Welded metal fence: 9 tips for choosing and installing

The realities of our life are such that any private territory without fail needs fencing. It is necessary both to clearly define boundaries and to ensure an appropriate level of security. In one case or another, sometimes the security issue may be relegated to the background, and its decorative function may become the initial function of the fence. Of course, ideally, all these three aspects are harmoniously combined in one product, which was not so difficult to find. Welded metal fences are widespread among consumers precisely because of their versatility combined with affordable cost. In addition, the service life of metal products is tens of years, and their care is minimized. We can safely say that welded metal fence - This is the best option for fencing, which has many advantages. Let's try to figure out howchoose such a fence and install it, consider the types of metal fences and the disadvantages of each of them.

1. Functions of the fence

Whether it is a summer cottage, the territory of a residential or country house or any other private facility, in most cases a fence is installed around it. For what he is needed?

- For a clear definition of the boundaries and delimitation of the site with neighbors. The least requirements are put forward to fences, which are designed to highlight the territory of summer cottages. They can have the most unpretentious appearance, withstand small external loads and not be characterized by high strength. However, everything is purely individual and depends primarily on the preferences of the customer;

- For protect private territory from excessive interest from annoying neighbors or bystanders. For these purposes, fences are suitable, at least 1.8 meters high with continuous sections. A striking representative of this type of fence is the fence of corrugated boardwhich is quick and easy to install and meets all the requirements;

- To protect a private area from intruders. In this case, not always solid fences, for example, of the same brick, will be more reliable than metal. Sometimes, to overcome a high obstacle is much easier than a metal one, the top of which is made in the form of sharp peaks;

- In addition to protection from people, the fence prevent penetration to the site of animals. It can be both stray dogs and other animals that can live in nearby green stripes. Sometimes they can cause great inconvenience in the form of garbage scattered across the territory, etc .;

- Some people prefer the above just a decorative function. In this case, the height of the fence may be minimal, but its design will be complex and unusual.

Optimal view The fence will combine all or most of the functions, which is an ideal option.

2. How to choose the height of the fence?

After you have decided on the set of functions necessary for you, you need to choose the optimal height of the fence, which will correspond to them.After all, this parameter primarily depends on the purpose of the fence, and only then on your preferences. Distinguish the following standard sizes:

- Tall 0,5 meter - such fences perform an exclusively decorative function and are installed directly within the territory. They can highlight the borders of the garden, a summer terrace is fenced and many other elements of the landscape or architecture;

- Tall 1,2-1,5 meters - we can say that this is the average standard size range. It is most often used to enclose private objects located outside large cities;

- Tall 1,7-2,0 meters - such fences are called capital fences and are designed to protect private possessions within the city. Most often, such fences are combined. That is, on a foundation of brick, buta or concrete, welded metal sections or sheets of corrugated board are installed. Such designs are more complicated in construction and require large expenses both for installation and for the purchase of the necessary material;

- Tall more than 2.0 meters - are rarely used for installation in a private area. You can meet such designs in industrial areas or in commercial construction, so we will not focus on them.

It follows that the best option for use on a personal or residential territory are structures whose height lies in the range from 1.2 to 2.0 meters. Such a fence will be able to provide a high level of protection and will not look too bulky and strict. Also, do not forget that the height of the welded metal structures can be determined by the wishes of the customer, which in turn will affect the cost of the finished product.

3. Advantages and disadvantages of metal fences

If you compare metal fences with the same brick or wooden fences, which are also quite popular, you can clearly highlight the following advantages:

- Metal fits perfectly into exterior of most objects and does not spoil the appearance of the territory. In addition, if you select the appropriate color of the coating, the fence may completely “dissolve” and become practically invisible;

- Metal is perfectly combined with other materials, for example, with brick, stone, polycarbonate, etc., which allows you to create a combined type of fencing that fully meets the requirements of the consumer;

- Sectional welded fences have increased rigidity and stability;

- Due to the fact that the metal is coated special protective compounds, adverse environmental factors practically does not have a detrimental effect on it. Elements do not oxidize, do not absorb moisture, do not respond to direct sunlight or frosty wind. Of course, this is provided that there is no damage to the protective coating;

- Metal surface not subject to formation and spread mold or fungus;

- In addition to periodic dyeing in order to restore protective properties, metal fences do not require special care;

- The service life of metal products can reach several tens of years (about 50);

- Unlike wooden structures, a fence welded from metal rods is very difficult to break, bend, and sometimes even scratch;

- Installation of welded structures can be performed quite quickly and is not a particularly difficult task;

- Welded metal fences are much more affordable than forged structures, and their appearance and degree of reliability are not inferior to anything;

- At the request of the customer, it is possible to make a welded fence of the most diverse design, and to increase its aesthetic qualities, add design with individual forged elements;

- Most fences are translucent, which positively affects both the green spaces near it and the perception of the territory as a whole.The perimeter does not seem closed and limited, which does not exert a pressure on the psyche.

