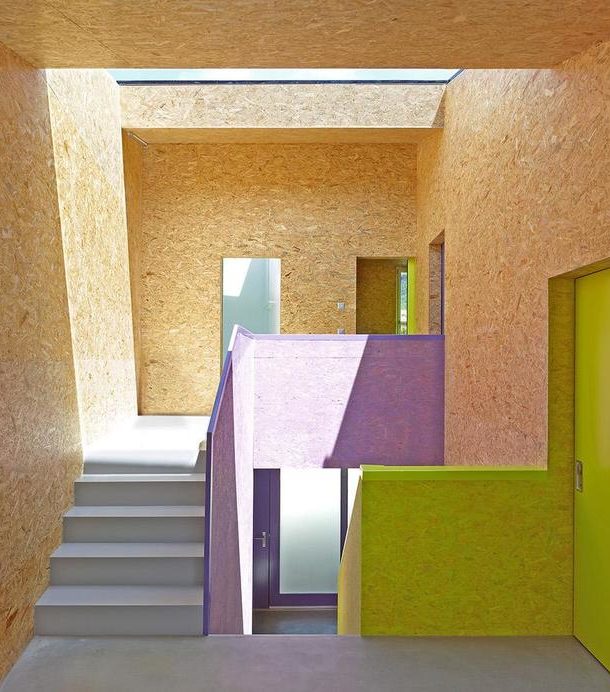

How to paint the OSB plate outside and inside the house: 8 tips

OSB boards, as affordable and reliable material in terms of performance, are widely used both for interior and exterior decoration, as well as for the construction of lightweight frame buildings. In view of this, the question often arises - what is the best way to paint OSB boards outside or inside the house? And why do you need to make coloring, and is it always relevant? You will find answers to these questions in our article.

Briefly about the material

Oriented Chipboard (OSB) 90% consists of natural wood in the form of large shavings.  Crushed wood chips are interconnected by gluing different types of resins, polymers and adhesives. The result is a dense and solid material. But, as you know, natural wood is afraid of moisture and can swell under its influence. To protect the plates, they are impregnated with various chemical impregnations. It is the type of impregnation used and the labeling of the plates depends. Surely you noticed that the abbreviation OSB also has a number in the name. What does she mean?

Crushed wood chips are interconnected by gluing different types of resins, polymers and adhesives. The result is a dense and solid material. But, as you know, natural wood is afraid of moisture and can swell under its influence. To protect the plates, they are impregnated with various chemical impregnations. It is the type of impregnation used and the labeling of the plates depends. Surely you noticed that the abbreviation OSB also has a number in the name. What does she mean?

- OSB-1 - has a minimum level of moisture protective impregnation in its composition, therefore, it is suitable for use only in dry, heated rooms.

- OSB-1 able to withstand only short-term and insignificant effects of moisture;

- OSB-2 - designed for indoor decoration with an average level of humidity;

- OSB-3 - able to withstand exposure to high levels of humidity, and even short-term wetting;

- OSB-4 - the most moisture resistant material category. Recommended for outdoor use.

What is painting for?

Staining OSB plates produce for many reasons.

- Firstly, the paint layer forms a stable dense film on the surface, which is an additional protection against exposure to excessive moisture and ultraviolet rays;

- Secondly, some coloring compositions have a rather dense texture, which allows you to completely smooth out the uneven surface of the plates. Not many people like the primordial appearance of this finishing material;

- Thirdly, staining is the most budgetary way to protect and decorate the surface of OSB boards. Often it is this reason that plays a decisive role.

