10 tips for decorating a flexible stone wall

Flexible stone, stone wallpaper, flexible sandstone - does this name tell you anything? If not, then this is not surprising, because it is completely new material which recently appeared on the construction market. Its scope is quite wide, mounting incredibly simple and the end result is just amazing. Finish flexible stone Walls are increasingly being used by modern designers. This makes it possible not only to achieve a unique design of the premises, but also to use environmentally friendly material for cladding your home.

1.read more about material

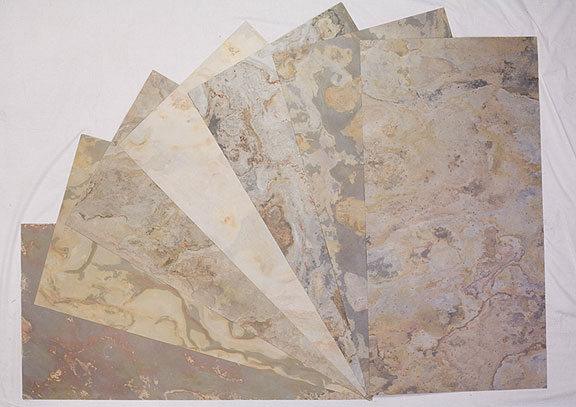

Flexible stone appeared not so long ago, but has already gained considerable popularity. It is very lightpractical material which has a thickness of not more than 6 mm and includes of three thinlayers. First - non-woven fabric or flexible fabric base, second - an adhesive, in this case an epoxy solution, third - small crumbs of natural marble, quartz or granite. Flexible sandstone suitable for both interior decoration and cladding building facades. It is very practical durable and is able to keep its properties and appearance attractive unchanged more than 25 years. Its surface has a slight roughness, and variety of colors will allow you to choose a sample for every taste. The patterns that are on the surface repeat the appearance of natural marble, sandstone, granite and other types of natural stones.

Flexible sandstone suitable for both interior decoration and cladding building facades. It is very practical durable and is able to keep its properties and appearance attractive unchanged more than 25 years. Its surface has a slight roughness, and variety of colors will allow you to choose a sample for every taste. The patterns that are on the surface repeat the appearance of natural marble, sandstone, granite and other types of natural stones.

2. Production technology

This interesting material was invented in Germany and its production process involves two of possible place of manufacture - directly in quarries or in special workshops. These processes are distinguished by the method of applying the last, third layer, that is, the pattern.

The first option is quite painstaking and specific. For production in a quarry, you must first find a suitable source with interesting rocks, then prepare an even cut of sandstone with a beautiful natural pattern, sand it to achieve an almost perfectly smooth surface. After that, a special adhesive solution of deep penetration is applied to the prepared area. For these purposes, epoxy resin-based binders are used. A thin layer of textile base is applied to the impregnated surface, the material is thoroughly smoothed to avoid wrinkles and left to dry completely. Highly important Allow the material to dry completely, so that when removed all the grains of sand remain on the base, and do not stick in separate places. It is very difficult to remove the sheets, because they have a very small thickness. For this, special equipment is used that, as it were, cuts off the top layer of the stone surface together with the base. Thus, a flexible sheet is obtained that completely copies the color and is environmentally friendly.  Advantage This type of production is the completely natural origin of the material. But there are a number of significant disadvantages:

Advantage This type of production is the completely natural origin of the material. But there are a number of significant disadvantages:

- Search for a suitable career, which actually may not happen as fast as we would like;

- Low variety colors and textures;

- High cost time and money to prepare a suitable surface;

In case of production in specialized workshops everything happens much faster. The pattern is formed artificially by mixing several varieties of components. The benefits this method has a lot, but it has not yet discovered any drawbacks:

- There is no need to seek a career;

- Color gamut and texture highly diverse and practically unlimited;

- The appearance of the surface is 100% similar to natural rocks;

- Only used for production natural ingredients.

3.Production at home

From the moment the flexible stone went on free sale, many immediately began to wonder whether to make him in home conditions. We tried to figure this out and came to the conclusion that, in principle, yes. For this you will need prepare the workplace, which should have a flat, smooth and sufficiently large work surface. A desk will do. A place is also needed for drying the finished sheets. Ideal for this are smooth wooden palletsplaced in a well-ventilated place, such as a balcony.

