4 tips on how to choose screws: types of screws, sizes, purpose

Surely, at least once in your life you had to repair or fasten something yourself. It's no secret that this requires special fittings, and the selection of all kinds of nails, nuts, screws, screws and other fasteners in modern building stores is very impressive! You stand, look and just your eyes run up. Anyone, for sure, will be confused in such a store, and to prevent this from happening to you, we suggest that you consider in detail such kind of accessories as a self-tapping screw, and figure out how to choose the self-tapping screws, what they are and for fixing what materials can be used.

1. What is a self-tapping screw?

Self tapping screw - this is fastener in the form of a rod with an external triangular sharp thread and a head, which simultaneously with twisting also cuts the thread in the connected element. The screws managed almost completely replace ordinary nails, because the connection with their participation is much more reliable, self-tapping screws can be fastened not only tree, but many other materials, in addition, you do not risk being injured during work.

2. Types of screws

Material for making screws

- Carbon steel - It is an alloy of iron and carbon without any impurities. Differs in the increased durability.

- Stainless steel - steel with a chromium content of at least 10.5%, which makes it corrosion resistant and very durable, stainless steel self-tapping screw will never rust and has an almost unlimited service life, in addition, they are the cheapest. Stainless steel products also have hygienic properties, which allows them to be used even in medicine.

- Brass Is a copper alloy with the addition of zinc, sometimes tin, nickel, lead, manganese or iron. Brass self-tapping screws have established themselves as very reliable and wear-resistant. In addition, brass has non-magnetic properties, anti-corrosion properties and is resistant to low temperatures.

Self-tapping screw

- Phosphated (black) self-tapping screws are made of carbon steel, followed by phosphate treatment. Used in rooms with high humidity.

- Oxidized (black color). These screws are made of carbon steel with a protective oxide film. Suitable for use in rooms with normal humidity.

- Galvanized self-tapping screws are also made of carbon steel, followed by zinc coating. Suitable for both indoor and outdoor use.

- Galvanized yellow self-tapping screws differ from the previous ones only in color, they are used mainly for door hinges of decorative golden color, since they are visually less noticeable against their background.

- Without cover. Used for interior use at normal humidity.

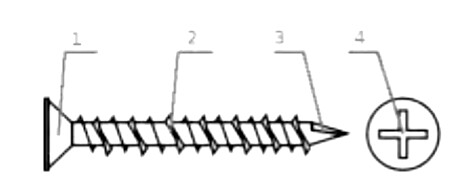

Self-tapping screw construction

Head (1)

This is the upper part of the self-tapping screw, with the help of it torque is carried out. It comes in various forms:

- Secret after twisting, the self-tapping head is completely immersed and does not protrude above the material to be fixed.

- Half-secretthe head has a smooth transition from the rod to the thread and, when twisted, is buried both in the material and in the counterpart. This allows you to apply more force when twisting.

- Semicircularhas a large clamping surface, due to which it holds the fixed element more firmly.

- Semicircular with a press washer used for fastening sheet materials, has an increased bearing surface area and a reduced height.

- Truncated cone (“flea”) used for fastening metal profiles, sheet metal, drywall boards. Such screws have a phosphate coating.

- Hexagonthe head allows you to twist the screw with a power tool with a special nozzle.

- Cylindricalthe head has self-tapping screws that are screwed into a pre-drilled hole.

Thread (2)

- Rare. It uses screws with rare thread for fastening soft materials without the use of a dowel, for example, for wood, gypsum, plastic, asbestos. Possible thread diameters - 3.5-5.0 mm, length - from 16 to 150 mm.

- Averagethe thread is universal, designed for all types of fasteners. Thread diameter from 3.0 to 6.0 mm, length - from 12 to 220 mm.

- Herringbone profile mediumused to attach to concrete or brick surface method of driving into the dowel. Thread diameter - 5.0, 7.5 mm, length - 40, 50, 60, 70 mm.

- Frequent threads are used for fastening to metal sheets up to 0.9 mm thick without using a dowel, but with preliminary drilling, may have a drill bit on the tip. Thread diameters 3.0 - 8.0 mm, length - from 12 to 200 mm.

- Asymmetric carving is intended for fastening furniture elements made of wood, chipboard, plywood. Pre-drilling required. Thread diameter - 5.0, 7.5 mm, length - 40, 50, 60, 70 mm.

Tip (3)

- Acute the tip is used to connect soft materials, its sharpness is enough to start twisting just by sticking it into the surface.

- Drill the tip is used for working with metal, when twisting, a hole is first drilled on the metal surface, and then, directly, the screed of two elements.

Slot (4)

This is a recess of a special shape and the end of the head.

- Straight and cruciform slot option - these are the most common options to tighten such a screw, it is enough to have a suitable screwdriver or screwdriver with appropriate nozzle.

- Hexagon the slot may be external or internal. The outer is twisted with a special key with a nozzle, which allows you to apply more force to tighten the elements. Internal - regular hexagon, suitable size. Also in the internal hexagon, which is used for fastening furniture elements, you can insert a special plastic plug in the color of the product so that the self-tapping screw does not spoil the aesthetic appearance.

- Torx - a type of slot in the form of a six-pointed star. It is twisted with a special key, or with a screwdriver with the corresponding nozzle.

3. Appointment

- Universal the self-tapping screw has a countersunk head with a cross-shaped slot and a sharp tip. Has a galvanized coating. It can be used both outdoors and indoors, suitable for decoration in wet rooms. It is used for fastening wood, plywood, chipboard, sheet metal (with preliminary drilling), artificial stone and other materials. They have a length of 12 to 200 mm, a thread diameter of 3 to 6 mm.