Material features affecting paint selection

OSB boards can be called a specific material due to the pronounced texture of individual chips on the surface and some other features.  Before proceeding with the selection of a particular type of paint, Consider the following points:

Before proceeding with the selection of a particular type of paint, Consider the following points:

- Without surface pretreatment, the paint may adhere poorly or unevenly to the substrate. This is due to poor adhesion or because the boards are treated with special impregnations, which in turn formed a film on the surface;

- Water-based formulations are not recommended due to the fact that excess moisture can cause surface swelling;

- A rough surface will require more paint;

- If the plates, even after careful preparation, are poorly painted, it means that they were stored incorrectly.Material that has been lying on the street for more than one year must be thoroughly cleaned of dust and other contaminants, sanded and treat with antiseptics;

- At the ends of the plates have a more porous structure, respectively, will require more paint to fill the voids. To avoid excessive consumption, it is recommended to pre-weld.

The choice of compositions for interior painting

OSB plates are made from wood waste, so any coloring composition suitable for application to a wooden base is suitable for staining them.  Choosing paint for internal work, be sure to pay attention to its environmental friendliness. Most suitable will be:

Choosing paint for internal work, be sure to pay attention to its environmental friendliness. Most suitable will be:

- Oil paints. They have a high level of viscosity, due to which they are practically not absorbed into the base. After complete drying, a very strong, but thin film is formed on the surface. The disadvantages of oil paints include a long drying time and their instability to various atmospheric influences. That is why this option is used only for interior decoration;

- Alkyd paints and enamels. They are able to penetrate deeply into the structure of plates, filling voids, and form a strong, moisture-resistant film on the surface. The surface painted with alkyd composition does not need subsequent varnish coating, which in turn allows to reduce the cost of purchasing material. The coating will be durable, there is almost no unpleasant odor during operation. But keep in mind that alkyd paints are flammable;

- Transparent or color varnish. If you like how the surface of the plates looks, it is enough to cover them with a transparent or colored varnish in several layers to provide protection from moisture and sunlight;

- Stain. Using this composition, you can give the surface an aged effect. To do this, a thin layer of stain is applied to the surface, and then rubbed with a piece of foam. You can cover the surface completely, it all depends on preferences and the interior. A coat of varnish must be applied on top of the stain;

- Latex paint. This is a water-based composition with the addition of synthetic rubber polymer. It can be used for interior decoration only if the walls are sheathed with OSB-3. It has the following advantages - moisture resistance, additional thermal insulation, profitability due to the possibility of uniform distribution with a thin layer, short drying period, safety for health. As for the disadvantages - not resistant to low temperatures, high cost. Also surface prone to formation mold and mildew, therefore, requires additional impregnation. A thin coat of paint will not hide the characteristic texture of the plates;

- Glaze azure. This is a water-based glazing composition that, after drying, forms a transparent or translucent film on the surface. The coating thickness is minimal, due to which it does not crack or peel over time. The use of such blue will save the structure of the plates and give them an interesting shade.

How to paint the facade of OSB?

For compounds designed for exterior decoration, more strict requirements - they must be resistant to low and high temperatures, sudden changes in temperature, humidity and ultraviolet rays.  In addition to this, you must decide how you ultimately want to see facade of your house - matte or glossy, completely smooth or with chip texture. We mentioned that for exterior decoration it is best to use OSB-4 boards because of their resistance to moisture. This means that water-based paints and compositions can also be used to cover them. Let's consider in more detail:

In addition to this, you must decide how you ultimately want to see facade of your house - matte or glossy, completely smooth or with chip texture. We mentioned that for exterior decoration it is best to use OSB-4 boards because of their resistance to moisture. This means that water-based paints and compositions can also be used to cover them. Let's consider in more detail:

- If you decide not to mask the structure of the plates, then for the outer coating you can use special paints from UV filters. In fact, these are ordinary varnishes, but on a different basis - on water, oil or acrylic. The main components of the composition are alkyd resins. A feature of such acrylic based varnishes is that after drying, the surface becomes dull. There are semi-matte compositions. Water-based varnish will be glossy. In order to make the coating uniform, it is recommended to pre-treat the plates with water-based impregnation;

- Stain also suitable for outdoor use. After the composition has completely dried, the surface is necessary primerand then open with clear varnish. This way of protecting the slabs will not hide their texture, but will make the appearance of the facade more interesting;

