeze the brush well, and after one layer has dried, you can apply the next. By the way, the varnish does not dry for long, so you won’t have to wait.

If the surface of the plaster was additionally painted, then this layer must be fixed with water-based varnish. It is better to dilute it with water in a ratio of 1: 1, so that it penetrates better into the structure of the plaster. The varnish is applied with a brush in 2-3 layers: carefully with drips, you need to squeeze the brush well, and after one layer has dried, you can apply the next. By the way, the varnish does not dry for long, so you won’t have to wait.

In conclusion

Although Venetian stucco remains the prerogative of professionals, it’s also quite realistic to apply any other type of decorative stucco on your own.This is absolutely nothing complicated: you just need to skillfully prepare the base, and boldly apply the solution itself, forming a pattern - and that's it, a unique and environmentally friendly coating is ready.

Acrylic plaster - This is a synthetic material, which includes acrylic resin. It gives the material properties such as ductility, the ability to repel water, and excellent adhesion to the mineral base. But the material is able to burn, therefore, for example, next to mineral wool insulation it is better not to use it. But working with it is not difficult: it is easy to apply, it is easy to form a texture either with a filler, or with a roller and spatula. True, such a finish requires high-quality preparation of the base and

Acrylic plaster - This is a synthetic material, which includes acrylic resin. It gives the material properties such as ductility, the ability to repel water, and excellent adhesion to the mineral base. But the material is able to burn, therefore, for example, next to mineral wool insulation it is better not to use it. But working with it is not difficult: it is easy to apply, it is easy to form a texture either with a filler, or with a roller and spatula. True, such a finish requires high-quality preparation of the base and