Damping tape for floor screed: 6 tips for choosing

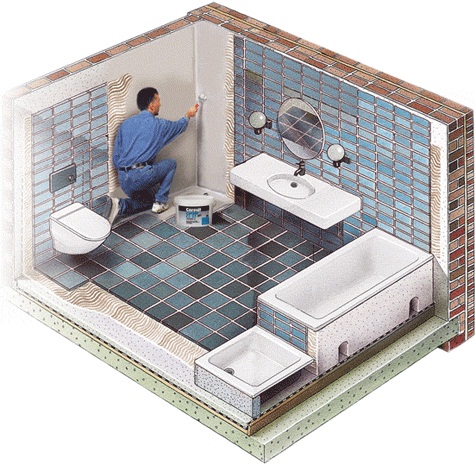

The final step in preparing the subfloor is often the arrangement concrete screed. It is carried out in order to level the surface or when pouring floors in a new building - it does not matter, the main thing is to achieve a solid foundation that does not crack with time under the influence of various factors. And there are quite a lot of them, despite the strength of fully hardened concrete. These are temperature differences at which any material narrows or expands, and soil shrinkage, etc. Any changes in volume carry a change in the coefficient of linear expansion coefficient. Moreover, if there is no gap between the screed and adjacent walls, which would be able to compensate for the expansion and minimize the concrete pressure on the walls, cracks are inevitable. Moreover, their appearance may not occur immediately after the screed has dried, but also after some time, when you already have time to cover the concrete with a finish coating. To avoid such troubles, which, incidentally, may require additional and considerable costs for their elimination, a rather simple, even primitive, but very effective tool was invented, namely - damper tape for floor screed. In this article we will consider the main properties material kinds tapes and popular manufacturers.

1. Is it always necessary to use damping tape?

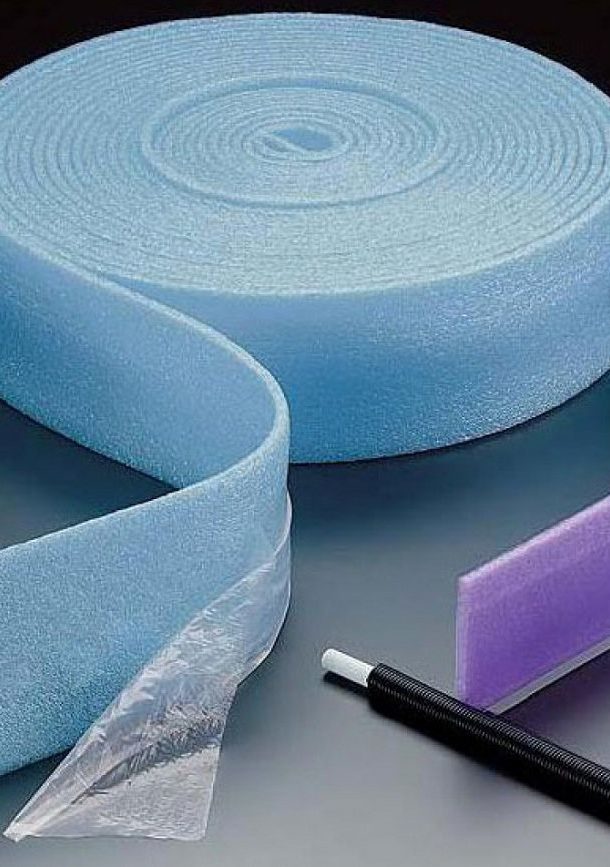

Damper tape is nothing but a strip of foamed polyethylene. This material is very light, soft, working with it is easy and simple, so the installation process itself does not require any special skills and does not take much time. This moment also had an important influence on the popularity of the use of this invention in arranging various types of screed. Damper tape recommended use at:

- organization of floors using floor heating systems;

- when performing dry or semi-dry screed.

The only case when can be neglected the need to use this material, it is during the pouring of self-leveling solutions. This is due to both the small thickness of their layer and the fact that, in essence, self-levels are referred to as contact types of coatings.

