10 tips for choosing a hammer drill for home and work: types, manufacturers

Surely each of you has faced a situation where it is necessary execute fastenersfor example, a kitchen cabinet to a concrete wall. Not only that material highly lasting and an ordinary drill is beyond the power, so also fastener must be screwed into the dowel for greater reliability. In this situation, you can not do without a punch. how choose a hammer drill For home or more professional needs, this article will tell.

1. The concept of "punch" and the features of its design

Hammer drill Is a working tool that, in addition to percussion movements provides and rotational moment. Its use allows you to quickly and easily make a hole in both soft and very hard materials, such as stone, concrete or brick. Hammers can also be used to dismantle coatings made of solid materials or to lay channels. There are various models of rotary hammers that differ from each other by the presence or absence of certain functions. But they all have in their design essential elementswithout which their work is impossible. The most important parts of the hammer drill are its engine, gearbox, shock mechanism and cartridge.  The shock mechanism that performs the main function of this device may be electro-pneumatic or crank. The first type works on the principle of converting the engine gear torque to a piston, which creates an oscillating moment and compresses the air space between itself and the ram, causing it to repeat vibrations, and that, in turn, strikes the striker. Such a mechanism is equipped with a function self shutdownthat occurs when the tool is not touching the surface.

The shock mechanism that performs the main function of this device may be electro-pneumatic or crank. The first type works on the principle of converting the engine gear torque to a piston, which creates an oscillating moment and compresses the air space between itself and the ram, causing it to repeat vibrations, and that, in turn, strikes the striker. Such a mechanism is equipped with a function self shutdownthat occurs when the tool is not touching the surface.

Unlike the first type, crank hammer It does not convert the rotational moment into an oscillatory moment, but immediately transfers the blow to the piston, which in turn compresses the air space between itself and the ram and makes a blow to the striker.

Gearbox plays the role of a transmitter of the torque of the engine gear to the cartridge, thereby actuating the shock mechanism. It consists of a set of different gears - bevel, cylindrical and worm gears and, in most cases, has a constant number of gearing moment.Cartridge punch has a significant difference from the cartridge drill. You know that the part of the drill for the drill, which is inserted into the chuck, has the shape of a cylinder, which allows the drill to scroll if there is little resistance. The drill chuck is designed in such a way that the drill must not only be inserted into the chuck, but also cranked up, once in special grooves. This ensures a secure fit even with great effort. Many rotary hammers are additionally equipped safety clutch, which serves to preserve the integrity of the tool and protect the person performing the work. For example, if during operation the punch jammed, the coupling will stop the rotation of the cartridge, thereby preventing the engine from burning out.

Many rotary hammers are additionally equipped safety clutch, which serves to preserve the integrity of the tool and protect the person performing the work. For example, if during operation the punch jammed, the coupling will stop the rotation of the cartridge, thereby preventing the engine from burning out.

Another useful feature is anti-vibration system, which is a counterweight to the spring, which takes on a significant part of the vibration and dampens most of it.Housing The perforator is made of metal or impact resistant plastic. But most of all, these two materials combine. With prolonged use, the case becomes very hot, and the metal removes heat better and prevents the tool from overheating, while the plastic inserts on the handle protect against burns.

2. Types of punchers

The whole variety of rotary hammers can be divided into two main groups:

- Household. Designed to perform simple tasks and work with both soft and hard materials. For convenient operation of such a tool as a home assistant, it is enough that it has a power of 500 - 800 W, impact force 1.2 - 2.2 J, was equipped with a special speed control switch, had a protective coupling, included at least two, and better three modes of operation. Useful additional the functions there will be a replaceable chuck for switching to conventional drills so that you can use the tool as an ordinary drill, and a set of special keys for changing the drill.

- Professional. If you practice construction or repairs, then you can’t do without a reliable tool. A professional hammer drill must have a power of at least 900 W, the impact force of such a tool should be from 8 to 15 J, the impact and rotation frequency should be large enough, but not more than 1500 rpm, otherwise such a tool will quickly wear out, be three-mode.