- For wood. Wood screws are used to connect plywood, wood, as well as their varieties. Fastening wooden products with self-tapping screws is much strongerthan fasteners made with nails, this is due to the presence of thread. Even after a long time spontaneous twisting never screw will not happenas happens with nails. With proper installation, you will never spoil the material, since the screwing of the self-tapping screw is more smooth, and the sharp tip sets the direction, using a nail you can split a wooden surface, accidentally falling between the fibers.Wood screws are of different sizes, depending on the thickness of the connected elements, but they will all have distinctive features: countersunk or semicircular head with a cross-shaped slot, a rare thread pitch and a sharp tip. Basically, black or yellow screws are used to fix wooden elements. Choose a length of self-tapping screw so that when twisting two elements, the thread enters the second no lessthan on ¼ part thickness of wood, then your fastening will be reliable and will be able to withstand loads.

- For drywall.Drywall can be attached either to special metal profiles or to a wooden frame, depending on the material they will have differences and self-tapping screws necessary for installation. For fastening to metal profiles, you should choose a self-tapping screw with a frequent thread pitch and a drill at the end, then you will not have to do preliminary drilling, which will significantly reduce installation time. For fastening to a tree, choose a self-tapping screw with a rare thread pitch and a sharp end. Before twisting, stick the sharp end into the drywall approximately 1 mm deep. Whatever installation method you choose, self-tapping screws for drywall will have common features: black colorwhich talks about corrosion resistance due to oxide or phosphate coating, countersunk head, which should be 1 mm deep in the sheet, cruciform slotso that you can tighten the self-tapping screw not only with a screwdriver, but also with a screwdriver.

- For metal profiles and sheet metal.Metal screws have acute or drill tip and head in the form of press washers, which increases the area of fit and provides a more tight pressing sheet elements to each other. The benefits of drill the tip is the lack of the need for pre-drilling, self-tapping screws and so enough easily screwed into the hard surface of the metal, excluding the formation of chips or scratches. Self-tapping screws with a drill tip are very durable and can withstand heavy loads, and also have anti-corrosion properties. The thread pitch of such fasteners is rare, which eliminates the need for special bits or drills. Screws with sharp tip have a frequent thread pitch, which allows good bonding of materials of various densities. They are used mainly for fastening wood to metal, up to 2 mm thick. They also have anti-corrosion properties and high strength properties. To connect metal products, self-tapping screws with a drill tip and hexagon the head or truncated cone screws ("fleas») And a drill tip. "Fleas" are used for a metal thickness of not more than 2 mm. Hexagon screws are very convenient to tighten with a key. To choose the right length screw, you need to know the thickness of the part that you want to attach to the base and add to this thickness 10 mm. Since for reliability and durability of fasteners, a self-tapping screw should go into the base to a depth of at least 10 mm. The diameters of the thread of the self-tapping screw for metal are 3.5 - 5.0 mm in increments of 0.5 mm.

- For a window profile.A separate category of screws for plastic windowsas such, no, but very often it is necessary to attach the same profile for slopes, or the same handle. Manufacturers of plastic windows, in addition to various fittings, put galvanized self-tapping screws with a countersunk head and a sharp end. But from practice, this type of self-tapping screw is not the most convenient - the sharp end slides off, scratches the plastic at the same time, or does it scroll after installation, so experienced installers recommend using self-tapping screws with a drill at the end. They do not lead away when twisting, the window frame does not deteriorate and they are much easier to screw in. The size of the screws is determined by the thickness of what you want to screw to the window.For example, if we are talking about a plastic, thin profile for future slopes, it is better to use small "fleas»With a drill at the end and a head in the form of a press washer, if the handle is with a hidden head with a crosswise slot. For reliable fastening, no more than 2-3 mm of thread entry into the window profile is sufficient.

- On concrete.In order to fasten something to concrete or brick, it must be borne in mind that during installation the self-tapping screw will be subjected to very large loads. For concrete work, choose a self-tapping screw galvanized steel with a sharp end and cruciform or six pointed slot. The diameter of the thread should be at least 7.5 mm, the possible length of self-tapping screws for concrete is 50-200 mm. If the base is loose, then you can do without preliminary drilling, with a solid base it is necessary to make a preliminary deep hole.

- For corrugated board.To pin metal tile and metal profilechoosegalvanized self-tapping screws, visually similar to screws. The head of such screws has hexagon the shape is covered with a polymer material of various colors, which allows you to choose a self-tapping screw in one color with a metal tile. Also complete with such self-tapping screws there is a neoprene washer with rubber gasket that fits snugly the roof and prevents moisture from entering the hole. The diameter of such screws is from 4.8 to 6.3 mm, and the length is from 190 to 250 mm.

4. How to choose the "right" self-tapping screw

It is not enough to determine the type of self-tapping screw, which is necessary for a certain type of work, it is necessary, also among many optionsselect really quality, durable fasteners that will not fail at the most crucial moment. Just carefully inspect the screw. It must match such simple criteria:

- The same color scheme. All self-tapping screws of the same batch should be of the same color and shade when it comes to black or yellow self-tapping screws. If all products are designed in the same color, this may indicate that the entire batch underwent the same type of processing under the same conditions and has the same strength and corrosion resistance.

- Dimensions self-tapping screws of one batch should not visually differ from each other.

- Step between turns thread must be the same.

- If these are self-tapping screws with a drill at the end, then it should not have burrs on the edges, the sharp end of the self-tapping screw should be no burr and not be broken off.

- Hole, in the form of which the slot is made, should be clearsymmetrical and sufficiently deep.

- Quality screws usually have marking in the form of a capital Latin letter. This indicates factory production, and even this is a little clue to you in case you have to buy the missing fasteners.

If you see that the screws you have chosen meet the above criteria, then you can be sure that you are holding really high-quality fasteners that will not break during installation.