For information - traditional cement-sand screed mixtures capable of expanding with increasing temperature by 0.5 mm per linear meter. Just imagine how hard the screed in the room will press 10 square meters on the adjacent walls. And if the house is relatively new and shrink foundation not yet fully completed, the walls will have some progress. With a rigid dock with concrete floor, cracking of concrete will be impossible to avoid. With to compensate for expansion and to minimize any kind of stress, a damper tape is placed around the perimeter of the room. Thus, the screed "lives" on its own, without affecting the walls, and they, in turn, do not create stress on the floor during shrinkage.

Many consultants in construction stores, not having sufficient experience and understanding of the elementary laws of physics, can discourage you from acquiring the tape, arguing that allegedly with small areas this is not necessary.We strongly discourage listening to the opinions of such “experts.” After all, you still won’t get significant savings, which could at least somehow justify such a decision, and the consequences will not be long in coming.

From personal experience I can add that when performing the screed in our apartment, we nevertheless heeded this advice, which we soon regretted. The screed in the room, whose area was only 7.8 squares, a couple of months after drying cracked in two places. I had to cut concrete with a grinder, raise a large amount of dust, re-fill the solution and again wait for it to dry. As a result, the finishing process was delayed for a decent period of time. Therefore, we can say that area no premises affects not the need to use tape, but only affects to choose her thickness and the need for laying intermediate expansion joints, but more on that later.

As a result, the finishing process was delayed for a decent period of time. Therefore, we can say that area no premises affects not the need to use tape, but only affects to choose her thickness and the need for laying intermediate expansion joints, but more on that later.

2. The advantages of the material of the damper tape and its use

Previously, in order to maintain the integrity of the concrete pavement, builders used various methods. They laid pieces around the room linoleum or roofing material, polystyrene or thin wooden planks. But each of these materials had its own characteristic flaws. For example, the same polystyrene decayed into separate fragments over time, although the wood could withstand the load, it decayed, and linoleum or roofing felt turned out to be too rigid and did not provide the necessary level of compensation. It is difficult to say when and who exactly thought of using foamed polyethylene, but this decision entailed a lot of advantages and helped forever solve cracking problem screeds. Of course, if the laying technology itself and the proportions of the mixture were strictly observed.

Of course, if the laying technology itself and the proportions of the mixture were strictly observed.

- Polyethylene refers to safe materials that do not emit harmful substances into the environment;

- Due to the fact that the structure of foamed polyethylene consists of closed cells, the material does not absorb moisture at all. Accordingly, it does not expand spontaneously and remains constant in size;

- Unlike wood, it does not form on its surface moldmicroorganisms and various fungi;

- Small rodents also do not show interest in this material;

- Polyethylene does not rot, which ensures a long life;

- Over time, the elasticity and elasticity of the material does not decrease;

- It is not susceptible to ultraviolet radiation.

As for the positive aspects directly related to the use of the damper tape:

- Besides the fact that this element takes on all the loads and successfully compensates for various voltages, it serves as an excellent sound insulator;

- Also, the tape is actively used if necessary to exclude heat loss in places of leaky joints of the floor and walls;

- In addition to everything, the tape provides tightness;

- It is able to damp not only stresses, but also various kinds of vibrations;

- Under the influence of significant loads, it maintains dimensional stability, is fully restored to its original size upon reverse compression of concrete, and is characterized by a zero value of the coefficient of linear deformation;

- The tape is used not only inside, but also outside buildings. For example, when arranging a blind area at home;

- With all of the above, installing a damper tape is a quick and easy task.

Are there limitations at the damper tape? Some believe that its price is too high. In addition, there are no more minuses.

3. Types of damper tape

The use of tape is relevant when arranging any type of screed, especially when organizing underfloor heating. Given the characteristics of a particular room and upcoming work, sometimes you have to use the tape not in the form of ordinary stripes, but in a slightly different configuration. Therefore, manufacturers produce several varieties of compensation tape:

- Standard or straight tape is a regular strip of material. For fastening of this type, different fasteners are used. For example, to drywall you can just shoot the tape with building glue or nail with small cloves. It can be glued to the plastered walls with liquid nails. Or you can just pointly put a small layer of mortar mixed for screed in such a way that it presses the tape against the wall. The distance between the fixation points should be such that the tape does not lag behind the wall;

