The laminate sighed: 7 tips on what to do

Currently laminate occupies a leading position among flooring, and this is not surprising. It looks great, has a huge selection of colors and textures, which allows you to choose the right coating for any design. In addition, it is easily and quickly mounted even independently without the help of workers, is unpretentious in operation and has a low cost.However, despite all the advantages of this coating, there is one drawback - under the influence of various factors, the laminate can swell. This can cause liquid to enter the floor, improper installation or poor quality material.

To eliminate this defect, it is not necessary to contact specialists, you can do everything yourself, but you need to establish the cause of the swelling, then resort to methods of eliminating it. So what to do if the laminate has swollen? We understand the features of the problem and how to solve it.

Design

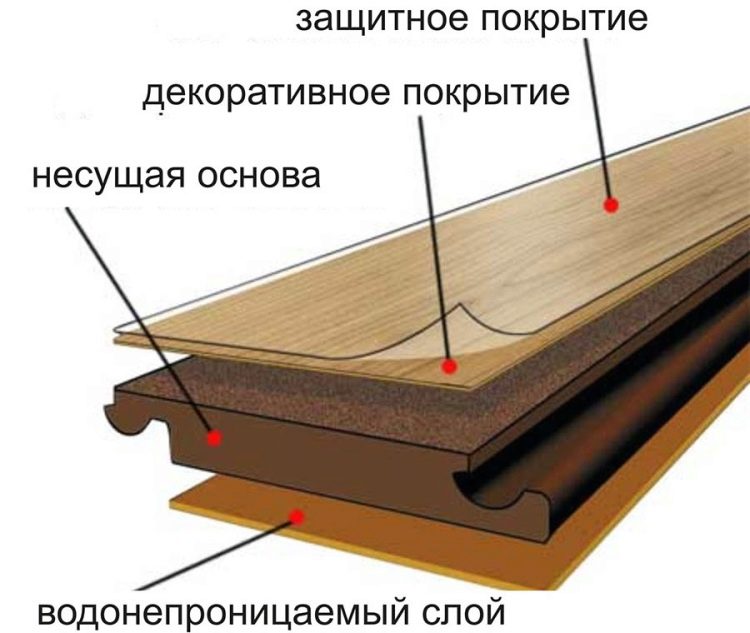

If you decide to deal with the laminate yourself, you need to understand how it works. The panel is based on a fiberboard or chipboard board, on both sides of which there are small connectors-locks for the possibility of connecting plates during installation. The strength of the coating depends on the thickness of this layer. On its lower side is a protective layer. It resembles a thick sheet of paper, which on one side is covered with a waterproof film and protects against moisture.

On the upper part of the fiberboard there is a decorative layer. This is the paper on which the drawing is applied. The melamine layer and the acrylic resin layer cover the paper. This coating protects the plate from external influences, and the better it is, the better the protection and, therefore, the higher the price of the laminate.

Manufacturers can add additional layers: natural wood veneer, backing, protective front coating or waterproof cover. Naturally, the addition of layers entails an increase in the cost of the facing material.

Laminate Classifications

Before installing such a cladding, it must be taken into account that it has a classification of wear resistance and moisture resistance.

Wear resistance

This parameter determines the place where the laminate can be laid. Each class is indicated by numbers and is indicated on the package:

- 21, 22, 23 classes — low level of wear resistance. The coating does not tolerate high levels of humidity or high traffic. Such a laminate is used in bedrooms, or for temporary flooring. 23rd grade is considered more stable and can be laid in residential premises, but it is worth considering that it can not withstand heavy loads.

- 31, 33 class - laminate capable of withstanding intense workload. It can be used for corridor floors, hallways, etc.

- 34th grade — the most wearproof material. 34 class laminate is able to be exposed to water for a long time without the threat of deformation. Such coverage is intended for public institutions (cafes, restaurants, cinemas, etc.).

- 42, 43 class - material of the highest class. It is made exclusively to order. It is used in rooms where the floor must withstandmaximum load (train stations, airports etc.). In residential premises, a laminate of this class is irrational and inexpedient to use.