Without disadvantages also could not have done:

- Due to their light transmission, such fences will not protect the site from dust if it is located near the roadway. From the piercing wind, which is sometimes impossible to avoid due to the geographical and climatic characteristics of the territory;

- Welded fences will not be able to properly protect the site from prying eyes. An exception may be only combined structures, between the rods of which there are inserts of their opaque polycarbonate;

- The process of painting a welded fence can be time-consuming and difficult. Especially if its design is different from the standard fence-grille;

- On particularly hot summer days, the metal surface can heat up to high temperatures. This must be taken into account in order to prevent possible burns;

- If the protective coating is not renewed in time and its integrity is not monitored, the metal may be corroded.

4. Lattice welded fences

There are actually a lot of varieties of welded metal structures. However by common and in demand an option is a fence whose sections are made of profiled pipe, bar or fittings. The latter option can be called budget. Reinforcing Fences often installed in places where external aesthetics play no role or as temporary fences. Yes, they really differ in simple appearance, but they also have some advantages:

- Affordable cost;

- Ease of manufacture;

- Easy and quick installation.

More attractive fences made of a profile pipe or rod have an appearance.

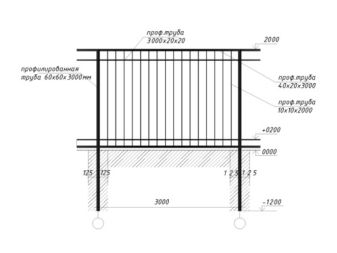

- They can only have vertical rods. Then for their fastening several horizontal partitions are used, to which individual rods are welded. Finished items resemble large grilles. The upper contour can be the most diverse in shape. And horizontal jumpers can have a protruding or curved shape. This is done for added protection. It is worth noting that the installation and welding of such a fence is carried out on site. Pre-cut parts from the profile pipe are brought to the object and welded to installed metal posts;

- Or include both vertically and horizontally located elements. Then, for their fastening, prefabricated metal frames (frame) of appropriate sizes are used. Such fences are called sectional.

Sectional designs can have a variety of designs. They are a reliable protection of a private territory and can even become its decoration. Them the benefits are:

- Durability;

- Reliability and stability;

- Aesthetics;

- Easy installation, which is carried out directly at the installation site;

- Affordable cost;

- Possibility of custom production.

5. Forged-welded fencing

Welded metal fences with forging elements can be called an intermediate product between the available welded and expensive forged fences. They are made from the same rod or different metal rolling - channel, square, corners, and include only individual parts made by forging. To their the benefits include:

- More interesting and presentable appearance. Such a product will help once again emphasize the status of the owner of the territory;

- Considering that only decorative elements are made by forging, the production time of the fence itself will be much shorter than a completely forged fence;

- The presence of forged elements also does not affect the duration of the installation process and its complexity;

- The price of the product remains affordable;

- The customer has the opportunity to purchase a fence, whose appearance may be unique.This is achieved by the possibility of choosing decorative elements and combining them;

- Thanks to this, it is possible to choose a fence that will maximally match the style previously installed bars on the windows. This approach will create a harmonious exterior;

- Also plays an important role and weight finished welded section, which will be significantly less than the weight of the forged. Sometimes this is a necessity, due to the peculiarity of the soil.

6. Welded metal mesh fence

This kind of welded fences differs significantly less weight. The design can be either frameless or with a frame. The mesh can be made by spot welding of wire of various thicknesses. Cells may be different in shape and size. The simplest are square or rectangular cells, more complex and decorative - rhombic, trapezoidal and other polygonal shapes. Depending on the protective coating of the wire, the following are distinguished: grid views for fences:

- FROM polymer coating. The protective layer is applied by powder coating or by dipping the wire in a special solution. Most often, such a grid has a green color, which allows you to make the fence as inconspicuous as possible. Other colors are also possible;

- Galvanized - can be made of already galvanized wire, or covered with a protective layer after welding the wire into a finished mesh. Non-galvanized products can also be found on sale, but they are more susceptible to corrosion;

- Galvanized from polymer coating - The most durable option, which, respectively, is the most expensive.

The above types of mesh are supplied in rolls and can have different heights and thicknesses of wire no more than 3 mm. More reliable will be a sectional fence from 3d mesh polymer coated whose standard thickness is 4-5 mm.  Such fences can serve as reliable protection of the territory, both from the penetration of animals and outsiders. They are completely translucent, however, this drawback can be easily eliminated by planting climbing plants along the perimeter of the fence. In addition, the grid will be a great support for them. Advantage sectional mesh fences is:

Such fences can serve as reliable protection of the territory, both from the penetration of animals and outsiders. They are completely translucent, however, this drawback can be easily eliminated by planting climbing plants along the perimeter of the fence. In addition, the grid will be a great support for them. Advantage sectional mesh fences is:

- Ease of construction;

- Aesthetics;

- Affordable cost;

- Practicality;

- Simplicity and speed of installation;

- Long term of operation;

- Increased structural rigidity due to the presence of bends on the mesh web.

7. How to calculate the required number of sections?

Whatever kind of welded fence you choose, before placing an order, let alone proceeding with the installation of the structure, you need to decide on the desired number of sections. To do this, follow these steps.