- Direct with adhesive layer. This type is more convenient to install and can significantly save time. On the outside of the tape, usually in the middle, there is an adhesive layer covered with a protective layer. To stick the tape you need to remove the protection and press it firmly against the wall. It is better not to expose the entire sticky layer at once so that dust does not have time to stick to it or small debris to collect, otherwise the tape may not stick or lag;

- Tape with a skirt. It can be either ordinary or self-adhesive. Its difference lies in the fact that one of the edges has an additional strip of thin polyethylene. The width of this strip can be from 3 to 10 cm. It is necessary to fasten such a tape so that the skirt rests on the floor. This is necessary to prevent leakage of liquid or solution into possible voids at the junction of the floor and walls and create a tight coating;

- L-shaped tape. Has on its surface a shallow technological slot, which allows you to bend it with the letter "G". In this case, the long edge should lie against the wall, and the short edge should be on the floor. Both strips may have an adhesive layer. This kind of edge tape allows you to provide the best damping performance and create the most airtight base;

- T-shaped tape. They are used on large areas or in rooms where one of the walls is longer than 8 meters. In this case, using such a tape, the screed is supposedly divided into several rectangles, which minimizes internal stresses.

Any type of tape must be trimmed after drying. concrete layer. This is usually done using a regular clerical knife. But manufacturers and this process decided to make it as simple and fast as possible and equipped the product perforation or in small incisions every 4-6 mm. This makes it easy to tear off the excess in seconds.

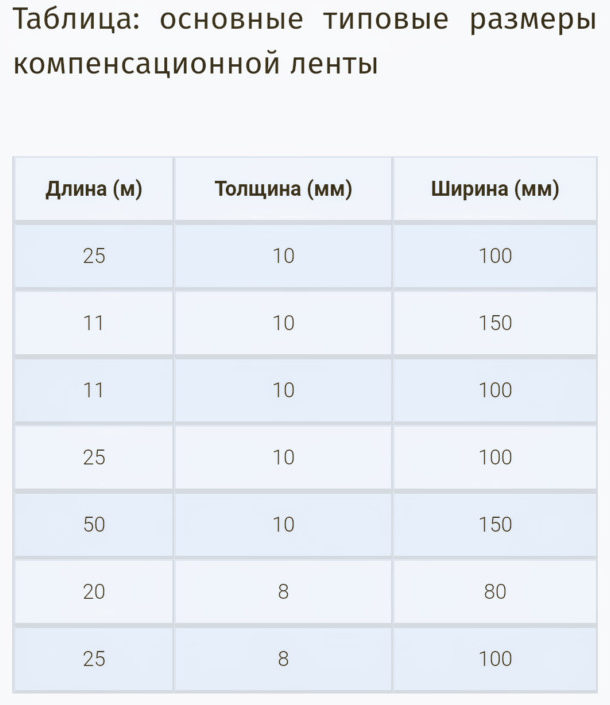

4. Standard sizes of a compensation tape

Any kind of damper tape has the form of release in the form of rolls. Which in turn can have different lengths. This option is mainly dependent on the width of the tape.

- Standard length rolls is from 10 to 100 meters;

- Width strips can lie in the range of 20-150 mm;

- Her thickness can be from 3 to 10 mm.

When choosing the right size, you should rely on the area of the future screed and its thickness.

- Width tapes is selected from the calculation: the height of the screed in the highest place + 2 cm. The tape must protrude above the concrete in order to completely eliminate even the slightest contact with the wall;

- The larger the fill area, the thicker the damping tape should be. This is necessary in order for voltage compensation to occur fully. With significant areas it is better to use the T-shaped variety;

- When calculating the required amount of tape, one should take into account not only the length of all the walls, but also remember to go around various protruding surfaces - the columns, partitions, etc.