Moisture resistance

With the right choice of material for this parameter, we can say that the problem with the swelling of the laminate due to moisture on it will not occur. So, by moisture resistance, the laminate is divided into:

- Moisture resistant - a coating that is not afraid of moisture. Such material has an additional wax coating or resin coating with a moisture resistant effect. Designed for rooms with high humidity (bathroom, kitchen etc.).

- Water resistant - material that can withstand direct contact with the liquid for several hours.

A competent choice of laminate according to the degree of moisture resistance gives a guarantee that the influence of external factors will not adversely affect the coating and, accordingly, will not cause swelling of the lamellas. If deformation occurs, we can safely exclude the influence from the outside and look for another reason.

Causes of laminate swelling

It is believed that with the appearance of swelling, it is necessary to dismantle and completely replace the entire floor covering. However, it is not. It is necessary to assess the damage and find out its cause. In some cases, you can do with the replacement of one or more slats.

What can provoke a swelling of the laminate? Consider these reasons in more detail:

- Poor quality products. To choose a quality coating, you need to familiarize yourself with its parameters: the laminate should be suitable for cladding your chosen room. It’s better not to save money and choose a quality product from a reputable company, since saving money when buying material can lead to much greater losses in the near future for its repair.

- Violation of the technology of assembling the base under the laminate. In the process of laying the base surface, it is necessary to ensure dryness and evenness of the base, otherwise deformation will occur on the plane of the laminate. It happens that a new laminate is placed on top of an old one, without using the substratethat absolutely must not be allowed! It is equally important to ensure that the quality of the substrate matches the selected board.

- Lack of laminate assembly technology. If the laminate is assembled on its own, then violation or non-observance of the necessary gap between the wall and the laminate is most common. Laminate boards tend to change in size when the temperature or humidity level is violated. To ensure the ability to compensate for the distance and maintain the shape of the coating without deformation, it is necessary to leave a gap between the coating and the wall in the amount of 1-1.5 cm during the laying of the laminate. Otherwise, the boards will deform. It happens that the panels are fastened with nails. This destroys the layers that protect the laminate from external influences, which affects the panel.

- Water ingress. Unfortunately, the laminate is very susceptible to water. Even a small volume of fluid can deform it. Of course, a better material has a high resistance to moisture, but in rooms with a high level of humidity it is recommended not to use the laminate.

The reason why the laminate was swollen helps us to identify the nature of the deformation:

- Joint deformation. Such deformation is characteristic under the influence of water. If the lamellas have a loose connection due to improper installation or poor-quality material, water penetrates to the wooden base of the laminate. This causes it to expand and entails damage to the coating.

- Wave formationarises if during laying the compensation gap between the wall and the floor was not taken into account.

Swelling Tips

If you used the services of the repair team when installing the laminate and violation of the relief surface occurred during the warranty period, contact the agency that serves you. They must either restore the panels or pay monetary compensation.

With low quality material

If the laminate is swollen due to substandard materialneed to produce replacement total coverage.This option must be foreseen and thought out in advance to avoid double payment. It is advisable to purchase a quality laminate (33 classes) in order to exclude such a defect and protect against the occurrence of such troubles.

When exposed to water

If onlaminate hit water, it is necessary to remove the damaged panels in order to remove the liquid under the coating. For this, close to the deformed area, they are removed carefully skirting board and disassemble the panels to the right place, dry them and be sure to replace the substrate. If the repair started quickly and the water did not stagnate, then this operation is quite enough - you can put the laminate in place.

If water has been acting on the laminate for a long time, it is necessary to replace several lamellas, since irreversible processes could begin in them. Cheap laminate models are more prone to deformation, and full replacement of lamellas is usually required. A better coating after full drying returns to its original state, and the purchase of new lamellas can be avoided.

It happens that it is necessary to replace a small part of the cladding, and it is very difficult to choose the right boards with the appropriate color, pattern and texture. In this case, you can use the lamellas that are under the furniture. To do this, the laminate in the hidden zone must be replaced with a laminate of the same company and the same series, but of a different color. The main thing is that the locks match. Thus, you will have the necessary laminate to replace the damaged area.

In the future, when calculating the required amount of coating, it is necessary to take into account several lamellas in reserve.