When you have decided which puncher to choose, you can consider in more detail the main characteristics that include both groups. Usually there are three types of perforators, but for the possibility of more exact choicewe highlight five.

3. Types of perforators by the number of operating modes

The number of modes is one of defining characteristicson which productivity and overall performance depend. Depending on the number of modes, all perforators are divided into three groups:

- Single-mode

The simplest form of this tool and the least productive. Designed only for drilling relatively soft materials, such as wood, drywall or thin sheet metal.

- Dual-mode

Includes not only drilling mode, but also drilling with impact. It is used for harder materials, including concrete and brick. This is the best option for domestic use.

- Tri-mode

The most productive and common type. It includes the drilling mode, drilling with impact and the impact mode without rotation, which allows you to use it as a jackhammer.

4. Types of type of drive

There are four main types of drives, each of which has its own advantages. The choice of drive must be carried out depending on the features of the work performed.

- Petrol drives will become indispensable if you carry out repairs roadbed, or do work in an open area, where no access to electricity. These rotary hammers have an internal combustion engine, they have a very high impact force, and low fuel consumption allows you to work for two hours from the moment of refueling the tank. Along with the benefits, they have a number of disadvantages: you will need a supply of fuel, you will not be able to regulate the force of the impact, from which undesirable destruction can occur, they have a very large weight, dimensions and a very high price.

- Electric perforators are the most used in repair and construction works. The constant availability of a power source makes the operating time unlimited, they have good performance and sufficient powerare additionally equipped with an anti-vibration system, which greatly facilitates their use, mainly include three regime works, have a speed controller and an affordable price. disadvantagesUnfortunately, this type also has one: the radius of your movements will be limited by the length of the power cord, of course there is an output in the form of an extension cord, but still if the voltage in the network is unstable, then the tool’s performance will be unstable, the wear of the chuck during prolonged use and extra spending on buying a new one.

- Rechargeable rotary hammers are very convenient in places where not access to electricity or during repair building facadeswhere you can hardly get with a power tool. They possess low weight and compact body, which makes them very comfortable in use. Despite using a battery, they have constant frequency rotation, which can be adjusted, and sufficient power that allows you to drill even concrete. TO disadvantages limited time, which directly depends on the capacity of the battery, the need for recharging, which requires a long time, which means you can not use the tool immediately after it is discharged and stagnation occurs. Sometimes buying a new battery can be a daunting task, and if you accidentally drop such a tool, it will also fail.

- Pneumatic Perforators are mainly used in explosive rooms, since the principle of their operation is based on the conversion of compressed air. They have a low weight, a sufficiently high speed and impact power. The disadvantages of such a tool are significant: for continuous operation, you will need a compressor that will supply air. The movement area will be limited by the length of the hose connecting the compressor and the hammer, and most importantly - the high cost of such a tool.

5. Types of power drill

The impact force of the punch directly depends on power his engine. This indicator determines with what force the drill or drill will go into the necessary material. The higher this indicator, the higher the speed of the work performed.

- Easy the tool has a weight of up to 4 kg, the impact force of such a perforator reaches a maximum of 3 J, power up to 0.8 kW. Such equipment is used exclusively for domestic purposes and only for drilling not too hard materials.

- Average the device has a weight of up to 8 kg, the impact force reaches 9 J, and the power is in the range of 0.8 - 0.9 kW. Used to make holes in reinforced structures or in materials with a high degree of hardness.

- Heavy Hammers have a weight of more than 8 kg, their impact force reaches more than 17 kJ, and the power is more than 1.2 kW. Such a tool is used in professional activities and has practically unlimited possibilities.

Before making the final choice, you need to understand that not only the strength, but also the frequency of the blows depends performance tool and speed work. Even if the impact force is high, but at the same time its frequency will be small, you will slowly move forward and spend a lot of time. Optimal frequency strokes for a household punch lies in the range of 3-4 thousand units / min, and for professional should reach an indicator of approximately 5000 thousand units / min.