- Acrylic paint widely used for facade decoration. It creates a strong, wear-resistant film on the surface, it lies perfectly and is easy to apply on a rough base and has a wide color gamut. In addition to an interesting color, you can choose the degree of gloss of the coating - matte, semi-gloss, glossy. It is convenient to work with acrylic paint - it does not spread during painting and dries quickly. Color fastness persists for a long time even under direct sunlight. An important fact is that the protective coating is vapor and moisture permeable, resistant to sudden changes in temperature. Staining can be carried out at any ambient temperature but lower than -20 ° C;

- Alkyd Compounds also suitable for outdoor use, if you are not confused by their instability to alkali and the ability to quickly ignite. The advantage of the composition is high strength and resistance to low temperatures;

- Silicone paint. Such compositions are the most expensive, but they can be called ideal for use outside the building. They are resistant to mechanical stress, cracking and peeling, are moisture repellent. Even if the facade from OSB has already been painted previously with a different paint, which has burned out or exfoliated, silicone paint can be applied on top of it.

What is fire protection?

OSB stoves burn as well as any wood product. During combustion, very corrosive substances are released into the atmosphere, including poisonous hydrocyanic acid. Often it is poisonous smoke that leads to irreversible consequences. To increase the resistance of the OSB to ignition, special compounds are used called "fire protection". The most common at the moment are 2 compositions:

Often it is poisonous smoke that leads to irreversible consequences. To increase the resistance of the OSB to ignition, special compounds are used called "fire protection". The most common at the moment are 2 compositions:

- Soppka. This is a paint with the addition of resins, which is designed specifically for application to OSB. Unlike conventional antiseptics, it is more thick and viscous. After drying, a strong film forms on the surface, which is not washed off in the rain due to the deep penetration of the composition into the structure of the base. The service life of the coating exceeds 15 years;

- "Valtti Color Satin." This is a high-quality facade azure with high coating ability and protecting wood from decay.

Both compounds, in addition to protection against ignition, are and antiseptics preventing the development of mold.

Both compounds, in addition to protection against ignition, are and antiseptics preventing the development of mold.

Plate preparation and painting technology

Properly conducted preparatory work is the key to a good result.  Painting work indoors can be divided into 4 main stages:

Painting work indoors can be divided into 4 main stages:

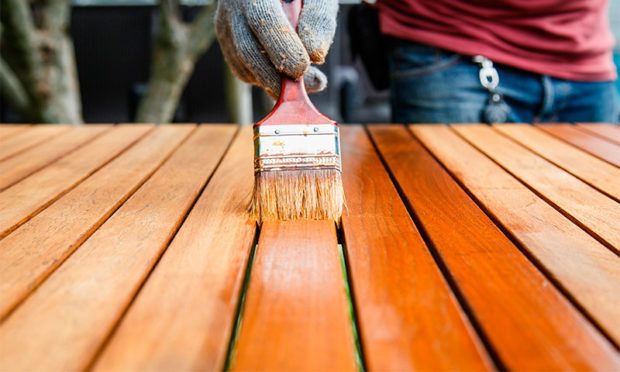

- Alignment surface. Made by grinding. Grinding allows you to smooth the surface of the plate and make it unrecognizable. As a tool, it is most convenient to use a grinder with a grinding wheel. Do not apply much effort, just a light touch. It is especially necessary to grind the surface of OSB-3 and OSB-4 boards to remove the protective wax coating, which prevents the penetration of the primer into the structure and reduces adhesion to the paintwork;

- Sealing joints. Seams between plates and attachment points screws it is best to fill with an elastic filler compound. If there is a need to create the effect of a monolithic surface and mask the joints in color with the plates, add the sawdust remaining after trimming the sheets to the putty. If after drying you see that the composition has come out beyond the seams, the surface can be sanded. If you need to make a perfectly smooth surface for monophonic painting, the seams can be glued with a special airtight tape “Rapid Cell”;

- Padding. After you remove the top layer of material, the internal pores will open. The chips of the OSB board are connected using various resins, waxes and paraffins, which also prevent the rotting process. These substances must necessarily remain inside the structure. To "seal" the pores, special barrier primers are used, for example, FI M194, which must be applied with a spray gun. The soil must be allowed to dry completely;

- Applying a coloring composition. If we are talking about painting the facade, then after the priming stage it is necessary to fix the fiberglass mesh around the entire perimeter, fill the surface with a moisture-resistant and frost-resistant composition, and only after it has dried, proceed to paint. It is recommended to carry out work in dry, calm weather.