In case of non-compliance with the compensation gap

In this case, it is necessary to dismantle the skirting boards and determine where the slats are located right next to the wall. Then it is necessary to remove and trim the lamellas. The resulting gap will be closed by the baseboard.

For, to avoid the complete dismantling of the coating, it is necessary to remove the furniture from the room, remove the skirting boards and measure 10-15 mm from each wall. Then, along the marked line with a jigsaw, cut the laminate boards. When carrying out such manipulations, the coating is leveled in a few days.

To speed up the process of leveling the laminate, a heavy object must be placed on the damaged area. When the flooring returns to its original position, you can put the baseboard back in place and close the resulting gap.

Exist another way to avoid completely dismantling the coatingbut it is more labor intensive. This is a replacement only for damaged boards. To do this, draw a rectangle inside the deformed board, which is several centimeters smaller than the perimeter of this plate. Then carefully cut the rectangle along the intended line and pull it out with a chisel. When the coating joints loosen, pull out the rest of the cut lamella. A number of boards adjacent to this panel must be knocked 10 mm against the wall and cut the lock from the void side. Next, take a new panel, treat it with glue along the perimeter and lower it at an angle of 45 degrees into the formed niche. Press down with a heavy object for a while.

It is very important to respond in time to the appearance of deformation.

Measures to protect the laminate from moisture

In order to prevent moisture from entering the inside of the lamella, a special wax is used. It protects the coating during wet cleaning and from accidentally spilled liquid. Wax fills the gaps in the joints with a waterproof layer so that the liquid does not penetrate through them into the coating.

Before processing the laminate with wax, it is imperative to remove all stains, wipe off the dust and dry the laminate.Then, using a spatula, apply a thin layer of wax to the joints between the boards and polish the floor with an absorbent cloth or a monodisk polishing machine. After polishing, it is necessary to check that the wax has filled all the joints and cracks, if any, but in no case remained on the surface of the laminate. It is very important! After 3-4 hours, re-polishing is carried out. Walking on the floor after polishing is possible only after 10 hours.

When working with polish, it is imperative to wear a respirator and ventilate the room well, since when dried, the wax releases vapors that can harm human health.

To protect the laminate from moisture, there are also special polishes. They create a water-repellent film on the surface of the floor covering, which prevents moisture from entering the inner layers of the lamellas.

It should be noted that these methods protect the laminate from deformation only when contact with water is not long. With abundant moisture or a puddle, deformation cannot be avoided.

Deformation Prevention Rules

To avoid the appearance of swelling of the laminate, you should adhere to the following rules for the operation of the coating:

- Make your choice only in favor of quality products from trusted manufacturers. In this case, there is confidence that the coating is made of quality materials and will not deform even with prolonged contact with water.

- Product class must be appropriate for its use.

- The substrate under the laminate should be carefully prepared and have a reliable layer of waterproofing.

- When installing lamellas, it is necessary to comply with all requirements and take into account the compression space between the floor and walls.

- Wet cleaning must be done carefully. There should not be puddles on the surface of the laminate.

- Do not violate the integrity of the coating. If it is necessary to fix furniture, a radiator, etc. to the floor, it is necessary to connect objects through the holes in the panels directly with the screed.

- Use special waxes or polishes to protect the laminate from periodic exposure to moisture.

Laminate Care Rules

The durability depends on the quality of care for the surface of the laminate. To maintain an aesthetic appearance and attractiveness, it is necessary to remove moisture and dirt in time, carry out dry cleaning with a broom, broom or vacuum cleaner. To avoid damage to the laminate floor, it is allowed to wash the floors no more than twice a week with special care.

To preserve the original appearance of the laminate, you need to use some rules:

- Eliminate the use of abrasive and ammonia detergents.

- Protect the coating from mechanical stress.

- Limit the use of detergents.

- Timely remove moisture, hot and acidic liquid.

Slight scratches can cause permanent damage. Since through them moisture can penetrate to the base of the lamellas and spoil them. If a scratch occurs, use a special pencil.

Stains and stubborn stains must be removed only after consulting a specialist.

With proper care, the laminate will serve you faithfully for a long time. And in case of damage, you can easily fix the defect on your own, following our instructions.