6. Types of perforators by type of cartridge

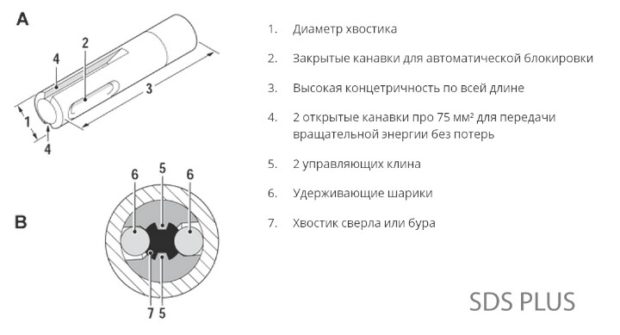

We have already said that the perforator cartridge differs significantly from the drill cartridge due to the special clamping method. These cartridges are called SDS, which is an abbreviation and literally translates as "insert, rotate, clamp." This type of cartridge was invented by the well-known company Bosch in the late 70s. There are five types of such cartridges:

- Sds The chuck allows you to insert the shank of a drill or drill with two grooves, designed for a shank with a diameter of 10 mm, which is included in the cartridge to a depth of 40 mm. Has 100% compatibility with SDS + cartridge.

- SDS + the most common type of cartridge used for light and medium class rotary hammers weighing from 2 to 4 kg. He has 2 closed + 2 open slots. The diameter of the shanks for such a cartridge is 10 mm, and the approach depth is 40 mm. Able to drill a hole up to 26 mm.

- Sds top fairly applied seldomas it is intended for a shank with a diameter of 14 mm and a depth of approach of 70 mm. It is used for a middle class tool weighing 4 kg and is designed for drill diameters from 4 to 32 mm.

- Sds max It has 3 open and 2 closed groove. Designed for shanks with a diameter of 18 mm and a depth of approach of 90 mm. Designed for professional rotary hammers weighing more than 5 kg. Able to drill holes up to 20 mm in diameter.

- Sds quick as fasteners uses not grooves, but special protrusions, which allows you to insert bits and drills with a hexagonal shank ¼ inch into the cartridge.

- Sds hex applies exclusively to jackhammers and is designed for peak and chisel use.

7. According to the location of the electric motor

First of all, the location of the motor on the punch, can tell you what is in front of you for the tool - domestic or professional. There are only two options:

- FROM horizontal location to the axis. For the most part, this is a household hammer drill. Such a tool has small dimensions with elongated and narrowed shapes. This allows you to use it in confined and uncomfortable places. The power of such devices is not too high - up to 0.9 kW, but they are very light and convenient to use. These models are most convenient for use in home repair and installation in horizontal planes, and their price is more than affordable. Disadvantage low power and difficult cooling of the engine, which leads to overheating. To avoid this, you need to take frequent breaks in work.

- FROM verticalThe location of the motor is most often produced by professional punchers. They have large dimensions and considerable weight, respectively, and the power they produce is much larger. In addition, the vertical orientation contributes to the rapid cooling of the engine, which significantly reduces the load on the device and protects it from overheating. Such a hammer will not be equal when working in the vertical direction, in addition, it is able to withstand significant loads for a long time. TO disadvantages the high weight of the tool and the high price can be attributed to the fact that this type of tool belongs to the category of professional and very powerful.

8. Recommended hammer drill manufacturers

In order for the tool you have chosen to be reliable, justify its value and the declared characteristics, special attention should be paid to the manufacturer. Having analyzed the reviews of ordinary consumers and specialized workers, we identified five major manufacturing companies that have established themselves as reliable and proven:

- Makita. This Japanese concern has conquered the market of America, Europe and Asia due to the highest quality of its products. For its tools, the company uses only high-quality materials, the assembly of devices is always performed without complaints. This manufacturer produces light and heavy type of perforators. Pricing starts from 130$.

- Bosch. We are all used to the fact that when they say Bosch, product quality is not in doubt. It is not surprising that this company was in the top three, because it is thanks to it that perforators have such a convenient and reliable form of fixing drills in a cartridge as SDS. This German company is a leader in the production of power tools. Pricing starts around 150$.

