10 tips for choosing a jigsaw for home

In the arsenal of the real owner must necessarily be several high-quality, versatile tools with which you can quickly and easily perform any repair work around the house. In this list, you can safely make a jigsaw. In the article we will consider the scope and design of the tool, its main characteristics and possible additional functions, and also give Tips for choosing a jigsaw for home and select the most appropriate models.

1. Brief description and scope

Jigsaw, aka jigsaw, refers to an electric hand tool used for sawing different materials. It has low weight and modest dimensions, so the duration of continuous work does not depend on the need for periodic rest of the performer. Any cut occurs with a saw blade performing reciprocating movements. Choosing one or another type of saw, it is possible to process materials of different density and thickness, perform complex cuts and much more. And it's not just about ability to process familiar materials like wood or metal, but also drywall, ceramic tile, a rock, plastic and glass.

The scope of the jigsaw is quite extensive:

- In furniture production - for cutting out individual structural elements that may have a curved or complex profile;

- For quick and accurate cutting of connecting elements;

- For cutting at an angle and ensuring accurate joining of two elements with each other;

- For curly and decorative cutting. Using a jigsaw, you can create stunningly beautiful pieces of furniture.

- For cutting blind holes. Since the cutting blade has a free edge, it is unnecessary to violate the integrity of the element in order to make a groove or hole in it. You probably had to observe how to install kitchen worktopbore diameter the sink it is cut with an electric jigsaw;

- When arranging the frame for the future roof, it is faster to adjust the bars to the required length with this particular element;

- For wall cladding clapboard, MDF panels or other similar materials;

- For independent flooring laminate flooring.

In fact, this is not the whole list. Having learned about all the features of the jigsaw, you yourself will see that it is really practically indispensable in the household and multifunctional.

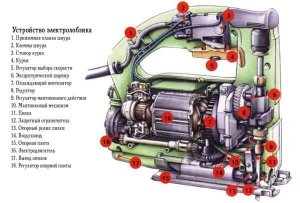

2. The design of the jigsaw

Most often, the owners of several serious units of the working tool prefer to fix minor malfunctions on their own and can accurately determine when to do without the help of a specialist and which part should be replaced. No wonder that such knowledge directly depends on the understanding of devices and the principle of operation of a device. Consider in detail the design of the jigsaw, shown in the figure.

- The basis of the mechanism of any electric jigsaw is the engine, gearbox and rod;

- It is these elements that set the cutting element in motion;

- In many models, a cooling fan is connected to the engine, and modern jigsaws additionally have a built-in swing mechanism;

- On the handle of the case there is a start button, which sometimes is responsible not only for supplying electric energy to the engine, but also for adjusting the cutting speed;

- Inside the body, energy is repeatedly converted. Getting on graphite brushes, it starts the process of rotation of the rotor around its axis;

- From it, the torque is transmitted to the gearbox, which in turn converts the rotational motion into reciprocating;

- And only after that they are transmitted to the rod, at the end of which there is a fastener connecting the saw blade to the rod. In this way a robust, interconnected movable structure is created;

- The sole of the case has the ability to change its angle of inclination, thereby allowing you to perform small saws. In some models, it is possible to remove the sole. It is very comfortable. If you need to cut parts with different projections in height;

- To maintain evenness and straightness of the cut, the jigsaw is equipped with a guide rail.

I would also like to dwell on hilt of a jigsaw. It can be of various forms, on which the convenience of performing certain works directly depends. There are three options:

- Bracket-shaped handle - the most convenient for performing precise cutting operations;

- D-shaped - It is more convenient to achieve smooth and large cutting lines. Allows more precise control of turning radius, etc .;

- Mushroom - It is maximally adapted for performing work on curly cutting. Thanks to this form, changing the position of the hand during operation can be very quick, and the brush can be positioned in different ways, without losing convenience and controllability.

Also, depending on the design, jigsaws can be divided into two large groups:

- Stationary They have cardinal differences. They are large devices with a fixed plate. All electronics in this case is hiding precisely under it. When working on such a tool, it is necessary to move the workpiece directly, while the saw blade remains in place. Such devices have a huge resource and high accuracy. You can work with such a jigsaw for many hours in a row, without fear of overheating. In addition, stationary models have high power. It is rational to purchase them for the home only if you have a small carpentry workshop where it is important to ensure long-term work and minimal energy consumption;

- Wearable. This is the most common design of both household and professional jigsaws. It is these models that can be equipped with many useful features.