For the manufacture of the stone itself needs: base material, such as fiberglass, natural sandstone in the form of fine crumbs or quartz sand, acrylic glue, drill for mixing and capacity.  Spread the required length of fiberglass on the table, sprinkle stone chips on top, simulating a natural cut of stone, and pre-level it. Knead the glue and soak it with the entire surface of the sheet along with the crumb, then finally smooth it with a spatula. The layer should turn out thin and uniform, for this slightly press the spatula. Then put the resulting sheet on a pallet, straighten and leave until completely dry. In terms of its decorative properties, a self-made flexible stone will be inferior to factory production, however, its technical characteristics will be similar. In order to to diversify the look iron oxides can be used to color stone chips. This dye is the most durable, in addition, completely natural.

Spread the required length of fiberglass on the table, sprinkle stone chips on top, simulating a natural cut of stone, and pre-level it. Knead the glue and soak it with the entire surface of the sheet along with the crumb, then finally smooth it with a spatula. The layer should turn out thin and uniform, for this slightly press the spatula. Then put the resulting sheet on a pallet, straighten and leave until completely dry. In terms of its decorative properties, a self-made flexible stone will be inferior to factory production, however, its technical characteristics will be similar. In order to to diversify the look iron oxides can be used to color stone chips. This dye is the most durable, in addition, completely natural.  Fiberglass It is recommended to use due to its high strength and good adhesion with adhesive components. You are unlikely to make a large batch, but a few square meters for wall decoration or fireplace areaquite realistic to do at home.

Fiberglass It is recommended to use due to its high strength and good adhesion with adhesive components. You are unlikely to make a large batch, but a few square meters for wall decoration or fireplace areaquite realistic to do at home.

4. Use in the interior

Due to its lightness, flexible stone use in the design of interiors in the most different options.

- For wall decoration, how in living room or hallwayso in kids room and in rooms with high humidity. Particularly attractive are the walls of a large hall in a private house, lined with this material. Due to the fact that it is very easy to clean and easy to clean, it can also be used in the kids' room and are not afraid that the children will paint the walls and permanently ruin the surface. In operation during wet rooms it was noted that moisture does not collect at all on the surface in the form of condensate, which means that the material is breathable. This is one of the most practical uses.

- For decoration fireplace area. Many people like to install electric fireplaces in the living rooms of their apartments. These appliances are often built-in, which implies arrangement of special niches for them. Naturally, to quickly and easily cope with this task, many use drywall, which is further decorated with various materials. The most common is considered fake diamond or gypsum bricks. But not always drywall construction can withstand weight facing materials, in this case it is actual to use a flexible stone.Surface of it not afraid high temperatures and is suitable for facing even real fireplaces and furnaces.

- Cladding surface decorative columns. This element of architecture has not yet gone out of fashion and is actively used to design modern interiors. Of course, not everyone can afford to use natural stone as a material, and this design will have considerable weight. Therefore, gypsum plasterboards of a round or rectangular shape are often made, which are decorated depending on one's preferences. Finishing options for rectangular pillars columns very much, but with round shape more complicated. This is either painting, or decorative plasterthat not everyone likes. Finishing with a flexible stone will allow you to easily cope with this task, without leaving even a hint of joints. A monolithic surface with a natural color will not make you doubt your naturalness.

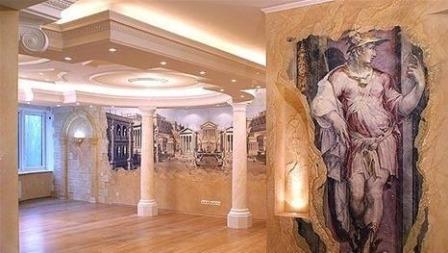

- Frescoes based on flexible stone will help create a unique indoor environment. This is especially true for rooms, the options for diversifying the decoration of which are not so many. For example, in the bathroom where there is always high humidity and it is necessary to approach the choice with special practicality facing materials, Now it is possible to decorate the walls with various drawings. It can be both magnificent gardens, and the sea coast. The drawing is applied to the base with UV printing and is completely safe for health. Even after several years, such a mural does not lose the brightness of colors and clarity of the picture.

- This unique material found its application in the main room of each apartment - on the kitchen. Work zonewhich is often protected from steam, moisture and grease splashes tile or tempered glass skins, It may well be lined with a flexible stone. You have the opportunity to get a natural pattern without seams and save some money if you compare it with a glass apron. By the way, you can give preference not only to monophonic surfaces, but also to the same UV printing. Such coverage will be practical, simple in care durable and original.