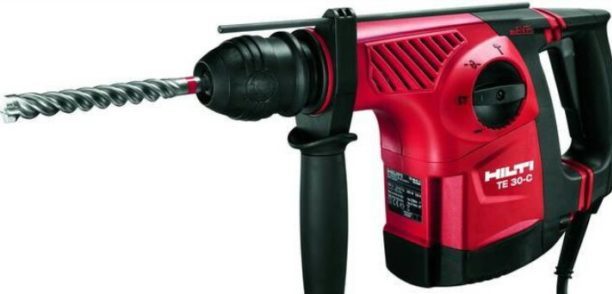

- Hilti. This is a Ukrainian brand that has fairly well recommended its products. Affordable pricing, a variety of models of both light and heavy tools will delight many consumers.Reviews of Hilti punchers are only positive, build quality and materials used are also on top. The unique service of this brand is warranty service throughout the entire life cycle. Pricing policy from 150$.

- Dewalt is a Czech manufacturer that has established its tools as high-quality professional equipment. In its production, the company uses powerful electric motors, reliable materials for impact mechanisms and high-end electronics. The price of their instrument starts from 140$.

- Hitachiis a Japanese corporation that is constantly striving for improvement. Their equipment is designed to work with solid materials such as concrete and stone. They are distinguished by high reliability, ease of use, quality materials and a wide range. The price of Hitachi punchers starts at $ 110.

9. Terms of use

On how muchright you use a punch, it will directly depend performance and term service. First of all, it is advisable to use only "native" components that are suitable for this model. After completing any work, be sure to cleaning and greasing tool. Once in a certain period of time, which depends on the intensity of operation, it is better to carry out internal cleaning in specialized service centers. The constant ingress of dust into the instrument over time will lead to the failure of the power button or other mechanisms.

When performing large volumes of work, it is necessary take regular breaksto allow the tool to cool, otherwise you risk exposing the engine to overheating. If the task is to drill a deep hole, it is better perform work in several approachesby constantly removing the drill from the hole. So you can simultaneously clean the hole and let the hammer drill rest.

Not costs too much crush on the tool when working, so you will only achieve a premature exit of their system of the impact mechanism or overheating of the engine armature. The heaviest mode for the tool is the chiselling mode, use on short time intervalsby taking regular breaks of several minutes or by switching the rotary hammer to rotation mode. This will not only cool the tool, but also make it possible to evenly distribute the lubricant.

Duster and brushes replace immediately as soon as this need arises. Do not forget about protective equipment when working with a puncher for yourself - be sure to use safety glasses when working with hard surfaces and do not forget about a respirator. Take care of your instrument and then, being in capable hands, it will serve you long years.

10. Tips for choosing a hammer drill

The most important thing to do before choosing a hammer drill is to decide for what purpose you will use it. Depending on the frequency of operation and the volume of work performed, you must understand whether it will be household or a professional hammer drill. About engine power, impact force and speed for these two groups we wrote above. In addition to these basic characteristics, there are a number of additional functionswhich are equipped with some rotary hammers and which can significantly increase the usability.

For instance, the presence of reverse. This function is optional, but very convenient, especially when pulling the drill from deep holes. Availability gear shifter will make work with the tool more controlled. To avoid jerking when turning on the tool and involuntary touching the surface at the same time, there is a system soft start. With an uneven load on the tool and the speed of rotation will be different, to adjust this figure, there is speed stabilization system. So that when drilling walls, dust does not fly into your eyes and does not impair visibility, there are special dust collectorswhich have various sizes and configurations.  Remember that the more functions a tool is equipped with, the more convenient it is to work with it, and the higher its value. Before choosing the puncher with the most functions, think about whether you will use them at all. Maybe it’s not for you specifically for you. And one more highlight - do not buy a cheap tool, even if you need a household hammer drill with one single drilling mode, it is better to choose verified brandthan further paying for regular repairs.

Remember that the more functions a tool is equipped with, the more convenient it is to work with it, and the higher its value. Before choosing the puncher with the most functions, think about whether you will use them at all. Maybe it’s not for you specifically for you. And one more highlight - do not buy a cheap tool, even if you need a household hammer drill with one single drilling mode, it is better to choose verified brandthan further paying for regular repairs.