3. Advantages and disadvantages of using a jigsaw

Any tool has both advantages and some disadvantages. Perhaps knowing everything advantages jigsaw as a hand tool, it will be easier for you to make your choice or you will finally make sure that you need to purchase it:

- The main advantage is its universality. This is especially true for newer and more powerful models that allow you to process a large number of materials with different densities;

- Wide range of will allow you to choose the tool that is most suitable for you in terms of characteristics and capabilities, as well as cost;

- An even wider range of saw blades with different pitch between teeth, thickness and general purpose. This is the determining factor responsible for the universality of the tool as a whole;

- Safe and easy replacement of the cutting element;

- The ability to perform fairly accurate both straight and curved cuts;

- Ample speed of work;

- With the correct selection of saws and compliance with the recommended cutting conditions for a particular material, the possibility of cracking or chipping can be almost completely eliminated. Thanks to this, you can save and purchase the exact amount of finishing materials, and not "in reserve";

- The presence of an electric drive, which greatly facilitates the work and does not require the application of additional physical effort;

- The relatively small weight of the tool makes the user practically not tired;

- The presence of additional useful functions, which in certain cases are indispensable.

Among disadvantages can distinguish:

- The ultimate power of the tool is a limited parameter that directly affects the weight of the jigsaw. The more powerful you need a model, the more it will weigh. Although, this flaw applies to all tools;

- Limited is the maximum thickness of the processed material;

- Short stroke of the cutting blade;

- Considering that the saws are mounted on one edge, they should be of sufficient thickness so that they simply do not break every time they have to deal with solid materials. And, as you know, the thicker the canvas, the lower its flexibility. This may affect the ability to perform curly cutting;

- When cutting thick parts, the output of chips significantly deteriorates, which in turn leads to a decrease in saw speed.

4. Main technical specifications

Obviously, the more powerful the model, the faster and more productive it is, that is, it can cope with the greater thickness of the part. But this is not the only important parameter:

- Possible engine power lies in the range from 300 to 1000 watts. It is this run that determines whether the model belongs to household or professional ones. In the first case the best option would be jigsaws with a power rating of 400-500 watts. Such a tool is able to cope with most household needs, for example, with sharp sheet steel with a thickness of 2 to 4 mm. Models with power over 700 W belong to a professional tool and are capable of sawing steel, up to 10 mm thick or aluminum, up to 20 mm thick;

- Stroke frequency. This parameter determines the productivity of the tool and is measured in the number of reciprocating movements of the saw blade in 1 minute. Frequency adjustment can be carried out using the button on the case, both before turning on the device, and during its operation and usually ranges from 300 to 3000 times / min;

- Amplitude of cut Depends on the model of the jigsaw. The standard value is 18 mm, for powerful models - 26 mm;

- Depth of cut. Wood cutting for models of medium power can be carried out with a thickness of up to 65 mm, for more powerful - up to 130 mm. Metal cutting is possible with a thickness of about 6 mm, for powerful models - up to 10 mm.

5. Overview of advanced features

In addition to the main characteristics, there are a number of useful functions that modern manufacturers have generously endowed with their products. Naturally, the more "bells and whistles" at the tool the higher will be him cost. However, operating with the established stereotype “the more expensive the better” is not worth it in this case. Perhaps some of the functions for you will be completely unnecessary and useless, so why pay extra for them?

- ABP - anti-vibration system. The presence of this function significantly reduces the vibration transmitted to the performer from the engine through the housing. Thus, this contributes to less fatigue and greater controllability with a jigsaw. Tool life is also increased. It is advisable to purchase models with ABP if you plan to perform work often and for several hours in a row;

- Frequency adjustment saw blade stroke. This feature is very useful if you plan to work with a jigsaw with different materials. Also, this moment determines the ability to achieve a clean cut.After all, wooden workpieces are best processed at a high stroke frequency, while avoiding the formation of teeth at the edges of sheet metal can be obtained only at low speed;