5. Useful installation tips

We can say that the installation process of the damper tape is intuitive and does not require special explanations. But there are some nuances which are worth considering:

- If we are talking about fastening tapes with an adhesive layer, then first you need to clean the walls of dust and dirt and let them dry;

- Although the adhesive base is distinguished by high adhesive properties to many types of surfaces, including concrete and plaster, you can additionally treat their surface with a degreasing agent and dry well;

- It is not recommended to carry out work at subzero temperatures. First of all, this will adversely affect the quality of the screed itself;

- The protruding parts of the tape do not need to be cut off if installation is planned in the future baseboards;

- You should be careful when laying tape with a plastic skirt. This element must necessarily be well spread so that the edge exactly lies on the floor and make sure that it does not move with the solution;

- When laying a warm floor, the damper tape can be laid not only around the perimeter, but also can be used to divide the area into several parts. Then the heating elements in the formed rectangles should form independent from each other contours;

- It is not advisable to perform contour laying of the tape from many segments. A large number of joints will not allow in the future to talk about the complete tightness of the coating;

- Also, in no case can you make passes and leave even small areas that are not covered by tape;

- In the place of the doorway it is better to use a T-shaped tape;

- To evenly press the tape against the wall, you can use a solid construction roller;

- You need to finish mounting the tape at the same point from where it began to be laid. This is usually one of the corners. In this case, you need to leave a small overlap and carefully cut the tape with a knife.

To save money, many are trying to find substitute finished damper tape. Given the material from which it is made, most often the same foamed polyethylene is purchased for this, but in large rolls, and then it simply dissolves into strips of the required width. Sometimes its various modifications are used - penoizol, penofol, etc. But it is worthwhile to understand that it will be difficult to achieve completely similar properties. After all, these materials do not differ in such a high coefficient of noise and heat insulation.

6. Overview of popular manufacturers and product costs

As you know, demand creates supply, and the higher it is, the easier it is to get confused in the variety of options. There are a lot of manufacturers of damper tape. But, despite this, there is still an option to purchase low-quality goods. Defects may be, for example, in:

- violation of the integrity of the tape;

- the backing of the protective layer from the adhesive surface, which in the future will lead to the fact that the tape simply does not stick to the wall;

- strip thickness may be different over the entire length;

- the bottom edge will be cropped unevenly.

There are many nuances, especially often they appear on frankly cheap products. Therefore, it is better to purchase goods manufacturers which are can recommend professional construction crews. For instance:

- Kermi - German manufacturer of tape compatible with the same name floor heating system. It has a standard height of 16 cm, a thickness of 8 mm. It is delivered in rolls, 25 m long. The price per roll is about 900 rubles;

- Oventrop - a self-adhesive tape with a perforated line from a German manufacturer is used for laying ordinary concrete screed. Its height is 12-15 cm with a thickness of 10 mm. Rolls can have different lengths - from 25 to 50 m. This is an expensive tape, whose cost is from 790 to 3075 rubles, depending on the length of the roll;

- Uponor - Swedish manufacturer of adhesive tape. Its application is universal. A slight difference is that the material does not contain freon. The height of the tape is 15 cm, its thickness is 10 mm. It is delivered in rolls 50 m long. Material cost about 3500 rubles;

- Energoflor - the basis of the tape from this manufacturers use not foamed polyethylene, but a plastic film. Nevertheless, the tape meets all the requirements. It is delivered in rolls 11 m long. The width of the product can be 10-15 cm, thickness - 10 mm.the price is 450 rubles per roll;

- Tilit Super - it is applied at the device of a floating look of a coupler. On the one hand, the product is equipped with a protective apron. Operating temperature is very wide and ranges from -40 ° C to + 95 ° C. The width of the tape is 10 cm, the thickness is 10 mm. It is delivered in rolls 25 m long. The cost of one roll is about 930 rubles.

- Thermoflex - Perhaps the most economical offer. Indeed, the tape of this manufacturer is supplied in rolls with a length of 50 m and a width of 1 m. Thickness can be from 6 to 15 mm. This makes it possible to independently cut strips of the required width. Which is very convenient when arranging screeds of different heights. The price per roll is from 1250 to 3650 rubles.

Hello! Please tell me how the damper tape is processed in the bath, between the floor screed and the foundation. A friend told me that after trimming the tape, it is necessary to process the seam around the perimeter with a special elastic compound so that moisture does not get into the seam. thanks

Many sources note that in fact the damper tape is nothing more than polyethylene. The material is not afraid of moisture. In order to further protect the screed itself, you can fill the seam with a waterproof, transparent sealant.