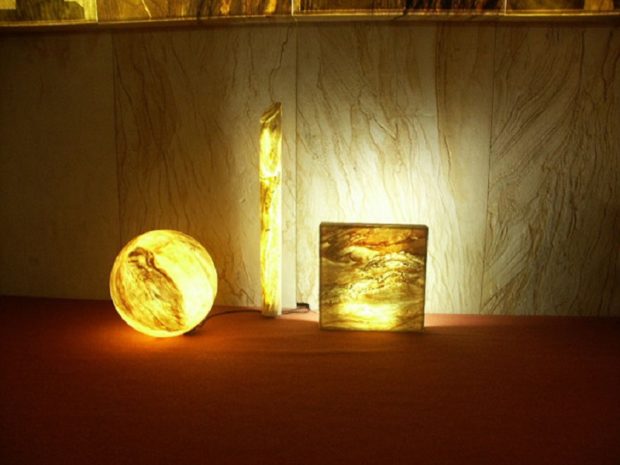

- An interesting feature of this material is its light transmission. You can make your own unique decorative lighting. If you glue the surface of the lamp with a flexible stone, it will not only look very impressive, but will also emit a soft, pleasant light. Luminous spheres, flat light panels or wall lamps, the surface of which is pasted over with this material, look very beautiful and unusual. Such elements will help to create a special atmosphere in the room.

5. Types of material

IN addictions from layer thickness stone chips distinguish three possible types of supply:

- Roll - is the most common option. Thickness The decorative layer varies from 1 to 3 mm. It has two standard size - 1020 × 2200 mm or 1200 × 2600 mm. It is with this material that it is most convenient to wall or wall columns.

- Tile - It has thickness sandstone 2.5-3 mm. In this case, your choice is already three the size - 80 × 265 mm, 160 × 265 mm, 340 × 550 mm. Due to the variety of dimensions, it is suitable both for wall cladding and fireplace areas, as well as for decorative step finishes or arched vaults.

- Plate, has the greatest thickness crumbs - up to 6 mm and only one standard the size - 1000 × 2500 mm. This type is most often used for cladding. building facades.

Next, we will consider in more detail the first option and all the stages associated with its installation.

6. Surface preparation

Since this finishing material is very thin and flexibleoh, he is able to repeat with accuracy all bends and irregularities.If there are defects on the surface of the walls, they will certainly be noticeable, so you need to pay special attention to the surface preparation so that the final result will please you.  The wall is necessary good clean and remove the remnants of old wallpaperin, glue, paints and other excess materials. All chips, pits, deep risks and highly noticeable irregularities recommend putty. Treat the surface before applying putty. special soil deep penetration to improve adhesion and wait for it to dry completely. After plastering work, clean the surface with special nets and remove excess putty. After that, re-treat the wall with soil to remove dust, otherwise the sheets of flexible stone will lag behind with glue. Now necessary perform markup. For these purposes, the easiest and quickest way to use a homemade plumb. Draw one vertical line that will become a guideline for the first strip. The remaining sheets will be glued back to back with the first. When the preparation is done let's get started to myself installation.

The wall is necessary good clean and remove the remnants of old wallpaperin, glue, paints and other excess materials. All chips, pits, deep risks and highly noticeable irregularities recommend putty. Treat the surface before applying putty. special soil deep penetration to improve adhesion and wait for it to dry completely. After plastering work, clean the surface with special nets and remove excess putty. After that, re-treat the wall with soil to remove dust, otherwise the sheets of flexible stone will lag behind with glue. Now necessary perform markup. For these purposes, the easiest and quickest way to use a homemade plumb. Draw one vertical line that will become a guideline for the first strip. The remaining sheets will be glued back to back with the first. When the preparation is done let's get started to myself installation.

7. Installation of flexible stone

This process is very resembles wallpapering. If at least once you had to do this, then you will not have any difficulties. The only thing you really need note, this is that the glue needs to be applied only to the wall. The reverse side of the flexible stone must always remain dry. You will need: a flat and notched trowel, a clerical knife, a rubber roller and a building hair dryer. The latter can be rented at almost any hardware store.