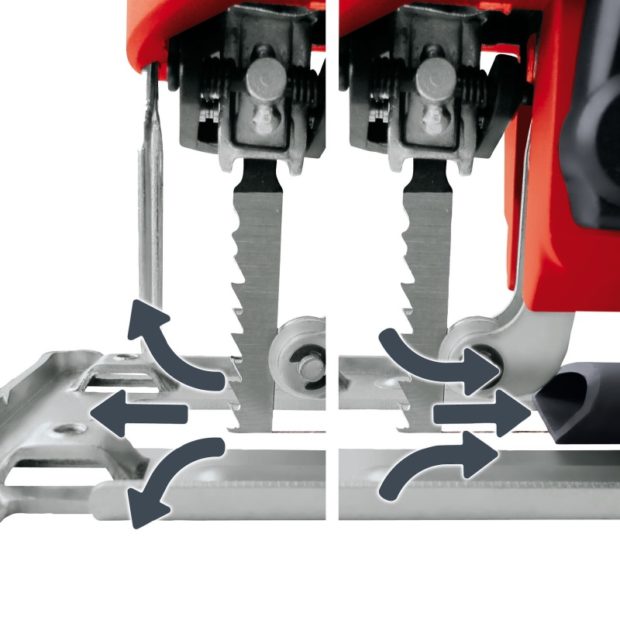

- Pendulum move. The presence of this element makes it possible to move the saw not only up / down, but also forward / backward. This greatly speeds up the cutting speed, but degrades its cleanliness and reduces tool handling. Most often, models with this function acquire, if necessary, frequent sawing a large number of wooden parts;

- Drank at an angle. The ability to make an oblique cut is possible only if the sole of the tool can change its position. In this case, the angle can be 0-45 degrees. You will have to set the desired angle yourself, focusing on the corresponding marks. More expensive models have a clearly fixed position of the sole at an angle of 15, 30 or 45 degrees. After tilting it to the required angle, it will be fixed with the built-in stop. It is advisable to purchase jigsaws with this function if you are engaged in the manufacture of furniture or, for example, window glazing beads;

- Smooth start. The possibility of a smooth start, firstly, will allow to preserve the integrity of the workpiece at the beginning of work, and not tear out pieces at the beginning of the cut. Secondly, it will protect the motor from high inrush current;

- Opportunity connecting a vacuum cleaner. In this case, a special nozzle for removing sawdust will be connected to the jigsaw base. The function is useful even, which allows for “clean” work and minimizes the amount of wood or metal dust that the user inevitably inhales when working;

- Backlight places drank. A convenient little thing that makes the markup more visible, which means that the cut will be more accurate;

- Laser marker. It can be implemented as a point or line. Allows you to provide the direction of the cut and prevent its deviation from the marking;

- Quick change system saw blade. Allows you to remove a worn or broken saw with one click of a lever;

- Dust blowing and sawdust from the cut line. In some models, the fan, which is necessary for cooling the engine during operation, can also perform an additional function of blowing debris from the workpiece;

- Protective screen. It is called upon to protect the organ of vision from dust or chips getting into them, and their transparent plexiglass is performed;

- Little table for fastenings. With this element, a conventional portable tool can turn into a stationary one.

6. Factors affecting choice

After you have familiarized yourself with all the possible additional functions and technical characteristics, you need to summarize and highlight main factors which should influence the choice:

- Before choosing the most powerful and expensive model, try to accurately determine the front of the upcoming work, their duration and frequency. Perhaps an average power tool is enough for you;

- In addition, high power inevitably leads to weight gain;

- Also pay attention to type of unit power. After all, there are models that are directly powered by the network, and there are those that have the ability to work on battery power. There are also jigsaws combining these two possibilities. The battery will become indispensable if you need to perform work in an open area remote from the voltage source;

- Do not forget to decide on handle shape. Try to hold various models in your hand before buying, in order to understand which option is more convenient for you;

- Try sway the mounting mechanism, if it has a large backlash, then with a high precision and cleanliness of cut such a tool cannot be achieved. The less backlash, the better;

- Pay attention to engine's type. It can be brush or brushless. Graphite brushes transfer energy to the engine and, under constant friction, are often subject to planned replacement.The efficiency of such motors is lower than brushless, but they are also cheaper;

- If you settled on the first type of engine, be sure to choose a model with the ability to quickly access the brushes. This will greatly facilitate the process;

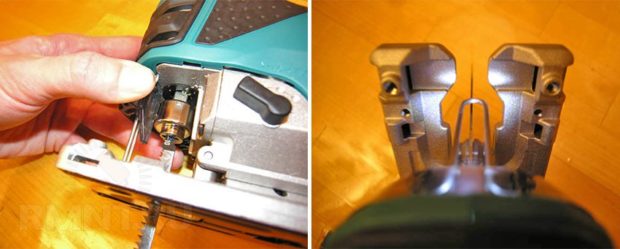

- Chuck for attaching the saw blade It can also be of two types - key or keyless. The first option involves fixing the saw with a hexagon corresponding to the diameter. In the second case, everything happens much faster. He bent the bracket, pulled out the old one tightly, inserted a new one, returned the bracket to its original position. Just a couple of seconds and the tool is ready to work again.