- First of all, you need mark up territory, or rather, to define clear boundaries of the site. This can be done most easily and clearly using small pegs and a rope. To start driving in pegs should be from the place where the gate or gate is supposed to be. Then you need to mark all the corners. And only after that drive in intermediate pegs. Now pull the rope, carefully look to see if the resulting boundaries require adjustments, and use a tape measure to measure the length of the future fence. Of course, if you go to any company for services, they will measure. However, in order to save money, many prefer to perform this stage and the installation itself;

- Also important calculate necessary quantity assembly columns to which the grid will be attached with the help of special brackets or the lattice section will be welded. In order for the structure to be rigid and reliable, the recommended distance between the columns should not exceed 2 meters. Important point - The installation of the columns starts from the corners.Sectional fences usually have a standard element length, which may exceed 2 meters. In this case, you can calculate the number of columns immediately after choosing the design and size of a particular section.

After all the calculations are made, we advise once again to double-check everything and only after that make a purchase.

8. Tips for installing support columns

Installation of a welded fence from the grid should begin with the installation of support columns, which are made of a metal pipe of square section:

- Get started installation with angular supports. At the location of each column, you need to dig a recess with a depth of at least 0.5 meters and a size of 25 × 25 cm .;

- The greater the length of an individual section and the greater its weight, the deeper it is worth immersing the columns in the ground. At this stage, it is important not to miscalculate and order columns with a height that will take into account the depth of the dive. That is, if the future fence will have a height of 1.5 meters, and the columns are supposed concrete by 0.8 meters, the height of the column, respectively, should be 1.5 + 0.8 meters;

- After that, you need to organize the foundation in the recesses. It is necessary to prepare a solution, which will include sand, cement, small gravel and water. All components are thoroughly mixed in concrete mixer;

- Do not immediately knead a large amount of solution if you are working alone, otherwise it may dry out;

- The pits should be filled with a solution and driven in columns until the composition is seized;

- To speed up the process, you can immediately install the columns with the help of spacers, not forgetting to control the evenness of their installation by the building level, and then fill all the places at once;

- Proceed to further attachment to the columns of the grid or sections after three days, when the composition is finally crystallized.

9. Tips for installing various types of fences

Both the netting net and the welded net and lattice welded sections can be attached to the columns set in this way. Let's consider some features of fastening of each type separately. For fixing the chain link to the supporting posts you need:

- Weld metal strips, the size of which should be at least 5 × 25 cm, where 5 is the width;

- It is necessary to fix the strips at a distance of about 225 cm from the edge of the column from below and above;

- Next to these strips you need to weld a section from the grid;

- If we are talking about rolled material, then to secure it, you also need to provide tensioners that will not allow the canvas to sag under its own weight. A thicker wire is well suited for these purposes;

- The edge of the roll is attached to the first column using special brackets. Then it is gradually unwound, a wire-tensioner is threaded into the cells from above and from the bottom of the canvas and also attached to the posts by twisting around it or using special fasteners. It is important to ensure tight tension;

- Therefore, you should move from column to column.

Sections from welded 3d wire fasten a little differently:

Sections from welded 3d wire fasten a little differently:

- Finished sections should be previously laid out between the columns;

- Then weld metal corners to the supports;

- In the corners, you should drill holes for the screws with which the sections are fixed. Usually they come with the kit;

- The same holes should be drilled in the corner parts of the section;

- Now you need to screw the grid in the frame to the metal corners on the posts and tighten it securely;

- Instead of screws, you can use the familiar welding. Then the frame is simply welded to the corners.

Welded wire mesh or forged and welded sections are attached to the support columns as follows:

- The fastening of individual bars of the trellised fence should begin with the welding of horizontal jumpers to the posts;

- Then the rods are laid out on the ground, according to the sketch;

- Carefully measured the distance between the elements;

- Each rod is welded separately.At the stage, it is important to control each step with a building level so that the final result meets your expectations;

- You also need to pay attention to the quality of the welds, which should be solid, without voids and tears;

- Sectional fences, if they are not sold in the form of already welded structures, should be mounted starting from the welding of the frame;

- Then, rods and decorative elements are welded onto the frame. It is most convenient to do this on earth;

- And only after the final assembly, the finished section is welded to the supporting posts.

It should be noted that the installation of trellised fences for a person who does not have sufficient welding skills can become quite complicated and time-consuming. It is possible that you will be disappointed with the appearance of the finished fence or its strength. Therefore, sometimes installation work better entrusted to special teams. Most often, companies that manufacture and sell metal welded fences offer installation services. AND finally - so that the fence made of the profile pipe lasts longer, be sure to choose products with a protective coating and do not forget to install a plug on top of each bar. It can be made in the form of spades, rhombus and other shapes. However, its role is not only decorative. It also protects the structure from precipitation inside, thereby preventing the formation of corrosion.

AND finally - so that the fence made of the profile pipe lasts longer, be sure to choose products with a protective coating and do not forget to install a plug on top of each bar. It can be made in the form of spades, rhombus and other shapes. However, its role is not only decorative. It also protects the structure from precipitation inside, thereby preventing the formation of corrosion.