Apply glue on the wall a uniform layer of medium thickness with a smooth spatula. With a notched trowel, completely distribute it, observing one direction. So recommend do manufacturers stone wallpaper for better connection to the surface. Manipulation is like a process tile laying. After applying the adhesive, spread the roll face down on a clean floor. Carefully inspect back surface. It should not have garbage or grains of sand. Use a dry cloth or soft bristle brush to clean the surface if necessary. Now you can attach the sheet to the wall. Start off recommend from the corner, first pressing the top of the canvas, and smoothly move down. Be sure to align the edge of the sheet with the mark on the wall. After that, gently smooth the glued piece with a rubber roller. If excess glue begins to appear on the sides, immediately remove it with a damp cloth. Stick the next strip back to back with the previous one, so you can perform seamless pasting and reduce material consumption.

Start off recommend from the corner, first pressing the top of the canvas, and smoothly move down. Be sure to align the edge of the sheet with the mark on the wall. After that, gently smooth the glued piece with a rubber roller. If excess glue begins to appear on the sides, immediately remove it with a damp cloth. Stick the next strip back to back with the previous one, so you can perform seamless pasting and reduce material consumption.

If you preferred pasting lap then to smooth the joints, you need a building hair dryer. The edges must be warmed up until the mass becomes pasty and plastic and smooth them with a spatula. This option is applicable during corner trim or surfaces with non-standard geometry.

After the glue has completely dried, it is necessary to prime the finished surface. To do this, use wide brush and make movements from the bottom up. Priming will create a thin protective layer that will protect from moisture and simplify maintenance. It is recommended to apply in two passes after the first layer has completely dried. If during installation end-to-end you still have gaps between the sheets, do not despair. Trimming material will help to quickly and completely fix this nuance. Just rub the joints with the front of the scraps, like sandpaper. The top layer will begin to exfoliate and fill the voids. After completing the work, simply brush away excess particles with a dry cloth or brush.

8. An interesting way of laying

There is one very interesting way styling called "Wild stone." It is suitable for facing both indoors and outdoors.This method is unusual in that the finished wall, finished in this way, is very similar to a wall of natural rough rough stone. Because of this is created feeling of strength and reliability.  Process installation at all simple. Surface preparation is similar to preparation for mounting rolls. We will imitate the irregular shapes of natural boulders. To do this, lay the sheet face down on the floor. On the back with a pencil mark up. Irregularly sized medium fragments are what you need for a small room. You must have seen the high fences from natural granite around private homes. This is what the markup should look like. Using ordinary scissors or an office knife, carefully cut the fragments, keeping them in order. We will also lay them from the upper corner, but between them it is intentionally necessary to leave gaps several millimeters wide.

Process installation at all simple. Surface preparation is similar to preparation for mounting rolls. We will imitate the irregular shapes of natural boulders. To do this, lay the sheet face down on the floor. On the back with a pencil mark up. Irregularly sized medium fragments are what you need for a small room. You must have seen the high fences from natural granite around private homes. This is what the markup should look like. Using ordinary scissors or an office knife, carefully cut the fragments, keeping them in order. We will also lay them from the upper corner, but between them it is intentionally necessary to leave gaps several millimeters wide.

Press each piece with a rubber roller and let the whole composition dry well. Seams must be wiped with a special compound, which often comes with the material itself. After drying, apply two coats of water-repellent primer. Your impregnable wall is ready! In this way, you can only finish fragments surfaces for example around the fireplace or around the arch.

9. What to choose as an adhesive

The choice of glue for installing flexible stone should not be treated negligently. After all, this particular component is guarantee of a long term service. There is no need to invent anything supernatural. Sometimes it’s enough to carefully read the manufacturer’s recommendations on the packaging or use the adhesive mixture that often comes with the kit. Usually the glue is dissolved in a specified amount of water and continuously mixed, avoiding education lumps let it brew for 10 minutes, then mix again. If this is not the case, choose an adhesive with enhanced adhesive properties. Great for composition for tile installation or universal acrylic adhesive, for example, Crazy Velcro.  It differs from wallpaper in that it dries much more slowly. This will give you the opportunity to process several square meters of the wall at once, thereby speeding up the process pasting. To protect the skin of the hands, all work must be done with rubber gloves.

It differs from wallpaper in that it dries much more slowly. This will give you the opportunity to process several square meters of the wall at once, thereby speeding up the process pasting. To protect the skin of the hands, all work must be done with rubber gloves.

10. Advantages and disadvantages

Finally, let's take a closer look positive and negative sides this unique facing material.

- Absolutely safe product from an environmental point of view, for the production of which only natural components are used, which during subsequent operation do not emit any harmful substances. This makes it possible to use it in any room.