7. TOP-3 most “tenacious” jigsaws for home

Of course, after such a careful selection, I would like to purchase a really reliable tool for long-term use. The variety of products offered is unrealistically large. And the more you look at directories, the more you can get confused. It has long been known that in order to acquire a really thing, you need to pay attention to trusted manufacturers and not skimp. We have selected for you several models of jigsaws that confirm their durability and reliability with a large number of positive reviews from real consumers. For information - the serial number in the list does not play a role.

- Everyone starts their reviews with famous brands such as Makita, etc., we also did not overlook this brand, but decided to start with the manufacturer, originally from Simferopol, which is famous for its successful models of jigsaws. Many professional workers note that the firm’s model Fiolent PMZ-600 E they have been operating for a long time in a fairly intensive mode and have never failed. The jigsaw can handle wood thicknesses up to 85 mm, steel up to 10 mm thick and aluminum, up to 20 mm thick. The engine power is 600 W, and the frequency of movement of the saw blade is 2600 times / min. Experts note the high quality of the filling of the tool, which definitely has a margin of safety. The sole of the tool is made of thick stamped steel, and has the ability to tilt at an angle of 45 degrees. There is a function for adjusting the number of revolutions and a swingarm, which can be disabled if necessary. TO disadvantages can include the weight of the model, which reaches 2.4 kg. Maybe the first time, it will not be very convenient and hard for you to work;

- Makita 4351 FTC. A jigsaw from a well-known manufacturer of high-quality tools has a mushroom-shaped handle and is more suitable for those who organized a small carpentry workshop in their garage or at the cottage, rather than for a single household use. At the same time, people testing this device noted that the jigsaw body is quite large and wide. Grabbing the tool with one hand and locking it securely can be problematic. The engine has a power of 720 W, and the frequency of movement of the saw blade can be adjusted and lies in the range of 800-2800 times / min, the blade stroke is 26 mm. High power was reflected in the weight of the instrument, which reaches 2.4 kg, like the previous model. The jigsaw works quietly, does not create strong vibrations, easily copes with large thicknesses in accordance with the specifications specified by the manufacturer. The sole is very solid, made of aluminum, has a fixation in the zero position and at an angle of 45 degrees. The kit includes a plastic anti-slip and protective sole pad. The cartridge is quick-clamping and reliably fixes cloths of different thicknesses. Among the additional functions are present - smooth running, pendulum three-mode running, illumination of the working area;

- Bosch PST 650. A very convenient and compact jigsaw with a D-shaped handle from a well-known German manufacturer immediately captivates with its weight, which is only 1.6 kg.In this case, the engine power is 500 W, and the maximum number of reciprocating movements of the saw element is as much as 3100 times per minute. Due to such a high speed, the maximum thickness of a wooden billet, according to the manufacturer, is 65 mm, steel - 4 mm. The sole of the tool is made of durable steel, has a rigid fixation in the zero position and at an angle of 45 degrees. The chuck is also quick-clamping, however, it does not fix all the thicknesses of the saws. The jigsaw is equipped with a sawdust cleaning function that can be adjusted. We can say with confidence that this is one of the best and most reliable models for home use.

8. Tips for choosing saw elements

It is a wide variety of working equipment that makes the jigsaw so versatile and indispensable. Probably, you could not fail to notice that all saw blades have different markings on the shanks. She not only says what material the canvas is made of, but also why it is best used. Consider standard markings:

Consider standard markings:

- Hss - A saw made of high speed alloy steel. Designed to work with various stones at high speeds - with brick or concrete, or with metal. It is characterized by increased strength, hardness and resistance to high temperatures;

- Bim - a cloth made of bimetallic material. Suitable for cutting hardwood, laminate, ceramic tile or plexiglass;

- HCS - cutting element made of high carbon steel. Suitable for processing almost all types of wood, except especially hard, or plastic;

- Hm - A particularly hard web made of tungsten carbide alloy. Most often used for cutting ceramic tiles or fiberglass;

- CV - A saw made of their chrome vanadium steel. It has increased characteristics of plasticity, viscosity and elasticity, which makes the canvas ideal for working with soft materials - drywall, particleboard, fiberboard and some wood species.