Unusual staining methods

No matter how carefully you grind the surface of the plates, it is very difficult to completely mask its characteristic pattern with ordinary paint.  Not every interior will fit such a finish. Therefore, there are several ways how to perform decorative staining.

Not every interior will fit such a finish. Therefore, there are several ways how to perform decorative staining.

Stone surface imitation

This technology will require a lot of time and patience, as it is a multi-layer staining.

- First of all, draw or download an image with the desired stone pattern from the Internet. Do not choose too intricate textures, it will be difficult to reproduce them;

- Determine how many colors you need and paint the desired surface with the base paint base color. Usually, the lightest is used as the base shade. Please note that the surface does not need to be sanded. To ensure that the paint is evenly distributed over an uneven surface, it is best apply it with a spray gun;

- After drying the paint, lightly clean the surface to emphasize the relief and make it deeper;

- Using a pencil, transfer the masonry contour from the image to the floor surface;

- Now draw the outline with a thin brush and darker paint;

- After that, individual “pebbles” can be additionally tinted with other colors to add volume;

- After that, update the circuit in the right places;

- After the paint dries, the result is fixed with varnish.

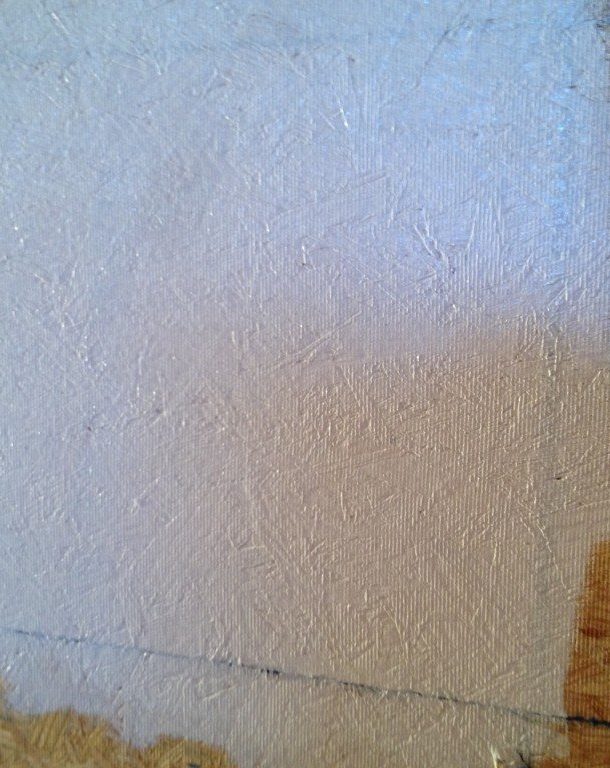

Stucco staining

This method does not require an artist to have artistic talent.

- First of all, the surface needs to be polished. The purpose of grinding is only to remove a layer of wax protective coating;

- Padding;

- Pigment primer application. Color should be chosen based on personal preferences;

- To obtain such a pattern as in our photo example, white soil was used;

- After the soil has completely dried, the surface is again polished, but already using a circle with finer grain;

- Dust removal from the surface;

- Next, you can apply the composition with the effect of nacre or patina, or you can use this and that, but in turn. Each composition must dry before applying the next. Patina will give an aging effect. After applying it, you need to wait 5-7 minutes and walk along the surface with a block of sandpaper;

- Clean the surface of dust;

- Fix the result by applying a clear or tint varnish.