- Simplicity in care and installation which does not require the performer to possess special skills.

- Functionality and universality. Due to the small thickness and flexibility under the influence of hot air, they can be coated with both round and curved surfaces. Be sure to warm up the material before bending. If this is not done, after some time, in places of sharp bends, it will begin to crack and crumble.

- Variety of shapes deliveries, which avoids unnecessary cuts and choose the most convenient size.

- Lack of reaction constant exposure to moisture and regular contact with water. This makes it possible to take a fresh look at the decoration of problematic rooms such as bathrooms, pools or saunas, which are not particularly distinguished by the variety of interior finishes.

- The ability to easily perform Seamless styling thereby achieving a monolithic surface effect.

- If necessary you easy you can cut flexible stone with simple scissors or any other cutting object.

- Material is an completely fireproof. It is not subject to ignition and does not support the combustion process. That is why, it is increasingly used for decorating stoves and fireplaces.

- Increased frost resistance and immunity to sudden changes in temperature. Range very large - from -45 ° С to + 650 ° С. This makes it possible to successfully use it for cladding building facades, even in the northern regions.

- Light weight. On average, one square meter weighs 3-4 kg. When the edge is the question of the weight of the facing material, it practically has no equal.

- Unique pattern as well as a wide selection of colors and textures. You can hardly find two identical rolls, which makes the interior extremely unique. And the fact that the picture completely imitates the surface of natural stone rocks will help create very realistic compositions.

- Light transmission flexible sandstone cannot be ignored. Decorated in this way floor or wall lights will help create a cozy, relaxed atmosphere. Or make unusual lampshades for small table lamps or candlesticks.

- Long term of operation. With proper installation, which consists not only in the successful selection of the adhesive mixture, but also in the final coating of the surface with soil, this coating will easily last you more than 25 years. The protective film will protect it from direct sunlight and peeling stone chips.

- Breathability which is able to support the natural ventilation and prevent the formation of condensation, will ensure normal indoor conditions.

If you think carefully and analyze the reviews of real people who have been exploiting this material for some time, you can probably add a couple more points. We have listed the most obvious pluses. Now let's move on to disadvantages:

- One of the few, but the most significant minus - high price. If we are talking about quality coverage from a trusted manufacturer that has all the certificates and has its own production, then the price for 1 m2 starts from 1300 rubles. This is probably why many are interested in self-made technology. Too it is or is quite acceptable, given all the advantages, it's up to you to decide. Yes, this price is close to the cost of natural stone, but its installation is much more complicated and requires additional costs.

- High demand to face surface which should be perfectly smooth. This significantly increases the installation time and incurs additional costs.

- Availability a large number fakes. It is no secret that a copy is always cheaper than the original. But many do not recommend resorting to such a purchase. In this case, not an epoxy resin, but an acrylic adhesive, which makes material more rude and badly bending. Because of this, during installation, the sheets do not adhere well to the surface; over time, a lot of cracks form, even if the process is followed. In places of curvature, stone chips crumble, even though it is covered with soil. Therefore, you can strongly give up and regret the money spent.

AND remember any kind of finishing material requires proper care. In the case of a flexible stone, it is enough to periodically wipe it with a damp rag. Due to the rough surface, dust accumulates on it over time, which can be removed using a conventional vacuum cleaner.

Class! Very helpful!

“The presence of a large number of fakes. It is no secret that a copy is always cheaper than the original. But many do not recommend resorting to such a purchase. In this case, not an epoxy resin, but an acrylic adhesive is used as a bonding element, which makes the material more coarse and poorly bending. ”And now we read on the manufacturer’s website with a bunch of certificates:“ Considering analogues as an alternative to our flexible stone, it should be borne in mind that:

the use of epoxy glue instead of acrylic composition, or acrylic composition with cheapening additives leads to the fact that the canvas becomes stiff, brittle and cannot tightly adhere to the surface. As a result, creases and cracks inevitably appear during fastening. "So, it’s not clear what the manufacturer should have with certificates and what the fake should have.

In many articles, opinions differ, some write that the flexible stone should contain epoxy and that acrylic glue is used to reduce the cost, as it is written in our article. And others write that acrylic glue is better. But of course, everyone will praise their products, and the technology allows the use of both binders.

Good day. Tell me, please, how to draw a picture: travertine, shell rock, Dagestan stone? Thank you in advance.