In addition to material and purpose, saws differ in shank shape and may be:

In addition to material and purpose, saws differ in shank shape and may be:

- T-shaped

- U-shaped;

- With two holes - marking MA.

The recommended form is indicated in the technical specifications of the jigsaw.

9. Recommendations for use

To work with the tool was easy, and its service life was maximum, you must comply simple rules:

- When cutting any material, you don’t need to put pressure on the saw blade, thereby “helping” it move faster. So you only speed up the process of heating and failure;

- Change the saw blade more often to minimize the load on the engine, which increases significantly when working with a blunt tool;

- When cutting metals, the blade can be lubricated with machine oil. This will facilitate the operation of the tool, and the saw will remain sharp longer;

- To avoid excessive vibration when cutting thin sheet metal, place a sheet of plywood under it. This will make the cut more accurate;

- Periodically let the instrument rest, especially if you are working at low revs. In this mode, the engine is not cooled sufficiently;

- Do not store the instrument in contaminated form. After work, clean it from chips every time and lubricate it;

- Do not lay the tool so that it rests on the cutting blade. This can lead, at best, to its curvature, at worst, to the fact that the straightness of the cut will be lost;

- Store the tool in a special case to protect it from dust and accidental impacts;

- Do not use the tool with gloves on. This will significantly reduce the reliability of fixing the jigsaw in the hand, which can lead to its fall, your injury or damage to the workpiece;

- Be sure to wear safety glasses and a respirator for your own protection.

10. The most common malfunctions

Frequent and prolonged or not quite correct operation of any tool sooner or later will necessarily lead to some kind of malfunction. Consider the most common mechanical types of breakdowns jigsaws, in which the engine itself continues to work normally, but it is not possible to achieve an accurate or clean cut:

- Crooked drank. It happens that the saw blade significantly leads away from the intended line during operation. In this case, either the rod itself or the saw attachment mechanism may be faulty. Also, do not exclude the possibility of wear of parts or their excessive pollution. To begin with, it is worth trying to remove the above elements and clean them thoroughly. If the problem persists, replacement of fasteners or stem is inevitable;

- Too tangible vibration and noise. If you notice that over time the device began to make sounds that were not typical for it before and vibrate very much, this may be a consequence of a gearbox failure. There may be no lubrication or the gears have broken down on the gear. For an accurate determination, you need to remove part of the case from the side and inspect the mechanism. If there is a breakdown, the mechanism must be replaced;

- Strong shocks at work. If you feel that the jigsaw started to hit hard during the cut, this may be due to the failure of the pendulum mechanism or rod, which will have to be replaced. Before replacing, try to untwist and completely clean and lubricate the mechanism, sometimes this is enough.

Not always malfunctions can be the result of failure or breakdown of one or another structural part. Sometimes malfunctioning maybe electronics. Then the characteristic types of breakdowns will be:

- The device does not turn on. If the jigsaw does not respond in any way to pressing the start button, then there is no connection between the electricity source and the motor. The power cord may be broken. Ring it all the way, and also check the internal elements of the jigsaw wiring. If everything is in order, the reason may lie in the button itself. Connect the wiring directly to the engine, bypassing the button, if the tool comes to life, then the reason is really in it;

- Does not work under load. If the tool ceases to cope with the simplest tasks or even stops on materials of small thickness, the cause may be engine damage. Loss of power can be caused by a short circuit, due to which the anchor for a jigsaw is not able to create a sufficient speed. Given that the start of energy conversion occurs in the stator and rotor, it is these details that must be checked with a voltmeter. The part where the short circuit is detected must be replaced. In most cases, such a breakdown is accompanied by the smell of burning and the formation of sparks;

- Periodic power reduction accompanied by the smell of burning. If during operation you notice characteristic power surges in a smaller direction and smell the burning, carefully pay attention to wiring. Perhaps the contact has weakened or charred somewhere;

- Education a large number spark If, under normal loads, a working tool generates an excessive amount of sparks in the area of the collector, this may be a signal of a malfunction of the engine or a defect in graphite brushes. To get started, try replacing them with new ones.